Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

South African Journal of Industrial Engineering

On-line version ISSN 2224-7890

Print version ISSN 1012-277X

S. Afr. J. Ind. Eng. vol.34 n.3 Pretoria Nov. 2023

http://dx.doi.org/10.7166/34-3-2961

SPECIAL EDITION

Factors that influence world class manufacturing adoption in developing countries

W. MaisiriI, *; F. MakwangudzeII; L. BilibanaII

ISchool of Industrial Engineering, North-West University, Potchefstroom, South Africa

IISaint-Gobain Construction Products South Africa, South Africa

ABSTRACT

The prevailing global competitive environment requires continuous improvement approaches that integrate the entire organisation, from strategic management to operational performance. World class manufacturing (WCM) is a continuous improvement strategy that defines the logic, rigour, and detail of how organisations can achieve sustainable operational performance and customer satisfaction improvements. The paper investigates the factors influencing the successful implementation and sustaining of WCM in the South African manufacturing industry. A qualitative descriptive approach is employed to probe the views and opinions of WCM practitioners in a global manufacturing company with a footprint in South Africa and in other African countries, who were enrolled via purposeful sampling. The findings revealed that management commitment significantly influences achieving a successful WCM system. Furthermore, running WCM as a system could mitigate noticeable barriers identified in this study. The study could substantially enhance industrial engineering practice by revealing aspects to consider when implementing and running a WCM system.

OPSOMMING

Die heersende globale mededingende omgewing vereis deurlopende verbeteringsbenaderings wat die hele organisasie integreer, van strategiese bestuur tot operasionele prestasie. Wêreldklasvervaardiging (WCM) is 'n deurlopende verbeteringstrategie wat die logika, strengheid en detail definieer van hoe organisasies volhoubare operasionele prestasie en verbeterings in klanttevredenheid kan bereik. Die artikel ondersoek die faktore wat die suksesvolle implementering en handhawing van WCM in die Suid-Afrikaanse vervaardigingsbedryf beïnvloed. 'n Kwalitatiewe beskrywende benadering word gebruik om die sienings en menings van WCM-praktisyns in 'n wêreldwye vervaardigingsmaatskappy met 'n voetspoor in Suid-Afrika en in ander Afrikalande te ondersoek, wat deur middel van doelgerigte steekproefneming ingesluit is. Die bevindinge het aan die lig gebring dat bestuurstoewyding die bereiking van 'n suksesvolle WCM-stelsel aansienlik beïnvloed. Verder kan die gebruik van WCM as 'n stelsel die merkbare hindernisse wat in hierdie studie geïdentifiseer is, versag. Die studie behoort bedryfsingenieurspraktyk aansienlik te verbeter deur aspekte te openbaar wat oorweeg moet word wanneer 'n WCM-stelsel geïmplementeer en bestuur word.

1. INTRODUCTION

Manufacturing companies worldwide have been implementing world class manufacturing (WCM) to increase their global competitiveness and improve their productivity [1, 2]. According to De Felice and Petrillo [3], WCM has been proven to be an effective continuous improvement strategy, and has assisted organisations to regain their competitive edge. WCM focuses significantly on continuous improvement and cost reduction [1, 3].

De Felice et al. [4] pointed out the benefits of adopting WCM, such as increased competitiveness, driving technology innovation, promoting flexibility, promoting effective communication between management and production employees, supporting employee empowerment, and making products of the highest quality.

Furthermore, studies such as that of Terra et al. [5] show that combining the WCM method and Industry 4.0 principles could boost organisational productivity. Organisations could leverage shop floor monitoring, apply advanced analytical tools, and strengthen the culture of continuous improvement [5].

This paper presents the purpose of the study in section 2 and an overview of WCM in section 3. The study methodology is outlined in section 4, while section 5 presents the study's findings. Section 6 discusses the study's findings and presents its limitations and recommendations, with section 7 concluding the paper.

2. PURPOSE

The study investigates practitioners' perceptions of the factors influencing the successful implementation and sustaining of WCM in the South African manufacturing industry. We achieved the purpose of the study by answering two research questions (RQ):

a) RQ1 - What factors contribute to the failure to sustain and achieve the continuous progression of WCM performance?

b) RQ2 - How can manufacturing companies achieve successful implementation of the WCM system?

3. WORLD CLASS MANUFACTURING

3.1. World class manufacturing overview

Basing their argument on the literature, De Felice and Petrillo [3] pointed out that there is no commonly agreed definition of WCM. However, practitioners and authors agree on the underlying principles and objectives of WCM. The underlying driving factors in WCM are competitiveness and continual and rapid improvement [3]. According to Ebrahimi et al. [1], WCM is a continuous improvement framework that defines the logic, rigour, and detail of how organisations can sustain improvements in operational performance and customer satisfaction. WCM is a set of "concepts, principles and techniques for managing the operational processes of companies" [1]. Edi [6] pointed out that continuous improvement is an enabler of the successful implementation of WCM.

De Felice and Petrillo [3] outlined the main principles of WCM:

a) Dedication to quality - a significant focus on meeting customers' requirements with agility, high reliability, and quality;

b) Employee involvement - ensuring that employees are motivated and are regarded as valuable assets;

c) Measurement - decisions must be based on data measured and its analysis;

d) Continuous improvement - "having a culture of continuous improvement by doing more with less, eliminating waste, reducing lead time"; and

e) Achieving top-line growth - "constant innovation in the products and services by being first to market and providing end-to-end solutions".

The WCM model contains toolkits to solve operational problems with logic, pace, and rigour to ensure sustained long-term success. Organisations must use the WCM model intelligently and pragmatically to improve their operational performance.

Poor et al. [2] viewed WCM as a collection of methodologies and techniques that drive quality, reliability, and efficiency. WCM is noticeably inclined to Kaizen, a Japanese management system that focuses on production and manufacturing processes [2].

Therefore, it is paramount that business leaders know how to use the WCM model to help them achieve their business improvement objectives. The WCM model could be seen as the way to accomplish this, and not as the objective itself.

3.2. World class manufacturing award status

A series of WCM awards - bronze, silver, gold, platinum, and diamond - recognise the improved performance achieved by implementing the WCM model. WCM focuses on achieving sustained improvements in operational performance and customer satisfaction, and not on winning an award. However, progression in award status could demonstrate successful implementation and sustaining WCM in an organisation.

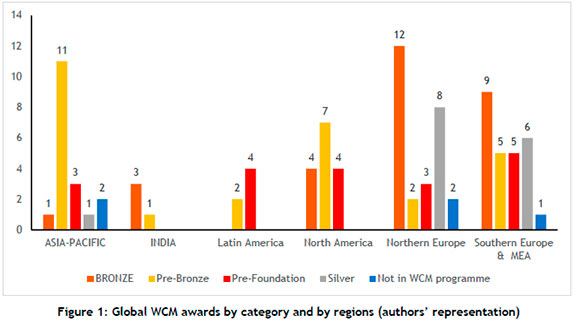

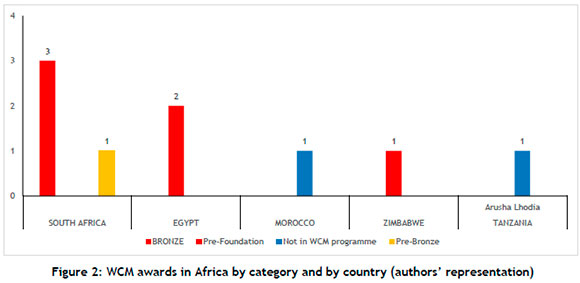

Although WCM could assist manufacturing companies in improving their global competitiveness, there has been a slow uptake of WCM and not much successful implementation, especially in developing countries. This study analysed the WCM awards status (Figure 1 and Figure 2) for a global manufacturing company with a footprint in South Africa and in other African countries.

The data presented in Figure 1 show that a significant number of sites have pre-bronze and lower award statuses (55%) or bronze award status (29%), with only a few sites having been given silver award status (15%). Furthermore, the data suggest that no sites currently hold gold or diamond award status. The data were analysed further for sites in Southern Europe, the Middle East, and Africa, as shown in Figure 2.

Although not exhaustive, the data presented in Figure 1 and Figure 2 confirm that the multinational company faces obstacles in achieving, sustaining, and progressing through the WCM award levels. Addressing the question 'Why?' could significantly contribute to solving the industrial engineering practice puzzle in WCM, and assist organisations in implementing strategies and solutions that could instil continuous improvement. Therefore, a study investigating the factors that inhibit manufacturing organisations' ability to achieve, sustain, and progress through the WCM awards level and aspects could add value.

3.3. Barriers to and drivers of world class manufacturing overview

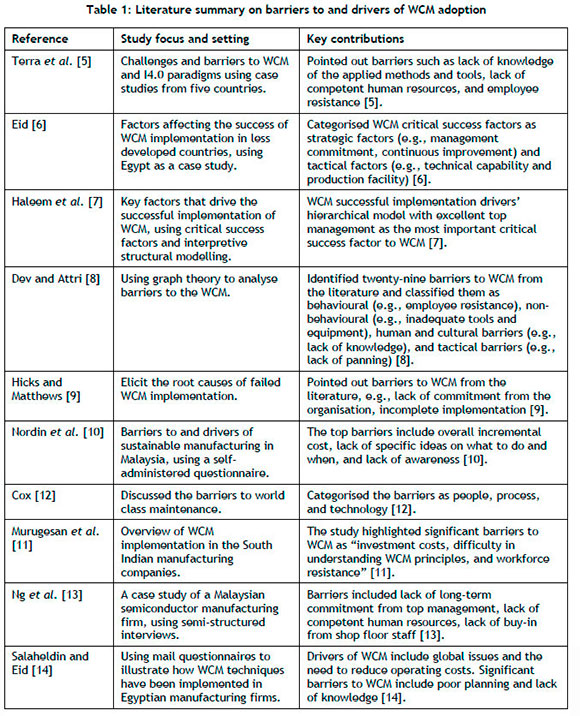

Table 1 summarises the barriers to adopting WCM from selected studies [5-14] that were chosen for their diversity and comprehensive contribution to understanding the barriers to and drivers of adopting WCM in various settings.

The empirical studies presented in Table 1 were conducted in various settings, such as Egypt [6, 14], South India [11], and Malaysia [10, 13]. Terra et al. [5] selected participants from different countries, with South Africa represented by only one participant from the food industry. This reveals a significant gap in empirical studies on the factors influencing WCM adoption in developing countries such as South Africa. Furthermore, the dominant research approach in the reviewed papers included literature reviews supported by other non-empirical techniques [7-9, 12] and empirical studies that used self-administered questionnaires [6, 10, 11, 14]. Terra et al. [5] used self-administered semi-structured interviews, which limited that study from securing comprehensive practitioners' perceptions of WCM implementation. The present study presents the opportunity to conduct face-to-face, in-depth, semi-structured interviews to solicit WCM practitioners' views on the factors that influence adopting and sustaining WCM in manufacturing industries.

4. METHOD

The study followed a qualitative descriptive interview-based approach [15-17] to investigate the perceptions of WCM practitioners on the factors influencing the successful implementation and sustaining of WCM in the South African manufacturing industry, and other aspects thereof.

4.1. Research settings and participants

The study was undertaken in a global manufacturing company, focusing on its South African sites in various provinces and in other African countries. We conducted semi-structured interviews with practitioners practising WCM, ranging from artisans to senior management. The objective was to obtain the views of participants representing diverse organisational levels, since WCM is about total employee participation [12].

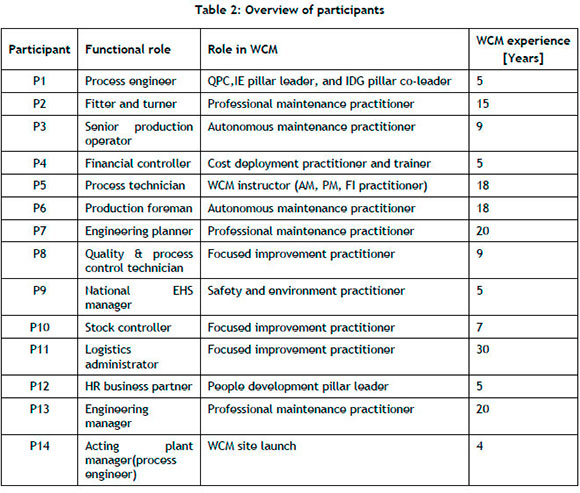

The researchers purposefully enrolled potential participants involved with WCM in their organisations. We choose purposeful sampling, among others, because it provides an opportunity to select participants who are deemed potentially information-rich [18, 19] - in this study, those who were rich with WCM information. The participants were selected based on the following inclusion criteria: practising in a global manufacturing company's sites in Africa, being involved in WCM at any level, and being willing to participate in the study.

Potential participants were invited through a discussion with their site managers and then directly via email once we had been granted permission to contact them directly. The invitation included a one-page document describing the study, and an informed consent request. Participating in the study was voluntary; the researchers used no coercion or persuasion. We gave all of the participants an opportunity to withdraw at any time during or after the interview. We continued enrolling participants until we had reached data saturation in our analysis, which we achieved with participant P14. Each participant was assigned a name, P1 to P14, to ensure confidentiality, as presented in Table 2.

4.2. Data collection

Semi-structured interviews, which provide the opportunity to collect a rich data set and are commonly used in qualitative descriptive research, were employed in this study [16, 17, 20]. An interview protocol was designed and used as the data collection instrument [21]. The interviews were conducted on Microsoft Teams to ensure an accurate recording of the participants' views and perceptions. All interviews were recorded and auto-transcribed with permission from the participants. The researchers collected field notes to complement the data set during the data collection.

To address the research questions in this study, four standard open-ended questions guided each interview:

a) What is the importance of adopting/implementing WCM in your organisation?

b) What are the most important factors to consider when implementing WCM?

c) What are the significant challenges you see in achieving the next level of the WCM performance award?

d) What are the reasons that contribute to WCM failure in manufacturing companies?

The interviews' duration ranged from 25 to 45 minutes, depending on the number of follow-up questions raised during the interview and the depth of the opinions and explanations from the participants.

4.3. Data analysis

Auto-transcribed transcripts downloaded from Microsoft Teams initiated the data analysis process. The two researchers who conducted the semi-structured interviews compared the audio recording with the auto-transcribed transcripts, and made necessary corrections. To ensure verbatim transcription, the third researcher listened to the audio recording and verified the accuracy of the scripts from the other two researchers.

The study applied thematic analysis to gather patterns and themes in the data, allowing the researchers to stay close to the data while capturing the participants' perceptions. The data analysis process included familiarisation, initial code list generation, reviewing codes and grouping them into sub-themes, searching for themes, theme review, and theme generation [22, 23].

The researchers read through the interview transcripts before uploading them into ATLAS.ti software. We initiated the coding process by taking note of potentially exciting data segments and phrases using the free quotations functions in ATLAS.ti [24]. The researchers used 'Apply Codes' open coding and the 'Code in Vivo' [24] function to generate the initial code list with 99 codes.

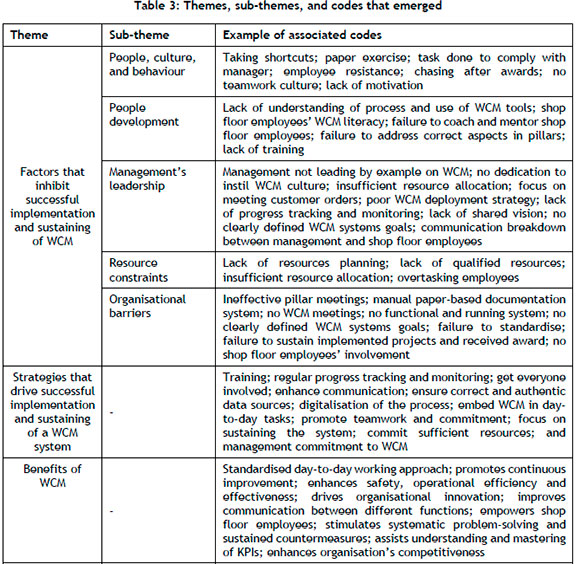

The codes were refined and merged using the merge and rename functions until a refined list of 60 codes had been generated. The process was followed by grouping codes using the group function [24], thus generating sub-themes that were further grouped into descriptive themes. The generated codes, sub-themes, and emerging themes maintained participants' views in line with the objectives of the qualitative descriptive study [15, 16, 25]. Data saturation was reached with participant P14, leading to the final list of themes, sub-themes, and codes in Table 3. The researchers then used the networks, relationships, and links functions in ATLAS.ti to generate connections between the codes within each sub-theme.

5. FINDINGS

Three key themes emerged from our data analysis: factors that inhibit the successful implementation and sustaining of WCM; strategies that drive the successful implementation and sustaining of a WCM system; and the benefits of WCM. Table 3 outlines the themes, sub-themes, and associated codes, which are analysed in sections 5.1 and 5.3.

5.1. Factors that inhibit successful implementation and sustaining of WCM

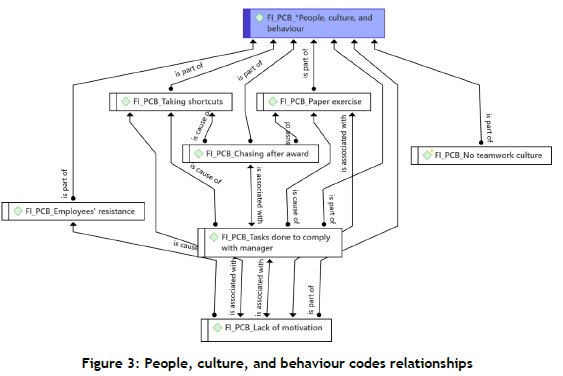

The factors that inhibit the successful implementation and sustaining of WCM have five sub-themes: people, culture, and behaviour; people development; management's leadership; resource constraints; and organisational barriers. It emerged that management commitment factors contribute, influence or are associated with one of the other sub-themes.

5.1.1. People, culture, and behaviour factors

All of the participants (P1 to P14) agreed about people significantly influencing the successful implementation and sustaining of WCM in the manufacturing industry. Lack of motivation results in employees taking shortcuts and doing WCM tasks as paper exercises (Figure 3), leading to a failure to reap the full benefits of WCM:

...if you don't follow the proper WCM structure, you probably take[s] shortcuts, you might not get the complete benefit of it because there are certain risks that you didn't identify because you wouldn't follow the process. [P1]

Furthermore, a lack of motivation noticeably causes employee resistance, including among those new in the organisation but do not adopt WCM, which leads to WCM failure:

. I think also it's the reluctance of accepting the methodology because it's more about no, I can't do this . I can do this in my own way, I don't have to show that visibility. So, I think once we can change that mindset of people that are joining the company and introduce it in a way that there's quite an understanding. [P10]

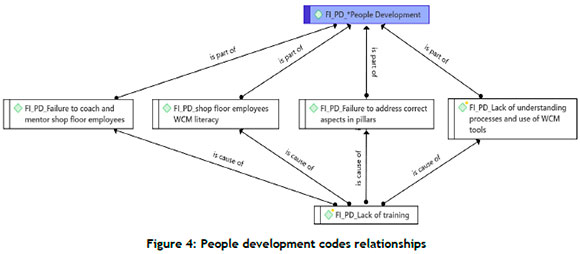

5.1.2. People development factors

It emerged that a lack of training resulted in all the other people development inhibiting factors, as shown in Figure 4. A significant number of participants agreed that a lack of understanding of processes and the use of WCM tools contributes to the failure to implement and sustain WCM. We noticed that there was consensus among the participants about shop floor employees' lack of capacity to participate meaningfully in WCM projects:

... the challenge which can be there is when you can't really train or put a point across someone who is using the machine to understand. So, if we can improve on to understand each other and teach each other in terms of how it works, then I think it will be easier to get to the next step. [P2]

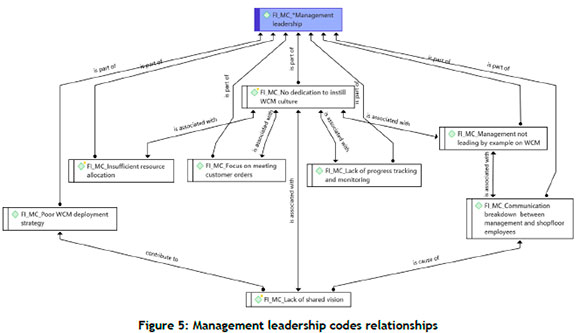

5.1.3. Management leadership factors

The findings of the study demonstrated that all of the other sub-themes for factors that inhibit the successful implementation and sustaining of WCM arise from a lack of management commitment. Management's failure to enforce adherence to WCM rituals and routines is supported by the codes identified in this category:

. it's coming from leadership to the shop floor, and then just in together with that, enforcing systems. I feel like we have beautiful systems, but they're not enforced due to time constraint . [P1]

Figure 5 shows the relationships between the codes in the management leadership category.

5.1.4. Resource constraints factors

The findings demonstrated that a lack of human and capital resources significantly contributes to WCM failure in the manufacturing industry:

For our plant [it] is the use of tool from shop floor [employees]. It's a huge challenge for the plant; we are trying to filter it down, push it for even team leaders to [use] certain tools, initiate and drive actions. It's a huge struggle. [P7]

In addition, participants highlighted that time is a significant resource that is not provided for WCM standard kaizen projects:

... so when we say we need to do a standard kaizen, allow sufficient resources ... your time meaning you have three months to do a standard kaizen, but also provide [other] resources ... the huge challenge for us as well as [with] the different sites that I've seen is sometimes teams are very few and there's lots and lots of WCM systems and projects that you need to work on . [P1]

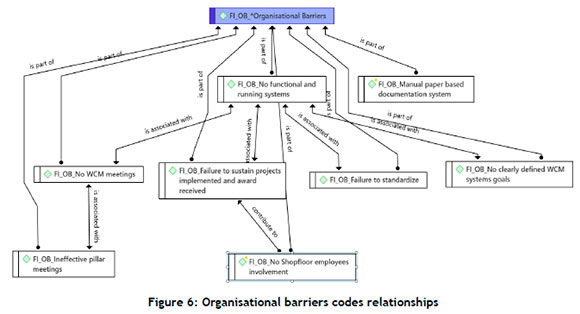

5.1.5. Organisational barriers factors

Figure 6 presents the organisational barriers codes relationships. It emerged that WCM is mainly driven to get awards, and the organisation fails to sustain the implemented projects and the awards that have been received. Although various sites have implemented WCM, the system is not functional, and there is no involvement of shop floor employees, which is characterised by low employee turnover:

.we are not getting to that level because we are not running a system that we can hand over to the shop floor [employees] where the turnover is minimal, because when we handle system to the shop floor [employees] then you know you will be able to maintain it. [P9]

Moreover, the organisation is dominated by a manual, paper-based documentation system, which is viewed as tedious and tiresome by employees:

... I think in general WCM is a good tool. It's a bit too much in paper. [P4]

Participants identified the strategies that organisations could implement to mitigate the factors that inhibit the successful implementation and sustaining of the WCM system. The outstanding strategy that was pointed out was to focus on running a functional system and maintaining the project results and awards that had been achieved:

... but also maintaining that system, the maintenance of the system for me [is] the biggest thing because you've got plants [sites] now that are chasing silver [award] now. But when you go and audit them, there are many gaps in the previous levels . but they're already going for silver . [P9]

Running a successful and sustainable WCM system could be enhanced by ensuring that there are regular system internal audits:

It's to make sure that first so we sustain our bronze award before targeting for silver, we have to do internal audits that you see where we can close the gaps before we have bigger audit . [P6]

Organisations could run a successful and sustainable WCM system by getting everyone involved, from shop floor employees to top management, coupled with WCM training:

When using WCM you need to involve everyone, shop floor [employee], management, and everyone in the plant. Take people to practitioner course[s] to understand what WCM is about and to expand their knowledge ... [P11]

Management must promote the WCM culture so that employees do not see it as extra work but as embedded in their daily tasks. Furthermore, management must commit resources such as time and sufficient human resources to do the tasks:

... you need to get buy-in from management because they'll drive that through their teams and [get] resources [from them] in order to implement the system. [P14]

Participants identified the digital transition from a paper-based system as another strategy that would eliminate the unnecessary tediousness of the WCM paper system:

... if we can move more to the digitalisation of WCM, it would be a good thing . and just go the digital route. [P4]

Management commitment would consolidate all of the suggested strategies, and management should enforce WCM rituals and routines to instil the WCM culture. Successful and sustainable WCM comes with the benefits identified by the participants and presented in section 5.3 and Table 3.

5.3. Benefits of WCM

Citing practical examples, all of the participants pointed out that there are benefits if organisations implement WCM correctly. WCM benefits both the organisation and individual employees who participate in implementing it. Driving a systems approach when implementing and running WCM could assist employees in mastering their KPIs and achieving them:

. my understanding is [WCM is] very structured and system-driven, and if you really work through it, you will yield the results that you are looking for in terms of mastering your KPI

. [P12]

The participants agreed that the correct implementation and sustaining of the WCM system would assist organisations in achieving continuous improvement:

. it's something that I've seen, if you actually follow through, it does work. It does help in terms of improving your efficiency . does improv[e] your cost. [P4]

WCM provides a framework for solving problems systematically, using tools such as root cause analysis and data analysis, which would lead to achieving the correct solutions:

WCM is a problem-solving tool ... we need to eliminate losses and save costs by implementing projects ... using data analysis. [P11]

P10 emphasised that the WCM drives collaborative effort in implementing problem-solving projects, thus raising the need to enhance communication within and outside teams:

It's a tool that helps employees in terms of problem-solving in [a] collaborative effort because you'll need the team to resolve whatever issues that you have. [P10]

6. DISCUSSION AND RECOMMENDATIONS

6.1. Discussion

To respond to the research questions presented in section 2: the findings explicitly answered RQ1 in section 5.1 by pointing out the factors that inhibit the successful implementation and sustaining of the WCM system; and they addressed RQ2 in section 5.2 by stating the strategies that could drive the successful implementation and sustaining of the WCM system.

Our qualitative descriptive empirical study confirmed the findings from the literature [7], that management's commitment is a critical success factor in implementing and sustaining the WCM system in an organisation. Our study also showed how management's commitment is related to other factors that inhibit successful implementation, using the views of WCM practitioners.

Although this study agreed with Ng [13] that the resistance of shop floor employees is a barrier, our study revealed that there is little shop floor involvement by the management, and that shop floor employees do not receive the necessary training in WCM. However, those employees play a significant role in running a successful WCM system, since there is a low turnover in this employee class. Furthermore, how management deploys WCM significantly impacts shop floor employees' perceptions of the system.

The study's outstanding finding, which is not emphasised in other studies, is the need to recognise the importance of a systems approach and of running WCM as a system. Running a functional system could assist organisations in mitigating noticeable barriers such as chasing after awards, taking shortcuts, and employee turnover. WCM is a proven system [1, 2, 4], and implementing it correctly reaps benefits, some of which are pointed out in Table 3 and Section 5.3. Furthermore, if teams focus on maintaining the system and on continuous improvement, then the issue of WCM awards should not be a problem; instead, they would come as rewards for running a functional system.

Sustaining developed systems, project results, and awards requires an improved culture that is aligned with the WCM philosophy and behaviours that promote the maintenance of these achievements by overcoming organisational barriers such as having ineffective or no meetings from shop floor to management level, and a failure to sustain project results.

Although Terra et al. [5] pointed out the difficulties in integrating WCM and Industry 4.0, the study's finding pointed out that continuing to do WCM as usual would not reap many benefits. Even incremental movements towards a complete digitalisation of the WCM system would be significant. For example, moving from a manual, paper-dominated system to a digital system would eliminate the tediousness of completing the paperwork, which was one of the identified barriers. Industry 4.0 focuses on driving organisational competitiveness; thus coupling WCM principles and Industry 4.0 could enhance organisational innovation and help organisations to achieve global competitiveness.

6.2. Study's limitations and recommendations

Although the study's findings should contribute to understanding practitioners' perceptions of implementing and sustaining WCM, the researchers acknowledge that there were limitations to the study. It is not the first to investigate the factors influencing the successful implementation and sustaining of WCM [5-14]. However, it is the first to address the issue in the South African context. Furthermore, the research methodology should have contributed to closing the gap identified in section 3.3.

The study's sample size could also be considered a limitation, although it included practitioners who are experts in WCM, and the enrolling of more participants stopped when data saturation was reached. Although we cannot generalise the study's findings, they offer significant directions to understanding the implementation and sustaining of WCM in the context of a developing country. Further studies could include a comparative study that uses practitioners' perceptions of organisations that are based in East and North Africa, which form part of the Southern Europe and Middle East & Africa region.

We recommend that WCM be embedded into day-to-day practice and not used simply to fulfil audits or inspection requirements, which could apply to all other industrial engineering systems and tools. Coupled with adopting a systems approach and running WCM as a system, organisations could mitigate the various barriers identified in this study and in the literature. Furthermore, we recommend that WCM not depend on individuals (classic leadership) who might leave the organisation or change roles. Organisations could achieve this by running a sustainable and functional system. Successful change needs excellent leadership and a committed approach from management, which management could cultivate in the leadership teams before and during WCM deployment.

Industrial engineers play a significant role in integrating people, processes, and technology; therefore, we recommend that industrial engineers take the lead in driving and sustaining WCM systems and leverage Industry 4.0 technologies to improve the benefits of WCM.

7. CONCLUSION

The study explored the factors influencing the successful implementation and sustaining of WCM in a South African manufacturing industry. Therefore, it could offer direction on how organisations in developing countries could leverage WCM to enhance continuous improvement and achieve global competitiveness. Apart from confirming findings in the literature, our study identified strategies that organisations could adopt to implement and sustain WCM successfully. Our study should contribute significantly to enhancing industrial engineering practice by revealing the aspects to consider when implementing and running the WCM system.

REFERENCES

[1] M. Ebrahimi, A. Baboli, and E. Rother, "The evolution of world class manufacturing toward Industry 4.0: A case study in the automotive industry," IFAC - PapersOnLine, vol. 52, no. 10, pp. 188-194, 2019. [ Links ]

[2] P. Poor, M. Kocisko, and R. Krehel, "World class manufacturing (WCM) model as a tool for company management," in Proc. 27th Daaam International Symposium on Intelligent Manufacturing and Automation, 2016, pp. 1-7. [ Links ]

[3] F. de Felice and A. Petrillo, "Optimization of manufacturing system through world class manufacturing," IFAC-PapersOnLine, vol. 48, no. 3, pp. 741-746, 2015. [ Links ]

[4] F. de Felice, A. Petrillo, and S. Monfreda, "Improving operations performance with world class manufacturing technique: A case in automotive industry," Operations Management, pp. 1-30, 2013. [ Links ]

[5] J. D. R. Terra, F. T. Berssaneti, and J. A. Quintanilha, "Challenges and barriers to connecting world class manufacturing and continuous improvement processes to Industry 4.0 paradigms," Engineering Management in Production and Services, vol. 13, no. 4, pp. 115-130, 2021. [ Links ]

[6] R. Eid, "Factors affecting the success of world class manufacturing implementation in less developed countries: The case of Egypt," Journal of Manufacturing Technology Management, vol. 20, no. 7, pp. 989-1008, 2009. [ Links ]

[7] A. Haleem, Sushil, M. A. Qadri and S. Kumar , "Analysis of critical success factors of world-class manufacturing practices: An application of interpretative structural modelling and interpretative ranking process," Production Planning & Control, vol. 23, no. 10-11, pp. 722-734, 2012. [ Links ]

[8] N. Dev and R. Attri, "Analysis of barriers to world class manufacturing using graph theory," in Proceedings of the Twelfth AIMS International Conference on Management, 2015, pp. 1319-1327. [ Links ]

[9] B. J. Hicks, and J. Matthews, "The barriers to realising sustainable process improvement: A root cause analysis of paradigms for manufacturing systems improvement," International Journal of Computer Integrated Manufacturing, vol. 23, no. 7, pp. 585-602, 2010. [ Links ]

[10] N. Nordin, H. Ashari, and M.G. Hassan, "Drivers and barriers in sustainable manufacturing implementation in Malaysian manufacturing firms," in Proceedings of the 2014 IEEE International Conference on Industrial Engineering and Engineering Management, 2014, pp. 687-691. [ Links ]

[11] T. Murugesan, B. S. Kumar, and M. S. Kumar, "Competitive advantage of world class manufacturing system (WCMS): A study of manufacturing companies in South India," European Journal of Social Sciences,vol. 29, no. 2, pp. 295-311, 2012. [ Links ]

[12] M. Cox, "World-class maintenance: Barriers to success; people, process and technology can either hinder or help your success," Plant Engineering, vol. 70, no. 5, pp. 37-40, 2016. [ Links ]

[13] K. C. Ng, G. G. G. Goh, and U. C. Eze, "Barriers in total productive maintenance implementation in a semiconductor manufacturing firm: A case study," in Proceedings of the IEEE International Conference on Industrial Engineering and Engineering Management, 2012, pp. 377-381. [ Links ]

[14] S. Ismail Salaheldin and R. Eid, "The implementation of world class manufacturing techniques in Egyptian manufacturing firms: An empirical study," Industrial Management & Data Systems, vol. 107, no. 4, pp. 551-566, 2007. [ Links ]

[15] M. Sandelowski, "What's in a name? Qualitative description revisited," Research in Nursing Health, vol. 33, no. 1, pp. 77-84, 2010. [ Links ]

[16] W. Maisiri, L. van Dyk, and R. Coeztee, "Factors that inhibit sustainable adoption of Industry 4.0 in the South African manufacturing industry," Sustainability, vol. 13, no. 3, 1013, 2021. [ Links ]

[17] J. K. Magilvy and E. Thomas, "A first qualitative project: Qualitative descriptive design for novice researcher," Journal for Specialists in Pediatric Nursing, vol. 14, no. 4, pp. 298-300, 2009. [ Links ]

[18] M. Sandelowski, "Whatever happened to qualitative description?" Research in Nursing Health, vol. 23, no. 4, pp. 334-340, 2000. [ Links ]

[19] I. Etikan, S. A. Musa, and R. S. Alkassim, "Comparison of convenience sampling and purposive sampling," American Journal of Theoretical and Applied Statistics, vol. 5, no. 1, pp. 1 -4, 2016. [ Links ]

[20] P. A. C Miguel, "Qualitative research approach in production engineering: An assessment of a research project and a sample of Master of Science dissertations," Exacta, vol. 9, no. 2, pp. 197206, 2011. [ Links ]

[21] J. W. Creswell and J. D. Creswell, Research design: Qualitative, quantitative, and mixed methods approaches, 4th ed., Newbury Park, CA: Sage, 2017. [ Links ]

[22] M. Maguire and B. Delahunt, "Doing a thematic analysis: A practical, step-by-step guide for learning and teaching scholars," The All Ireland Journal of Teaching and Learning in Higher Education, vol. 9, no. 3, pp. 3351-3364, 2017. [ Links ]

[23] V. Braun and V. Clarke, "Using thematic analysis in psychology," Qualitative Research in Psychology, vol. 3, no. 2, pp. 77-101, 2006. [ Links ]

[24] S. Friese, "ATLAS.ti 8 Windows User Manaual," 2019. [Online]. Available from: http://downloads.atlasti.com/docs/manual/atlasti_v8_manual_en.pdf [Accessed 5 June 2019]. [ Links ]

[25] M. A. Neergaard, F. Olesen, R. S. Andersen, and J. Sondergaard, "Qualitative description: The poor cousin of health research?" BMC Medical Research Methodology, vol. 9, no. 1, pp. 1-5, 2009. [ Links ]

* Corresponding author: whisper.maisiri@nwu.ac.za

ORCID® identifiers

W. Maisiri: https://orcid.org/0000-0002-4892-2675

F. Makwangudze: https://orcid.org/0009-0004-9141-2146

L. Bilibana: https://orcid.org/0009-0000-1671-0443