Serviços Personalizados

Artigo

Indicadores

Links relacionados

-

Citado por Google

Citado por Google -

Similares em Google

Similares em Google

Compartilhar

South African Journal of Industrial Engineering

versão On-line ISSN 2224-7890

versão impressa ISSN 1012-277X

S. Afr. J. Ind. Eng. vol.34 no.2 Pretoria Ago. 2023

http://dx.doi.org/10.7166/34-2-2846

CASE STUDIES

Capturing the reality of industry 4.0 readiness dimensions and indicators in a developing country: an analysis of applying I4.0 in Indonesia

H. HasbullahI,*; S.A. BareduanII

IDepartment of Industrial Engineering, Faculty of Industrial Engineering, Universitas Mercu Buana, Indonesia

IIFaculty of Mechanical and Manufacturing Engineering, Universiti Tun Hussein Onn, Malaysia

ABSTRACT

Indonesia has the lowest Industry 4.0 (I4.0) readiness in South East Asia, and uses the INDI 4.0 instrument (Indonesia Industry 4.0 readiness index), which is not as comprehensive and accurate as it could be. An Initial survey confirmed that only 56.86% of respondents agreed that INDI 4.0 accurately measured readiness in manufacturing operations. Unlike the primary I4.0 indices, INDI 4.0 lacks comprehensive I4.0 dimensions and characteristics. This paper aims to identify the dimensions and indicators of I4.0 readiness to enhance INDI 4.0 through an exploratory mixed-method research approach with a multiphase research design. The first phase consisted of a qualitative approach through a documentary review, interviews, and observations to explore the dimensions and indicators of I4.0 readiness. This phase successfully identified four dimensions that experts, academics, and practitioners validated: technology, data life cycle, I4.0 design principles, and smart factory. These dimensions were broken down into 27 indicators of I4.0 readiness, then validated again through a statistical approach before being affirmed by a survey with a Pearson's correlation > 0.361 and Cronbach's alpha of 0.987, which indicated validity and reliability. The second phase, using a quantitative approach through a survey, confirmed the four dimensions and 27 indicators for measuring I4.0 readiness levels; these were 'not ready', 'early stage', 'moderate readiness', 'readiness ripe', and 'already implemented'. This finding comprehensively measured I4.0 readiness based on feedback from industries struggling to adopt I4.0, especially in developing countries such as Indonesia. This finding also differed from existing indices (Acatech, RAMI 4.0, Dreamy, SIMMI 4.0. IMPULS) from developed countries and industries already stable in implementing 14.0.

OPSOMMING

Indonesië het die laagste industrie 4.0 (14.0) gereedheid in Suidoos-Asië, en gebruik die Indonesië Industrie 4.0 indeks (INDI 4.0) instrument, wat nie so omvattend en akkuraat is as wat dit kan wees nie. 'n Aanvanklike opname het bevestig dat slegs 56,86% van die respondente saamgestem het dat INDI 4.0 die gereedheid in vervaardigingsbedrywighede akkuraat gemeet het. Anders as die primêre I4.0-indekse, het INDI 4.0 nie omvattende I4.0-dimensies en -eienskappe nie. Hierdie artikel het ten doel om die dimensies en aanwysers van I4.0-gereedheid te identifiseer om INDI 4.0 te verbeter deur 'n verkennende gemengde-metode navorsingsbenadering met 'n multifase navorsingsontwerp. Die eerste fase het bestaan uit 'n kwalitatiewe benadering deur 'n literatuur oorsig, onderhoude en waarnemings om die dimensies en aanwysers van 14.0-gereedheid te verken. Hierdie fase het vier dimensies suksesvol geïdentifiseer wat deur kundiges, akademici en praktisyns bevestig is: tegnologie, datalewensiklus, I4.0-ontwerpbeginsels en slim fabriek.

Hierdie dimensies is opgebreek in 27 aanwysers van I4.0 gereedheid, dan weer bekragtig deur 'n statistiese benadering voordat dit bevestig is deur 'n opname met 'n Pearson se korrelasie > 0.361 en Cronbach se alfa van 0.987, wat geldigheid en betroubaarheid aangedui het. Die tweede fase, met behulp van 'n kwantitatiewe benadering deur 'n opname, het die vier dimensies en 27 aanwysers vir die meting van I4.0-gereedheidsvlakke bevestig; dit was 'nie gereed', 'vroeë stadium', 'matige gereedheid', 'gereedheid ryp', en 'reeds geïmplementeer'. Hierdie bevinding het I4.0-gereedheid omvattend gemeet op grond van terugvoer van nywerhede wat sukkel om I4.0 aan te neem, veral in ontwikkelende lande soos Indonesië. Hierdie bevinding het ook verskil van bestaande indekse (Acatech, RAMI 4.0, Dreamy, SIMMI 4.0. IMPULS) van ontwikkelde lande en nywerhede wat reeds stabiel is in die implementering van I4.0.

1. INTRODUCTION

1.1. Industry 4.0

Dr Johanes Helbig, in the document Germany vision in I4.0 [1], said:

Implementing the [Industry 4.0] vision will enable employees to control, regulate, and configure smart manufacturing resource networks and manufacturing steps based on situations and context-sensitive targets. Employees will be freed up from performing routine tasks, enabling them to focus on creative, value-added activities. They will thus retain a key role, particularly in quality assurance. Simultaneously, flexible working conditions will enable excellent compatibility between their work and personal needs.

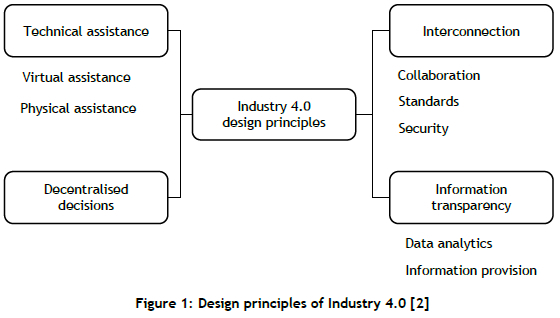

There is no consensus about a definition of the Industry 4.0 (I4.0) concept, except that it provides benefits, vision, and technology. Still, much of the literature mentions that I4.0 consists of four design principles in implementing I4.0: interconnection, information transparency, decentralised decisions, and technical assistance. It was first proposed by Mario Hermann, Tobias Pentek, and Boris Otto from Dortmund University in Germany [2]. Figure 1 shows the design principles of 14.0.

'Interconnection' refers to machines, devices, and sensors connected by wireless communication through the Internet of Things (IoT). 'Information transparency' means the interconnection of objects, such that people quickly access all the information for the right people or objects, providing a virtual copy of the physical object. 'Decentralised decisions' make the interconnection of things and people more transparent in using multi-source information. 'Technical assistance' refers to virtual assistance to provide decision support systems to empower people to drive decision-making by transforming data into visualising information. Furthermore, technical assistance provides physical assistance, such as advanced robotic technology, to support a factory floor's operations.

Implicitly, these four design principles of I4.0 (Figure 1) are similar to some technological elements as the dimensions of I4.0 [3] [4] [5]:

a) Real-time capability and system integration

b) Big data analytics, machine learning, and artificial intelligence

c) Decision support systems and automated decision making

d) Vertical and horizontal system integration and cyber-physical systems

I4.0 delivers the most relevant qualifying technologies frequently cited in the literature, such as big data, the Internet of Things, cloud computing, autonomous robots, additive manufacturing, cyber-physical systems, and augmented reality [6]. I4.0 has four dimensions that are affirmed in some literature reviews:

a) Data life cycle [7] [8] [9] [10] [11] [12] [13] [14] [15] [16]

It is a data journey that requires advanced technology from the source, collecting, transmitting, storing, processing, analysing, and transforming data into helpful information to support a decision.

b) Technology elements [2] [5] [17] [18] [19] [20] [21] [22]

The top seven technologies most frequently cited in the literature related to I4.0 topics [18] are the Internet of Things (IoT), big data, cloud computing, cyber-physical systems (CPS), additive manufacturing, autonomous robots, and augmented reality.

c) Smart factory [7] [16] [19] [23] [24] [25] [26]

The smart factory uses smart design, smart planning and process optimisation, smart material distribution and tracking, smart production, smart monitoring, smart maintenance, and smart quality [7].

d) I4.0 design principles [2] [27] [28] [29]

This concept is the primary reference in I4.0 research and digital transformation and is referenced in many leading papers. It consists of four I4.0 design principles: interconnection, information transparency, decentralised decisions, and technical assistance [2].

In addition, various references describe the characteristics of I4.0 in these terms:

a) Decentralisation decisions involve the role of technology in the form of computer systems [8] [28] [29] [30] [31] [32] [33].

b) Robot support and virtual support are available, supported by IoT technology [2] [23] [28] [29] [34] [35].

c) Having transparent information by transforming raw data and information from the physical and virtual worlds [30] [36] [37] [38].

d) Using I4.0 technology, such as the IoT, cyber-physical systems, cloud, big data, and artificial intelligence [2] [5] [17] [18] [19] [20] [21] [22].

e) Various resources and work operations are interconnected quickly (even in real-time) and efficiently, and there is communication among all participants [2] [28] [29].

f) Decision-making through transforming data into information by data analytics [7] [13] [25] [39].

g) Vertical and horizontal integration functions are distributed throughout the network and interact across hierarchy levels [19] [27] [40] [41] [42].

h) Machines, equipment, and facilities run autonomously and are self-controlling [7] [18] [27] [43] [44] [45].

i) Employees are freed up from performing routine tasks, enabling them to focus on creative, value-added activities [1] [6] [46] [47] [48].

j) Dynamic business and engineering processes enable last-minute changes to production and deliver the ability to respond flexibly to disruptions and failures (agility - flexible system and machines) [5] [19] [49] [38] [50].

k) Real-time capability [5] [6] [7] [14] [43].

1.2. Industry 4.0 readiness index and INDI 4.0

The I4.0 readiness index is an instrument to measure the readiness level for adopting I4.0. This paper aimed to identify the dimensions and indicators for measuring I4.0 readiness to enhance INDI 4.0 by converting an I4.0 concept, with its dimensions and characteristics as a variable, to be an operational variable that could be measured by exploring its dimensions and indicators. In this research, 'variable' refers to a concept, person, place, thing, or phenomenon that can be measured [51] [52]. Dimensions and indicators of I4.0 were explored from documents and then discussed and explored again through interviews; so the readiness factors were based on the realities from interviews industry, practitioners, experts, professionals, and academics involved in implementing I4.0 in Indonesia. Furthermore, the I4.0 readiness index in Indonesia was also compared with the main I4.0 readiness index, using several literature reviews, to capture the reality of the I4.0 readiness dimensions and indicators.

Despite there being no literature, reference, or I4.0 index that contains a complete and perfect instrument model that meets the needs of I4.0, this study followed the recommendations and suggestions of previous research:

a) Increasing the practicality of implementing I4.0 in the organisation [53].

b) Developing organisational factors or other important or specific aspects of the system in detail in I4.0 [49].

c) I4.0 initiators are generally from developed countries, so the companies that are studied are only those that have implemented and carried out I4.0 projects [49].

d) The research requires a different perspective - for example, from industries striving for the transformation of I4.0, especially from developing countries such as Indonesia [49].

e) Some research is too focused and oriented on technology [49].

f) Use different tools, taking into account a more diverse number of dimensions, kinds of support, and indicators to ensure that the integrity of the developed model is maintained [18].

Based on their dimensions, some I4.0 indices focus on technology and IT [42] [49] - for example, SIMMI 4.0 and RAMI 4.0, - while others consider organisational, management, and even cultural factors such as Acatech, the Singapore I4.0 smart index, and Dreamy, even when a portion of their version is familiar with innovation and new technology as a developed country. INDI 4.0 is unlike other major indices: all of its questions are designed for a single organisation's overall general scope. Some major indices, such as the Singapore smart industry readiness index, have questions designed for an organisation's functions: its facilities, shopfloor, and enterprise levels, while RAMI 4.0, DREAMY, Acatech, and so on have all of their questions designed for other functions of an organisation, such as production, quality, research and development, logistics, services, and marketing.

INDI 4.0 only measures with instruments with narrow indicators and does not collect enough comprehensive information about readiness or the characteristics of I4.0 - at least, not as described in the main literature reviews and instruments used by other countries. For example, INDI 4.0 measures the I4.0 readiness of aspects of factory operations with only four closed and multiple-choice questions that lack comprehensiveness and accuracy [54]: 1) Where is data stored? 2) What technologies are adopted in the logistics system? 3) What is the percentage of automation in the process? and 4) What advanced system is adopted in maintenance? It was confirmed by an initial survey of the industries involved in adopting I4.0 in this study. The survey result indicated an assessment of INDI 4.0 as capturing I4.0 readiness relating to the factory operations. Only 56.86% of the respondents agreed that the current INDI 4.0 assessment was accurate. Also, in the second survey, only 42.11% of the respondents answered that INDI 4.0 reported I4.0 readiness. These results indicated a low percentage and suggested that this concern required improvement, especially in the dimensions and indicators of I4.0 readiness.

2. METHODOLOGY

Pragmatism is the philosophical framework underpinning the mixed methods approach to provide a set of assumptions about knowledge and inquiry. It is distinguished from quantitative and qualitative approaches, which are respectively based on the philosophies of positivism and interpretivism [55] [56]. This study used a mixed methods approach to address its research objectives, so it is associated with the pragmatic paradigm and seeks to answer the research questions correctly using a multiphase research design.

Table 1 shows that Phase 1 of the multiphase method adopted a qualitative approach through a literature and document review, interviews, and observations to explore the dimensions and indicators of I4.0 readiness. The goal of this phase was to ensure that all statements about the importance level of every indicator for each dimension were valid and reliable, besides being validated by experts. Phase 2 consisted of a quantitative approach, through a survey, to confirm the relevance of the indicators of the dimensions of I4.0 readiness.

Phase 1 is a Qualitative method for collecting data through interviews, focus group discussion, literature review, and document review (as noted in Table 1). Eleven interviewees had the necessary qualifications and a deep understanding, knowledge, experience, position, and involvement in I4.0 adoption projects in Indonesia. Phase 2 is a Quantitative method for collecting data through a survey. The 51 survey respondents represented industries, academics, and practitioners of I4.0. The survey was based on a non-probability and purposive sample for some reasons. The Government of Indonesia chose just twenty-five sample companies in its assessment of I4.0 readiness in April 2018 because, initially, the I4.0 project invited a few companies to participate [54]. From 2018 to 2022, only 903 companies in Indonesia assessed I4.0 readiness, with 8.52% of them at the level of maturity readiness and implementing I4.0. A self-assessment of I4.0 readiness was also part of the I4.0 project [57]. A limited number of companies in Indonesia are experienced, involved, and have deep knowledge of the I4.0 concept and its adoption.

3. RESULTS AND DISCUSSION

RQ1: What are the dimensions and indicators of Industry 4.0?

The literature review was an early step in collecting related research and selecting the most relevant of it. Next, it was necessary to identify the research gap; understand the I4.0 dimensions, principles, indicators, and characteristics; explore related research; review backgrounds, concepts, and theories; and consider the most suitable research method. In achieving the research objective - to identify the dimensions and indicators of I4.0 readiness - the study explored existing models available in the literature, such as journal papers, books, internet articles, magazines, and government documents. Reviewing and analysing such kinds of literature was done in the initial steps of the research and in each of the steps. In the first research phase (the qualitative method), one of the crucial outcomes of the literature review was the development of the framework of semi-structured questions for interviews about the scope of I4.0's dimensions or pillars that were confirmed previously by experts and practitioners with qualifications in the digital transformation field and Industry 4.0.

Table 2 shows that Phase 1 of the research consisted of semi-structured interviews to collect data to identify the dimensions and indicators of readiness for implementing I4.0 in the manufacturing industry and to classify the readiness levels. The study analysed the results of interviews about the essential indicators (Column 4 in Table 2) for adopting I4.0. The interview results were then recorded and analysed using NVivo 1.2 software.

Table 2 shows a summary of the indicators (column 4) based on a summary of the interviews about the characteristics of I4.0 and its indicators. This phase identified four dimensions and 27 indicators. All of these indicators were summaries derived from interviews, which were analysed manually by looking at the verbal answers of the respondents or interviewees and analysing them with QSR NVivo12 software to organise, integrate, code, and analyse the data. The main outcomes from the qualitative interviews were four dimensions and 27 indicators:

a) Data-life cycle category (defined by six indicators, No. 1 to 6)

b) Design principle of the I4.0 category (defined by four indicators, No 7 to 10)

c) Smart factory (defined by six indicators, No.11 to 16)

d) Technology category (defined by eleven indicators, No. 17 to 27)

RQ2: How the level of importance in terms of conformity of every indicator to dimensions to represent I4.0 characteristics

Table 3 shows the survey's results, confirming the 27 leading indicators; the respondents gave their opinions on how important the levels of these indicators were to these four I4.0 dimensions (Columns 4, 6, 8, 10). Column 11 is the approval level for the 27 indicators. A six-point Likert scale was used that reflected the degree of importance of every leading indicator:

a) Very high = 6

b) High = 5

c) Moderate = 4

d) Low = 3

e) Very low = 2

f) Not suitable = 1

For analysing the results, this study used a scale for the median values that reflected the level of importance, as follows:

a) 5.51 - 6.00 = Very high

b) 4.51 - 5.50 = Important

c) 3.51 - 4.50 = Moderate

d) 2.51 - 3.50 = Low

e) 1.41 - 2.50 = Very low

f) < 1.40 = Not suitable

The median is the most informative measure of the central tendency for skewed distributions or distributions with outliers. For example, the median is often used to measure the central tendency for income distributions, which are generally highly skewed. Because the median only uses one or two values, it is unaffected by extreme outliers or non-symmetric distributions of scores. In contrast, the mean and mode can vary in skewed distributions.

There are 27 leading indicators of I4.0 in four dimensions in Table 3. All indicators obtained a median from 5 to 6 (columns 4, 6, 8, 10) as results from the survey. It meant that most indicators were relevant because the median levels ranged from 4.51 to 5.50 = important and from 5.51 to 6.00 = very important. Also, Column 1 shows the approval level of the respondents for the 27 indicators as 'important', with a median of 5. Only indicator No. 21, real-time technology, with a median of 6, was 'very important' as an I4.0 readiness indicator. The instrument was also validated again through a statistical approach before being affirmed by a survey with a Pearson correlation > 0.361 and Cronbach's alpha = 0.987 > 0.6, which meant it was valid and reliable.

4. CONCLUSION

Based on the literature review, I40 existing indices, and related documents, Industry 4.0 comprises four dimensions - data life-cycle, technology, I4.0 design principles, and smart factory - broken down into 27 indicators. It was confirmed by a survey of the industry and stakeholders involved in the I4.0 project; thus, it was aligned with reality and with the implementation practices associated with the indicators of I4.0 readiness. All of the dimensions and indicators are relevant to I4.0 readiness, with 'important' and 'very important levels as I4.0 readiness indicators. These findings could enhance INDI 4.0, which assesses an entire organisation in general terms, with general questions and some capturing of the comprehensive dimensions, characteristics, and indicators of I4.0 readiness, as described in the literature review.

The interviews revealed other dimensions, such as management, people, and smart maintenance. Smart maintenance has been included in the smart factory. At the same time, the dimensions of management and people, in general, are generally required by other concepts, apart from I4.0, because they are not unique to I4.0. In addition, this study only focused on I4.0 in the factory operation area. Further research would need to explore other dimensions to complement and improve the accuracy in measuring I4.0 readiness, especially those that are important for I4.0 readiness.

The major I4.0 indices (Acatech, IMPULS, RAMI, DRAMY, SIMMI 4.0), which are widely adopted around the world, are all from developed countries [18] [61 ] [62] [63], which have many different variables from those of developing countries such as Indonesia, including culture, people, priorities, industry characteristics, starting points, challenges, opportunities, politics, and so on. This study offers a more comprehensive instrument, especially for industries that are struggling to adopt I4.0. This study has done what previous research recommended: exploring more perspectives to complete the existing indices [18] [49]. Further research is expected to do the same.

REFERENCES

[1] H. Kagermann, W. Wahlster, and J. Helbig, "Securing the future of German manufacturing industry: Recommendations for implementing the strategic initiative INDUSTRIE 4.0," Final report of the Industrie 4.0 working group Federal Ministry of Education and Research, Germany 2013. [ Links ]

[2] M. Hermann, T. Pentek, and B. Otto, "Design principles for Industrie 4.0 scenarios," Proc. Annu. Hawaii Int. Conf. Syst. Sci., vol. 2016-March, pp. 3928-3937, 2016. doi: 10.1109/HICSS.2016.488 [ Links ]

[3] L. Cannavacciuolo, G. Ferraro, C. Ponsiglione, S. Primario, and I. Quinto, "Technological innovation-enabling Industry 4.0 paradigm: A systematic literature review," Technovation, vol. 124, no.102733, 7 March 2023 p. 1-16, 2023. doi: 10.1016/j.technovation.2023. [ Links ]

[4] G. B. Benitez, A. Ghezzi, and A. G. Frank, "When technologies become Industry 4.0 platforms: Defining the role of digital technologies through a boundary-spanning perspective," Int. J. Prod. Econ., vol. 260, no. November 2021, p. 108858, 2023. doi: 10.1016/j.ijpe.2023.108858. [ Links ]

[5] B. Gärtner, "Industry 4.0 maturity index," Acatech - National Academy of Science & Engineering, Germany, vol. 61, no. 12, pp. 32-35, 2018. [ Links ]

[6] X. F. Shao, W. Liu, Y. Li, H. R. Chaudhry, and X. G. Yue, "Multistage implementation framework for smart supply chain management under Industry 4.0," Technol. Forecast. Soc. Change, vol. 162, no. 120354 6 October 2020, . Page 1-11, doi: 10.1016/j.techfore.2020. [ Links ]

[7] F. Tao, Q. Qi, A. Liu, and A. Kusiak, "Data-driven smart manufacturing," J. Manuf. Syst., vol. 48, pp. 157-169, 2018. doi: 10.1016/j.jmsy.2018.01.006 [ Links ]

[8] M. Suvarna, K. S. Yap, W. Yang, J. Li, Y. T. Ng, and X. Wang, "Cyber-physical production systems for data-driven, decentralised, and secure manufacturing - A perspective," Engineering, vol. 7, no. 9, pp. 1212-1223, 2021. doi: 10.1016/j.eng.2021.04.021 [ Links ]

[9] K. Rahul and R. K. Banyal, "Data life cycle management in big data analytics," Procedia Comput. Sci., vol. 173, , pp. 364-371, 2020. doi: 10.1016/j.procs.2020.06.042 [ Links ]

[10] J. L. Kourik and J. Wang, "The intersection of big data and the data life cycle: Impact on data management," International Journal of Knowledge Engineering., vol. 3, no. 2, pp. 32-36, 2017. doi: 10.18178/ijke.2017.3.2.083 [ Links ]

[11] W. Wei, J. Yuan, and A. Liu, "Manufacturing data-driven process adaptive design method," Procedia CIRP, vol. 91, pp. 728-734, 2020. doi: 10.1016/j.procir.2020.02.230 [ Links ]

[12] G. Schuh, T. Potente, and A. Hauptvogel, "Sustainable increase of overhead productivity due to cyber-physical-systems," 11th Glob. Conf. Sustain. Manuf., pp. 332-335, 2013. [ Links ]

[13] Q. P. He, J. Wang, D. Shah, and N. Vahdat, "Statistical process monitoring for IoT-enabled cybermanufacturing: Opportunities and challenges," IFAC-PapersOnLine, vol. 50, no. 1, pp. 1494614951, 2017. doi: 10.1016/j.ifacol.2017.08.2546 [ Links ]

[14] P. O'Donovan, K. Leahy, K. Bruton, and D. T. J. O'Sullivan, "An industrial big data pipeline for data-driven analytics maintenance applications in large-scale smart manufacturing facilities," J. Big Data, vol. 2, no. 1, pp. 1-26, 2015. doi: 10.1186/s40537-015-0034-z [ Links ]

[15] A. Siddiqa, I. A. T. Hashem, I. Yaqoob, M. Marjani, S. Shamsherband, A. Gani, and F. H. Nasaruddin, "A survey of big data management: Taxonomy and state-of-the-art," J. Netw. Comput. Appl., vol. 71, pp. 151-166, 2016. doi: 10.1016/j.jnca.2016.04.008 [ Links ]

[16] S. M. Saad, R. Bahadori, H. Jafarnejad, and M. F. Putra, "Smart production planning and control: Technology readiness assessment," Procedia Comput. Sci., vol. 180, pp. 618-627, 2021. doi: 10.1016/j.procs.2021.01.284 [ Links ]

[17] Y. Lu, "Industry 4.0: A survey on technologies, applications and open research issues," J. Ind. Inf. Integr., vol. 6, pp. 1-10, 2017. doi: 10.1016/j.jii.2017.04.005 [ Links ]

[18] A. P. T. Pacchini, W. C. Lucato, F. Facchini, and G. Mummolo, "The degree of readiness for the implementation of Industry 4.0," Comput. Ind., vol. 113, p. 103125, 2019. doi: 10.1016/j.compind.2019.103125 [ Links ]

[19] M. Ghobakhloo and N. T. Ching, "Adoption of digital technologies of smart manufacturing in SMEs," Vol. 16 No 100107, J. Ind. Inf. Integr., p.1-19 100107, 2019, doi: 10.1016/j.jii.2019.100107 https://www.sciencedirect.com/science/article/abs/pii/S2452414X19300020?via%3Dihub [ Links ]

[20] G. Erboz, "How to define Industry 4.0: The main pillars of Industry 4.0," presented at Managerial trends in the development of enterprises in globalization era, Slovakia, 2017. [ Links ]

[21] X. Xu, Y. Lu, B. Vogel-Heuser, and L. Wang, "Industry 4.0 and Industry 5.0 - Inception, conception and perception," J. Manuf. Syst., vol. 61, no. October, pp. 530-535, 2021. doi: 10.1016/j.jmsy.2021.10.006 [ Links ]

[22] M. Cugno, R. Castagnoli, and G. Büchi, "Openness to Industry 4.0 and performance: The impact of barriers and incentives," Technol. Forecast. Soc. Change, vol. 168, 120756, 2021. doi: 10.1016/j.techfore.2021.120756 [ Links ]

[23] A. G. Frank, L. S. Dalenogare, and N. F. Ayala, "Industry 4.0 technologies: Implementation patterns in manufacturing companies," Int. J. Prod. Econ., vol. 210, pp. 15-26, 2019. doi: 10.1016/j.ijpe.2019.01.004 [ Links ]

[24] P. O'Donovan, K. Leahy, K. Bruton, and D. T. J. O'Sullivan, "Big data in manufacturing: A systematic mapping study," J. Big Data, vol. 2, no. 1, pp. 1-22, 2015. doi: 10.1186/s40537-015-0028-x [ Links ]

[25] Y. Liu, J. Jin, P. Ji, J. A. Harding, and R. Y. K. Fung, "Identifying helpful online reviews: A product designer's perspective," CAD Comput. Aided Des., vol. 45, no. 2, pp. 180-194, 2013. doi: 10.1016/j.cad.2012.07.008 [ Links ]

[26] L. Kaupp, H. Webert, K. Nazemi, B. Humm, and S. Simons, "CONTEXT: An Industry 4.0 dataset of contextual faults in a smart factory," Procedia Comput. Sci. , vol. 180,, pp. 492-501, 2021. doi: 10.1016/j.procs.2021.01.265 [ Links ]

[27] M. Akerman, "Implementing shop floor IT for Industry 4.0," PhD thesis, Department of Industrial and Materials Science, Chalmers University of Technology, Sweden, 2018. [ Links ]

[28] N. Davis, A. Companiwala, B. Muschard, and N. Petrusch, "4th Industrial Revolution design through lean foundation," Procedia CIRP, vol. 91, pp. 306-311, 2020. doi: 10.1016/j.procir.2020.03.102 [ Links ]

[29] M. Ebrahimi, A. Baboli, and E. Rother, "The evolution of world class manufacturing toward Industry 4.0: A case study in the automotive industry," IFAC-PapersOnLine, vol. 52, no. 10, pp. 188-194, 2019. doi: 10.1016/j.ifacol.2019.10.021 [ Links ]

[30] Y. Zhang, G. Zhang, J. Wang, S. Sun, S. Si, and T. Yang, "Real-time information capturing and integration framework of the internet of manufacturing things," Int. J. Comput. Integr. Manuf., vol. 28, no. 8, pp. 811-822, 2015. doi: 10.1080/0951192X.2014.900874 [ Links ]

[31] D. S. Cochran, D. Kinard, and Z. Bi, "Manufacturing system design meets big data analytics for continuous improvement," Procedia CIRP, vol. 50, pp. 647-652, 2016. doi: 10.1016/j.procir.2016.05.004 [ Links ]

[32] M. Bortolini, E. Ferrari, M. Gamberi, F. Pilati, and M. Faccio, "Assembly system design in the Industry 4.0 era: A general framework," IFAC-PapersOnLine, vol. 50, no. 1, pp. 5700-5705, 2017. doi: 10.1016/j.ifacol.2017.08.1121 [ Links ]

[33] M. Marques, C. Agostinho, G. Zacharewicz, and R. Jardim-Gongalves, "Decentralised decision support for intelligent manufacturing in Industry 4.0," J. Ambient Intell. Smart Environ., vol. 9, no. 3, pp. 299-313, 2017. doi: 10.3233/AIS-170436 [ Links ]

[34] M. T. Ballestar, Á. Díaz-Chao, J. Sainz, and J. Torrent-Sellens, "Impact of robotics on manufacturing: A longitudinal machine learning perspective," Technol. Forecast. Soc. Change, vol. 162, no. 120348 , 2021. doi: 10.1016/j.techfore.2020.120348. [ Links ]

[35] A. Hidayatno, A. R. Destyanto, and C. A. Hulu, "Industry 4.0 technology implementation impact to industrial sustainable energy in Indonesia: A model conceptualization," Energy Procedia, vol. 156, pp. 227-233, 2019. doi: 10.1016/j.egypro.2018.11.133 [ Links ]

[36] P. Roh, A. Kunz, and K. Wegener, "Information stream mapping: Mapping, analysing and improving the efficiency of information streams in manufacturing value streams," CIRP J. Manuf. Sci. Technol., vol. 25, pp. 1-13, 2019. doi: 10.1016/j.cirpj.2019.04.004 [ Links ]

[37] D. A. Rossit, F. Tohmé, and M. Frutos, "A data-driven scheduling approach to smart manufacturing," J. Ind. Inf. Integr., vol. 15, pp. 69-79, 2019. doi: 10.1016/j.jii.2019.04.003 [ Links ]

[38] www.bdva.eu, Big data challenges in smart manufacturing, vol. Version I. 2018. [ Links ]

[39] F. Ungermann, A. Kuhnle, N. Stricker, and G. Lanza, "Data analytics for manufacturing systems - A data-driven approach for process optimisation," Procedia CIRP, vol. 81, pp. 369-374, 2019. doi: 10.1016/j.procir.2019.03.064 [ Links ]

[40] P. Bhunia, "The Singapore smart industry readiness index," Singapore Economy Development Board, 2017. https://www.edb.gov.sg/content/dam/edb-japan/key-activities/advanced-manufacturing/the-singapore-smart-industry-readiness-index/the-sg-smart-industry-readiness-index-whitepaper.pdf [ Links ]

[41] Q. Li, Q. Tang, I. Chan, H. Wei, Y. Pu, H. Jiang, J. Li and J. Zhou, "Smart manufacturing standardization: Architectures, reference models and standards framework," Comput. Ind. , vol. 101, , pp. 91-106, 2018. doi: 10.1016/j.compind.2018.06.005 [ Links ]

[42] K. Schweichhart, "RAMI 4.0 reference architectural model for Industrie 4.0," InTech, vol. 106, no. 2, 2019. [Online]. Available: https://ec.europa.eu/futurium/en/system/files/ged/a2-schweichhart-reference_architectural_model_industrie_4.0_rami_4.0.pdf [ Links ]

[43] G. Schuh, R. Anderl, J. Gausemeier, M. ten Hompel, and W. Wahlster (Eds), Industrie 4.0 maturity index: Managing the digital transformation of companies, Munich, Germany: Acatech - National Academy of Science & Engineering, 2017. https://www.acatech.de/wp-content/uploads/2018/03/acatech_STUDIE_Maturity_Index_eng_WEB.pdf , accessed 26 March 2020. [ Links ]

[44] J. Wang, W. Zhang, Y. Shi, S. Duan, and J. Liu, "Industrial big data analytics: Challenges, methodologies and applications," IEEE Trans. Automat. Sci. Eng. pp. 1-12, 2015. [ Links ]

[45] M. Russmann et al., Industry 4.0 The Future of Productivity and Growth in Manufacturing Industries, World Economic Forum. April 2015 , Boston Consulting Group BCG, 2015. https://www.bcg.com/publications/2015/engineered_products_project_business_industry_4_future_productivity_growth_manufacturing_industries [ Links ]

[46] M. Bortolini, E. Ferrari, M. Gamberi, F. Pilati, and M. Faccio, "Assembly system design in the Industry 4.0 era: A general framework," IFAC-PapersOnLine, vol. 50, no. 1, pp. 5700-5705, 2017. doi: 10.1016/j .ifacol.2017.08.1121 [ Links ]

[47] MITI Malaysia, Industry 4WRD: National Policy on Industry 4.0, Minstry of International Trade and Industry, Malaysia, Kuala Lumpur 2018. https://www.my-iot.org/wp-content/uploads/2018/11/3-Panel-Session-Industry4wrd-MITI.pdf [ Links ]

[48] A. C. Pereira and F. Romero, "A review of the meanings and the implications of the Industry 4.0 concept," Procedia Manuf., vol. 13, pp. 1206-1214, 2017. doi: 10.1016/j.promfg.2017.09.032 [ Links ]

[49] C. Leyh, T. Schäffer, K. Bley, and L. Bay, "The application of the maturity model SIMMI 4.0 in selected enterprises," Twenty-third Am. Conf. Inf. Syst., no. August, pp. 1-10, 2017. [Online]. Available: https://pdfs.semanticscholar.org/ce1e/e1bf3faf17b67d3ff835bdd21d610c29fb58.pdf [ Links ]

[50] R. Geissbauer, J. Vedso, and S. Schrauf, "Industry 4.0: Building the digital enterprise," 2016 Global Industry 4.0 Survey. PWC, Global Digital IQ Survey, 2015, pp. 1-39, 2016. doi: 10.1080/01969722.2015.1007734 [ Links ]

[51] M. S. Brown, "Transforming unstructured data into useful information," in Big data, mining, and analytics: Components of strategic decision making, S. Kudyba (Ed.). New York: Auerbach Publications, 2014, pp. 211-230. doi: 10.1201/b16666-14 [ Links ]

[52] C. M. Firdausy and D. A. Budisetyowati, "Variables, dimensions, and indicators important to develop the multidimensional poverty line measurement in Indonesia," Soc. Indic. Res., vol. 162, no. 2, pp. 763-802, 2022. doi: 10.1007/s11205-021-02859-5 [ Links ]

[53] C. Leyh, K. Bley, T. Schaffer, and S. Forstenhausler, "SIMMI 4.0 - A maturity model for classifying the enterprise-wide IT and software landscape focusing on Industry 4.0," Proc. 2016 Fed. Conf. Comput. Sci. Inf. Syst. FedCSIS 2016, vol. 8, pp. 1297-1302, 2016. doi: 10.15439/2016F478 [ Links ]

[54] Ministry of Industry, Indonesia, "Indonesia Industry 4.0 readiness index." 2018. https://sindi4.kemenperin.go.id/assets/content/INDI4.0_Full_v1.pdf [ Links ]

[55] R. B. Johnson and A. J. Onwuegbuzie, "Mixed methods research: A research paradigm whose time has come," Educ. Res., vol. 33, no. 7, pp. 14-26, 2004. doi: 10.3102/0013189X033007014 [ Links ]

[56] M. Denscombe, "Communities of practice: A research paradigm for the mixed methods approach," J. Mix. Methods Res., vol. 2, no. 3, pp. 270-283, 2008. doi: 10.1177/1558689808316807 [ Links ]

[57] Ministry of Industry of the Republic of Indonesia, "Award Sektor Manufaktur Nasional Bertransformasi Digital," 2022. https://www.kemenperin.go.id/artikel/23766/INDI-4.0-Award-Bukti-Sektor-Manufaktur-Nasional-Bertransformasi-Digital [accessed May 20, 2023]. [ Links ]

[58] A. de Carolis, M. Macchi, B. Kulvatunyou, M. P. Brundage, and S. Terzi, "Maturity models and tools for enabling smart manufacturing systems: Comparison and reflections for future developments," IFIP Adv. Inf. Commun. Technol., vol. 517, no. October, pp. 23-35, 2017. doi: 10.1007/978-3-319-72905-3_3 [ Links ]

[59] C. G. Machado, M. Winroth, D. Carlsson, P. Almström, V. Centerholt, and M. Hallin, "Industry 4.0 readiness in manufacturing companies: Challenges and enablers towards increased digitalization," Procedia CIRP, vol. 81, pp. 1113-1118, 2019. doi: 10.1016/j.procir.2019.03.262 [ Links ]

[60] A. Schumacher, S. Erol, and W. Sihn, "A maturity model for assessing Industry 4.0 readiness and maturity of manufacturing enterprises," Procedia CIRP, vol. 52, pp. 161-166, 2016. doi: 10.1016/j.procir.2016.07.040 [ Links ]

[61] A. de Carolis, M. Macchi, E. Negri, and S. Terzi, "A maturity model for assessing the digital readiness of manufacturing companies," IFIP Adv. Inf. Commun. Technol., vol. 513, pp. 13-20, 2017. doi: 10.1007/978-3-319-66923-6_2 [ Links ]

[62] K. Lichtblau, V. Stich, R. Bertenrath, M. Blum, M. Bleider, A. Millack, K. Schmitt, E. Schmitz, and M. Schröter, Industrie 4.0 Readiness. Cologne: Cologne Institute for Economic Research (IW) / Aachen: FIR at RWTH Aachen University, 2015. [ Links ]

[63] S. Vaidya, P. Ambad, and S. Bhosle, "Industry 4.0 - A glimpse," Procedia Manuf., vol. 20, pp. 233238, 2018. doi: 10.1016/j.promfg.2018.02.034 [ Links ]

Submitted by authors 5 Dec 2022

Accepted for publication 19 July 2023

Available online 25 Aug 2023

* Corresponding author: hasbullah@mercubuana.ac.id

ORCID® identifiers

H. Hasbullah: https://orcid.org/0000-0003-3555-3214

S.A. Bareduan: https://orcid.org/0000-0003-4685-7053