Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

South African Journal of Industrial Engineering

On-line version ISSN 2224-7890

Print version ISSN 1012-277X

S. Afr. J. Ind. Eng. vol.33 n.3 Pretoria Nov. 2022

http://dx.doi.org/10.7166/33-3-2810

SPECIAL EDITION

Mechanical reclamation of waste sand produced by additive manufacturing processes

A. MotlhabaneI, *; K. NyembweI; M. van TonderII

IUniversity of Johannesburg, Department of Engineering Metallurgy, Johannesburg, South Africa

IIVaal University of Technology, Technology Transfer and Innovation, Vanderbijlpark, South Africa

ABSTRACT

Metal casting manufacturers are increasingly adopting three-dimensional printing in their workflows as a way to remain competitive. Despite all the innovative development, strict environmental regulations and the intrinsic value of sand still make the recycling of waste sand an essential matter to consider when implementing the rapid sand-casting process. During the printing of the furan-bonded sand cores using binder jetting processes, waste sand is produced. This paper investigates the possibility of mechanically reclaiming the waste sand generated during the printing of sand cores. In this study, waste furan-bonded sand that was generated by three-dimensional printing using the Voxeljet VX 1000 printer was collected from the Vaal University of Technology. The collected waste sand was first characterised before being mechanically reclaimed using dry attrition, followed by dry screening and wet attrition, which involved washing the waste sand in a liquid solution of water and isopropyl alcohol. The results showed that mechanical reclamation using wet attrition is more effective in removing the residual binder in the sand than mechanical reclamation using dry attrition.

OPSOMMING

Metaalgietvervaardigers neem toenemend driedimensionele drukwerk in hul werkvloeie aan as 'n manier om mededingend te bly. Ten spyte van al die innoverende ontwikkeling, maak streng omgewingsregulasies en die intrinsieke waarde van sand steeds die herwinning van afvalsand 'n noodsaaklike saak om in ag te neem wanneer die vinnige sandgietproses gei'mplementeer word. Tydens die druk van die furaangebonde sandkerne met behulp van bindmiddelstraalprosesse, word afvalsand geproduseer. Hierdie artikel ondersoek die moontlikheid om die afvalsand wat tydens die druk van sandkerne gegenereer word, meganies te herwin. In hierdie studie is afval-furaangebonde sand wat gegenereer is deur driedimensionele drukwerk met behulp van die Voxeljet VX 1000-drukker van die Vaal Universiteit van Tegnologie afgehaal. Die versamelde afvalsand is eers gekarakteriseer voordat dit meganies herwin is deur droe afslyting, gevolg deur droe sifting en nat afslyting, wat behels het dat die afvalsand in 'n vloeibare oplossing van water en isopropylalkohol gewas is. Die resultate het getoon dat meganiese herwinning met nat afslyting meer effektief is om die oorblywende bindmiddel in die sand te verwyder as meganiese herwinning met droe afslyting.

1. INTRODUCTION

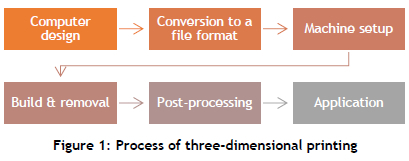

Three-dimensional printing is an additive manufacturing process that employs digital model data to construct a variety of complex structures and forms in a layer-by-layer fashion [1]. The general procedure involved in three-dimensional printing is shown in Figure 1.

Rapid sand casting is the direct fabrication of sand moulds and cores for metal casting using additive manufacturing technologies [2]. As an alternative to traditional moulding and core-making techniques, rapid sand casting provides the foundryman with various benefits, including design flexibility and the removal of tooling, allowing for cost savings and reduced lead design times [2]. The available three-dimensional printing technologies for rapid sand casting include the ZCast, ExOne, and Voxeljet; these are just some of the most visible examples on the market that are used to produce sand moulds and cores using binder jetting technology [3].

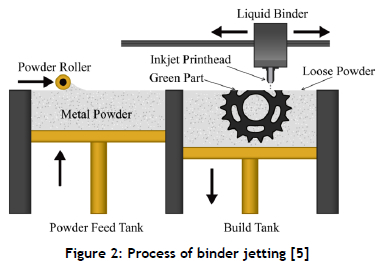

Binder jetting involves depositing a liquid binder onto a powder substrate to bond the powder particles together chemically [4]. A print head deposits the binder onto the loose powder in the form of droplets with an average diameter of 80 urn. Only the part's geometry on a specific layer is printed onto the powder. Following the completion of one layer, the next layer is applied, and the procedure is continued until the entire construction is finished. The process is shown in Figure 2. To enhance the item's strength, the printed part usually needs to be heat cured. The post-production operations include removing the excess loose powder and cleaning the printed component, disposing of the waste powder, and infiltrating or baking the part [4].

The amount of waste sand generated per cycle, which depends on the size of the part being printed, is referred to as the nesting density, which is the percentage of used sand versus unused sand [4]. One other factor that determines the amount of waste sand produced is the part's surface area, which will determine the ratio of non-activated to semi-activated sand, as the sand near the part is semi-activated owing to the binder fumes that partially activate the sand.

Up to 40% of the waste sand that is generated can be reused in a typical rapid sand-casting application. However, this amount of used sand can be reduced if the strength of the sand parts is not within the required specifications [5].

A previous study was conducted to characterise the waste sand generated during three-dimensional printing on a Voxeljet VX 1000 in relation to the foundry properties, including size distribution, pH, loss on ignition (LOI), grain size, and chemical analysis [6]. The pH and the chemical analysis of the used sand samples confirmed the presence of residual sulfonic acid and furfuryl alcohol resin in the spent sand samples obtained during the cleaning stage of the three-dimensional printing process [6]. Consequently, the used sand needed to be reclaimed before further reuse as the chemical contaminants might have affected the resulting foundry performance of the used sand.

The Vaal University of Technology (VUT) houses a Voxeljet VX1000 platform that runs on the furan process, and currently stores the waste furan sand produced for a maximum of one month. This is because a longer storage period might lead to moisture pick-up in the sand, which would affect the strength of the furan-bonded sand parts when reused. As the adoption of binder jetting processes is set to increase worldwide, so will the waste sand from the rapid sand casting applications. This waste sand still holds intrinsic value because of its price and the fact that it has been coated with an activator. As such, the material cannot be simply discarded. In addition, South Africa, as a developing country, is moving towards seeking greener solutions that would effectively preserve the environment; therefore, the management of industrial waste is becoming a vital area of study. The advantage of sand reclamation is that it results in the economical use of sand, self-sufficiency, no freight or delays, and no need for a bulk inventory [7].

Mechanical reclamation is one of the available methods that could be used to treat the generated waste sand to restore it to its original condition and enable it to be reused. The process involves rubbing and removing the residual binder from the sand grains [8]. The major benefit of using mechanical reclamation is that it is a low-cost method of reclaiming waste sand efficiently - and up to 90% of the reclaimed sand can be reused [8].

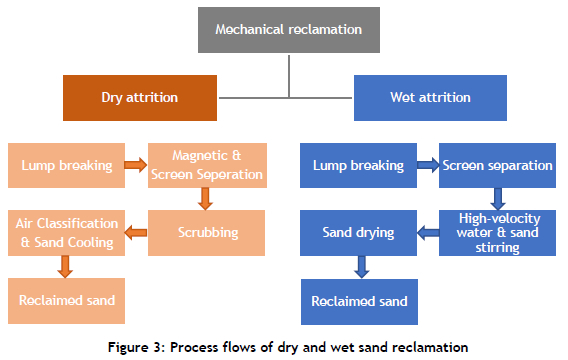

There are two types of mechanical reclamation methods - namely, dry and wet attrition, as depicted in Figure 3. The type of method selected will depend on the type of binder system used. Dry attrition requires, inter alia, dry sieving pans or vibrating screens, jaw crushers, and scrubbers. After the crushing and scouring, a line-removing exhaust stage is usually followed by a mechanical device that separates big particles, metallics, and other tramp materials [9].

Wet attrition, on the other hand, entails the use of water, often in conjunction with mechanical agitation or a breakdown agent to remove any remaining binder [8]. Wet attrition works on the principle of disintegration and severe attrition in the reclaimer container's aqueous environment; heat is therefore required to dry the sand [10].

Sand reclamation of waste sand is a cost-effective measure that would do away with escalating purchase and disposal costs while conforming with strict environmental regulations that are aimed at instilling greener solutions. Such research would also comply with the United Nations Sustainable Development Goals (SDGs). The UNSDGs, also known as the Global Goals, were set in 2015 as a global call to action to eradicate poverty, safeguard the environment, and guarantee that everyone lives in peace and prosperity by 2030 [11]. The UNSDGs also aim to implement a ten-year framework of sustainable consumption and production programmes with all participating countries, with developed countries taking the lead, and taking into account the development and capacities of developing countries [11].

The research would also adhere to South Africa's environmental laws, such as Section 24 of the Constitution of the Republic of South Africa, Act 108 of 1996, which guarantees the right to a healthy and safe environment, and requires the government to take legislative and other actions to:

• Prevent pollution and ecological deterioration

• Conserve the environment

• Ensure long-term environmental sustainability

• Make effective use of natural resources while fostering sustainable economic and social growth [12].

2. METHODOLOGY

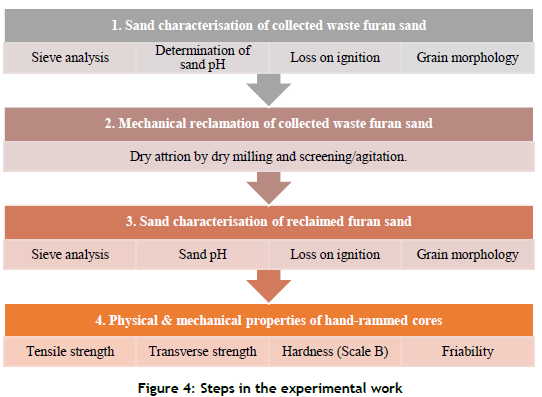

Waste furan-bonded sand generated from three-dimensional printing using a Voxeljet VX 1000 printer was reclaimed in this study, using mechanical sand reclamation. This section explains the experimental design, standards, and equipment that were used to collect data for this study. The flow chart in Figure 4 shows the overall design of the experimental work.

2.1. Sand characterisation

The tests described below were performed to characterise the waste sand sample, and were conducted according to the American Foundry Society (AFS) testing procedures [13]:

2.1.1. Sieve analysis - AFS 1105-12-S

One hundred grams of the sample was screened through a series of sieves with progressively smaller meshes. Particle size distribution was determined by weighing the material retained in each of the sieves and dividing these weights by the total weight of the sample to obtain the sand AFS and %fines.

2.1.2. Determination of pH - AFS 5113-00-S

Twenty-five grams of sand was mixed with 100 ml distilled water and stirred for five minutes, after which the pH of the sample material was measured.

2.1.3. Loss on ignition - AFS 5100-12-S

Ten grams of the sand sample were subjected to 1000 °C in a muffle furnace for four hours. The sample was then removed from the muffle furnace and allowed to cool to room temperature and weighed to obtain the loss-on-ignition content.

2.1.4. Grain morphology analysis - AFS 1107-00-S

This was done to examine the sand grains with a stereomicroscope at magnifications ranging from 10x to 40x. The stereo microscope provides a three-dimensional image of each particle of sand.

2.2. Mechanical reclamation

The waste sand was mechanically reclaimed using two different methods: dry attrition and wet attrition. The processes are briefly described below.

2.2.1. Dry attrition

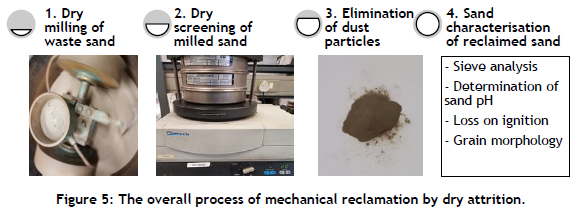

Mechanical reclamation by dry attrition was achieved by dry milling the waste sand to allow the sand grains to rub against each other, followed by dry screening to eliminate the fine resin content that might have been present as dust. Figure 5 below illustrates the overall process.

2.2.2. Wet attrition

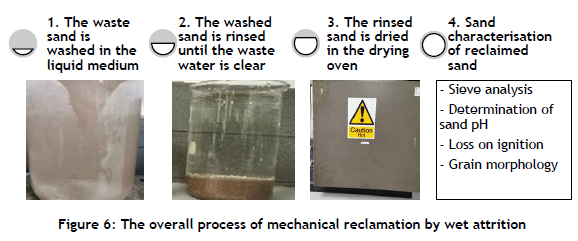

The wet attrition mechanical reclamation involved washing the waste sand in a liquid solution of water and alcohol. The alcohol was used to help remove the furan binder from the sand grains. The entire procedure is shown in Figure 6 below.

2.3. Physical and mechanical properties of hand-rammed cores

2.3.1. Sand mixing and core making

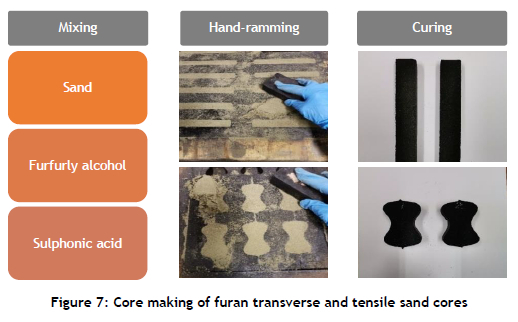

A Kenwood mixing machine was used to mix the catalyst, the reclaimed sand, and the resin for three minutes. 1000g of reclaimed sand was weighed and transferred into the mixing bowl, and the catalyst was added and mixed with the sand first to avoid the resin being in contact with high concentrations of the acidic catalyst. This was done to prevent a rapid reaction rate between the catalyst and the resin.

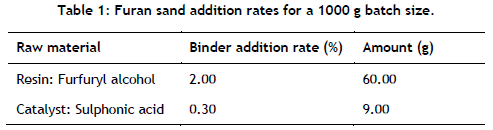

The mixture was poured into the clean and dry core box cavities and compacted. The hardening process continued for 24 hours to allow air curing of the sand cores. Table 1 shows the addition rates used to make up the sand cores.

Both the furfuryl alcohol and the sulphonic acid were referenced to the sand weight. Thus, the activator was 15% of the binder, based on sand weight. The addition rate used is applicable to additive manufacturing using the Voxeljet VX1000 printer.

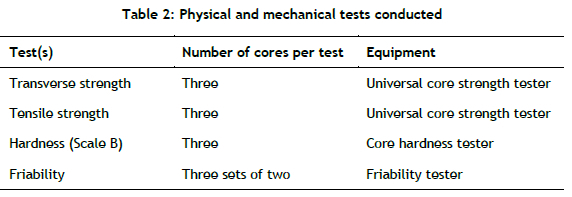

2.3.2. Sand core properties

The hand-rammed sand cores were assessed for the physical and mechanical properties shown in Table 2, following the American Foundry Society (AFS) standard testing procedures [13].

3. RESULTS AND DISCUSSION

3.1. Sand grain distribution and grain fineness number

Figure 8 below shows the grain size distribution of the waste sand before and after sand reclamation by dry and wet attrition. It can be seen that the overall grain size distribution after sand reclamation of the collected waste furan sand remained narrowly spread across sieve sizes 0.150mm and 0.106mm.

Figure 9 shows the American Foundry Society grain fineness number (AFS GFN) of the waste sand before and after sand reclamation by dry and wet attrition. The waste sand also showed an initial AFS GFN of 80.35, which dropped to 79.73 after dry attrition and 78.04 after wet attrition. This could be explained by the fact that both methods of mechanical reclamation included a process of removing a certain quantity of fine particles. In dry attrition, the retained material, which may be present as fines or dust, was disregarded, thus lowering the overall grain fineness of the sand. On the other hand, the fine particles present in the waste sand were washed away during wet attrition.

The AFS GFN of the waste sand reclaimed by dry attrition was found to be high and, as such, the reclaimed sand would produce sand cores with a higher density and a smoother surface finish. This sand type would also require a high amount of resin to avoid producing sand cores with low strength.

3.2. Sand pH

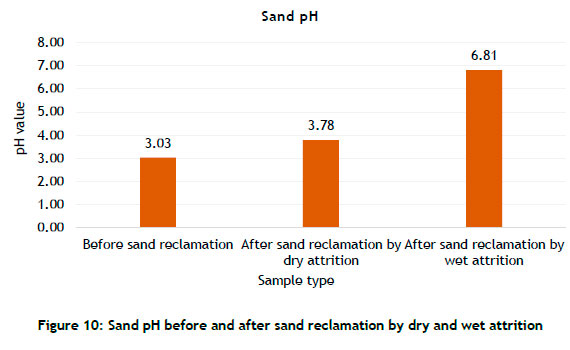

The pH results depicted in Figure 10 below showed an increase in sand pH value from 3.03 before mechanical reclamation to 3.78 and 6.81 after mechanical reclamation by dry and wet attrition respectively. These values indicated a decline in the sulphonic acid present in the sand. It can also be seen below that mechanical reclamation by wet attrition showed a drastic increase in sand pH value, proving to be more effective in removing the residual binder in the sand than mechanical reclamation by dry attrition.

3.3. Sand loss on ignition

Figure 11 below shows the waste sand loss-on-ignition results after dry and wet attrition. The loss-of-ignition content after wet and dry attrition showed a decreasing trend, with wet attrition showing a drastic decrease from 0.54% to 0.31%, indicating a decline in residual binder content or impurities present in the sand sample.

3.4. Sand grain morphology

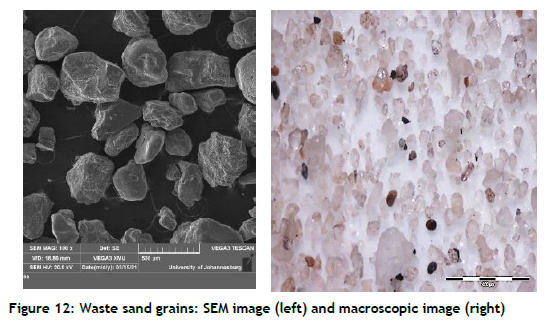

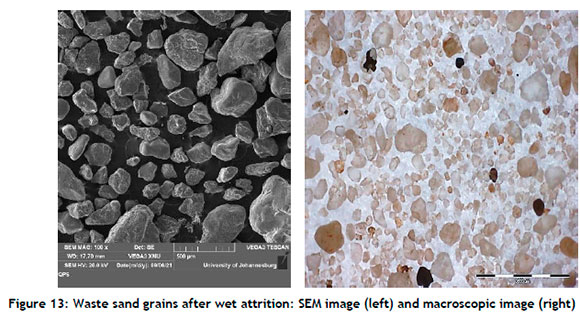

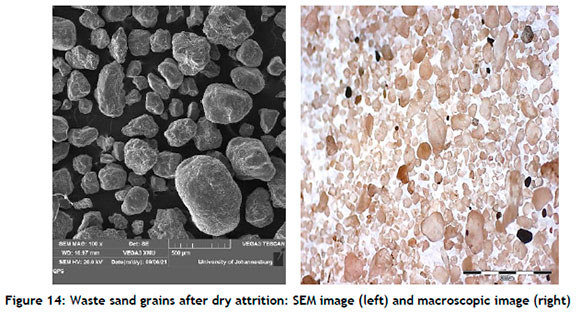

Figures 12 to 14 show the SEM and macroscopic imaging of the sand grains before and after sand reclamation by dry and wet attrition. It can be seen that the sand grains before mechanical reclamation were angular to sub-angular with a medium sphericity.

It can also be seen that, after wet attrition, the grains were sub-angular with a medium to low sphericity and that, after dry attrition, the sand grains were sub-rounded with a medium sphericity. The results indicated that there was a slight change in grain profile as the sand grains were hitting and grinding against each other

3.5. Physical and mechanical properties of hand-rammed cores

3.5.1. Sand core transverse and tensile strength

Figures 15 and 16 show the average transverse and tensile strength of the sand cores produced from sand reclaimed by dry and wet attrition. It can be seen from the results below that the average tensile and transverse strength results of the sand cores produced from mechanically reclaimed sand using dry attrition were lower than for the sand cores produced from mechanically reclaimed sand using wet attrition. However, the results obtained were above the minimum strength requirement of 220 N/cm2 for the production of three-dimensional printed cores, ranging between 535 and 556 N/cm2 average transverse strength and between 220 and 272 N/cm2 average tensile strength.

Nyembwe et al. (2016) found that, at an addition rate of 1.50% binder content, the average transverse strength of virgin silica sand cores was between 160 and 180 N/cm2 under uncured conditions and between 395 and 400 N/cm2 under cured conditions, and that the average tensile strength of virgin silica sand cores was between 70 and 80 N/cm2 under uncured conditions and between 100 and 110 N/cm2 under cured conditions. The 1.50% addition rate was based on the traditional method of mould- and core-making, which was slightly lower than what was required for additive manufacturing using the Voxeljet VX1000 printer.

After dry attrition, the sand's AFS GFN was found to be slightly higher than for mechanically reclaimed sand by wet attrition. A high sand AFS GFN is known to increase the surface area of the sand, thus reducing the overall core strength. To remedy this problem, more resin addition would be required to coat all the sand grains adequately and to restore the overall strength of the core. However, it is recommended that the resin addition rate be increased with caution by adding just the precise amount required to avoid an excessive amount of resin, which can increase the chances of developing gas-related defects during casting.

3.5.2.Sand core hardness and friability

Figures 17 and 18 show the average core hardness and friability of the sand cores produced from sand reclaimed by dry and wet attrition. It can be seen that the sand cores produced from sand that was mechanically reclaimed by dry attrition had a lower hardness and were found to be more friable. This was expected, as the final strength of the cores was lower than for the sand cores produced from sand that was mechanically reclaimed by wet attrition.

This suggests that sand core friability is largely related to the final hardness of the sand core; sand cores with a higher hardness will be less friable. Nyembwe et al. (2016) found that, at an addition rate of 1.50% binder content, the hardness (B-scale) of virgin silica sand cores was 93 uncured and 94 cured, while the friability was between 30% and 40% under uncured conditions and between 10% and 20% under cured conditions. The trend that was observed evidently supports the recent hardness and friability trend seen with mechanically reclaimed sand cores.

4. CONCLUSION

This paper highlighted the possibility of mechanically reclaiming waste furan bonded sand generated during the three-dimensional printing of sand cores. From all the observations and findings that were made, it can be concluded that mechanical reclamation by dry attrition is capable of removing the residual binding agent in furan bonded waste sand that is generated during the printing of sand parts using the Voxeljet VX1000 printer.

The pH and loss-on-ignition results demonstrated that mechanical reclamation by wet attrition was more effective in removing the residual binder in the sand than mechanical reclamation by dry attrition. The sand characterisation results from both mechanical reclamation methods, as well as the mechanical properties of the cores produced from the reclaimed sand, were within the required specifications for the three-dimensional printing of sand parts using the Voxeljet VX1000 printer.

Future work will involve extensively investigating the use of the reclaimed sand in the traditional foundry industry (coldbox, greensand, etc.), as well as reintroducing it into the process of additive manufacturing rapid sand casting. Other important properties of the reclaimed sand, such as refractoriness, flowability, and surface fineness, will be studied.

REFERENCES

[1] K. N. Hui, "Additive manufacturing (3D printing): Review of materials, methods, application, and challenges," Science Direct, vol. 143, pp. 172-196, 2018. [ Links ]

[2] M. S. R. Chhabra, "Rapid casting solutions: A review," Rapid Prototyping Journal, vol. 5, pp. 328350, 2011. [ Links ]

[3] K. Nyembwe, M. Mashila, P. J. M. van Tonder, D. J. de Beer, & E. Gonya, "Physical properties of sand parts produced using a Voxeljet VX 1000 three-dimensional printer," South African Journal of Industrial Engineering, vol. 3, pp. 136-142, 2016. [ Links ]

[4] I. Gibson, D. Rosen, & B. Stucker, Additive manufacturing technologies: 3D printing, rapid prototyping, and direct digital manufacturing, 2nd ed. New York, Springer, 2015. [ Links ]

[5] P. J. M. van Tonder, "Development of a quality assurance framework for chemical coated sand used in additive manufacturing technologies," Master's thesis, North-West University, 2019. [Online] Available at https://repository.nwu.ac.za/bitstream/handle/10394/34388/Van%20Tonder%20PJM%2028365194.pdf?sequence=1&isAllowed=y [Accessed 24 July 2021]. [ Links ]

[6] A. Motlhabane, M. Matjila, T. Thaba, K. Nyembwe, & M. van Tonder, "Characterization of waste sand generated during the Voxeljet rapid sand casting process," In RAPDASA 2021 Conference Proceedings, 2021, pp. 185-188. [ Links ]

[7] J. Danko, M. Holtzer, & R. Danko, "Factors influencing selection of effective reclamation techniques and assessment methods of the reclaimed material quality," Foundry Engineering, vol. 7, pp. 29-32, 2007. [ Links ]

[8] J. Brown, Foseco Ferrous Foundry's handbook. Oxford: Elsevier Butterworth- Heinemann, 2000. [ Links ]

[9] Castings SA, "Hands on advice for successful sand reclamation," 2012. [Online] Available from https://castingssa.com/hands-on-advice-for-successful-sand-reclamation/ [Accessed 24 February 2021]. [ Links ]

[10] J. S. Danko, M. Holtzer, & R. Danko, "Factors influencing selection of effective reclamation techniques and assessment methods of the reclaimed material quality," Foundry Engineering, vol. 4, pp. 29-32, 2007. [ Links ]

[11] United Nations Development Programme, "Sustainable development goals," 2021. [Online] Available from: https://www.undp.org/sustainable-development-goals [Accessed 05 May 2021]. [ Links ]

[12] W. Beech & N. Veltman, Environmental law and practice in South Africa: Overview. Thomson Reuters, 2021. [Online] Available from: https://uk.practicallaw.thomsonreuters.com/4-502-7865?transitionType=Default&contextData=(sc.Default)&firstPage=true [Accessed 23 October 2021]. [ Links ]

[13] ASTM International, "Standard terminology for additive manufacturing technologies," ASTM F2792-12, 21 March 2012. [ Links ]

* Corresponding author: accolademotlhabane@gmail.com

ORCID® identifiers

A. Motlhabane: 0000-0001-7316-3749

K. Nyembwe: 0000-0003-1802-699X

M. van Tonder: 0000-0003-4756-8747