Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

South African Journal of Industrial Engineering

On-line version ISSN 2224-7890

Print version ISSN 1012-277X

S. Afr. J. Ind. Eng. vol.33 n.2 Pretoria Jul. 2022

http://dx.doi.org/10.17159/2411-9717/1574/2022

GENERAL ARTICLES

Factors influencing decision-making models for the estimation of competitive effectiveness among third-party logistics providers

M. NarasimharajanI, *; R. VenkatesanII

IDepartment of Mechanical Engineering, Mahendra Institute of Technology, Anna University, Chennai, India

IIDepartment of Mechanical Engineering, Kumaraguru College of Technology, Anna University, Chennai, India

ABSTRACT

In the modern supply chain management (SCM) environment, the selection of logistics providers is one of the most critical decision-making processes, for which the existing literature enumerates several criteria that needs to be simplified through a scientific approach based on analysis. This investigation explores and illustrates the effects of selected factors for evaluating competitive effectiveness among third-party logistics (3PL) providers from managerial perspective, focusing on the various decision-making aspects (DMA). In order to rank the criteria, a well-structured and self-administered questionnaire was used to gather the primary data. In the structural equation modelling (SEM) approach, the findings were analysed using a graphical user interface-based partial least squares software tool (Smart PLS) to draw inferences for this study. An analytical hierarchical process (AHP) was applied to rank the criteria, and the rankings were compared with those of the convenience sampling method. The framework provided could help the industry leaders to conceptualise, enlarge, and learn the strategies to be adopted for identifying 3PL providers.

OPSOMMING

In die moderne omgewing van voorsieningskettingbestuur is die keuse van logistieke verskaffers een van die mees kritieke besluitnemingsprosesse waaroor die bestaande literatuur verskeie kriteria bevat wat vereenvoudig moet word deur 'n wetenskaplike benadering gebaseer op analise. Hierdie ondersoek verken en illustreer die uitwerking van geselekteerde faktore vir die evaluering van die mededingende doeltreffendheid onder derdeparty logistieke verskaffers vanuit bestuursperspektief, met die fokus op die verskillende besluitnemingsaspekte. Om die kriteria te rangskik, is 'n goed gestruktureerde self-geadministreerde vraelys gebruik om die primere data in te samel. In die strukturele vergelyking modellering benadering, is die bevindings ontleed deur gebruik te maak van 'n gedeeltelike kleinste kwadrate sagteware instrument met 'n grafiese gebruikerskoppelvlak (Smart PLS). 'n Analitiese hierargiese proses is toegepas om die kriteria te orden en die rangorde is vergelyk met 'n gemaksteekproefmetode. Die raamwerk wat aangebied word, kan leiers in die bedryf help om die strategiee wat aangewend kan word om derdeparty logistiek verskaffers te identifiseer te konseptualiseer, uit te brei en te leer.

1 INTRODUCTION

Third-party logistics (3PL) service providers have become an inevitable part of the SCM network. 3PL can be defined as an operating paradigm for integrated business practice that provides products, information, and services, adding value to the clientele and to other stakeholders [1]. In this scenario, 3PL operations have picked up significantly owing to the approach of organisations in adopting trust, cost-savings, and collaborative networks. However, selecting the wrong supplier can give rise to risks as a result of the use of strategic outsourcing such as information technology or information systems [2].

The aim of this research is to rank the competitive effectiveness and the decision-making aspects by using SEM and AHP. The study enables a more effective ranking methodology, and examines the causal links between decision-making aspects such as inventory management, transportation, delivery quality, budgeting, project planning, and vendor selection. Competitive effectiveness covers issues of time, cost, and competitive edge. In this research, a two-phased approach is attempted, in the first phase, 3PL criteria have been ranked by using both the convenience sampling method and the AHP method, and the inference of both methods have been compared. In the second phase, a framework has been recommended to those needing to choose a 3PL service so that they can select the provider based on the short-listed supply chain (SC) support functional criterion.

The rest of this study has been arranged as follows. In section 2, 3PL selection criteria and selection methods using analytical tools are discussed. Section 3 presents the research methodology adopted in this paper. Section 4 explains the two-pronged approach using the SEM and AHP methods to rank 3PL. In Section 5, the results of the analysis using the SEM and AHP methods are compared and discussed. Section 6 outlines the framework using the shortlisted SC functions. Finally, the overall findings and the concluding discussion are found in section 7.

2 LITERATURE REVIEW

In this section, a review of the literature on 3PL helps to look at various decision-making aspects that are considered by researchers and market players in evaluating performance and strategic planning. 3PL, also known as logistics outsourcing or contract logistics, plays a significant role in improving service quality and cultivating relationships between partners [3], [4]. 3PL offers a more comprehensive multipurpose service to customers who have a corporate approach [5-8]. Studies have found that rapidly changing market structures in business to customer (B2C) and business to business (B2B) have an impact on goods and service delivery, virtual inventory and e-procurement and supply visibility. Here, the literature survey gives more importance to tools for supplier selection criteria and selection methods, in order effectively to analyse the decision-making aspects and their competitive effectiveness.

2.1 SPL supplier selection criteria

3PL usually provides numerous value-added services, apart from transportation and warehouse functions [9]. Likewise, 3PL adds value by increasing operating efficiencies and resource sharing among customers [10]. The outsourcing of logistics functions enhances the customer service level, and reduces overall logistics costs to achieve a competitive advantage [11].

Numerous studies of 3PL have addressed aspects related to material handling, work-in-progress, improve quality and cost from the 1950s to the 1980s [12], [13]. Recent reviews have also revealed that delivery, net price, and quality are the criteria that are most often mentioned and cited [14]. Further, they argue that the competitive effectiveness of the outsourcing industry includes the shipping costs and shipping time for the global market [15]. Croom [16] explored the factors influencing the selection of 3PL providers by measuring capability, experience, general information, product costs, Internal organisational practices, market position, reputation, financials, flexibility, manageability, operating and running costs, payment terms, quality, and support and services.

Aguezzoul [17] identified and ranked 25 factors in choosing providers decreased asset commitment, global capabilities, special expertise, service, quality, cost reduction, price, reliability, system capabilities, variable available services, labour problems, personal relationships, modification of disruptions, competitions, on-time performance, flexibility, innovation, order-cycle time, customer support, customer service, vendor reputation, communication, management quality, competence, location, and special expertise.

Sonmez and Moorhouse [19] outlined a number of factors: product features, ability to measure training effects, experience, knowledge, and understanding product features. Vinodh et al. [20] examined specific buyer/supplier relationships based on the categories of quality, extent of fitness, service, risks, and business growth. Sevkli et al. [21] identified performance criteria via the categories of quality system assessment, manufacturing, business criteria, performance assessment, human resources, and use of information technology.

Chou and Chang [22] addressed the 3PL factors by dealing with the categories of organisational culture, strategy, technical capacity, cost, quality, and delivery. Lam et al. [23] stated that the categories for the selection criteria were previous performance, service, buyer/supplier relationship, assurance of supply, cost, quality, and payment terms. Du Toit and Vlok [24] proposed a performance measurement framework based on sC support functions and SCM enablers. In that study, 'SC support functions' included inventory management, relationship management with suppliers, demand/supply forecast logistics management, distribution, customer service management, and process integration; and 'SCM enablers' consisted of human resource management, information system, and infrastructure.

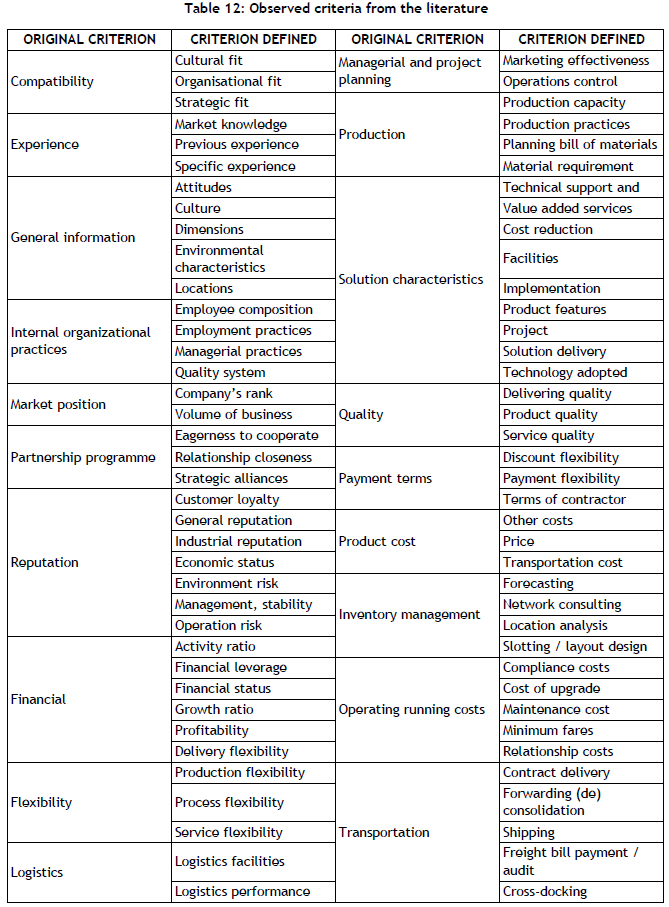

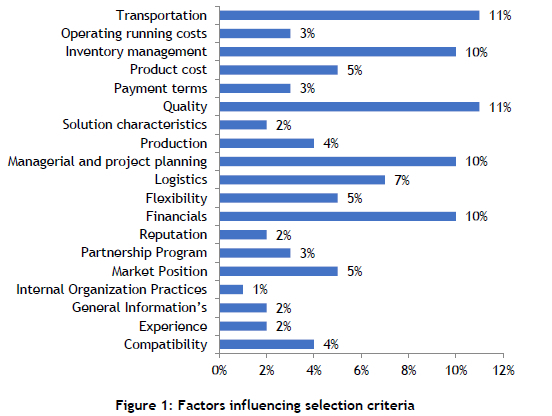

A number of studies [25-28], after combining the criteria from various other studies, noted that more than 20 criteria were outlined, and provided their own categorisation of criteria according to their own interpretation. Many different terms emerged, although several of them referred to the same aspects. There is an extensive range of terms relating to 3PL; and it appears that the criteria used in the majority study are also not clearly defined. To strength this study, the reviewed criteria are shown in Figure 1 below.

Overall, it can be inferred from the above discussion that the most influential criteria and the factors contributing least, out of a large number of factors, were considered in the literature to be valid in decisionmaking and competitive effectiveness. The 3PL functionalities pertaining to the observed variables, in the 3PL selection criteria, mentioned so far from the literature are explained for their importance, and to extract the factors influencing the selection criteria in our analysis. Furthermore, the important selection criteria that were mainly found and analysed in the literature and chosen for consideration in 3PL selection are listed in Table 12 (in the Appendix). From this list, the decision-making criteria in the 3PL selection process will be identified, based on realities on the ground and on feedback from company managers.

Figure 1 contains the criteria that influence 3PL selection decision-making aspects and competitive effectiveness. These were mentioned and consolidated through a literature survey on SCM performance evaluation and 3PL provider selection strategic planning. It can be inferred from the chart that the most influential criteria and least contributing factors out of umpteen numbers of factors considered valid in decision-making and competitive effectiveness in literature. The observed variables, related to the 3PL selection criteria, that have been mentioned so far from the literature are listed in the Appendix for the reader's information.

2.2 3PL provider selection methods

There are many advanced analytical approaches to assessing 3PL providers, from the individual method to the hybrid fuzzy method. Evaluating logistics providers is a complicated and multi-criteria decision-making method (MCDM). The most familiar approaches to 3PL provider selection are classified as follows: individual methods, hybrid methods, and fuzzy hybrid methods. The individual method includes analytic network process (ANP), analytic hierarchy process (AHP), goal programming, linear programming, total cost ownership (TOC, and statistical approaches [29]. Strategies for 3PL assessment can be classified into five groups: MCDM systems, measurement methodologies, computerised as reasoning, scientific programming, and crossover techniques [33].

Hwang and Yoon [30] classified 3PL selection methods into main five approaches: mathematical programming, artificial intelligence, the total cost of ownership method, the statistical model, and linear weight models. In this survey, the selection methods are further reviewed and classified based on the techniques and approaches they use. To choose suitable 3PL service providers, the process involves more than scanning both the qualitative and the quantitative data on operational efficiency and cost; the selection depends on factors that involve various individual and integrated MCDM methods that have been proposed for 3PL selection. An attempt is made to analyse the various approaches to 3PL selection for their possible merits and demerits so that they can be used to analyse the problem at hand.

3 METHODOLOGY

3.1 Research process framework

Numerous analyses have been published of research in the field of 3PL provider selection. After a detailed review of the literature and studying the various strategies, a final screening of the criteria was carried out.Section2presented the literature review and the study's strategies for screening the criteria. In this research, a two-phased approach using AHP and SEM identified the most important factors for selecting 3PL. The suitable method and techniques were chosen, as described in Section 3. The chosen criteria were ranked by using SEM and AHP, as shown in Sections 4.1 and 4.2. Section 5 presents a comparative analysis of the criteria by using SEM and AHP. Section 6presents the framework of 3PL provider selection using the shortlist of SC functions. The study's findings are presented in the final section.

In this research, the 3PL selection problem is addressed on the basis of the influential criteria and sub-criteria that act as latent variables among various observable variables. The structure of these latent variables, which forms the basis of the function for providing a framework for an integrated decision model for the 3PL selection process in supply chain management, is illustrated in Figure 2. The evaluation and selection of a 3PL process, based on the chosen selection criteria, is performed, using the adopted research framework, in a structured way.

These were the factors used in computing the relative importance weights of the selector factors and selecting a 3PL provider during the second survey process. However, a pair wise comparison was made to evaluate the relative importance weights of 3PL providers using selection methods such as SEM method and AHP. The questionnaire, in two parts, requested background information from the respondents, and contained questions using a 7 seven-point Likert scale to assess the vital criteria for the 3PL selection process.

In the first questionnaire survey, the selection criteria for the 3PL selection procedure were identified through various factors found in the literature review and from pilot testing it with some logistic managers. From the data collected, the main factors influencing 3PL selection were classified using the exploratory factor analysis (EFA) and confirmatory factor analysis (CFA) techniques to confirming the measurement model for 3PL selection. In the second questionnaire survey, the relative importance weights among the main factors extracted from the first survey were assessed, and the 3PL service providers were prioritised.

4 DESCRIPTION OF THE RESULTS AND DISCUSSION

4.1 Supply chain support function ranking using the structural equation modelling method

When taking into account the number of respondents in the logistics departments, an upper limit of 55.8% of such departments are have less experienced (LE) employees, whereas the remaining 44.2% of the logistics departments have highly experienced employees (HE).

The important and major Decision-makers were logistics managers and general managers who made up 42.17% and 33.59% respectively of the overall sample. Among the less experienced, the top two decisionmakers were entrepreneurs and general managers, comprising 37.10% and 34.39% of the sample respectively. Among the highly experienced, the top two were logistics managers and general managers, who comprised 59.43% and 32.57% respectively. The results revealed the significance of entrepreneurs as the decision-makers in less experienced group and of logistics managers as the decision-makers in the highly experienced group.

The focal numbers of departments per element in the current study were taken the values greater than 10 and 5-7, with 101 and 111 respondents respectively. Among the less experienced, the top two numbers of departments per unit were taken the values 5-7 and less than 5, which had 65 and 35 respondents of the total respectively. Among the highly experienced, the top two were those greater than 10 and those between 8 and 10, at 58% and 43% of the total respectively. The analysis revealed that the number of departments was known to be greater among highly experienced than among the less experienced.

In order to evaluate the structural equation models along with the variables that were not available for measurement and also taking measurement error into account, Fornell and Larcker's validity determination criteria were considered. For convergent validity, the composite reliability (CR) for the construct must not exceed 0.70 and the average variance extracted (AVE) be greater than 0.5. Likewise, for discriminant validity, it was observed that the AVE of any of the latent variables remained higher than the squared correlation between the latent and other variables [32].

The factor 'competitive effectiveness' (CE) included three variables that explained it 71.23%, since its Cronbach's alpha 0.7123. The consistent factor loadings of the variables ranged from 0.7421 to 0.5241, which revealed the content weight. The implication of the't test figures of the consistent factor loadings of the criteria under the CE factor referred to its convergent validity, which has a clear impact on performance measurement in strategic planning. It is also confirmed by its aggregated reliability, and the AVEs are greater than it's unspecified level of value, considered as a minimum level of significance as 0.50 and 50.0%respectively.

The six variables considered for evaluation under the factor 'DMA' showed that its extent was 82.1%, since its Cronbach's alpha was 0.821. The standardised factor loadings of the variables under the DMA factor we are larger than 0.60 (0.752), which revealed the content validity. An exception was made for vendor selection, for which the considered CR was 0.70, as its consistent factor loading was 0.6785, and played a vital role in the DMA. The t' statistics of the consistent factor loadings of the variables under DMA revealed its convergent weight. It was also supported by the multiple reliability and the AVEs are more than the standard minimum of 0.50 and 50.00% respectively.

The scores of the nine factors were incorporated into the PLS analysis to narrate the variables and factors in the model building. The legality of the statistics for the PLS analysis was tested and evaluated with the help of the least squares measure of sampling sufficiency and the average variance extracted. Both analyses showed the validity and the internal consistency of the statistics for the PLS analysis, while the least square measure was more than 0.60, and the RMR, RMSEA, AGFI, and Chi-square values achieved the required levels. The result of the PLS analysis is presented in Table. 6, and the DMA model based on it is illustrated in Figure 3.

The two constructs (decision-making aspects and competitive effectiveness) were identified by the CFA, since their eigen values were 3.4587 and 3.2651 respectively. The percentages of the AVEs of these two factors and the nine dimensions were 14.21% and 11.25% respectively.

On the one hand, the three competitive effects of the PLS analysis were saving time, cost saving, and competitive edge, since their eigen values were 3.123, 3.235, and 2.125 respectively. The percentages of the AVEs for these factors and dimensions were 12.31, 12.15 and 11.86 per cent respectively.

On the other hand, the decision-making aspects acknowledged by the PLS analysis were Inventory management, transportation and delivery, quality parts, budgeting, project planning, and vendor selection, since their eigen values were 3.235, 3.125, 3.251, 2.125, 3.568, and 2.023 respectively. This investigation of 3PL provider selection helped to reduce the number of steps that logistics managers need to follow to arrive at their strategic planning. The decision was taken collectively, especially by the owners, users, and logistics managers. The important factors and dimensions leading to their logistics decision when appointing the 3PL providers were saving time, cost saving, and competitive edge.

4.2 Supply chain support function ranking using AHP method

The second approach used to investigate and find the ranking criteria of the position, is the AHP method. The survey instrument used here, based on the model framework examined in earlier, produced similar investigation results. Depending on the developed model, the AHP survey instrument was specifically designed using the AHP.OS home tool for this study. The design of the questionnaire was based on the AHP pair wise comparison method.

The Delphi method uses a group of experts' judgements from the successive iteration of questionnaires that are based on a Likert scale used by the participants. This method is generally based on expert opinion and on the number of iterations to arrive at a consensus about the information. The first round was summarised through a statistical analysis of the participants' opinions, and the second round of analysis was based on feedback; the process was conducted online, and significant variations are noted for immediate reconsideration. The participants were also given a chance to reconsider their opinions, if they had new ideas or additional clarifications. Once the consensus had been arrived at, the process data, that was updated after a further round become void. The AHP group's consensus was very high at 95.6%, with the maximum composite reliability at 1.7%.

4.2.1 Analysis of questionnaire survey report

The population target of the study was manufacturing firms, and the targeted respondents were general managers, material managers, and other SC experts. The questionnaires were distributed to various industrial firms, from which 30 participants agreed to participate in the survey through a web portal. Research assistants were engaged to explain the questionnaire to those who had agreed to participate. The experts' characteristics analysed on the basis of their work experience in the same industry, Table 7 shows that 37.5% of the experts had 10-15 years 'experience; 31.25% of them had 15-20 years' work experience; 18.75% had more than 20 years' experience; and 12.5% of them had less than 30 years' experience.

The pair wise questionnaire consisted of two parts. The first dealt with a pair wise ranking of competitive effectiveness (CE), and the second part dealt with the decision-making aspects (DMA). In the expert opinion group, there were 32 respondents. For this study, the respondents had at least 10 years 'work experience. Two experts did not respond to competitive effectiveness (in the first questionnaire); for the decision-making aspects[32] valid responses were received through the OS-AHP results.

The competitive effectiveness rankings are presented in Table 8. The Implication of the results are that the 0 standard AHP linear scale, saving time, is a more important priority than cost or competitive edge. The Delphi-based decision- making AHP survey, as a first step, chose the selection factors from the SEM result, such as 'inventory management', 'transportation and delivery', 'quality parts', 'budgeting', 'project planning' and 'vendor selection'. All of these factors were compared with the consistent factor loading of the selection factor to select 3PL logistic service providers.

A pair wise comparison was used to apply the AHP techniques. The 32 participants were reported through the bpmsg.com online AHP survey. The consolidated result of this analysis revealed the strategies and an in-depth understanding of the social needs and the potential of the customers. Since, the experts' opinion and feedback had clear implications for the outcome, the AHP analysis results provided some interesting insights into the criteria that lead to a successful AHP ranking consistency analysis, illustrated in Table 9.

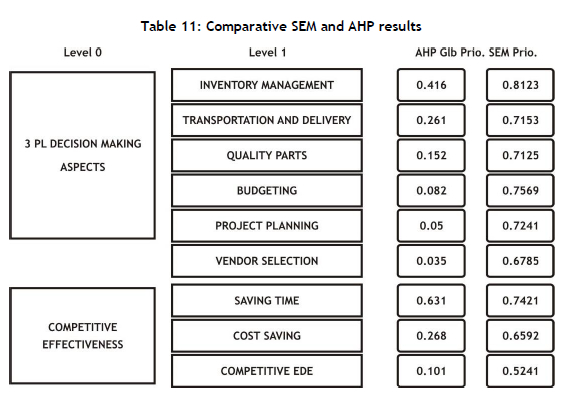

5 ANALYSIS OF SEM AND AHP COMPARATIVE RESULTS

The inferences drawn from the comparative analysis of the SEM and the AHP are revealed in this section in order to throw light on the framework that was developed for 3PL strategic selection planning for managers. The average value of the selection factors of competitive effectiveness and of the decision -making aspects that were evaluated by the first survey are compared to note the positions of priority and to illustrate the differences between the SEM and AHP rankings (Table 11).

The criteria comparisons between six of them are ranked sequentially, with a 0.416 consistent factor loading for inventory management (IM) as first priority, transportation delivery (TD) ranked second, quality parts (QP) in the third, and budgeting (BD), project planning (PP), and vendor selection (VS) in the remaining positions. The pair wise judgement of the criteria with respect to one another's latent variables, as represented in the consolidated decision matrix, is show in Table 10.

The CE results implied that the experts attached greater critical importance to saving time. In other words, managers are more sensitive about and respond to overall time saving when selecting a proper 3PL provider. In a nutshell, this investigation of the 3PL selection problem has helped to solve the appropriate existential problem of contractor selection, based on the outcome of the case study using the AHP method, which has proven to be a successful multi-criteria analytical tool specifically for decision-making and competitive effectiveness in a shorter time. However, this study is not intended to validate the application of the AHP method; but it could be considered in further research. Rather, this study pays more attention to short listing the criteria using a hierarchical structure that is suitable for different kinds of supplier selection problems, proved that the criteria can be customised with flexibility to rationalise the approach, which will be a challenge to enhance.

6 SCM FRAMEWORK

The framework reference model in the field of SCM was developed with reference to a 3PL selection provider problem, with an emphasis on the selection of latent variables that have direct implications for the outcomes of the SC support functions involved in the performance measurement process.

The proposed model provides a range of SCM literature, based on the proposed and modified framework presented in Figure 4. The framework taken as the basis [24] for this research investigation, is based on a comparative analysis using the SEM and AHP analytical tools to identify effectively the latent variables that have an impact on performance measurement.

Wisner [31] listed the fundamental SCM criteria as being: forecasting, resource allocation, inventory management, process integration, supplier relationship management, and sustainable procurement and sourcing and performance management. Du Toit's [24] framework includes the following support functions: supplier relationship management, process integration, customer service management, distribution and logistics management, inventory management, and supply and demand forecasting. This framework for the SCM environment was developed for the SC support function, based on 3PL managers' feedback andon on the reference framework developed earlier in [24], using the SEM and AHP approaches.

The supply chain environment has entities that are vital and basics functions for organisational strategy. The most important among them are: SC participants, SC support function, SC strategy, SC lifecycle activities, SC management plans, continuous improvement, and performance measurement to improve the organisation's strategy and to support supply chain enablers. Therefore, from the SCM literature that was reviewed and the SC participants who were surveyed, the SC life-cycle activities remain as given in the reference work for SCM. The proposed SCM framework for 3PL selection providers has modified the latent variables in the supply chain support function that have a direct bearing on the performance measurement to arrive at an organisational strategy, based on the comparative analysis using the SEM and AHP tools. The results of these two analytic tools have confirmed that the chosen latent variables are more-or-less similar in ranking and outcome. The restructured SC support function includes a few more items-namely, quality parts, budgeting, vendor selection with inventory management, transportation, and project planning in the performance measurement process.

7 CONCLUSION

The proposed framework for the 3PL provider selection problem was tackled in a more efficient and hierarchical way. As a result of SEM, the AHP ranking showed that an SC support function is feasible, and that it is useful to rank suppliers in competitive situations. In this study, the various SC support criteria suggested in the literature were critically reviewed and effectively shortlisted, using SEM and the AHP Delphi method, as six criteria. However, this investigation of the 3PL selection problem emphasised and recommended that an appropriate list of criteria has to be implemented for different kinds of firms. This research provides experimental support for the correlation between of the time, cost, and competitive edge of 3PL providers.

Even though a different firm follows different strategies, with reference to cost, time, and competitiveness, based on the proposed model, they need to identify their input, assessment area, and sample size. The purpose of this research was not to validate the SEM and AHP methods, but to demonstrate, the effectiveness of the shortlisted and recommended factors in the SEM and AHP methods, with which the rankings were often similar in nature.

The Investigation's results in comparing the 3PL decision-making aspects are listed hierarchically in Table 10. This suggests that inventory management, transportation and delivery, and quality parts are the main contributing factors in the decision-making process. Also, further research into competitive effectiveness significantly identified and prioritised saving time, cost saving, and competitive edge with respect to suppliers, manufacturers, distributors, retailers, and customers. In addition, the ranking revealed that budgeting, project planning, and vendor selection were ranked fourth, fifth, and sixth respectively as effective 3PL decision-making aspects. Even though the focus was on the SCM environment, because of rapid changes in that environment that directly affect organisational strategy, a firms needs to concentrate on and take environmental concerns to the next level. The AHP method enhances the effectiveness of the supplier selection decision for the industry. The framework provided with the theoretical model for 3PL selection acts as a basics SC function in order to evaluate organisational performance, and can be extended to strategic planning, to lay the foundation for future research on criteria and 3PL performance factors.

ACKNOWLEDGEMENTS

The authors would like to express their sincere thanks to AHP-OS author Klaus D. Goepel, BPMSG, and also wish to express their deep appreciation to the anonymous reviewers for their comments.

REFERENCES

[1] Lambert, D.M. & Cooper, M.C. 2000. Issues in supply chain management. Industrial Marking Management, 29, pp.65-85. [ Links ]

[2] Hoecht, A.&Trott, P. 2006.The innovation risks of strategic outsourcing. Technovation, 26, pp. 762681. [ Links ]

[3] Knemeyer, A.M., Corsi, T.M. & Murphy, P.R. 2003. Logistics outsourcing relationships: Customer perspectives. Journal of Business Logistics, 24(1), pp. 77-110. [ Links ]

[4] Lau, 1999. Importance of third party logistics. Shippers Today, 22(1), pp. 51-53. [ Links ]

[5] Africk, J.M. and Calkins, C. S. 1994. Does asset ownership mean better service? Transportation and Distribution, 35(5), pp. 49-61. [ Links ]

[6] Wester, E.E., Jr. 1992. The changing role of marketing in the corporation. Journal of Marketing, 56(4), pp. 1-17. [ Links ]

[7] Kopczak, L.R. 1996. Logistics partnerships and supply chain restructuring: Survey results from the US computer industry. Production and Operations Management, 6(3), 226-247. [ Links ]

[8] Laarhoven, P., Van Berglund, M. & Peter, M. 2000. Third-party logistics in Europe five years later. International Journal of Physical Distribution and Logistics Management, 30(5),pp. 425-442. [ Links ]

[9] Leahy, S.E., Murphy, P.R. & Poist, R.F. 1995. Determinants of successful logistical relationship: A third party provider perspective. Transportation Journal, 35 (2), pp.5-13. [ Links ]

[10] Berglund, M.P., Laarhoven, G.S. &Wendel, S.1999. Third party logistics: Is there a future? International Journal of Logistics Management, 10(1), pp. 59-70. [ Links ]

[11] Boyson, S., Corsi, T., Dresner,M. &Rabinovich, E. 1999.Managing effective third party logistics relationships: What does it take? Journal of Business Logistics, 20(1), pp. 73-100. [ Links ]

[12] Yuchtman, E. &Seashore, S.E. 1967.A system resource approach to organizational effectiveness. American Sociological Review, 32, pp. 891-903. [ Links ]

[13] Thompson, J.D. 1967. Organization in action. New York: McGraw-Hill. [ Links ]

[14] Cheraghi, H., Dadashzadeh, M.& Subramanian, M. 2004. Critical success factors for supplier selection: An update. Journal of Applied Business Research, 20, pp. 91-108. [ Links ]

[15] Richardson, L.J. & Snaddon, D.R. 2011. An exploratory study of long supply chain competition: Selection cases in the South African aerospace sector. South African Journal of Industrial Engineering, 22(1), pp. 155-165. [ Links ]

[16] Croom, S., Romano. P. & Giannakis, M. 2000. Supply chain management: An analytical framework forcritical literature review. European Journal of Purchasing and Supply Management, 6, pp. 67-83. [ Links ]

[17] Aguezzoul, A. 2014. Third-party logistics selection problem: A literature review on criteria and methods. Omega, 49, pp. 69-78. [ Links ]

[18] Chan, F., Kumar, N., Tiwari, M.K., Lau, H.C.W. & Choy, K.L. 2008. Global supplier selection: A fuzzy AHP approach. International Journal of Production Research, 46(14), pp. 3825-3857. [ Links ]

[19] Sonmez, M.&Moorhouse, A. 2010. Purchasing professional services: Which decision criteria? Management Decision, 48(2), pp. 189-206. [ Links ]

[20] Vinodh, S., Ramiya, R.&Gautham, S. 2011. Application of fuzzy analytic network process for supplier selection in a manufacturing organization. Expert Systems with Applications, 38, pp. 272280. [ Links ]

[21] Sevkli, M., Koh, S.C., Zaim, S., Demirbag, M. & Tatoglu, E., 2007. An application of data envelopment analytic hierarchy process for supplier selection: A case study of BEKO in Turkey. International Journal of Production Research, 45(9), pp. 1973-2003. [ Links ]

[22] Chou, S. & Chang, Y. 2008. A decision support system for supplier selection based on strategy-aligned fuzzy SMART approach. Expert Systems with Applications, 34, pp. 2241-2253. [ Links ]

[23] Lam, K.-C., Tao, R. & Lam, M.C.-K. 2010. A material supplier selection model for property developers using fuzzy principal component analysis. Automation in Construction, 19, pp. 608-619. [ Links ]

[24] Du Toit, D.& Vlok, P.J. 2014. Supply chain management: A framework of understanding. South African Journal of Industrial Engineering, 25(3), pp. 25-38. [ Links ]

[25] Avila P. Mota A. Putnik G, Costa L. Pires A, Bastos J.& Cruz Cunha, M.M. 2015. Proposal of an empirical model for supplier selection. International Journal for Quality Research, 9(1), pp. 10722. [ Links ]

[26] Ho, W., Xu X. &Dey, P.K. 2010. Multi-criteria decision making approaches for supplier evaluation and selection: A literature review. European Journal of Operational Research, 202(1), pp. 16-24. [ Links ]

[27] Igarashi, M., De Boer, L. &Fet, A.M. 2013. What is required for greener supplier selection? A literature review and conceptual model development. Journal of Purchase and Supply Management, 19, pp. 247-263. [ Links ]

[28] Govindan, K., Rajendran, S., Sarkis, J. & Murugesan, P. 2015. Multi criteria decision making approaches for green supplier evaluation and selection: A literature review. Journal of Cleaner Production, 98, pp. 66-83. [ Links ]

[29] Omotayo, A.A.&Melan, M. 2017. Factors influencing the information and communication technology of third party logistics in Malaysia. International Journal of Supply Chain Management, 6(2), 202208. [ Links ]

[30] Hwang, C. L.& Yoon, K. 1981. Multiple attribute decision-making: Methods and application: A state-of-the-art survey. New York: Springer-Verlag. [ Links ]

[31] Wisner, J.D.2001. Principles of supply chain management: A balanced approach. Cengage Learning. [ Links ]

[32] Fornell, C. & Larcker, D.F. 1985. Evaluating structural equation models with unobservable variables and measurement error. Journal of Marketing Research, 18 (1), pp.39-50. [ Links ]

[33] Yildiz, A.& Yayla, A.Y. 2015. Multi-criteria decision-making methods for supplier selection: A literature review. South African Journal of Industrial Engineering, 26(2), pp. 158-177. [ Links ]

Submitted by authors 05 Jun 2019

Accepted for publication 04 Nov 2021

Available online 29 Jul 2022

ORCID® identifiers

M. Narasimharajan: 0000-0003-0517-5988

R. Venkatesan: 0000-0001-8395-9636

* Corresponding author: narasimharajanm@mahendratech.org

APPENDIX