Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

South African Journal of Industrial Engineering

On-line version ISSN 2224-7890

Print version ISSN 1012-277X

S. Afr. J. Ind. Eng. vol.30 n.1 Pretoria May. 2019

http://dx.doi.org/10.7166/30-1-1986

CASE STUDIES

Analytic hierarchical method applied to brush cutter blade selection

T. ChucheepI, *, #; N. MahathaninwongI, #; S. JanudomII, #

IDivision of Industrial Management Technology, Faculty of Science and Industrial Technology, Prince of Songkla University Surat Thani Campus, Muang, Surat Thani 84000, Thailand

IIDepartment of Mining and Materials Engineering, The Center of Excellence in Materials Engineering (CEME), Faculty of Engineering, Prince of Songkla University, Hat Yai, Songkhla 90112, Thailand

ABSTRACT

The objective of this work was to use the analytic hierarchic process (AHP) to select the best replacement brush cutter blades. The seven decision criteria of the AHP included three mechanical property criteria and four commercial data criteria. The mechanical property criteria were based on wear rate, impact toughness, and hardness, all of which were tested, while the four commercial data criteria were set on price, weight, packaging information, and product distribution, which were surveyed. Four replacement brush cutter steel blades of types 65C, 72C, 73C, and 81C were included. The best alternative was the 65C steel blade according to the AHP method.

OPSOMMING

Die doelwit van hierdie werk is om die analitiese hiërargieproses in te span om die beste plaasvervanger bossnyerlemme te kies. Die sewe besluitnemingskriteria van die analitiese hiërargieproses sluit drie meganiese eienskappe en vier kommersiële eienskappe in. Die meganiese eienskappe is gegrond op slytasietempo, impak taaiheid en hardheid (wat almal getoets is), terwyl die kommersiële kriteria gegrond is op prys, gewig, verpakkingsinligting sowel as produkverspreiding (wat almal ondersoek is). Vier plaasvervanger lemme (tipes 65C, 72C, 73C en 81C) is by die ondersoek ingesluit. Die beste alternatief was 'n 65C staal lem.

1 INTRODUCTION

Replacement brush cutter blades (Figure 1) of portable brush cutters are important to farmers who mow the grass on their farms instead of using chemicals. Replacement brush cutter blades are replacement manufacturing equipment, and are not produced with the most advanced technology. Farmers operate them at high speeds, in the range of 6,800 - 12,000 rpm, and need to consider work safety when they select the blades [1, 2]. Chucheep, Mahathaninwong and Janudom [3] surveyed farmers' behaviours in buying replacement brush cutter blades in Surat Thani province, Thailand. They investigated 15 brands of replacement brush cutter blades that were available in the shops. They also found that AISI 1070 and 1080 carbon steel was applied in locally manufactured replacement blades, which matches the study of Lau et al. [4]. Wear is also an important property of replacement brush cutter blades, because it affects both the sharpness and the service life of the blades. Lau et al. [4] investigated the wear properties of the blades. The geometry and the thickness of the blade affected the wear, which is mainly caused by surface fatigue abrasion in the initial stage. The survey results of Chucheep et al. [3] also show that the sharpness and service life of the blades are the main factors that affect the farmers' buying selections, and that the wear of the blades shortens their service life - the farmers bought new blades every two years. The buying selection of these products is influenced by many factors. Park et al. [5] investigated the factors that affect buying selections for pneumatic pavement crack preparation devices. These factors are related to safety, productivity, and quality. However, Garwin [6] classified buying selection factors as performance, features, reliability, conformance, durability, service ability, aesthetics, and perception. The buying selection factors of agricultural products are of a multi-criteria and multi-decision (MDMC) type, which can be modelled by the analytic hierarchy process (AHP). The AHP proposed by Saaty [7] has been widely applied in the fields of operation strategy, product and process design, planning and scheduling resources, project management, and management of the supply chain [8]. Moreover, the buying selection of agricultural products is different from other products, partly because the community base (gossip marketing) plays a role in farmers' buying decisions. Agricultural products in Thailand are not subject to many standards, so the data on the labels of some products are not extensive. This makes buying decisions more difficult. Material types and manufacturers should be specified on the product labels in the Thai language, as the material types indicate the properties of products, although some uncertainties remain.

This research therefore aimed to analyse both the mechanical properties and the commercial data criteria for the buying decisions for replacement brush cutter blades, by using the analytic hierarchy procedure.

2 METHODOLOGY

2.1 Mechanical properties of replacement brush cutter blades

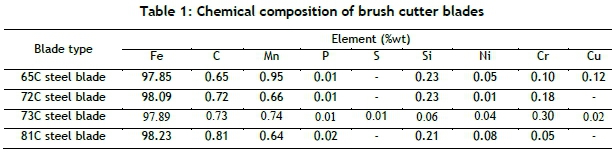

The four replacement brush cutter blade types investigated were selected based on survey results, as those four had the highest use locally. The chemical composition of the blades was examined by an optical emission spectrometer (OES), and is shown in Table 1. The carbon content, in particular, should relate to the wear rate, impact toughness, and hardness of the blades that were tested. Hardness of the blades was tested using Indentec (series ZHR4150LK) in the Hardness Rockwell Scale C (HRC), which the diamond indenter was applied under the load of 150 kg. . Wear was determined as the wear rate in equation (1) by using an abrasion test method [9, 10]. The wear specimens were cut into 1.0 xl.0 cm2 square shapes and tested at a polishing disc speed of 150 rpm, a load of 19.620 N, and for two-minute periods. Abrasive particles were from SiC particles coated on the sand paper, with a nominal particle size of 125 μm (P120).

Weight Loss = Weight before test - weight after test (mg) Contact Area = 1.0x1.0 cm2

The Charpy impact toughness was measured according to impact standard test method ASTM E23 [11]. The Charpy impact machine had a 300 lb-ft capacity. Sub-size (non-standard) specimens were used, with 55 mm length, 10 mm depth, 2 mm notch depth, and the width varied by brush cutter blade type. At least three tests were conducted for each blade type.

2.2 Commercial data on replacement brush cutter blades

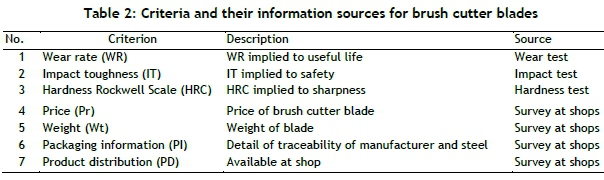

The price, weight, packaging information, and product distribution of the blades were surveyed in Surat Thani province, Thailand. Wear rate, impact toughness, hardness, price, shape, packaging information, and product distribution for the brush blade selection process were used as criteria in AHP analysis. The attribute factors and information sources for the brush cutter blades are summarised in Table 2.

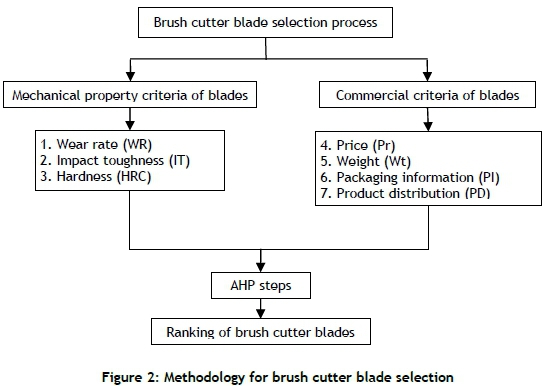

The brush cutter blade selection process for this investigation is shown in Figure 2.

3 ANALYTIC HIERARCHY PROCESS (AHP)

The analytic hierarchy process (AHP) proposed by Saaty [7] was applied in this work as follows: 1. Set criteria for a decision problem after identifying the criteria that may have an intrinsic or extrinsic impact. The quantifiable indicators for the criteria can be used as measures.

2. Construct a hierarchical structure where the objective, the criteria, and the alternatives are arranged, and represent it as a diagram. The diagram depicts the hierarchy for the problem.

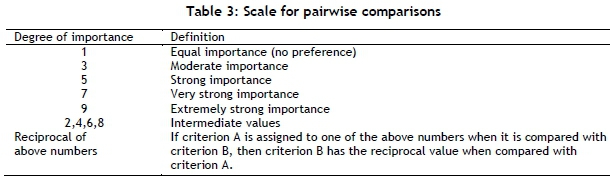

3. Assign the scale value for pairwise comparison to express the importance level in the decision. Table 3 shows the definitions of each pairwise comparison scale value. Perform pairwise comparisons of each criterion. The relative importance of each criterion is estimated. The pairwise comparisons matrix is formed for the criteria.

4. Check the consistency ratio (CR) to evaluate the pairwise comparison matrix. The pairwise comparison matrix will be available if its CR is less than 0.1. Brunelli [12] showed that the consistency ratio (CR) and consistency index (CI) can be calculated by equations (2) and (3).

CI = Consistency index

Xmax = its maximum eigenvalue

n = number of factors

CR = Consistency ratio

CI = Consistency index

RI = Random index

5. The normalised priority of each criterion is synthesised. The procedures were described by Ravisankar et al. [13] as follows:

(a) sum the values in each column;

(b) divide each element in the column by its column total, which results in a normalised pairwise comparison matrix;

(c) compute the average of the elements in each row of the normalised comparison matrix, thus providing an estimate of the relative priorities of the criteria.

6. Make the pairwise comparisons of the alternatives in the view of each criterion, and use the same pairwise comparison procedures to set the priorities for all the criteria in terms of the importance of each in contributing towards the objective.

7. The priority is synthesised in a manner similar to step 5.

8. Calculate the overall priority for each alternative, and select the alternative having the highest priority.

4 RESULTS AND DISCUSSIONS

4.1 Properties and commercial data on replacement brush cutter blades

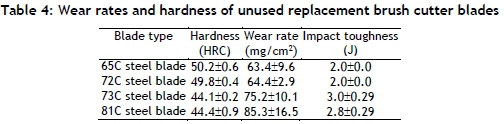

Four alternative blade types were selected, based on the survey results, as those four ranked the highest in purchaser selections. Typically, Thai farmers make their decisions to buy tools by following suggestions given by neighbouring farmers [3]. The decisions are not informed by data, but the suggestions are derived from real experience. In this investigation, the technical data of the select blades were examined in terms of hardness, wear, and toughness; the test results are shown in Table 4. The 65C steel blades had the highest average hardness of 50.2 HRC and the lowest average wear rate of 63.4 mg/cm2 (the best wear resistance). The average hardness and wear rate of 72C steel blades was not very different from those of the 65C steel blades. The average hardness decreased with increasing average wear rate (decreasing wear resistance), which matches the investigation of Gore and Gates [14]. The hardness and wear resistance had the following decreasing rank order of steel blades: 65C, 72C, 73C, and 81C. Higher wear resistance implies a longer service life [3], while hardness is also related to sharpness. Verhoeven et al. [15] found that high carbon steel, with high 61 HRC hardness, had a better cutting performance than low 41 HRC hardness. Conversely, the impact toughness of 65C and 72C steel blades is below those of 73C and 81C steel blades. The 73C steel blades had the highest toughness among the blades tested. Kwon et al. [2] used the impact test to predict the blades' response to collisions with a steel bar, following the test specifications for the Korean safety certificate. The impact toughness informed safety and reliability, which are requirements for high-speed products in foreign countries. The Korean safety certificate states that most of the tipped blades could not pass their safety testing [16]. The chips from blade tips that break off on impact with stones can seriously endanger humans.

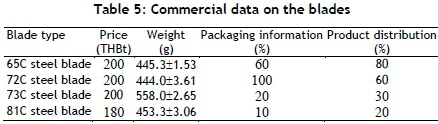

Previous survey results found that price, shape (weight), packaging information, and product distribution of the blades affected farmers' decisions when selecting which blades to buy [3]. In this work, the survey results of price, shape (weight), packaging information, and product distribution of the alternative blades are summarised in Table 5. The 81C steel blade had the lowest cost, while the others were not much more. If the mechanical properties of the blades were no different, the cheaper blade would surely be selected over more expensive ones. Kool et al. [17] found that farmers opted to buy familiar products rather than just going on price. On the other hand, the weight of the blade was a factor affecting the farmers' buying decision: the farmers favoured lightweight blades [3]. In our case, the 73C steel blade was heavier than the others. The packaging information reflected manufacturer reliability. Moreover, the farmers could contact the manufacturer directly, should they have problems with the blades. The 72C steel blade had 100 per cent packaging information traceability. The blades distributed by shops were given percentages (%) of product distribution. The 65C steel blade had the highest (80%) product distribution, indicating that 80 per cent of the shops had these blades on the shelves. Product distribution or product availability at shops reflects the marketing strategy [18].

4.2 The AHP method applied to replacement brush cutter blade selection

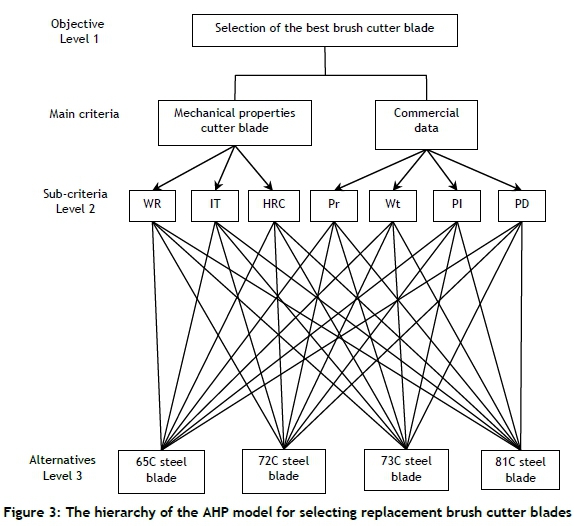

In engineering, the mechanical properties of materials typically serve as criteria for selecting between alternatives, with the Ashby approach [19] and the quality index method [20, 21] being developed for this. An AHP method was also applied to welding [12] and forming [22] processes. In this work, an AHP method using the mechanical properties and the commercial data was applied to select the best brush cutter blades. Seven sub-criteria for selection from four alternative brush cutter blades were set. Three criteria were for the mechanical properties of the blades: hardness, wear rate, and impact toughness. Other criteria involved price, weight, packaging information, and product distribution. The general methodology for selecting a specific blade is shown in Figure 3, which shows the schematic layout of the AHP model, and provides the hierarchy for the problem. The top level shows that the overall objective is to select the best brush cutter blade. On the second level, the main criteria and sub-criteria contribute to achieving the overall objective. On the bottom level, the four alternative blade types are presented, to be evaluated through the criteria in a unique manner.

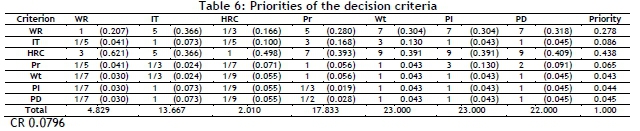

Table 6 presents the pairwise comparison of the blades with each of these criteria, which corresponds to the survey results in previous work [3]. In previous work, farmers considered sharpness as the first factor in the selection process, and service life as the second factor. Therefore, hardness positively correlating with sharpness has the highest importance. Wear rate is the next in importance, because it relates to service life. The impact toughness relates to safety and reliability, which are both important. However, the farmers considered this factor as the least important to them. Thus the importance of impact toughness is less than that of hardness and wear rate. The pairwise comparisons by each criterion in Table 6 reveal hardness as the most important criterion (priority=0.438), followed by wear rate (priority=0.278), and then impact toughness (priority=0.086). The values in parentheses were determined by step 5. The consistency ratio (CR) is calculated using eq. (3), which gives CR=0.079. This CR indicates that the data in Table 6 are available, as stated by Park et al. [5] and Saaty [7].

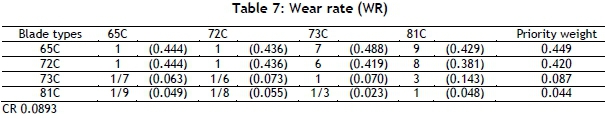

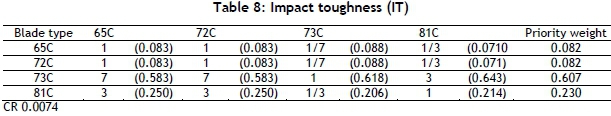

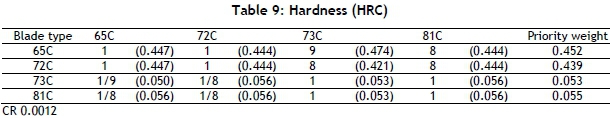

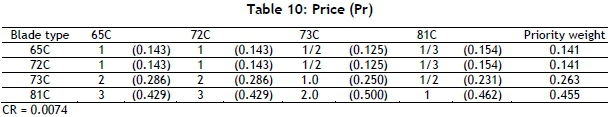

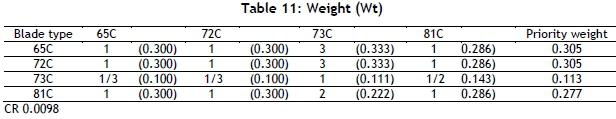

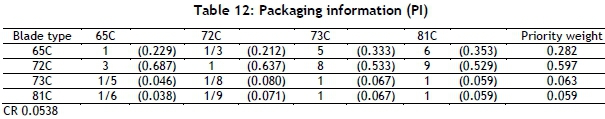

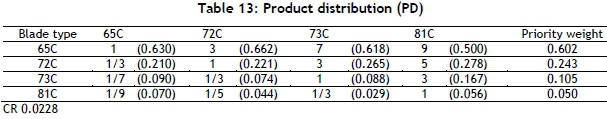

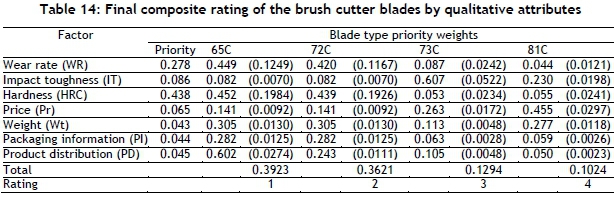

The scales for pairwise comparisons of the alternative blades by each criterion in Tables 7-13 are derived from the mechanical properties and the commercial data in the previous section. The values in parentheses were calculated using step 5. Considering each criterion, the 65C steel blade had the highest priority of 0.449 (Table 7), 0.452 (Table 9), and 0.602 (Table 13) for wear rate, hardness, and product distribution respectively. The 73C steel blade had the highest priority of 0.607 (Table 8) for impact toughness. The highest priority by price (Table 10) was 0.455 for the 81C steel blade. Both 65C and 72C steel blades had the highest priority of 0.305 (Table 11) for weight. The 72C steel blade also had the highest priority of 0.597 (Table 12) for product information. The results in Tables 7-13 are summarised in Table 14, in which the composite weight for each steel blade is determined. The best brush cutter blade type is the 65C, followed by 72C, 73C, and 81C, in that order. The best brush cutter blade found by AHP is consistent with the farmer survey results of Chucheep et al. [3]. In this survey, the farmers bought the brush cutter blades, considering sharpness first and service life second, using their own experience or word of mouth from their colleagues. In this work, the hardness and wear-rate criteria were related to sharpness and service life, with 65C and 72C having the highest hardness and wear resistance, but the 65C steel blade having better product distribution than the 72C.

5 CONCLUSIONS

This work aimed to select the best replacement brush cutter blades for farmers. Replacement brush cutter blade selection is a multi-criterion decision. Making such a decision by price only is not reasonable - long service life and sharpness of the blades also need to be taken into account. The AHP method can quantify intangible criteria such as mechanical properties and commercial data about the alternative blades. The best blade was selected based on hardness, wear rate, impact toughness, price, product distribution, product information, and weight. The AHP method applied to brush cutter blade selection identified the 65C steel blade as the best option. The 65C steel blade has high hardness and wear resistance, equal to the 72C steel blade, but the product distribution of the 65C steel blade is better than that of the 72C steel blade.

ACKNOWLEDGEMENTS

This research was partially supported by funding contract number SIT570808S and the Center of Excellence in Materials Engineering (CEME), Prince of Songkla University, and Prince of Songkla University, Surat Thani Campus (2016). The authors would like to thank Aj. Chanchai Haeoau and Aj. Noppadon Choosit, Suratthani Technical College, for their kind help. The authors would also like to thank Assoc. Prof. Dr Seppo Karrila for commenting on the manuscript.

REFERENCES

[1] Makita Corporation. 2015. Operating Manual RBC411 and RBC411U. http://www.makita.com.vn (accessed 13 December 2016). [ Links ]

[2] Kwon, Y.D., Park, S.J., Choi, W.G., Bang, S.I. & Kwon, H.W. 2014. Shear cutting theory for the peripheral edges of brush blades and test of its effectiveness. Int. J. Precis. Eng., 15, 1459-1465. [ Links ]

[3] Chucheep, T., Mahathaninwong, N. & Janudom, S. 2016. Brush cutter blade purchasing and using behaviour of farmers in Surat Thani province. J. Agr. Res. Ext., 33, 74-81. [ Links ]

[4] Lau, K.H., Mei, D., Yeung, C.F. & Man, H.C. 2000. Wear characteristics and mechanisms of a thin edge cutting blade, J. Mater. Process Tech., 102, 203-207. [ Links ]

[5] Park, J.W., Cho, Y.K. & Wang, C. 2015. Analytic hierarchical procedure and economic analysis of pneumatic pavement crack preparation devices. J. Constr. Eng. Prt. M., 5, 44-52. [ Links ]

[6] Garwin, D.A. 1987. Competing on the eight dimensions of quality. Harvard Business Review : November-December, 101-109. [ Links ]

[7] Saaty, T.L. 1980. Analytic hierarchy process. New York: McGraw-Hill. [ Links ]

[8] Subramanian, N. & Ramanathan, R. 2012. A review of applications of analytic hierarchy process in operations management. Int. Prod. Econ., 138, 215-241. [ Links ]

[9] ASM Handbook, Vol.8. 2000. Mechanical testing and evaluation. Ohio: ASM International. [ Links ]

[10] Chucheep, T., Mahathaninwong, N., Janudom, S., Haeoau, C., Onthong, C., Sakuna, C., Thongkaew, A. & Phaijit, S. 2017. A study of manufacturers and steel grades of replacement brush cutter blades in Surat Thani province. Thaksin Univ. J., 20, 64-73. [ Links ]

[11] ASTM E23. 2004. Standard test methods for notched bar impact testing of metallic materials., Pennsylvania: ASTM International. [ Links ]

[12] Brunelli, M. 2015. Introduction the analytic hierarchy process. http://springer.com/978-3-319-12501-5., Springer (online), (accessed 14 December 2016). [ Links ]

[13] Ravisankar, V., Balasubramanian, V. & Muralidharan, C. 2006. Selection of welding process to fabricate butt joints of high strength aluminium alloys using analytic hierarchic process. Mater. Des., 27, 373-380. [ Links ]

[14] Gore, G.J. & Gates, J.D. 1997. Effect of hardness on three very different forms of wear. Wear, 203-204, 544-563. [ Links ]

[15] Verhoeven, J.D., Pendray, A.H. & Clark, H. 2008. Wear test of steel knife blades. Wear, 265, 1093-1099. [ Links ]

[16] Korean Standards of Safety Certification. 2014. Metal blade for portable brush cutters., Chungcheongbuk-do: Korean Agency for Technology and Standards. [ Links ]

[17] Kool, M., Meulenberg, M.T.G. & Broen, D.F. 1997. Extensiveness of farmers' buying processes. Agribusiness, 13, 301-318. [ Links ]

[18] Howard, J.A. 1989. Consumer behavior in marketing strategy. Englewood Cliffs: Prentice-Hall. [ Links ]

[19] Ashby, M.F. 2005. Materials selection in mechanical design, 3rd ed. Oxford: Butterworth-Heinemann. [ Links ]

[20] Ammar, H.R., Moreau, C., Samuel, A.M., Samuel, F.H. & Doty, H.W. 2009. Effects of aging parameters on the quality of 413-type commercial alloys. Mater. Des., 30, 1014-1025. [ Links ]

[21] Alexopoulos, N.D. 2007. Generation of quality maps to support material selection by exploiting the quality indices concept of cast aluminum alloys. Mater. Des., 28, 534-543. [ Links ]

[22] Zafarani, H.R., Hassani, A. & Bagherpour, E. 2014. Achieving a desirable combination of strength and workability in Al/SiC composites by AHP selection method. J. Alloys Compd., 589, 295-300. [ Links ]

Submitted by authors 29 Apr 2018

Accepted for publication 20 Feb 2019

Available online 29 May 2019

* Corresponding author. thiensak.c@psu.ac.th

# The author was enrolled for a Doctor of Engineering (Materials Engineering) degree in the Department of Mining and Materials Engineering, Prince of Songkla University, Thailand