Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

South African Journal of Industrial Engineering

On-line version ISSN 2224-7890

Print version ISSN 1012-277X

S. Afr. J. Ind. Eng. vol.27 n.4 Pretoria Dec. 2016

http://dx.doi.org/10.7166/27-4-1478

GENERAL ARTICLES

A technologically-driven asset management approach to managing physical assets - a literature review and research agenda for 'smart' asset management

Asset Care Research Group, Department of Industrial Engineering, University of Stellenbosch, South Africa

ABSTRACT

The concept of 'smart' is increasingly used in the commercial environment, and relates to a perception of technological intelligence. The concept of 'Internet of Things' (loT) has also become a reality that makes a different approach to managing physical assets necessary. With this technological intelligence come vast quantities of asset data and the analysis thereof, which has proven to add value to asset management. To capitalise on and expand this value creation, smart asset management (SAM) came into being by incorporating proven methodologies and applying these in real-time management structures. This article offers a review of the existing literature, and aims to create industry awareness about the business potential of incorporating SAM into automated asset environments for strategic management decision-making.

OPSOMMING

Die uitdrukking 'slim', wat met die persepsie van tegnologiese intelligensie verband hou, is 'n konsep wat toenemend binne die kommersiële omgewing gebruik word. Die 'loT' ("Internet of Things") konsep dra verder by tot die behoefte aan verskillende benaderings tot batebestuur. Meer waarde word aan batebestuur geheg as gevolg van hierdie tegnologiese intelligensie wat binne batebestuur analise toegepas word. Vanuit hierdie agtergrond is 'slim batebestuur' ontwikkel. Dit is 'n nuwe benadering wat bestaande metodes inkorporeer en terselfdertyd binne eietydse bestuurstrukture toegepas word. Hierdie artikel gee 'n oorsig van die slim batebestuur literatuur, en poog om uit te brei op die voordele van slim batebestuur binne geoutomatiseerde bate-omgewings met die doel om strategiese bestuursbesluite te neem.

1 INTRODUCTION

William Edwards Deming was incorrectly quoted as saying, "You can't manage what you don't measure", when in fact he was adamant that the management of an organisation cannot be run on visible measures alone. His concerns were related to the long-term consequences that organisations confront but that cannot be measured in advance [1]. It is with this awareness in mind that the theory of asset management (AM) is an integral study. AM can be described as a way to plan in advance by substantiating the validity of a decision with information and measurements [2]. These decisions can then be used to justify future strategic processes and outcomes regarding physical assets. Thus the statement can be made that these strategic processes are partly biased towards the interpretation of information collected from individual assets and from an encompassing asset network.

Smart asset management (SAM), which is rooted in AM, emphasises the notion of technologically-driven processes to enhance the capture and processing of information to assist in making strategic decisions [3]. Asset-owning organisations rely on AM performance strategies to excel in the competitive business environment [4]. The proposed concept of SAM, discussed in this literature review, is a way to improve AM strategies in an organisation. SAM can offer a structure to validate and improve asset performance by collecting and incorporating reliable asset information in strategic business decision-making.

Although Deming's concerns have a number of merits, established quality models are also used to show that effective actions or decisions are based on a loop back of information, such as the define-measure-analyse-improve-control (DMAIC) cycle and the plan-do-check-act (PDCA) cycle, to which Deming was a contributor [1]. Also in this concept of information feedback is the inception of the 'Internet of Things' (loT), which is making vast quantities of information accessible to various sources. This requires a new approach to AM that can use this information effectively. Statistical analysis through the use of reliable figures is a measuring tool that is integral to achieving quality and performance standards [3]. Such tools emphasise the need to monitor assets continually, in order to evaluate the quality and performance of various processes and to control their outcomes. Performance management (PM) is another method where SAM can play an integral role. PM is defined as "the process of quantifying action, where measurement is the process of quantification and action leads to performance"; consequently the management of performance can be seen as "quantifying the efficiency and effectiveness of an action" [5]. In order to improve performance, organisations need to quantify action to be able to establish and realise benchmarks that lead to achieving the desired goals. SAM therefore plays a potentially important role in asset-owning organisations in support of PM.

As a result of the potential for enhanced asset analysis and the performance possibilities in organisations, the need arises for a clear definition of SAM and a delineation of its implementation in business structures. As this literature review will show, the current use of SAM in industry is not clearly documented, with only a few literature studies and white papers referring to the development and classification of smart assets [6] [7] [8] [9] [10]. Table 1 lists organisations that specifically refer to SAM in their value propositions. This list confirms the abundant examples that exist relating to SAM implementation, from retail data mining to financial asset maintenance. Although the concept of SAM is marketed by these organisations, its implementations differ extensively across organisations [6] [11] [12] [13] [14] [15] [16] [17] [18] [19] [20] [21] [22] [23] [24] [25] [26] [27] [28] [29] [30]. It is in this variety of interpretations of SAM that common factors needs be identified. Hence the need for a concise definition of SAM to avoid conflicting terminologies, and to establish a basis for future research. It is in these conflicting terminologies that various concepts have already been established in the literature [6] [7] [8] [9] [10]. Although these concepts are acknowledged separately, they relate to the central idea of technological process management. These separate ideas also need to be addressed to establish a foundation for the further development of SAM.

It can be said, further, that businesses operate in an era of technological performance in which electronic goods and technology are overwhelming industry, and in which market competition is a driving factor for organisations wanting to offer the latest expertise [31]. By investigating the organisations that claim to implement SAM (Table 1), it is evident that there is a business need in these industries. This makes the academic investigation of SAM necessary to establish the prerequisites for theoretical implementation. There is a clear link between technological performance management and electronic convergence, thanks to the availability of information through interconnected communication structures [32]. This link implies the potential for businesses to offer significant information across multiple platforms, making knowledge more accessible to various stakeholders in the organisation. It is in this wave of technical ability that organisations will be able to use technology in a number of ways to create market advantage. The Aberdeen Group has identified best-in-class industry characteristics that organisations are using in asset management strategies to reduce operational cost, improve profitability, and improve their competitive edge in the market place. This research speaks to managing resources effectively by reducing manufacturing costs in "technological interoperability" [33], where an increasing emphasis is placed on the use of technology to monitor physical assets to operate at optimal conditions, thereby delivering predetermined targets.

From this background it is apparent that asset managers are at the helm of this technology where tactical decisions about physical assets need to be addressed to make use of this technological potential. The purpose of this article is to delineate the domain and constructs of SAM, to provide an operational definition, and to introduce a comprehensive framework for directing future research. The article draws on the SAM literature on implementation, management, and engineering constructs to provide a review of the use and terminology of SAM.

2 SMART ASSET MANAGEMENT DESCRIBED

Because SAM clearly falls in the asset management domain, this may lead to the question: why is SAM exceptional, and does it need to be addressed independently? The rationale behind this study is highlighted in the importance of incorporating technological advances into operational management [34], combining the established fields of asset management and performance management, and improving their implementation by using technology. Industry in general has an increasing tendency to adopt automated processes that can provide more efficient, consistent control of various deliverables. The literature confirms the tendency to automate systems to achieve specific results. Wang [31] proposes that "IoT and cloud computing are conducive to helping conventional assembly modelling systems to evolve into an advanced system, which is capable of dealing with complexity and changes automatically", while James Meehan [35], past president of General Electric Industrial Automation, proposes that "integrated automation, the inter-linking of all the automated elements of a plant-robots, computers, machine tools, mechanical handling equipment, warehouses, was the key to long term survival for manufacturing enterprises. Successful automation depends not on how many production functions can be automated, but why the company automates its various manufacturing operations and how it goes about it. Some plants have achieved a quantum leap in performance simply by automating just one production function: others have automated their entire manufacturing operation and gained virtually nothing." It is in this fast-paced production environment that the need arises to manage assets efficiently to cope with this increasing tendency towards automation.

2.1 The Smart awareness

The Oxford Dictionary defines 'smart' as "having or showing a quick-witted intelligence" [36]. When 'smart' is used to describe a device, it can be defined as "programmed so as to be capable of some independent action". The Collins Dictionary [37] further describes smart as a "term for any piece of equipment that works with the help of a microprocessor... Designers are incorporating smart technology into an increasing range of products, such as a smart toaster, which can prevent toast from burning; smart furniture, such as chairs with cushions that adjust themselves according to the size and weight of a person sitting in them". As Grogan [38] points out, smart appliances will grow as a consumer trend. Here it is evident that the term 'smart' is a marketing term that is used to differentiate between ordinary household appliances and those with above-average intelligence.

López et al. [39] [40], Vaishnavi et al. [41] and Xu et al. [42] have all also contributed to the term smart object. Each study describes an object characterised by a degree of intelligence that is able to make informed decisions for itself or in a greater network of devices. Their research also details how smart objects are the basic building blocks for various automated systems, where each block possesses some of the following attributes:

• It has an individual identity

• It has sensory abilities to detect information

• It is able to store data about itself

• It is capable of communication in its own networked environment

• It has processing capability to participate in making decisions

• It can take various physical actions in response to information

'Smart fields', defined by de Best [34], are described as an integration of technology, processes, and resources. Three key components of a smart field are described:

1. Reliability of the data;

2. Tools to interpret the data and transform it into workable information;

3. Skilled operational advisors who can use the information the best interests of the organisation.

According to de Best [34], asset managers should strive for continuous measurement to allow better decision-making to take place. De Best [34] creates an association between the implementation of strategy and the risk management of assets, where accurate operational feedback allows for the management of opportunities to make more informed strategic decisions.

The word 'smart' therefore closely relates to being able to interpret information into workable knowledge that is useful to the end user. This creates the impression of artificial intelligence, where assets can think for themselves and, more so, for us.

2.2 Asset management (AM) and asset decision-making

AM is becoming a well-established field of research with a variety of definitions, academic sources, and alternative variants that further branch out into separate specialist studies. However, inherent in any asset management systemis the requirement of asset information and feedback systems [3]. AM is a management-based field of study that incorporates human operational structures for managing people who manage physical assets [3]. AM therefore supersedes asset maintenance, and requires management's buy-in to incorporate AM into organisational strategy and to implement asset-related strategies in the operational and the organisational structures [3].

As defined by ISO 55000 [43], an asset is an "item, thing or entity that has potential or actual value to an organization", where the "value can be tangible or intangible, financial or non-financial, and includes consideration of risks". This international standard is specifically created to define AM with respect to managing physical assets, where "physical assets usually refer to equipment, inventory and properties owned by the organization. Physical assets are the opposite of intangible assets, which are non-physical assets such as leases, brands, digital assets, use rights, licences, intellectual property rights, reputation or agreements". The management of these physical assets is defined as the "coordinated activity of an organization to realize value from assets"; and the "realization of value will normally involve a balancing of costs, risks, opportunities and performance benefits" [43]. A strategic asset management plan (SAMP), as used by ISO 55000, is defined as the "documented information that specifies how organizational objectives are to be converted into asset management objectives, the approach for developing asset management plans, and the role of the asset management system in supporting achievement of the asset management objectives" [43]. The Publically Available Specification (PAS) 55 [44] - a publication that preceded ISO 55000 - also highlights AM with respect to managing physical assets. This standard defines AM in the context of an organisational strategic plan, where AM implementation is defined as the "systematic and coordinated activities and practices through which an organization optimally manages its assets, and their associated performance, risks and expenditures over their life cycle for the purpose of achieving its organizational strategic plan".

The US Department of Transport defines AM, in the scope of the transport industry, as being "... a systematic process of maintaining, upgrading, and operating physical assets cost-effectively. It combines engineering principles with sound business practices and economic theory, and it provides tools to facilitate a more organized, logical approach to decision-making. Thus, asset management provides a framework for handling both short- and long-range planning" [2]. This example of AM illustrates how AM relates to strategic decision-making. Asset managers are constantly faced with the need to create structures for decision-making about the assets they manage. Taking strategic decision-making further, the psychologist Leon Mann [45] developed a decision-making framework to classify the basic elements required in a decision-making process. This process is used as the basis for teaching fundamental decision-making theories. Using the acronym GOFER, Mann highlights the following components that are required to make a decision [45]:

• Goals: review of values and intentions.

• Options: reflection concerning the variety of selections available.

• Facts: the pursuit of information.

• Effects: evaluation of the pro's and con's for each decision.

• Review: The implementation strategy and feedback of conclusions.

Just as Mann highlights these requirements for decision-making, so too these principles are applicable to decisions about management principles in, but not limited to, AM for strategic business development. Charlan Nemeth [46] describes good and bad decision-making aspects as follows: "Decision making involves choosing among alternatives based on the goals and values of the person or group making the decision. Good or quality decision making involves a thorough analysis of available information and a consideration of alternatives in an unbiased manner." It is further stated: "Defective decisions come from poor information search, selective bias in processing the information, a lack of considering alternatives, a failure to examine the risks of the preferred choice and a rush to judgment". Nemeth therefore highlights the importance of unbiased, quality information as a requirement for good decision-making. The concept of quality information is clearly reflected in the 39 subjects of asset management [3]. "The quality of asset data & knowledge should be assessed, understood and managed in order to ensure that it provides effective support to business decision making and processes" [3]. The AM literature further refers to "asset knowledge enablers", which consist of the following AM subjects [3]:

• Asset information strategy

• Asset knowledge standards

• Asset information systems

• Asset data and knowledge

These four asset knowledge enablers produce a flow from asset information to organisational knowledge via standards and systems. Arnaldo Oliveira [47] concludes that "rational decision-making models establish a weighing mechanism between choice and value. Rational methodologies lead to the optimization of the outcomes by emphasizing the process of choosing rather than on what is chosen. A certain alternative is always selected whenever its expected value is greater than that of other potential choices". Therefore, rational decision-making is defined by the process of choosing - in other words, the structures and standards that govern the choices we make. Quality information - and specifically knowledge - therefore forms the basis of quality decisions that could lead to quality results, when applied in a premeditated, systematic, and standardised operational process.

From these theories it is evident that AM standards are defined by an individual or a group who have considered which decisions might offer the best outcome, taking into account the probability of failure, and also acknowledging the potential risks associated with these decisions. This notion of rational decision-making illustrates how AM leaders need to make rational and strategic decisions about assets. Their decision-making processes should facilitate the growth and development of structures that focus on information becoming knowledge, in order to enable quality decisions that allow for an improvement in AM performance. It is in this decision-making process that SAM can play a vital supporting role to enhance the quality and consistency of these strategic decisions.

2.3 Smart Asset Management

From the synergy between 'smart' and AM, it is evident that the theoretical concept of SAM is related to the ability of assets to process information. This information is then further used to make more informed decisions about the environment in which these assets operate. It also implies that the asset itself should be inherently smart. A basic condition of the system is that the asset operates in a network of assets, contributing to the decision-making process established in the AM system. It is in this network of smart assets that an AM system can process information holistically, allowing individual assets to create knowledge for decision-making [7]. Figure 1 depicts the concept of communication between assets, in the context of the AM system and the organisational environment.

Assets are built to serve a purpose, and are bound by defined user limits. Therefore, by using technology, existing assets can be upgraded to achieve the basic requirements of a smart asset. Once the basic requirements are met, in order to ensure improved control and the ability to be better managed, these assets need to present essential decision-making information. This information can only be attained with sensory inputs, accumulating information in the desired focus areas. A thoughtful process needs to be applied to ensure what information is required that relates to the specific objective in mind. By focusing on assets that are critical in nature, or on bottleneck assets that limit production levels, they can be targeted to modify processes to operate more effectively [48]. With assets collecting information from various sensory inputs, this raw data needs to be processed into interpretable information. This information processing can either happen locally with the individual asset, or at a central data collection point. Each possibility has its own advantages and disadvantages that relate to the assets operating in an automated environment [7].

Because assets can operate in an automated environment, the concept of SAM becomes an important concept for managing them. SAM further implies the use of automated responses, based on digital capabilities, to enhance the control of organisational assets, where a techno-organisational environment can be created that allows technology to assist with implementing organisational performance management via the intercommunication between assets, using organisational feedback structures [7]. SAM is aimed at using technology to create streamlined approaches that can integrate asset management into other management systems more effectively, so that the supply of the required information to relevant sources can allow improved decisions to be made.

With AM being a key component of SAM, assets must have intellectual properties that offer the ability to support asset management and performance management more effectively. SAM explores these requirements by using technological advancements in communication infrastructure, processing, and integration of information in management structures.

3 TYPOLOGY FOR IDENTIFYING SAM

Currently the literature does not provide a clear definition or structure for SAM or its implementation; yet there are similar concept variations of SAM. One key concept related to SAM is the Internet of Things (loT), which is defined by the ability of objects to communicate over the Internet, making information available to any source that can access the Internet [31]. This leads to the potential of controlling assets anywhere, in any place that has an Internet connection, also making data globally accessible. The concept of cloud computing is also part of IoT, where processing information does not need to happen at the source [31]. This platform is conducive, therefore, to the implementation of SAM [49]. Other variations of SAM also contain the notion of creating a greater interdependence between objects using technology for achieving communication and information feedback [50]. The concept of SAM expands current AM performance initiatives to include an aspect of direct or real-time asset communication between assets in organisational management structures. This allows for the improved control of operational facets by focusing on asset performance in the greater organisational environment. SAM can therefore be viewed as applying AM in an automated environment, where assets are used to make strategic decisions or to use artificial intelligence - or even to use machine learning to improve their performance or that of other assets.

Luyer [8] defines SAM as a support for the management of organisations that allows asset intelligence to assist with strategic decision-making. "By acting smart, companies will move from an instinctive and intuition approach to a more fact-driven approach and from a corrective to a directive (preventive/predictive) approach. Real-time thinking instead of thinking in traditional years, months, weeks, moving to an action support type process, from not just efficient, but to an optimized approach (in terms of data, information, decisions)." Therefore asset decision-making should be based on facts, and decisions should take place in real-time, supported by a full understanding of the facts through measurements, alerts, and key performance indicators (KPIs). Luyer [8] also claims that 'smart manufacturers' are already using SAM capabilities to manage critical assets. This includes embedded information technology (IT) and software structures that provide critical information in the decision-making processes. Berger [50] supports this, describing SAM as "one of the most significant trends of the new century [which] is the transformation of physical assets such as plant equipment, facilities and vehicles, to smart assets. By adding a computer chip, RFID tag, GPS device or a sophisticated onboard computer, assets can be monitored and tracked from virtually anywhere. The digitization of assets has increased their value to the organization, and in turn, the need to better maintain them".

4 OPERATIONALISATION OF SAM

It is important that, although SAM is defined in the limitations of technological intelligence and AM, it should also be considered in its micro- and macro-environment. In the micro-environment, SAM requires the individual component to process the basic smart object requirements in a greater network of processes. It is in this greater network in an organisation that SAM can truly be applied in an operational decision-making sense. Therefore, for SAM to be considered truly successful, it must be able to demonstrate its value in an organisation.

4.1 Asset information analysis used in asset management

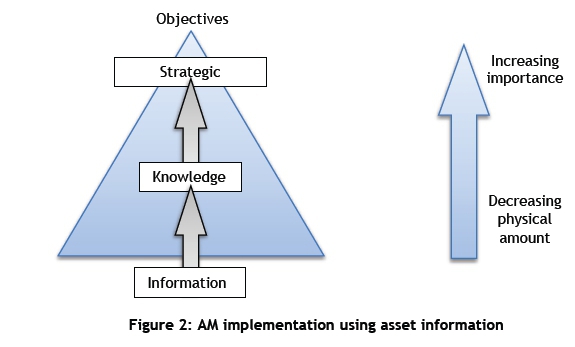

Pollard [51] wrote: "Information is a source of learning. But unless it is organized, processed, and available to the right people in a format for decision making, it is a burden, not a benefit." Asset information in this context could be regarded as the base of a triangular model of AM implementation (Figure 2), where the strategic decisions are centred on this information and lead to the objective at the apex of the model. The physical amount of information available in AM processes also represents the base of the model, with the final objects at the summit. However, asset information cannot be considered the starting point for achieving successful AM.

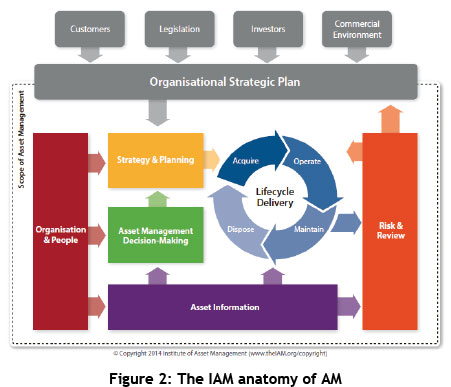

The scope of AM consists of six groups, illustrated in Figure 1 [3]. This flow diagram highlights the "intent[ion] to describe the complete scope of Asset Management. Therefore any person who intends to become demonstrably competent or expert in this field will need to know enough of the complete breadth of all the subjects in addition to any deep and detailed expert knowledge in any one of them."

According to this definition, expert knowledge of the context of asset information is important to understanding its implementation in AM strategic decision-making. Burnet and Vlok [52] identify organisations in the mining industry that are not using numerical decision-making due to its complexity and a lack of understanding. According to the research, this lack of understanding originates from "a tendency in practice not to use the techniques because of the great degree of complexity and the effort required". This is, however, a complex scenario for all asset informationintensive businesses, as a danger lies in two contrasting scenarios: first, where over-simplified automated structures can result in a lack of understanding; and second, collecting data without a thorough understanding of the end requirement. Berger [32] highlights this latter danger with respect to computerised maintenance management systems (CMMS). He says: "It's quite astonishing just how reliant management is on a CMMS to provide information such as budget variances, asset availability and performance, energy consumption, payroll hours consumed, work backlog and so on. Yet despite our thirst for information, there's sometimes little thought as to where the data is coming from and whether it reflects reality. It's our inexplicable blind faith in technology that is our weakness - as if anything the CMMS outputs to screen or paper must be accurate because a computer processed it. As many maintenance managers have discovered over the years, the quality of data input into the CMMS can be sadly lacking". It is evident, therefore, that emphasis should be placed on quality information that reflects the true current reality. True information also requires a thorough understanding of the structures used to interpret this information, which enables an organisation to gain knowledge to make effective decisions about their assets.

Aberdeen [4] identifies benchmark strategies that organisations have developed to improve AM maturity. Their research involves assessing the AM maturity levels of more than 160 organisations, based on the characteristics that serve as guidelines for best practices. According to the research, the following five characteristics correlate directly with best-in-class key performance indicators:

1. Process (the standardisation and management of processes across the enterprise);

2. Organisation (cross-functional teams established to create a corporate culture of reliability);

3. Knowledge management (using data-modelling capabilities to automate workflows);

4. Technology (the software and capabilities that are crucial for asset management);

5. Performance management (use of asset data to manage performance).

The research highlights that successful organisations (the best-In-class performance group) are more inclined to use technological information systems by implementing CMMS, plant floor automation (PFA) and enterprise asset management (eAm) than are the less successful 'laggard organisations'. The IAM [53] also refers to four important enabling factors on which asset-intensive organisations rely. These factors are important when undertaking both "strategic AM activities and operational activities". The four enablers are asset data, information, knowledge, and wisdom; and these interdependent factors ultimately lead to a greater understanding of the assets. This greater understanding should in due course lead to insight into what information is required in an asset management context, and how this information should be managed through collection, storage, analyses, and feedback. This process should also be repeated or amended over time.

Asset information puts knowledge at the disposal of asset managers. With this knowledge, structures can be created to make informed decisions. By integrating these structures, various established AM techniques can be used in real-time management structures. Such techniques include condition monitoring and overall equipment effectiveness (OEE). OEE is measured as a percentage of asset availability, throughput, and quality [4], and is an example of a standardised metric that gauges asset success and draws repeatable conclusions about individual asset performance. With this metric, consistent information can be collected to interpret historical data, and so to provide a trend analysis that leads to probability assessments - which in turn can assist with risk management decision-making. These concepts becomes even more valuable when applied as part of real-time feedback processes. Berger [50] describes the value of computerised support in analysis and decision support tools in "Pareto analysis to identify recurring problems, root cause analysis and lifecycle analysis".

It is under these conditions that Aberdeen describes technology as having a primary role of facilitating information sharing across an AM enterprise. Through this, employees gain greater insight into the manufacturing process [33]. Therefore, with technology the emphasis falls on measurement and communication. Shareholders are able to see more detailed information about an organisation in order to make decisions. Senior managers can identify strengths and weaknesses, and so determine opportunities and threats by benchmarking themselves against their competitors. A key concept that must also be taken into consideration is system integration, the lack of which is a potential roadblock. This is because some systems are created to function independently. Integrating asset information into business systems allows for streamlined maintenance operations, complete lifecycle planning, and higher-level or intelligent management decisions [33].

4.2 Operational SAM in Oil and Gas industry

The literature states that the oil and gas (O&G) industry is considered a forerunner of SAM due to the application of SAM concepts. Methods have been implemented to improve AM by using smart technology to collect information about assets, and processing this data in a live feedback system [54]. Currently, sources from the University of Stavanger and the Norwegian Oil Industry Association (oLF) have published various articles distinctly relating to the use of smart assets [54] [7] [48]. Still, no specific reference has yet been made to the operational aspects of SAM concerning its implementation. Langeland, Liyanage and Raza have published multiple academic sources elaborating on the use of technology to monitor physical assets in real-time applications in the oil and gas (O&G) industry [7] [54] [48] [55]. These research articles cover topics such as digital capabilities, and technical integrity and performance optimisation [48]. These articles illustrate the need to reduce operational cost and improve product efficiency due to an ageing asset base. The remaining oil prospect on the Norwegian Continental Shelf remains substantial. However, with declining production and significant challenges over cost, the implementation of a SAM system has become a priority [7].

These articles continue to express the need for integration between assets and what is referred to as 'e-operations' [7]. The literature highlights the joint exploitation of advanced technologies, digital information and communications technology (ICT) capabilities, and real-time operational systems using technical data to optimise decisions. This allows a closer integration of work processes and decision loops with an effective and efficient division of work to optimise AM activities. These studies are based on the requirement for offshore oil rigs to establish "a technological leap [that] not only systematically builds strategic digital capabilities, but also provides necessary digital environment for active knowledge and intelligent data management" [7]. Specific reference is also made to "the concept of smart assets focus[ing] heavily on the cost-effective use of resources, competencies and data demands an integration of multi-disciplined teams for technical integrity and performance optimization" [48]. Liyanage and Raza [48] also highlight the need to pay attention to system threats that are attributed to technical integrity and reliability. These issues can severely affect offshore production facilities. An integrated analytical learning framework is proposed with the intention of supporting offshore operators and onshore planning engineers to recognise early the incident potential for appropriate and timely decisions [54]. Liyanage [7] emphasises the concept of SAM as taking the idea of asset management further to imply the use of digital capabilities to enhance the control of these organisational assets. This will lead to a techno-organisational environment that allows technology to assist with implementing organisational strategy via the intercommunication between assets and the organisational infrastructure.

Further research emphasises the need for real-time communication infrastructure. Leung [55] refers to the need for the deployment of automated asset visibility used in supply chain acquisition, "from requisition to rig". Four key advantages to applying this system are identified:

• Reduce expenses;

• Reduce lost production;

• Facilitate regulatory compliance;

• Reduce errors.

In the O&G industry specifically, various commercial sources identify the need for SAM. They offer commercial products that illustrate the footprint that SAM has in this industry. These organisations include TEGO Inc. [17] and Xerify [56], which both use RFID Smart Asset Solution. Another organisation, Schneider Electric, has established a blog that relates to the implementation of the SMART field. The blog, Smart Oil and Gas Field, Real time data, Real time decisions [15], highlights the need to implement automated processes to deal with operational aspects in the O&G industry. The application of SAM in this industry verifies the need for organisational experience in making intelligent decisions using real-time information.

5 EMPIRICAL LITERATURE COMPARISONS

It has been established that business that use technology to collect information about assets can effectively implement improved AM and concurrently manage these assets for desired performance. Thus various organisations understand this potential of SAM, and attempt to monopolise this concept. Many organisations claim to authenticate this specialised service of SAM implementation in industry. However, few of these organisations provide any definition that is substantiated by the literature. It is in this literature void that various concepts related to SAM are investigated.

5.1 Smart asset management (SAM)

Various organisations' websites offer SAM services or products. These include Smartamsol (Smart Asset Management Solutions), consulting services for smart asset management implementation [57]; TEGO Inc, in the form of radio frequency identification (RFID) [17]; Smart Asset Manager with its vehicle tracking capacity [14]; Asset Smart, which provides AM software [12]; Tigo Energy, which highlights the use of SAM in solar PV monitoring tools; and Indra, which provides smart energy applications [16] (also refer to Table 1). However, all of these organisations discuss SAM from the perspective of their unique organisational offering and implementation methodology.

A universal understanding of SAM is needed, based on the consensus between industry role players - including, but not limited to, the organisations listed in Table 1. Firstly, a universally-acceptable definition for SAM is required that should address the requirement of smart objects, which is their ability to identify themselves and to communicate with a central point. A further consideration is to bridge the gap between virtual software and the physical asset. Philosophically, SAM could be regarded as a conduit between the physical asset realm and the virtual software realm, where communication infrastructures exist to mediate between the two realms. Media that enable SAM to facilitate this communication include serial (e.g., RS232, RS485), computer networks (e.g., ethernet, Local Area Network LAN, Wide Area Network WAN), and radio frequency identification (RFID) in various frequency ranges (Low Frequency - LF, High Frequency - HF, Ultra High Frequency- UHF). With the mediation of information also comes the requirement to distribute it to the required sources, where interpretation of this communication must occur to transform the information into workable actions, where example actions would be considered physical adjustments or tangible decisions. SAM focuses on the Physical Assets Management (PAM) in the physical realm, where SAM can be further used to interact with physical assets that might be stationary or moving. Some organisations have highlighted SAM as a way to keep track of these physical assets in a defined space by using smart technology to communicate information, such as positioning data to a central point, or real-time location system (RTLS) or global positioning software (GPS). These applications reflect some of the basic industry requirements, and can be used as a basis for classifying SAM.

5.2 The Internet of Things

Another industry concept related to smart assets that is gaining a lot of attention is the concept of the Internet of Things (IoT). Organisations such as Raspberry Pi Foundation, Microsoft, Samsung, Google, IBM, MECER, and Schneider Electrical are preparing themselves for the incorporation of large data sets shared over Ethernet-driven infrastructures. IoT and intelligent assets have become realistic theories that hold potential for asset managers. With the use of asset data analysis having been shown to facilitate the performance management of assets, there is a need to create a platform on which to create structures that allow informed, consistent, accountable, and real-time decisions to be made. Methods to collect and interpret this data therefore need to be addressed by asset managers for successful SAM. It is in this respect that a communication standard needs to be defined in which SAM can be established. IoT is one such platform that offers the most practical implementation opportunities for SAM.

There is research into the implementation and benefits of IoT, investigating its requirements and applications [49]. However, there is little literature on using AM in an IoT environment or vice versa. The literature does agree, however, that IoT consists of the same building blocks related to SAM - namely, smart objects that are able to communicate. The greatest difference, however, is in the application of the collected information. Van Kranenburg et al. [49] investigate the origin and policy ecology for the application of IoT by stating: "IoT will mainly consist of smart objects e.g. all forms of sensors, actuators, small devices connected together using radio technologies but also wired technologies. Iot applications will be used in a wide range of innovative areas like industrial automation, smart grids, smart cities, home and building automation to a name a few. In this sense IoT can be considered as an evolutionary process not as something completely new". SAM is also rooted, therefore, in the definition of IoT, where boundaries between these concepts are set apart due their intended implementation.

Various sources also refer to IoT as a business trend with great potential. Santucci [58] states: "For the economy, the Internet of Things will bring disruption - only companies that are able to exploit this new potential will survive". Bughin et al. [9] agree: "The combined effects of emerging Internet technologies, increased computing power, and fast, pervasive digital communications were spawning new ways to manage talent and assets as well as new thinking about organizational structures". Researchers therefore agree that IoT is related to an interconnected network of machines - i.e., assets that are able to communicate with a central source via the Internet and intranet. This is to allow for faster processing away from local data acquisition to a cloud platform that communicates with other assets. Wang, Bi and Da Xu [31] refer to IoT as a platform for communication, and list the factors that elaborate its implementation, drivers, potential applications, challenges, and how it enables the progression of technologies. They describe IoT as being able to "help companies to catch emerging opportunities and improve competitive advantage". IoT could be considered a requirement to process the amount of data generated from assets. In order for organisations to manage the amount of data generated from various sources, a central computing power is required to process raw data into sensible information that is applicable to management structures. This allows data to be processed faster; and, according to Glova [59], it leads to "shorter life cycles of product and services, requiring thus faster changing business models". The concept of IOT is therefore another key element in understanding how information is distributed from assets, and the ability of assets to 'make decisions' in a network of intellectual devices. IoT embedded in SAM is an application with great potential for improving asset management performance in automated management applications.

5.3 RFID TAGS

Radio frequency identification devices (RFID) are electronic tags or barcodes that are increasingly associated with asset management applications. Van Kranenburg et al. [49] describe the use of RFID as originating in the concept of IoT. These devices allow assets to define themselves in electronic systems such as CMMS. Lampe [10] identifies RFID as a key element in asset management because of its ability to "integrate the digital and the physical world by seamlessly connecting objects in the physical world with their representations in information systems". Dioguardi [60] describes the use of RFID in asset management systems for monitoring analytical instrumentation. He describes how "the technology provides details of asset location and it can monitor critical information pertaining to each asset; as such, RFID is fast becoming an integral part of everyday life". Dioguardi [60] is supported by other researchers [10] [56] in stating that RFID components encompass the application of SAM by using the ability of RFID technology in asset management. This identification technology is a basic step to applying the methodology of SAM. As Lampe [10] describes, RFID tags offer a method of integrating digital structures with physical assets - although this technology only illustrates a one-way communication system. RFID does not support a communication network, nor does it support the transfer of real-time data about the operational information of an asset. While RFID has a role to play in tracking assets, a more robust communication network is required to make full use of SAM principles.

5.4 Asset management integration

The integration of information into AM structures is a key component in decision-making, and also in the concept of implementing SAM. Bouleau et al. [61] conclude that "those companies that succeed in integrating their assets must have a clear strategy to guide the analysis of processes they need to modify. The ensuing changes can be difficult to implement, much less accept. But the companies that succeed in these efforts will be rewarded with a system in which validated data and customized workflows serve to improve the quality of decision making as they continually optimize their production". This theory illustrates the importance of an infrastructure that supports the feedback from assets as a way to steer operations towards optimised production and system stability. Raza and Liyanage [54] also apply this integration approach in the oil and gas sector. They refer to an artificial neural network, or an interconnected network of feedback from assets to a management system, that "...demonstrated how neural networks can learn and extract useful information from input data, ultimately transforming it into useful information about the system's condition...". These conditions "...can play a vital role in reducing uncertainties associated with the failure events". Koronios et al. [62] also describe the lack of AM integration as leading to a notion of "islands of information". "Such disconnects make it extremely difficult to bring real-time information from the plant into business systems".

5.5 Asset information management with respect to CMMS and EAM

Berger [50] refers to an industry movement towards smart assets. He defines this transition as "One of the most significant trends of the new century is the transformation of physical assets such as plant equipment, facilities and vehicles, to smart assets". According to his definition of SAM, an asset can be converted or made smart by adding an electronic device such as a computer chip, RFID tag, GPS device, or sophisticated onboard computer. Such electronic potential assets can be monitored and tracked from anywhere. Berger [50] adds that "the digitization of assets has increased their value to the organization, and in turn, the need to better maintain them using tools such as the CMMS".

Koronios et al. [62] refer to data quality in enterprise asset management (EAM), and consider CMMS and EAM as necessary to "translate the vast amounts of available asset data into meaningful management information to optimize their operation and control [in] the total asset base". Their research on data quality models for asset management in engineering organisations emphasises the need for organisations to collect and manage electronic data to distribute asset information effectively across various organisational structures. They also conclude that "the lack of process-to-product data transformation capabilities in linking business systems and plant floor EAM applications have significant data quality consequences and thus negatively affect data-driven decision-making".

5.6 Smart manufacturing and Industry 4.0

The concept of 'smart manufacturing' has been referred to by O'Donovan et al. [63] as a futuristic state of manufacturing in which the real-time interpretation of data retrieved from a factory manufacturing environment creates intelligence that can provide a positive impact across all aspects of operations. O'Donovan et al. [63] also reveal the creation of various initiatives and groups that have been formed to advance smart manufacturing. These organisations include the Smart Manufacturing Leadership Coalition (SMLC), Industry 4.0, and the Industrial Internet Consortium. These institutions are described as including industry, academic, and government partners who collectively aim to further the development of strategic policies, guidelines, and road maps that enhance the concept of smart manufacturing and its adoption.

The greatest driving force behind the concept of smart manufacturing, according to O'Donovan et al. [63], is the implementation of data-centric technologies. These are given various names - big data, machine learning, simulation, Internet of Things, and cyber physical systems - and are used to improve operations in a factory environment. This need for improved operations is defined by the ability to improve machine uptime and availability, and the importance of doing so. Thus the ideal use of smart manufacturing centres is in the analysis of data-driven, analytic systems that are used in conjunction with industrial equipment maintenance structures.

The main contributions of their research on smart manufacturing and big data is implemented in the maintenance environment, where data sets and system requirements are investigated to implement equipment maintenance applications in a smart industrial environment [63]. This research focuses on the information system model that provides a scalable and fault-tolerant big data pipeline for integrating, processing, and analysing industrial equipment data [63]. The contribution of this research of O'Donovan et al. is "considered in the context of highly regulated large-scale manufacturing environments, where legacy (e.g. automation controllers) and emerging instrumentation (e.g. internet-aware smart sensors) must be supported to facilitate initial smart manufacturing efforts".

6 CONCLUSION

Because SAM is still a new concept, its further exploration and expansion in industry is required, as a more in-depth analysis of its actual implementation and relevance would be beneficial. This should serve as a basis for creating a structural framework to investigate and define SAM further, along with its operational and implementational dynamics. From the reviewed literature, it can also be seen that the concept of SAM relates to being able to improve the management of assets in an organisation, based on the addition of a technological intellectual ability. Smart asset intelligence is related to being able to retrieve required information directly from the asset. This information can be anything from a unique identifying name or the operational condition of the asset, to the application of the asset in the form of automated maintenance. 'Smart' ability also includes the ability of assets to communicate with a central intelligent database interacting with organisational decision-making. This will allow assets either to manage themselves or to provide information to support more informed asset management decisions. The application of IoT and smart objects plays a vital role in the need for assets to be managed differently; artificial intelligence needs to be supported in management structures to enhance organisational performance. Furthermore, given the sectoral drivers established in the IoT industry applications, where mega-organisations are preparing to dominate the market, a SAM approach can be motivated as a requirement - indeed, as a basic necessity - in order to manage these sectoral drivers in a competitive environment by using concepts of automated artificial machine intelligence to facilitate the management of physical assets.

The concept of SAM therefore combines the fields of asset management, technology management, and organisational decision-making, especially in the current landscape, where the potential for adoption lies in multiple asset-owning industrial applications in local and global sectors. This highlights the potential for market competitiveness. SAM also requires that the management of assets be improved in an approach related to a 'techno-organisational environment' that allows asset managers to monitor assets consistently and to retrieve asset knowledge in an automated way, whether it is internal or external to the organisation, thus establishing a basis for improved, efficient asset decision-making with the possibility of external support.

From the definitions provided in this article, it is also evident that SAM aims to create a shift in the asset management mind-set, from a reactive approach that entails collecting asset information in a deliberate and conscious way, to a proactive approach that collects asset information automatically so that it is available at a central point for processing. The greatest feature of SAM is therefore its ability to interpret asset information in real time, allowing for flexible asset management decisions to be based on knowledge directly from the source. This further allows for a shift from asset status monitoring to asset performance monitoring, using technological intelligence. In the context of SAM technology, tools such as SCADA, CMMS, and EAM play a fundamental role in the effective application of SAM to assess asset performance. It is in this context that SAM is a powerful application that can be used by asset managers to highlight potential value and negotiate greater investment in asset management decision-making.

However, SAM has limitations. Adopting it has various cost implications related to hardware, computational capacity, software licences, human asset resource allocation to operate both hardware and software, and additional ICT security requirements (such as firewalls). The impact of these factors on organisations needs to be further investigated to comprehend fully the implications of incorporating SAM. Furthermore, the literature reviewed suggests that there is a need for future research into SAM to enhance current industry awareness and understanding of its operational aspects. It is suggested that further research be conducted that focuses on the implementation of SAM in an operational asset-owning organisation, such that it incorporates the smart objects and principles identified in this investigation. This research agenda should focus on the use of control and monitoring devices, such as SCADA and hardware capable of data acquisition, to analyse how implementing SAM improves AM performance. Currently, the private healthcare sector has been identified for the application of sAm, as certain of its assets play a critical role in hospital operations and in patient safety. For example, the performance of assets in a hospital's operating theatres is crucial to its financial operations: capital is lost for every minute of unanticipated downtime. Therefore, by identifying and monitoring these critical assets, unanticipated downtime could be avoided. Short-term goals to implement such a system include identifying a critical process and examining the assets that require the greatest attention and that would also have an impact on the performance of the application. Such a system would require a logical approach to monitoring these assets, one that is repeatable and autonomous. Long-term goals are to investigate the downtime before and after SAM has been implemented, to establish which aspects of SAM contribute both the least and the greatest value. This agenda would further reveal the potential for success in other industries wanting to implement SAM capabilities.

7 REFERENCES

[1] Edwards, D.W. 1994. The new economics for industry, government, education, 2nd ed. Cambridge, Massachusetts: MIT Press. [ Links ]

[2] U.S. Department of Transportation. 1999. Asset management prime, United States. [ Links ]

[3] The Institute of Asset Management. 2012. An anatomy of asset management: The 39 subjects and 6 subject groups. [ Links ]

[4] Aberdeen Group. 2008. Enterprise asset management: Maximizing return on assets and emerging trends. [ Links ]

[5] Neely, A., Gregory, M. & Platts, K. 1995. Performance measurement system design. International Journal of Operations & Production Management, 15(4) pp. 80-98. [ Links ]

[6] IBM Corporation. 2011. Smart asset management for the chemicals and petroleum industry. White paper. Somers, New York: IBM Corporation. [ Links ]

[7] Langel, T. & Liyanage, J.P. 2009. Smart assets through digital capabilities. IGI Global, pp. 3480-3485. [ Links ]

[8] Luyer, E. IBM Asset & Facilities Management blog. [Online]. https://www-304.ibm.com/connections/blogs/1f062ee8-a76e-4e2b-9554-819673462f3b/entry/what_does_smart_asset_management_mean_in_manufacturing10?lang=en_us. [ Links ]

[9] Chui, M., Manyika, J. & Bughin, J. 2010. Clouds, big data, and smart assets: Ten tech-enabled business trends to watch. McKinsey Quarterly. [ Links ]

[10] Strassner, M. & Lampe, M. 2003. The potential of RFID for moveable asset management, Switzerland. [ Links ]

[11] General Electric: Health Care Services. 2011. Smart asset management services. General Electric, Piscataway, NJ, Report for asset care services. [ Links ]

[12] AssetSmart. AssetSmart. Available at: http://www.assetsmart.com/s/19/ [accessed 10 August 2015] [ Links ]

[13] Tigoenergy. Tigo Energy. Available at: https://support.tigoenergy.com/hc/en-us/articles/201954387-Application-SMART-Asset-Management [accessed 10 August 2015] [ Links ]

[14] smartassetmanager. smartassetmanager. Available at: [accessed 10 August 2015]. http://www.smartassetmanager.com/software/software_01.html [accessed 10 August 2015] [ Links ]

[15] Schneider Electric. 2014. Smart Oil and Gas Field, Real time data, Real time decisions. Available at: http://blog.schneider-electric.com/machine-and-process-management/2014/12/04/oil-gas-fields-get-smart/ [accessed 10 August 2015] [ Links ]

[16] Indra Company. Smart Energy, Smart Asset Managment. Available at: www.indracompany.com [accessed 10 August 2015] [ Links ]

[17] TEGO inc - Oil and gas application brochure. 2014. Smart asset solution n for oil and gas. Available at: http://tegoinc.com/ [accessed 10 August 2015] [ Links ]

[18] bitplus. 2015. Smart asset. Available at: http://www.bitplus.co.in/smartasset.html [accessed 10 August 2015] [ Links ]

[19] Cognizant. 2015. Large-Utility-Gets-On-Track-with-Smart-Asset-Management. Available at:. http://www.cognizant.com/InsightsWhitepapers/Large-Utility-Gets-On-Track-with-Smart-Asset-Management-codex1430.pdf [accessed 10 August 2015] [ Links ]

[20] Eaglecmms. 2015. make-the-move-to-smart-asset-management. Available at: http://www.eaglecmms.com/make-the-move-to-smart-asset-management.htmjaccessed 10 August 2015] [ Links ]

[21] elutions. 2015. smart-assets. Available at: http://www.elutions.com/smart-assets-en.html [accessed 10 August 2015] [ Links ]

[22] Hera. 2015. Hera Group. Available at: http://eng.gruppohera.it/group/who_we_are/ [accessed 10 August 2015] [ Links ]

[23] Innovyze. 2015 innovyze. Available at: http://innovyze.com/ [accessed 10 August 2015] [ Links ]

[24] Minodes. 2015. smart-asset-management. [Online]. http://www.minodes.com/blog/smart-asset-management [accessed 10 August 2015] [ Links ]

[25] Olivetti. 2015. Available at: http://www.olivetti.com/EN/Page/t02/view_html?idp=363 [accessed 10 August 2015] [ Links ]

[26] Paconsulting. 2015. we-make-the-difference. Available at: http://www.paconsulting.com/about-us/we-make-the-difference/ [accessed 10 August 2015] [ Links ]

[27] SAP. 2015. smart-assets-infrastructure. Available at: http://go.sap.com/solution/industry/public-sector/future-cities/smart-assets-infrastructure.html [accessed 10 August 2015] [ Links ]

[28] smartasset. 2015. smartasset. Available at: http://www.smartasset.co.za/ [accessed 10 August 2015] [ Links ]

[29] strainstall. 2015. smart-asset-management. Available at: http://www.strainstall.com/systems/smart-asset-management/ [accessed 10 August 2015] [ Links ]

[30] Techsolution. 2015. smart assets. Available at: http://www.techsolution.co.za/Solutions/smartasset.html [accessed 10 August 2015] [ Links ]

[31] Bi, Z., Xu, L.D. & Wang, C. 2014. IoT and cloud computing in automation of assembly modeling systems. IEEE TRANSACTIONS ON INDUSTRIAL INFORMATICS, 10(2) pp. 1426 -1434. [ Links ]

[32] Berger, D. 2011. Ensuring maintenance data is good enough to trust: Understanding the characteristics of data quality. International Association for Information and Data Quality, 7(1). [ Links ]

[33] Aberdeen. 2007. Enterprise Asset Management: Technology interoperability. [ Links ]

[34] van den Berg, F. & de Best, L. 2006. Smart fields: Making the most of our assets. Moscow, Russia, [ Links ].

[35] Livermore, A. 2000. Computer horizons: Why automation is still not understood. [Online]. http://www.lexisnexis.com.ez.sun.ac.za/hottopics/lnacademic/?verb=sr6csi= 109396sr=HLEAD(Computer+Horizons %3A+Why+automation+is+stiU+not+understood.)+AND+DATE+IS+october+15+1985 [ Links ]

[36] oxforddictionaries. 2015. http://www.oxforddictionaries.com/definition/english/smart. Available at: http://www.oxforddictionaries.com/definition/english/smart [accessed 10 August 2015] [ Links ]

[37] Collins. Collins Internet-linked dictionary of science, in Collins dictionary of science. Glasgow: HarperCollins Publishers, 2003, p. 545. [ Links ]

[38] Grogan, A. 2012. Smart appliances. Engineering and Technology, no. Smart special: Consumer technology, pp. 44-45. [ Links ]

[39] López, T.S., Ranasinghe, D.C., Patkai, B. & McFarlane, D. 2011. Taxonomy, technology and applications of smart objects. Inf Syst Front, 13, pp. 281-300. [ Links ]

[40] López, T.S., Ranasinghe, D.C., Harrison, M. & McFarlane, D. 2012. Adding sense to the Internet of Things. Pers Ubiquit Comput, 16, pp. 291-308. [ Links ]

[41] Vaishnavi, V.K., Buchanan, G.C. & Kuechler, W.L. Jr. 1997. A data/knowledge paradigm for the modeling. IEEE TRANSACTIONS ON KNOWLEDGE AND DATA ENGINEERING, 9(2), pp. 275-291. [ Links ]

[42] Xu, G., Huang, Q.G. & Ji, F. 2015 Cloud asset for urban flood control. Advanced Engineering Informatics, 29, pp. 355-365. [ Links ]

[43] International Organization for Standardization. 2014. ISO 55000:2014 Asset management - Overview, principles and terminology. [Online]. https://www.iso.org/obp/ui/#iso:std:iso:55000:ed-1:v2:en [ Links ]

[44] British Standards (BSI) 2008. Asset management: Part1 Specification for the optimized management of physical assets. British Standards (BSI). [ Links ]

[45] Mann, L ., Power, C.N. & Harmoni, R. 1988. GOFER: Decision making in practice. Australia: Curriculum Development Centre. [ Links ]

[46] Nemeth, C.J. 2012. The psychological basis of quality decision making. The Institute for Research on Labour and Employment, 128(12). [ Links ]

[47] Oliveira, A. 2007. A discussion of rational and psychological decision-making theories and models. Electronic Journal of Business Ethics and Organization Studies, 12(2), pp. 12-17. [ Links ]

[48] Liyanage, J.P. & Raza, J. 2007. Technical integrity and performance optimization for enhanced reliability. Risk, Reliability and Societal Safety - Aven & Vinnem (eds), pp. 2509- 2516. [ Links ]

[49] Van Kranenburg, R. , Caprio, R., Anzelmo, E., Dodson, S., Bassi, A., Ratto, M., 2011. The Internet of Things," in 1st Berlin Symposium on Internet and Society, Berlin. [ Links ]

[50] Berger, D. 2010. www.plantservices.com. [Online]. https://www.plantservices.com/articles/2010/02AssetManager/ [ Links ]

[51] Pollard, W.C. 1996. The Soul of the Firm. Zondervan. [ Links ]

[52] Burnett, S. & Vlok, P.J. 2014. A simplified numerical decision-making methodology for physical asset management decisions, South African Journal of Industrial Engineering, 25(1), pp. 162-175. [ Links ]

[53] The Institute of Asset Management. 2009. Asset Information Guidelines (AIG). [Online]. https://theiam.org/knowledge/iam-project-work/subject-or-sector-specific-guidance/asset-information-guidelines-aig [ Links ]

[54] Liyanage, J.P. & Raza, J. 2011. An integrated qualitative trend analysis approach to identify process abnormalities: A case of oil export pumps in an offshore oil and gas production facility. [ Links ]

[55] Terence, L. 2011. Real-world business cases for real-time visibility across oil and gas supply. [Online]. https://www.iaccm.com/resources/?id=7175&cb=1429554207 [ Links ]

[56] XERAFY. 2010. RFID Implementation in Oil & Gas Industry. [ Links ]

[57] The Institute of Asset Management. Services and suppliers. [Online].https://theiam.org/directories/services-and-suppliers/smart-asset-management-solutions-limited [ Links ]

[58] Santucci, G. 2016. The Internet of Things: A window to our future. [Online].http://www.theInternetofthings.eu/content/g%C3%A9rald-santucci-Internet-things-window-our-future [ Links ]

[59] Sabol, T.,. Vajda, V. & Glovaa, J. 2014. Business models for the Internet of Things environment. Procedia Economics and Finance, 15, pp. 1122 - 1129. [ Links ]

[60] Smith, P. & Dioguardi, R.M. 2010. Use of RFID asset management systems for monitoring analytical instrumentation. Pharmaceutical Technology Europe, 22(9), pp. 66-70. [ Links ]

[61] Bouleau, C., Gutierrez, F., Gehin, H., Landgren, K., Miller, G., "The Big Picture:Integrated Asset Management," Columbia, 2007/2008. [ Links ]

[62] Koronios, A., Lin, S. & Gao, J. 2005. A data quality model for asset management, in University of South Australia. [ Links ]

[63] O'Donovan, P., Leahy, K. & Bruton, K. 2015. An industrial big data pipeline for data-driven analytics maintenance applications in large-scale smart manufacturing facilities, Journal of Big Data, a SpringerOpen Journal, no. 10.1186/s40537-015-0034-z. [ Links ]

Submitted by authors 17 Feb 2016

Accepted for publication 2 Aug 2016

Available online 6 Dec 2016

* wyhan@sun.ac.za

# The author was enrolled for an M Eng (Engineering Management) degree in the Asset Care Research Group, Department of Industrial Engineering, University of Stellenbosch