Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

South African Journal of Industrial Engineering

On-line version ISSN 2224-7890

Print version ISSN 1012-277X

S. Afr. J. Ind. Eng. vol.27 n.2 Pretoria Aug. 2016

http://dx.doi.org/10.7166/27-2-1241

CASE STUDIES

A fuzzy expert system for the integration of collaborative supply chains

H. Bautista-SantosI, *; J.L. Martinez-FloresII; M.B. Bernabé-LorancaIII; D. Sanchez-PartidaII; F. Sanchez-GalvanI

IInstituto Tecnológico Superior de Tantoyuca, Veracruz, México

IIUniversidad Popular Autónoma del Estado de Puebla, Puebla, México

IIIBenemérita Universidad Autónoma de Puebla, Puebla, México

ABSTRACT

The integration of supply chains has become a global operations strategy for many organisations because it allows them to improve customer service, minimise operating costs, and synchronise channels across the supply chain. This paper presents the design and implementation of a fuzzy expert system for the integration of collaborative supply chains. A measurement instrument that was statistically validated and formulated using a mathematical model was designed to implement the fuzzy expert system. This instrument was applied in 44 small-, medium-, and large-sized Mexican enterprises to determine their integration level. Specific actions were proposed, based on the results, to improve the attained integration level.

OPSOMMING

Die integrasie van voorsieningskettings is deesdae 'n omvattende strategie vir baie organisasies, omdat dit hulle toelaat om kliëntediens te verbeter. Die ontwerp en implementering van 'n wasige ekspertstelsel word voorgehou. 'n Statisties gevalideerde meetinstrument wat met 'n wiskundige model geformuleer is, is ontwerp om die wasige ekspertstelsel te implementeer. Dié meetinstrument is in 44 klein, medium en groot Meksikaanse ondernemings toegepas om hulle integrasievlak te bepaal. Spesifieke aksies, gegrond op die resultate, is aanbeveel om die integrasievlak te verbeter.

1 INTRODUCTION

Organisations and business activities are comprised of supply chains (SC) that are necessary to design, manufacture, and deliver a product or service. Companies depend on their SC to stay in the market and prosper. Each business fits into one or more SC, and each SC plays a different role in every organisation [1].

The goal of integrating SC is to synchronise the customer's requirements with the flow of materials from the suppliers, and to achieve efficiencies between customer service, inventory costs, and unit cost per product. The design and operation of an effective SC is essential for all organisations [2].

The integrated supply chain (ISC) deals with strategic issues, such as integrating internal and external business processes, developing solid links between members across various channels, and managing products and information. Within business and organisational boundaries, the ISC can also be a tactical tool applied to the management of operational activities. These activities can include customer service, control of the input and output flows of materials and information, and elimination of inefficiencies throughout channels and costs that extend from acquiring raw materials to manufacturing, distributing to the final consumer and, when necessary, product return through recycling or destroying [3].

The tactical and operational functions of decision-making are integrated throughout the SC, and are frequently monitored using specific performance indicators. These are set by the key members of each SC to determine the proper operation and to provide process feedback based on the obtained results.

The efficient management of a SC to meet the service level required by the customer is extremely difficult because there are diverse sources and complex interrelationships on different levels between the members. Furthermore, the design of a SC network is a difficult task because of the intrinsic complexity of the main subsystems of these networks and the several interactions between these subsystems. Uncertainty is found throughout the SC, and can arise from situations such as delays in deliveries from the suppliers, or because raw materials do not meet the specifications. Uncertainty also results from production processes and from ambiguous product demand because of inaccurate forecasts [4-7].

Theories, such as approaches and methodologies that use artificial intelligence tools to obtain reliable solutions that adapt with ease to changes in the parameters of inaccuracy, have arisen to solve management and administrative challenges found in the SC [8-14].

This article presents the design and implementation of an expert system that is based on fuzzy logic in 44 small-, medium-, and large-sized Mexican enterprises, and that allows the integration level in collaborative supply chains to be determined. The article is structured as follows: the introduction is presented in the first section, followed by a literature review in the second. The third section presents the materials and methods used, detailing the research methodology and the scientific tools. The fourth section describes and discusses the results. The last section concludes the study. Bibliographic references are also included.

2 LITERATURE REVIEW

2.1 Integration of supply chains

Four main premises are required for an ISC: transparent information, collaboration for a common objective, collaborative planning, and automated financial transactions. Tools in the following five categories are needed: information management for the flow of materials managed in real-time; real-time sharing of documentation; collaborative forecasting; collaborative materials planning; and implementation of automated payments [15].

Some of the achievements gained from successfully integrating the SC are: a genuine collaboration between all members in the SC with transparent information and resources; lower costs due to leveraged operations; lower inventory levels; economies of scale; and elimination of non-value-adding activities. Furthermore, performance is improved as a result of more precise forecasts, improved planning, a more efficient flow of materials, better customer service with shorter delivery times, more efficient deliveries, and greater customisation. Greater flexibility is also obtained by allowing organisations to react faster to changing conditions, standardising procedures, leveraging efforts among resources, and transparent information and planning, among others. Reliable quality is obtained with fewer inspections because of integrated quality management programmes [16].

From an economic perspective, an ISC requires the coordination of materials, information, and financial flows aimed at fulfilling the customers' demands. The objective is to improve competitiveness and generate an integrated plan of the SC as a whole. Long-term planning is the strategic objective for the design of the SC, considering factors such as cooperation, facility location, production systems, and distribution routes. Mid-term planning tasks include purchasing, material requirements, demand forecasting, and inventory. Short-term planning considers transportation, distribution, and production scheduling [17].

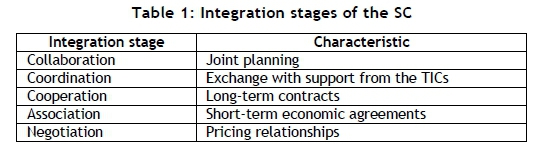

The ISC consists of five stages, beginning with negotiation and ending with collaboration [18]. Market negotiations include discussions focused on pricing, and relationships between organisations and suppliers. The association stage establishes economic agreements. The cooperation stage seeks to establish long-term contracts with suppliers. The coordination stage takes place with the support of the information and communication technologies (TICs). The collaboration stage is where the integration of the SC is manifested, joint planning is created, and technology is shared [18, 19].

Negotiations are essential in all channels throughout the SC, since merchandise and product movement is guaranteed. It is important to consider variables such as suppliers and customers in the different channels of the SC. In traditional SC, negotiation was considered a long and delicate process. This task has now been simplified with the use of information technologies, which have allowed for the development of informatics models that permit strategic management of the SC. There are different techniques and methods to solve the negotiation problem within the SC - for example, the multi-agents system. This system consists of multiple intelligent agents who interact with each other, and who can intervene, negotiate, and reach agreements. Service and the level of benefits are improved for the members of the SC [20-24].

The association stage between organisations represents a temporary link with special contracts, which introduces coordinated actions or tasks related to the behaviour of an economic group. Most of the associations between organisations are directly linked to the basic activities (purchasing to produce and sell), or are centred in the activities of the SC or sector to which they belong. The association is constituted to achieve more efficient construction, service, or supply development, making it possible to group either associations or corporations, as well as individual entrepreneurs [25] .

The cooperation stage implies aligning the members of the SC toward a common goal and a shared purpose; cooperation does not, however, suggest a tight working relationship, but rather a positive attitude toward the rest of the members in the SC. Pushed by globalisation and the resulting increased competitiveness, the different organisations that integrate the SC have understood the importance of information interchange, joint decision-making, and cooperation. Consequently, this is a method of synchronising local activities through global processes, establishing a collaborative relationship in the SC, and identifying malfunctions in the cooperation process, especially when large and small organisations are involved [26-28].

In the coordination stage, methods of interrelating the different activities of the SC are identified. Coordination is based on a win-win situation for all involved members. A minimum level of coordination indicates autonomy and independence in all the activities, partly contradicting the nature of the global organisation. On the other hand, the level of coordination will increase as the level of globalisation of the organisation increases. The most common coordination models work under either centralised or decentralised schemes, activated by implicit or explicit coordination mechanisms. The coordination mechanisms are applied to minimise the total costs of the SC [2933].

Collaboration is based on the information, functions, knowledge, and exchange of business processes. The goal is to create a competitive advantage for all members involved in the SC, including employees, customers, suppliers, and associates [34]. Collaboration between the associates starts when they acknowledge that the success of each member depends on the rest of the members, and on how they ultimately succeed in satisfying the end customer [19, 35]. Faced with intensified global competitiveness, organisations make efforts to reach a greater collaboration in the SC by leveraging the resources and knowledge of the main suppliers and valuable customers (strategic members in the SC). This reduces the uncertainty, minimises operating costs, provides transparent information, creates opportunities for learning and knowledge, and improves competitive position [36-38].

Collaboration implies simultaneous coordination of the decisions made by the decision-making members of the same temporal level (spatial integration) [24]. Collaboration in the SC is a strategy that allows for improvements in the performance of organisations that, through joint actions, obtain synergies that reduce costs, improve customer satisfaction, and face competitive challenges to be successful in the current environment [19,39]. As the last stage of integrating the SC, collaboration is distinguished by the kinds of objects that are exchanged between the various domains where collaborative plans are established. Emphasis is placed on sharing information about joint business plans and strategies, objectives, contracts, suppliers, purchasing, inventory, demand forecasting, distribution, routes, customers, indicators, and any exceptions that could be presented in contracts [19,37,40].

In Table 1, the integration stages (based on the bibliographic review) are shown. These stages measure the level of the SC's global integration, and are used to determine the inference rules for the fuzzy expert system. The negotiation stage represents the lowest integration of the SC, while the collaboration stage represents the highest integration.

2.2 Expert systems and fuzzy logic

Expert systems emulate the behaviour of a human expert in solving a problem; they store concrete knowledge about a determined field through logical deduction of conclusions. Through the use of these expert systems, an improvement in the quality and response time is sought, giving rise to an increase in organisational productivity [41].

Each expert system has two main parts: the knowledge base, and the reasoning or inference motor. These systems can store new knowledge in relational databases and form new deductive learning rules [42].

Fuzzy logic originated in the fuzzy sets theory developed by Zadeh in the 1960s. This theory proposes that an element always belongs to a set to a certain degree, but also never completely belongs to the set. This allows for the establishment of an efficient way to work with uncertain data or subjective knowledge, and for preparing the knowledge in the form of linguistic rules towards a quantitative plane [43]. The most popular fuzzy logic systems are Mamdani and Takagi-Sugeno.

Fuzzy logic has two principal components: membership functions and fuzzy rules. Using these, it is possible to represent linguistic expressions as mathematical models. This is useful when it is necessary to model an expert's experience [44]. Membership functions indicate the extent to which every element of a given universe belongs to a set. That is, the membership function of a set F over a universe U will be in the form: μF·.U - [0,1], where μF(u) = r, if r is the extent to which u belongs to F.

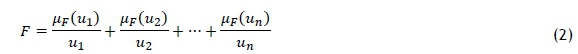

The fuzzy set that acts over discrete universes is defined as:

The notation for the elements associated with a discrete fuzzy set is:

where μ𝐹(𝑢)is the membership function of the fuzzy set F, so that it can be represented as:

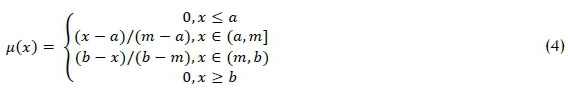

To be applied in different environments, the membership functions can take different forms according to the designer's experience and preference. In equation (4) the membership function for a triangular fuzzy set is shown:

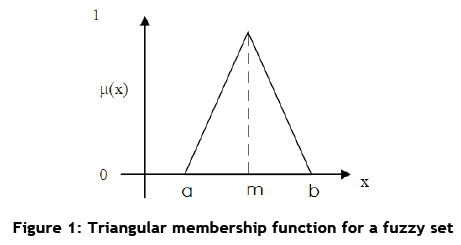

At the time of determining a membership function, simple functions are usually selected so that calculations are not complicated. The triangular and trapezoidal functions are most commonly used. In Figure 1, the graph of a triangular membership function for a given fuzzy set is shown.

The most common operations that can be performed over fuzzy sets are:

• Complement:

• Intersection:

• Union:

The Mamdani type system (Figure 2) is formed by four blocks:

1. Fuzzificator:

The inputs of the Mamdani system are usually numerical values that come from some sort of sensor or are the results of a process. To be able to model this value, Mamdani systems translate the value into a 'fuzzy' value that can be modelled by inference mechanisms. This translation is made by the fuzzificator, which converts the numerical values into fuzzy values that represent the membership level of the different system variables in every fuzzy set.

2. Fuzzy rules base:

This is how the fuzzy Mamdani sets represent the experience and the linguistic knowledge to solve a problem. A set of IF-THEN sentences contains two parts: antecedent and consequent (provided by linguistic expressions).

3. Inference mechanism:

Once the fuzzificator has translated the fuzzy values, these have to be processed to generate a fuzzy output. The task of the inference mechanism is to take fuzzy values and generate a fuzzy output using the fuzzy rules base. The inference mechanism uses the maximum-minimum criterion to calculate the output fuzzy value. First, the input values and the fuzzy rules base are considered to determine the set of rules that become active and the related conclusions (fuzzy sets of the output variable). To know the fuzzy value of the activated rule, the operations between fuzzy sets are employed. Equation 6 is used to determine the fuzzy value of an activated rule (inference mechanism input), and Equation 7 shows the union that is used to determine the fuzzy value of the set of activated rules (inference mechanism output).

4. Defuzzification:

The inference output of the system is a fuzzy output; therefore it cannot be interpreted by an external element that only operates numerical data. To make use of these data, the output is translated to a numerical format by the defuzzificator, using the gravity centre procedures (centroid) or averaged centres.

The centroid method is calculated as follows:

a) The fuzzy output is decomposed into regular figures, according to the membership degrees of two adjacent fuzzy sets (generating triangles and rectangles is used to ease the calculation of the areas).

b) The area is calculated for every figure obtained in part a).

c) The centroid is determined for each figure.

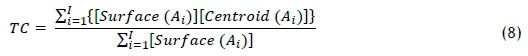

d) The total centroid (TC) is calculated according to the formula shown in equation (8).

e) The linguistic expression is determined for the output variable according to the determined value of the centroid.

Essentially, a fuzzy expert system is a structure based on knowledge, defined through a set of fuzzy rules of the IF-THEN format (antecedent and consequent), which contain a fuzzy logic quantification of the expert's linguistic description. In this work, triangular memberships are used as functions due to the nature of the employed variables, considering that they are the functions that best adjust to the input and output data of the model. The Mamdani-type fuzzy logic system was used because both the antecedent and the consequent of the rules are given by linguistic expressions.

The defuzzification process is used to convert the inference mechanism output into information that can be interpreted by any person. In this work, the gravity centre method (centroid) was employed.

3 MATERIALS AND METHODS

3.1 Methodology

For this work, a review of the existing literature was performed, allowing the definition of the variables to be used for the integration of the collaborative supply chains model. Next, a fuzzy logic-based expert system was designed, inference rules were devised with the collaboration of experts, and a measurement system was devised and validated in order to feed the model. Once validated, it was used in 44 Mexican enterprises for which the integration level was determined and improvement activities were suggested.

3.2 Model design for the integration of collaborative supply chains

From the bibliographic review, the variables to be used in the ISC model were defined as shown in Figure 3. The strategic integration considers the organisation's strategy, information, plans, and contracts. The tactical integration considers demand forecasting, suppliers, purchasing, and inventory. The operational integration includes distribution and routes. Model feedback (performance measurement) includes the indicators and exceptions found in the contracts.

Based on the scheme shown in Figure 3, a collaborative ISC model was formulated, formed by an input, a process, and an output (Figure 4).

a. Input:

The input considers the SC that will be evaluated, where there is a central organisation that seeks to integrate all the processes and members into its strategy, objectives, and plans. For this, it is necessary to make agreements, share information with the strategic members in the SC, and determine where the SC begins and ends, in order to define the total number of members and channels. A questionnaire is also included as an input that works as information to feed the model.

b. Process:

In this block, we define three levels of the integrating SC process:

• Strategic level: This focuses on the long-term planning and considers the organisation's strategy, business plan, and objectives, determining and regulating the flow of information, and defining the collaboration plans and the clauses of the contracts to be made with the strategic members of the SC.

• Tactical level: This is fed by the strategic level, and considers mid-term planning. It includes demand forecasting, suppliers and their performance, and purchasing planning and its relationship with inventory levels. The output of this level feeds the operational level.

• Operational level: This considers the distribution of merchandise and its traceability within the SC; it also considers vehicle routing.

c. Output:

The output shows the ISC level to determine whether the organisation is in the negotiation, association, cooperation, coordination, or collaboration stage. The output also provides information about the strategic indicators of the SC and the exceptions found in the established contracts. Model feedback and indicators are used to fix the tactical and operational level deviations, while the exceptions found are used to provide feedback to the strategic level.

The application of this ISC model will allow organisations at a strategic level to:

• Improve the joint business strategy and plan between the strategic members of the SC;

• Define and optimise the flow of information;

• Integrate and maintain updated plans and contracts.

At a tactical level:

• Improve the accuracy of demand forecasting;

• Optimise purchasing process;

•Reduce inventory;

• Run faster re-position cycles;

• Improve communication with and response to suppliers;

• Reduce logistics costs.

At an operational level:

• Improve the distribution planning of merchandise;

•Know the location of merchandise within the SC;

• Optimise merchandise distribution routes;

• Reduce delays when fulfilling orders.

3.3 Structuring and validation of the measurement instrument

A measurement instrument in the form of a questionnaire was designed to evaluate the ISC level, which considers each of the variables used in the proposed model. Feedback on this instrument was given by academic experts in Mexico and Cuba with PhDs in logistics, SC, and industrial engineering, as well as by personnel from the logistics and SC departments of some of the surveyed enterprises.

The measurement instrument was divided into three sections. The first section consisted of general information about the surveyed enterprise and those responsible for answering it. This revealed the sector in which the enterprise operated, the profile of the surveyed person, how long they had operated in this market, whether they had an established business plan, and whether they had contracts with customers and suppliers.

In the second section, the questionnaire provided input for the ISC model through 18 multiple-choice questions using a five-level ordinal scale that allowed the surveyed person to locate their company quickly on an integration level for each specific variable. The third section allowed the surveyed person to provide comments that were used to improve the instrument.

For the application, we designed a computational tool, programmed in Java, that sent the questionnaire to different enterprises by e-mail. The tool checked that the questions were answered and that the answers were automatically returned.

In Mexico, there are 163,653 economic units of small-, medium-, and large-sized enterprises [45], from which a sample was taken to validate the input questionnaire for the ISC model. The calculated sample size was n = 35.759, which was rounded up to n = 36 enterprises being surveyed. The questionnaire was administered between the months of May and August 2014. Enterprises were contacted through the local chambers of commerce or through the link departments of different professional and higher education schools that provide logistics services to these organisations. The chosen enterprises were located in the Mexican states of Veracruz, Tamaulipas, San Luis Potosí, and Hidalgo.

To determine its validity and reliability, the measurement instrument was evaluated with Cronbach's alpha, followed by an evaluation through factor analysis. With these results, the questionnaire was restructured and modifications were made to the proposed ISC model [46].

Cronbach's alpha coefficient method requires a single use of the measurement instrument, for which a coefficient is calculated. To create a reliable scale, it is desired that items are correlated with each other, with values greater than 0.75 being acceptable. Values over 0.9 are considered highly reliable [47,48].

The results are shown in Table 2. It can be seen that the instrument is reliable both in general and in each of the dimensions that constitute it.

The validity of the instrument was determined through a factor analysis that indicates how many dimensions integrate a variable, and which items conform to each dimension. Factor analysis is a data reduction technique that is used to find homogeneous groups of variables from numerous sets of variables. Test items that do not belong to a dimension (which means that they are 'isolated' and that their measure is not the same as the rest) must therefore be eliminated [47,48].

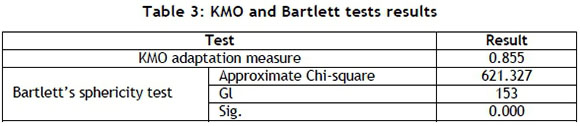

To analyse the validity of the instrument (factor analysis), calculations were performed with the SPSS ver. 20.0 software. Two statistics evaluate the adaptation or adjustment goodness of the analysed data to a factor model: Kaiser-Meyer-Olkin's sample adaptation measure (KMO) and Bartlett's sphericity test.

In Table 3, the results of both tests are shown. Values greater than 0.6 in KMO and less than 0.05 in Bartlett justify performing a factor analysis [46]. Having analysed the results, it could be concluded that the factor analysis could be properly applied.

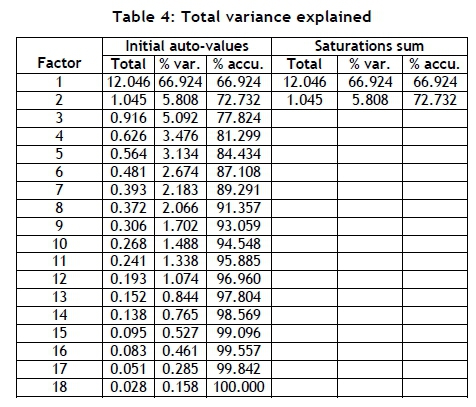

When applying a factor analysis, the principal components method can be used because the objective is to condense most of the original information into a number of factors for prediction purposes. The factors to extract are those that have auto-values greater than 1 [46]. The 18 variables of the designed instrument were analysed, obtaining the results shown in Table 4, where it can be observed that two factors obtain values greater than 1. This is the number of factors that will be removed.

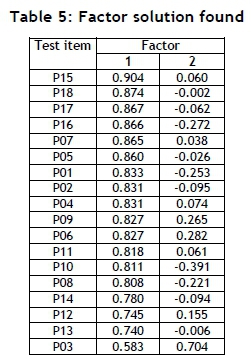

In Table 5, the factor solution obtained is shown. The table contains the correlations between the original variables and each of the factors. It can be seen that, excluding question P03, the rest of the questions saturate factor 1 within the correlations matrix (values greater than 0.71). Question P03 is the only item that presents a significant value (0.74) in factor 2.

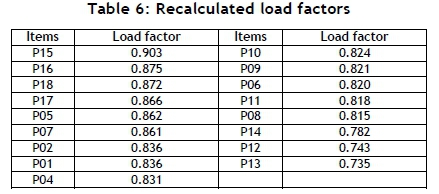

After analysing the results shown in Table 5, it was decided to work with only one variable, to be named 'global integration level'. To determine whether question P03 could be removed from the questionnaire, its information was excluded and the extraction process was repeated. The results (Table 6) showed load levels greater than 0.71 for every factor considered excessive [46]; for this reason, we determined to use all the questions (except for P03, which was eliminated) to feed the designed ISC model.

Considering the load factor of each question in Table 6 and regrouping them, we obtained new values for Cronbach's alpha coefficient for the different dimensions of the ISC model. Question P07, originally considered part of the tactical level, was regrouped with the strategic level due to the load factor it represented.

Table 7 shows the new distribution of questions that fed the model, and the corresponding Cronbach's alpha coefficients obtained.

With the results obtained from the analysis, the validity and reliability of the measurement instrument was confirmed.

3.4 Implementation of the fuzzy expert system

The fuzzification stage of the ISC model is shown in the block diagram in Figure 5. It can be seen that the strategic integration is provided by the combination of the strategy, information, plans, and contracts variables that in turn are fed by the results of the questionnaire applied to the enterprises. Likewise, the tactical and operational integration levels and corresponding model feedback are defined.

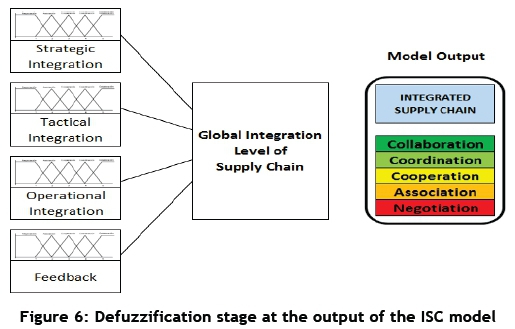

The global integration level of the supply chain is shown in Figure 6. It is formed by the fuzzy outputs from the strategic, tactical and operational integration and the feedback, resulting in a fuzzy value that is converted into a linguistic value (defuzzification), indicating whether the SC is in the negotiation, association, cooperation, coordination, or collaboration stage, according to the specific valuation.

To illustrate the calculation process, the calculation of the operational integration level for one of the evaluated enterprises is shown below.

1. Fuzzification stage:

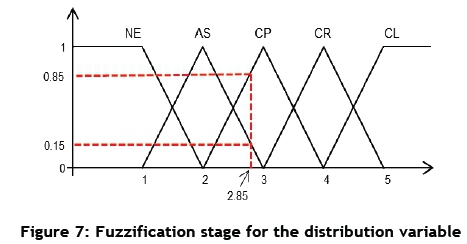

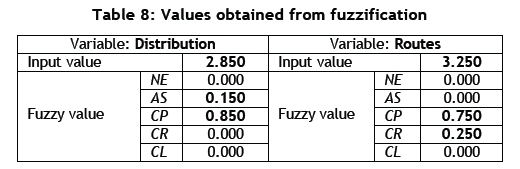

From the results of the application of our questionnaire to one of the studied enterprises, a value of 2.85 was obtained for the distribution variable and 3.25 for the routes variable. The application of equation (4) allows us to determine the membership degree for each fuzzy set, where x = distribution.

In Figure 7 we can see the intersection of the two fuzzy sets for the distribution variable and its respective membership degrees.

Analogously, the calculations were made for the routes variable obtaining the results shown in Table 8.

2. Fuzzy rules base:

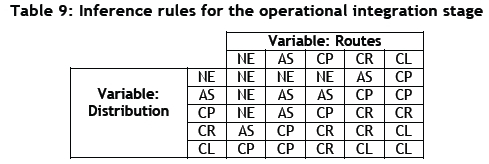

These rules were defined with the help of experts. They were a way of representing appropriate strategies or techniques when knowledge comes from experience or intuition. They were composed of linguistic variables that form the premise of the condition and a conclusion. They were written as antecedents-consequents IF-THEN sentence pairs, and saved in tabular form. The combination of the linguistic tags of the fuzzy variables forms the fuzzy rules base.

The values in the cells from Table 9 represent the consequent that describes each combination and corresponds to the linguistic categories or tags from the fuzzy subsets of the output variable. Thus NE corresponds to the negotiation stage, AS to the association stage, CP to the cooperation stage, CR to the coordination stage, and CL to the collaboration stage.

For example, if the distribution variable was in NE and the routes variable was in CP, then the activated inference rule would be number 3 (AS). If the distribution variable was in CP and the routes variable in CR, then the activated rule would be 14 (CR). For the development of the expert system, 275 inference rules were defined to determine the relationship between the different input variables; all the possible input combinations were considered, and a conclusion was assigned to each of them.

3. Inference mechanism:

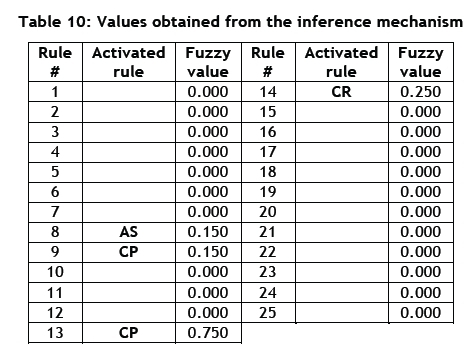

To determine the inference rules that become active with the fuzzy inputs, equation (6) was applied to the 25 defined rules, taking into account the input combinations. The activated rules were the ones that generated values greater than 0.

In Table 10, the values generated from the application of equation (4) for every input combination can be seen. The output of the inference mechanism was obtained by applying equation (7) to the inference rules according to the values from Table 9:

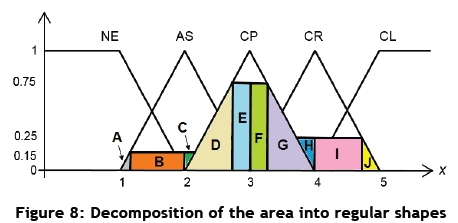

4. Defuzzification: To find the defuzzification value and determine the integration level, we applied equation (8) using the following procedure:

The fuzzy output was decomposed into regular figures, according to the membership degrees of two adjacent fuzzy sets, as shown in Figure 8 (generating triangles and rectangles to ease the calculation of the areas was sought).

The total centroid (TC) was calculated according to equation (8), obtaining a value of 3.0972 which corresponded to the linguistic variable CP.

Globally, the expert system indicated the variables that needed to be improved so that the enterprises could improve the integration level of their supply chains.

4 RESULTS AND DISCUSSION

Once the measurement instrument had been validated, the expert system for the integration of collaborative SC was fed with the answers to the questionnaire from the different enterprises, with the results shown in Table 11. From the 44 surveyed enterprises, 12 were found to be in the negotiation stage, 11 in association, 10 in cooperation, nine in coordination, and two in collaboration. It can be seen that most of the enterprises were found to be in the central integration stages (AS, CP and CR), while the collaboration stage was the most difficult to reach for these enterprises.

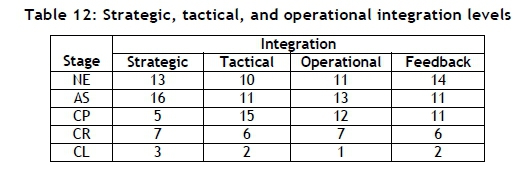

Analysing the strategic, tactical, and operational levels, and the feedback (measurement of the performance through indicators and exceptions) separately, the results shown in Table 12 were obtained. It can be seen that, at a strategic level, most of the surveyed enterprises were found to be in the lower stages of the integration process (34 enterprises in the NE, AS, and CP stages), while at a tactical and operational level, in measuring their performance they were found in the medium stages of the integration process (AS, CP, and CR with a total of 32, 32, and 28 enterprises respectively).

Although the maximum global integration stage (collaboration) was reached by only two enterprises, Table 12 shows that in the CL stage three enterprises were found at a strategic level, two enterprises at a tactical level, one enterprise at the operational level, and two in the measurement of the performance and exceptions.

Below are the recommendations that the expert system produced for the enterprises to improve. At a strategic integration level, it is recommended:

1. Design the strategy (business plan) of the enterprise, taking into account the global functionality of the SC and each member's strategies.

2. Define and agree on the information that must be exchanged with the strategic members of the SC.

3. Design the global planning of the SC as a whole with all the strategic members, considering their individual business plans.

4. Design the contracts, taking into account the criteria of the strategic members of the SC, considering information security clauses, rewards, and penalties.

At a tactical level, it is recommended:

1. Have an information system between the strategic members of the SC that allows them to know the real sales and forecasting adjustments in real-time throughout all the channels of the SC.

2. Standardise the criteria to select suppliers and to guide the objectives and plans of the organisation.

3. Have certified and reliable suppliers, and evaluate them at established times.

4. Perform purchasing according to the policies, norms, and procedures established between the organisation and its suppliers, based on the production plan; make adjustments in real-time as needed.

5. Have real-time information on warehouse inventory, security, in-transit, and purchase orders not yet supplied, that will help to determine when to purchase.

6. Have an information system that allows the products, amount and inventory costs to be known for real-time control, allowing decisions to be made between suppliers and customers.

In an operational level, it recommended:

1. Have a real-time information system that permits planning, controlling, managing, and coordinating the distribution of merchandise for every member within the SC, when needed.

2. Have an information system that allows all the members in the SC to trace the final product with its origin and the processes where it has been involved.

3. Have an information system that allows planning and sharing of the most appropriate routes between members in the SC, according to parameters such as distance, delivery times, transit flows, and restrictions.

For the performance measurement (feedback), it is recommended:

1. Standardise the performance indicators that allow comparative evaluations with competitors, and share them with the strategic members in the SC.

2. Know the strategic indicators of all members in the SC in real-time, allowing immediate detection of deviations.

3. Have a real-time information system through which members of the SC communicate the irregularities or deviations as detected, and propose and agree on joint solutions.

4. Document the irregularities or deviations detected by the members of the SC, and negotiate the inclusions in the contracts made between the strategic members of the SC.

5 CONCLUSIONS

The integration of collaborative SC must be approached with strategic implications for enterprises beyond integral logistics. Its success will depend on its ability to satisfy the customers' demands efficiently. An ISC is the most effective method to eliminate the whip effect, simultaneously reaching inventory stability and high levels of customer satisfaction.

This article has proposed the measurement of the integration level in collaborative SC through the design and implementation of an integration model that considers the strategic, tactical and operational levels.

The theoretical conceptualisation of the model was based on the analysis of scientific articles published in high impact journals, written by various authors who have worked on SC integration topics. It has attempted to establish the conceptual elements that allowed us to define a model for the integration of collaborative SC at strategic, tactical, and operational levels. In the same way, the characteristics that determine the integration stages as output of the model and their joint interaction were defined.

The measurement instrument was statistically validated with information provided from 36 small-, medium-, and large-sized enterprises The results indicated that the model could be applied to any enterprise that wished to measure and improve the integration level of the SC.

For the solution of the expert system, fuzzy logic - an artificial intelligence technique that allows linguistic expressions to be modelled as mathematical models - was employed. Experts define the relationship between the variables on a quantitative plane; furthermore, fuzzy logic adapts with ease to the uncertainty associated with the variables used.

As a result of the application of the expert system, it was determined that most of the enterprises were found to be below the average (cooperation level) in their integration level; and that they should implement actions, mostly at a strategic level (the lowest integration stage of the surveyed enterprises as a whole). The actions should be implemented together with the strategic members of the SC, and focus on improving their joint business strategy and plan, agreeing upon and optimising the flow of information, and integrating and keeping plans and contracts updated according to the indicators and operational exceptions found in the contracts.

Because of the implementation model, the enterprises studied here have identified strategic members of their SC, and have begun to define joint actions that will presumably improve their integration levels, allowing them to respond quickly to the demands of current markets.

In future work, the expert system will be applied to enterprises of specific productive sectors, to verify that the developed model can be implemented in those sectors. Additionally, a computational application will be developed, with the expert system embedded, that will allow the enterprises to monitor their integration level in real-time, and that will present them with the indicators that require attention to improve their current integration level.

CONFLICT OF INTERESTS

The authors declare that there is no conflict of interest in respect of the publication of this paper.

REFERENCES

[1] Hugos, M. 2003. Essentials of supply chain managements. John Wiley & Sons, Inc.: Hoboken, New Jersey, USA. [ Links ]

[2] Stevens, G.C. 1989. Integrating the supply chain. International Journal of Physical Distribution & Materials Management, 19 (8), pp. 3-8. [ Links ]

[3] Institute of Management Accountants. 1999. Implementing integrated supply chain management for competitive advantage. http://www.imanet.org/PDFs/Public/Research/SMA/Implementing%20Integrated%20Supply%20Chain.pdf, [20/01/2014]. [ Links ]

[4] Hokey, M. & Gengui, Z. 2002. Supply chain modelling: Past, present and future. Computers & Industrial Engineering, 43, pp. 231-249. [ Links ]

[5] Campuzano-Bolarín, F., Martínez-Caro, E. & Ros-McDonell, L. 2010. Cadenas de suministro tradicionales y colaborativas: Análisis de su influencia en la gestión de la variabilidad de la demanda. Dyna, 85 (1), pp. 33-40. [ Links ]

[6] Mirzapour Al-e-hashem, S.M.J., Malekly, H. & Aryanezhad, M.B. 2011. A multi-objective robust optimization model for multi-product multi-site aggregate production planning in a supply chain under uncertainty. International Journal of Production Economics, 134 (1), 28-42. [ Links ]

[7] You, F., Wassick, J.M. & Grossmann, I.E. 2009. Risk management for a global supply chain planning under uncertainty: Models and algorithms. American Institute of Chemical Engineers Journal, 55, pp. 931-946. [ Links ]

[8] Peidro, D., Mula, J., Polera, R. & Verdegayb, J.L. 2009. Fuzzy optimization for supply chain planning under supply, demand and process uncertainties. Fuzzy Sets and Systems, 160 (18), pp. 2640-2657. [ Links ]

[9] Wang, J.L. 2009. A supply chain application of fuzzy set theory to inventory control models - DRP system analysis. Expert Systems with Applications: An International Journal, 36, pp. 9229-9239. [ Links ]

[10] Yuh-Wen, C., Larbani, M. & Chen-Hao, L. 2010. Simulation of supply chain game with multiple fuzzy goals. Fuzzy Sets and Systems, 161 (11), pp. 1489-1510. [ Links ]

[11] Ghane, M. & Jafar, M. 2012. Multi-objective design of fuzzy logic controller in supply chain. Journal of Industrial Engineering International, 8 (10), pp. 1-8. [ Links ]

[12] Peidro, D., Mula, J., Jimenez, M. & Botella, M. 2010. A fuzzy linear programming based approach for tactical supply chain planning in an uncertainty environment. European Journal of Operational Research, 295 (1), pp. 65-80. [ Links ]

[13] Adarme-Jaimes, W., Arango-Serna, M.D. & Cogollo-Flórez, J.M. 2012. Medición del desempeno para cadenas de abastecimiento en ambientes de imprecisión usando lógica difusa. Ingeniería y Universidad [Online]. 16 (1). [08/11/13] Disponible: http://www.redalyc.org/articulo.oa?id=47723297006. [ Links ]

[14] Escobar-Gómez, E., Díaz-Núnez, J. & Taracena-Sanz, L. 2010. Modelo para el ajuste de pronósticos agregados utilizando lógica difusa. Ingeniería, Investigación y Tecnología, 11(3), pp. 289-302. [ Links ]

[15] Crespo Marquez, A. 2010. Dynamic modelling for supply chain management. Springer: London, pp. 171 188. [ Links ]

[16] Waters, D. 2003. Logistics: An introduction to supply chain management. Palgrave Macmillan: England, pp. 27-54. [ Links ]

[17] Albrecht, M. 2010. Supply chain coordination mechanisms, new approaches for collaborative planning, lecture notes in economics and mathematical systems, Springer: Germany, pp. 5-62. [ Links ]

[18] Pires, S. & Carretero, L. 2007. Gestión de la Cadena de Suministros, McGraw Hill: Espana. [ Links ]

[19] Sablón-Cossio, N. 2014. Modelo de Planificación Colaborativa Estratégico en Cadenas de Suministros en Cuba. Tesis en opción al grado de Doctora en Ciencias Técnicas, Departamento de Ingeniería Industrial, Universidad de Matanzas: Matanzas, Cuba. [ Links ]

[20] Hernandez, J., Mula, J., Poler, R. & Lyons, A. 2014. Collaborative planning in multi-tier supply chains supported by a negotiation-based mechanism and multi-agent system, Group Decision and Negotiation, 23 (2), pp. 235-269. [ Links ]

[21] Lopez, F. & Coelho, H. 2010. Bilateral negotiation in a multi-agent supply chain system. EC-Web, pp. 195206. [ Links ]

[22] Saberi, S. & Makatsoris, C. 2008. Multi agent system for negotiation in supply chain management. The 6th International Conference on Manufacturing Research (ICMR08), pp. 311-317. [ Links ]

[23] Putten, S.V., Robu, V., Poutré, H.L., Jorritsma, A. & Gal, M. 2006. Automating supply chain negotiations using autonomous agents: A case study in transportation logistics. AAMAS, pp. 8-12. [ Links ]

[24] Chao, Y., Lin, H.W. & Murata, T. 2010. Negotiation based collaborative planning in two-tier supply chain. Procedings of International Multiconference of Engineers and Computer Scientists, vol. 3. [ Links ]

[25] Kolka, A., Van Tulderb, R. & Kostwinderc, E. 2008. Business and partnerships for development. European Management Journal, 26 (4), pp. 262-273. [ Links ]

[26] Ming, Y., Grabot, B. & Raymond, H. 2014. A typology of the situations of cooperation in supply chains. Computers & Industrial Engineering, 67, pp 56-71. [ Links ]

[27] Yong, Y., Chen-Guang, L. & Ikou K. 2011. Cooperation and leadership policies in a serial supply chain. Journal of Manufacturing Systems, 30 (1), pp. 1-7. [ Links ]

[28] Hülsmanna, M., Grappa, J. & Li, Y. 2008. Strategic adaptivity in global supply chains - Competitive advantage by autonomous cooperation. International Journal of Production Economics, 114 (1), pp. 14-26. [ Links ]

[29] Moussawi-Haidara, L., Dbouka, W., Jaberb, M. & Osman, I.H. 2014. Coordinating a three-level supply chain with delay in payments and a discounted interest rate. Computers & Industrial Engineering, 69, pp. 29-42. [ Links ]

[30] Arshinder, K., Kanda, A. & Deshmukh, S. 2008. Supply chain coordination: Perspectives, empirical studies and research directions. International Journal of Production Economics, 115 (2), pp 316-335. [ Links ]

[31] Ximin, H., Jia-Wen, G., Wai-Ki, Ch. & Tak-Kuen, S. 2014. Impact of secondary market on consumer return policies and supply chain coordination. Omega, 45, pp. 57-70. [ Links ]

[32] Ma, P., Wang, H. & Shang, J. 2013. Contract design for two-stage supply chain coordination: Integrating manufacturer-quality and retailer-marketing efforts. International Journal of Production Economics, 146 (2), pp. 745-755. [ Links ]

[33] Arya, A., Löffler, C., Mittendorf, B. & Pfeiffer, T. 2015. The middleman as a panacea for supply chain coordination problems. European Journal of Operational Research, 240 (2), pp. 393-400. [ Links ]

[34] Ashayeri, J. & Kampstra, P. 2003. Collaborative replenishment: A step-by-step approach. Dynamic Green Logistics, 14. [ Links ]

[35] Hao, H., Xinggen, W. & Hongyu, L. 2012. Research on the collaborative plan of implementing high efficient supply chain. Energy Procedia, 16, pp. 1118-1123. [ Links ]

[36] Cao, M., Vonderembse, M., Zhang, O. & Ragu-Nathan, T. 2010. Supply chain collaboration: Conceptualisation and instrument development. International Journal of Production Research, 48 (22), pp. 6613-6635. [ Links ]

[37] VICS (Voluntary Interindustry Commerce Standards). 2010. Business Planning, Linking CPFR and SOP: A Roadmap to Integrated Business Planning. On-line http://hughfinerty.com/wp-content/uploads/2014/05/Link-SOP-with-CPFR-VICS.pdf [13-08-14]. [ Links ]

[38] Alemany-Díaz, M., Alarcón-Valero, F., Lario-Esteban, F. et al. 2010. Herramienta informática para el diseno y ejecución del proceso de planificación colaborativa en cadenas de suministro (1a parte). Dyna, vol. 85 (1), pp. 61-70. [ Links ]

[39] Arango-Serna, M.D., Adarme-Jaimes, W. and Zapata-Cortes, J.A. 2013. Collaborative inventory in supply chain optimization. Dyna, 181, pp. 71-80. [ Links ]

[40] Ta-Ping, L., Trappey, A., Yi-Kuang, C. and Yu-Da, C. 2013. Collaborative design and analysis of supply chain network management key processes model. Journal of Network and Computer Applications, 36 (6), pp. 1503-1511. [ Links ]

[41] Olugu, E.U. & Yew-Wong, K. 2012. An expert fuzzy rule-based system for closed-loop supply chain performance assessment in the automotive industry. Expert Systems with Applications, 39 (1), pp. 375384. [ Links ]

[42] Jin, C. & Rong, W. 2011. Modeling of expert system of quality standard in supply chain. Robotics and Computer-Integrated Manufacturing, 27 (1), pp. 56-61. [ Links ]

[43] Zadeh, L.A. 1965. Fuzzy sets. Information and Control, 8, pp. 338-353. [ Links ]

[44] Aguilar-Lasserre, A., Lafarja-Solabac, M., Hernandez-Torres, R., Posada-Gómez, R., Juárez-Martínez, U. & Fernández-Lambert, G. 2014. Expert system for competences evaluation 360<> feedback using fuzzy logic. Mathematical Problems in Engineering, 2014, p. 18. [ Links ]

[45] Micro, pequena, mediana y gran empresa. 2011. Estratificación de los establecimientos: Censos Económicos 2009 / Instituto Nacional de Estadística y Geografía (INEGI), México. [ Links ]

[46] Cano-Olivos, P., Orue-Carrasco, F., Martínez-Flores, J.L., Mayett-Moreno, Y. & López-Nava, G. 2013. Modelo de gestión logística para pequenas y medianas empresas en México. Contaduría y Administración, próxima publicación. [ Links ]

[47] Malhotra, N. 2008. Investigación de mercados, Prentice Hall: México. [ Links ]

[48] Hernández-Sampieri, R., Fernández-Collado, C. & Baptista-Lucio, M. 2010. Metodología de la investigación, McGraw Hill: México. [ Links ]

Submitted by authors 6 May 2015

Accepted for publication 7 Jun 2016

Available online 12 Aug 2016

* Corresponding author horacio.bautista@itsta.edu.mx