Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

South African Journal of Industrial Engineering

On-line version ISSN 2224-7890

Print version ISSN 1012-277X

S. Afr. J. Ind. Eng. vol.27 n.2 Pretoria Aug. 2016

http://dx.doi.org/10.7166/27-2-1328

GENERAL ARTICLES

A strategy to tailor performance interventions based on the nature of organisational maturity of south manufacturing firms

Nelson Mandela Metropolitan University, South Africa

ABSTRACT

The South African automotive component manufacturing sector is facing global pressure to remain competitive. Performance improvement interventions are often deployed in manufacturing companies that are aimed at improving competitiveness. The high failure rate of these performance improvement interventions should be considered when developing a programme strategy for implementation. Consideration should be given to the organisation's maturity and current performance when deciding which performance improvement intervention to select. The research objective was to establish the role of the organisational maturity variables in tailoring an integrated performance improvement intervention that develops organisational maturity and performance.

OPSOMMING

Die Suid-Afrikaanse motor komponent vervaardigingsektor staar huidiglik wêreldwye druk in die gesig om mededingend te bly. Prestasieverbeterings ingrypings word dikwels ontplooi in vervaardigingsmaatskappye met die doel om mededingendheid te verbeter. Die baie mislukkings van hierdie verbeterings ingrypings behoort in ag geneem te word wanneer dit kom by die ontwikkeling van die program strategie vir implementering. Oorweging moet gegee word aan maatskappye se volwassenheid en huidige prestasie wanneer daar oorweeg word watter prestasie verbetering ingryping geselekteer moet word. Hierdie navorsing se doelwit was om die rol van die maatskappy se volwassenheid veranderlikes vas te stel met betrekking tot die geintegreerde prestasie verbeterings ingryping wat organisatoriese volwassenheid en prestasie ontwikkel.

1 INTRODUCTION

The failure of performance improvement programmes to yield sustainable benefits presents an interesting challenge for South African companies to identify, first, which performance programme is best suited to them and second, and more importantly, how their existing maturity level aligns with the intended programme. Each of the performance improvement programmes presented as part of this research offers pathways to improvement; and these are based on certain unique programme tools that may be influenced by the firm's maturity level, in addition to its organisational performance needs. It is important to determine the state of a manufacturing firm's maturity level in order to recommend an appropriate performance improvement programme or a combination of the specific tools and techniques from the choice of programmes.

Leask [1] states that an integrative improvement approach is needed to ensure sustainability. Different performance improvement programmes have certain success factors necessary for their sustainability. Within the South African context, popular programmes include lean manufacturing, total productive maintenance, and Six Sigma. The term 'integrate' refers to the optimum

combination of tools and techniques from the various performance programmes' approaches [1]. The move towards a systems-based approach to performance programme integration is subject to a few distinguishing factors [1]. These are important, as they enable the manufacturing entity to assess its strengths and weaknesses and to make an informed decision about which performance improvement programme, or combination of approaches, is best suited to its requirements.

1.2 Research objectives

The primary research objective was to assess the role of organisational maturity as a factor in the selection of the appropriate performance improvement programme.

The secondary research objectives included the following:

1. To establish the interaction between organisational maturity factors and organisational performance factors

2. To establish the leading performance concerns of Eastern Cape manufacturers

3. To determine the interaction between performance improvement programme objectives and organisational maturity factors

4. To determine the performance improvement programme objective that would have the greatest impact on South African firms, based on the contributing causes of low organisational engagement maturity

5. To establish the defined organisational maturity factors that impact specific organisational performance factors - such as internal quality, output performance, and equipment availability

6. To establish the contribution of performance improvement programme objectives to organisational performance

2 LITERATURE REVIEW

South Africa's manufacturing productivity continues to decline [2]. Bozdogan [3] states that, to improve productivity performance, improvement programmes such as lean manufacturing, total productive maintenance, and Six Sigma can be used. These programmes have specific differences -but they can be synergised through the application of their unique tools [3].

The programmes are considered to have a high failure rate as a result of the low sustainability of the results achieved [3]. Fore and Zuze [4] indicate that there is a link between organisational maturity and performance.

2.1 Total productive maintenance

Paneerselvam [5] states that the implementation of total productive maintenance (TPM) can contribute considerably to improving organisational behaviour. TPM is a methodology directed at bringing critical maintenance skills and production workers together. Although sometimes considered part of the lean manufacturing bouquet of tools, the programme has evolved internationally to become a fully-functional production system on its own. TPM follows a structured format with eight pillars [5]:

• Quality maintenance

• Planned maintenance

• Autonomous maintenance

• Focused improvement

• Office TPM

• Safety and health

• Training and development

• Development management

A TPM programme shifts an organisation's paradigm from being reactive to being proactive, particularly in how maintenance teams respond. The concept of TPM allows employees at all levels to get involved through the concept of total employee involvement (empowerment). Changes to the organisational policy and strategy are also requirements of a well-structured TPM programme [6].

Thomas, Jones and Vidales [7] contend that TPM is more than a philosophy that is fit for organisations with lean immaturity. The goals of TPM may be applied in any organisation, regardless of its maturity level; in fact, it is required by organisations where equipment sophistication levels require a greater degree of TPM implementation. TPM may be viewed as having a focus on restoring equipment to optimal condition to increase uptime and therefore productivity.

TPM also has an iterative process for implementation, and is measured through overall equipment effectiveness (OEE), a metric used to determine the impact of three performance factors - internal quality, output performance rate, and equipment availability - in a typical plant [8]. Equipment availability is defined as the scheduled production time available. The equipment's performance rate is defined as the percentage of parts produced relative to the standard. And the internal quality rate is defined as the percentage of saleable parts produced relative to the parts started [9]. Pintelon and Muchiri [10] indicate that OEE is an important performance metric for competitiveness.

2.2 Six sigma

Six sigma applies the 'define, measure, analyse, improve, and control' (DMAIC) methodology as its chief problem-solving approach, and involves a wide range of statistical process control techniques. It also applies behavioural and managerial methods to improve business from the top of the organisation down to the functional and shop floor levels [11]. Henderson [12] states that Six Sigma, as a methodology, serves as a vehicle within the area of statistics. In turn, these statistics greatly benefit manufacturing.

Siviy, Penn and Stoddard [13] state that Six Sigma tools and techniques can be applied at the lower maturity levels and, in fact, contribute largely to higher maturity attainment. The measures of Six Sigma performance improvement programmes can be used at the lowest levels of manufacturing organisation maturity, but might not reflect performance improvement at this maturity level.

Breyfogle [14] highlights that Six Sigma is predominantly focused on reducing the variation in processes.

2.3 Lean manufacturing

According to Engelund, Breum and Friis [15], lean manufacturing started with the initiatives undertaken at Japanese car manufacturer Toyota.The term lean manufacturing is a Western interpretation of the Toyota production system (TPS) [16]. Lean manufacturing can be viewed as a systematic way to reduce waste [17]. The objectives of the Toyota production system, on which lean manufacturing is based, focus on shortening production runs, reducing set-up, eliminating waste, integrating suppliers, and synergising the entire business. The objective of this performance improvement programme is to enhance value to the customer through a focus on flow within the organisation [18].

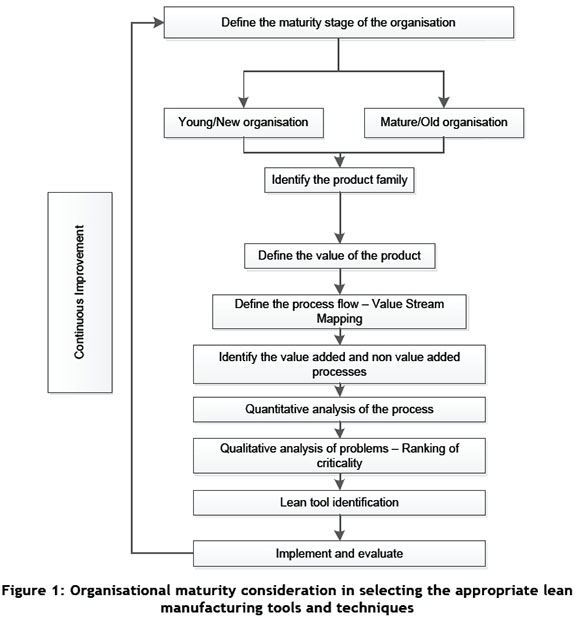

Liker and Morgan [19] state that there is a requirement to determine how to adapt lean manufacturing tools within specific organisations. New organisations have fewer resources and have very little experience with lean manufacturing tools and techniques. Similarly, Amin and Karim [20] highlight the need for lean manufacturing strategies to be developed and defined within the context of the respective organisations' maturity. This will help to maximise the gains made through the various defined and implemented projects. Figure 1 [20] below illustrates the process steps to identify which performance improvement programme tools to adopt as part of the implementation strategy.

2.4 Performance improvement programme considerations

Turesky and Connell [21] state that well-structured and clearly-specified performance improvement programmes often fail. Barriers to performance improvement programme results include poor leadership commitment, communication, project selection, training, employee engagement, desire to improve, management resistance to change, project team selection, accountability, and ownership.

Wong and Wong [22] highlight the prominence of the human factor in the improvement of organisations. The reason for a performance improvement programme is vitally important. This is clarified through effective communication with the workforce and alignment to the organisation's goals. The benefits of these programmes need to be illuminated by the executive and top management structures. Project teams are also required to be well-structured to facilitate communication. Teams must be equipped with the correct knowledge about the performance improvement programme if they are to execute the programme effectively [22].

Paneerselvam [5] highlights the various barriers that result in performance improvement programme failure. Critical success factors for TPM and the implementation of a lean manufacturing performance improvement programme include human factors, process factors, and others, as outlined below.

2.4.1Human factors

These include the commitment of top management, employee involvement. and cultural transformation.

2.4.2Process factors

These factors relate to the proactive strategy of maintenance, training and education and, ultimately, the prevention of failures related to equipment and quality defects in production [6].

2.4.3Cultural barriers

The ability of management to motivate employees to develop specific skills is regarded as important. And militant unions, ambiguous roles and responsibilities, minimal employee involvement, complacent attitudes towards poor quality, and a lack of consistency are also all cultural barriers towards performance improvement programme impact achievement [5].

2.4.4Technological barriers

Technological barriers relate to systemisation (including maintenance systems for predictive and preventative activities), production quick response systems, and automated data collection and analysis of various production processes. Tracking and measuring production- and process-related metrics are not effective, and are time-consuming and often inaccurate. Information in the organisation is not used as effectively for continuous improvement as specified in management targets. Insufficient training in the workforce, inadequate training in quality improvement methodologies, and poor flexibility in production due to long change-overs are additional barriers [5].

Abdulmalek and Rajgopal [23] classify performance improvement programme tools according to the organisations' maturity level, as defined in the organisational life cycle developed by Lester, Parnell and Carraher [24]. For new organisations with low maturity, support system tools are used. These tools detect problems and are used to identify opportunities for continuous improvement and quality enhancement. The second category of tools is used to reduce process variation; and the third category is used to solve problems that are external to the company's value stream [20].

Nave [25] states that the selection of the type of performance improvement programme should be dependent on the culture of the organisation. Each programme would be implemented at different speeds and levels of efficacy, depending on the cultural aspect or maturity of the organisation in question. Nave [25] states that the unique characteristics of each programme should be contrasted against the values found in each manufacturing organisation. Organisations that value analytical studies and the various relationships informed through data would suit Six Sigma as a point-of-programme initiation. For organisations that seek visual change and flow optimisation, the lean manufacturing programme is ideal.

2.5 Performance improvement programme integration

Various tools from the different programme types may be integrated to obtain synergistic benefits [1]. Jacob, Bergland and Cox [26] state that there is no need for companies to select only one programme methodology. The linking of programmes offers more depth to the results, and can facilitate varied levels of maturity within organisations. The failure to integrate may be attributed to the following:

• The methodologies are considered applicable only to specific uses and in specific scenarios

• Expertise in all three improvement methodologies is not always available

• An effective integration process for the various methodologies is not available

The requirements of the programmes are often spread across functional areas, with each area having differing views and expectations; so it is important that the improvement programmes have a holistic impact. The selection of one or more of the approaches is thus based on the one(s) that will provide the greatest return in reaching the intended objective [27].

It is also well understood that a single programme usually cannot address all the needs of an organisation. Each programme has specific strengths that should be leveraged, based on the particular needs of the organisation - often with selected aspects of the programmes being used in particular areas of the organisation. The three approaches and combinations are thus deemed to be applicable in the following scenarios:

• High process variability would best be solved through a Six Sigma improvement programme

• Total productive maintenance could be used to sustain lean and Six Sigma interventions, but also to have a strong focus on high equipment reliability, and to control production related costs

• Lean manufacturing would focus on the overall flow of the organisation's resources to ensure fast turnaround times [27].

Womack [28] states that, when comparing lean manufacturing, Six Sigma, and TPM, an interrogation of the company's value stream should be considered. The focus of all three improvement programmes should be on creating value for the customer. Through every step of the value stream, a series of questions may be posed to identify which improvement programme or tool from a specific programme should be employed. These questions include:

1. Is the step valuable? Is it necessary for the customer?

2. Is the step capable? Can it be conducted in exactly the same way every time?

3. Is the step available? Can it be performed whenever it is needed?

These three questions would allow one to select the correct improvement programme and its associated tools, according to Womack [28]. Step 1 could be attributed to selecting a lean manufacturing approach. Step 2 infers variation, and thus requires a Six Sigma approach. Step 3 requires up-time of equipment, and thus a TPM programme might be best. DMAIC is the approach for Six Sigma, while the kaizen event is the technique for lean manufacturing improvements. The Six Sigma DMAIC approach is more intricate in its application, and is also applied to more complex problems [29]. Kaizen events can be incorporated into Six Sigma, and the analysis techniques from the measurement and analysis phases of DMAIC can support kaizen events.

Theisens [30] highlights that Six Sigma contains many sophisticated tools that need to be applied in the correct way, whereas the human element is especially critical in lean manufacturing programmes. These factors are crucial in deciding which tool set to use or to combine, as is the case when embarking on a combination of improvement programmes such as the lean Six Sigma combination. The lean Six Sigma approach uses a combined set of tools and techniques from both improvement programmes to reduce lead times and operational costs and to improve quality.

2.6 Organisational maturity factors and considerations

Curtis and Alden [31] state that there are five maturity levels for organisations for business process improvement:

• Level 1: The organisation lacks consistent processes to perform business activities. Overburden is frequent, and frequent fire-fighting consumes management time.

• Level 2: Stable work units perform repeatable procedures.

• Level 3: Standard integrated end-to-end business processes.

• Level 4: Statistically-stable processes with predictable outcomes.

• Level 5: Proactive improvement actions to achieve the process capability required to meet the changing business objectives.

Stabilising the workload is vitally important to performance improvement programme selection and adoption. The maturity of the organisation at Level 2 requires the employees to be trained and to have balanced loading [31]. The selection and impact of the performance improvement programme would hinge on the management of the workforce. Level 2 maturity can be established by managing the processes and protocols [31].

Leask [1] proposes a model to determine maturity, considering nine themes across five stages of maturity:

1. Strategy

2. Standardisation

3. Integration

4. Transformation

5. Systemisation

6. Training and development

7. Roles and responsibilities

8. Knowledge management

9. Results and tracking

Pesic [32] states that there are six maturity steps to business excellence using performance improvement programmes. The initiation step states that managers do not consider a need to improve the business. The second step relates to the realisation of the need to improve. The third step has improvements, but they are project-focused, and lack sustainability when achieved through performance improvement programme systems. The fourth step shows significant project improvements due to some projects having effected continuous improvement and shown sustainable gains. Specific improvements are made in the fifth step, which relates to the specific processes that would have an impact on customers and would add value. The final step outlines an approach for all support and key processes to undergo a process of continual improvement.

The thirteen organisational maturity factors considered as part of this research will be assessed in terms of their influence on the implementation requirements of the performance improvement programme [1]. These factors are:

1. Strategic leadership: This is important, as it sets the objectives of the programme or tools against the organisation's objectives.

2. Roles, goals and responsibilities: This identifies specific roles in the development of key performance indicators (KPIs) and overall responsibility for achieving these.

3. Training and development: This seeks to create a motivating climate and to establish the requisite skills and capabilities in the workforce.

4. Results and tracking: As projects begin after the training has been conducted, the results need to be measured to compare against the improvement in key performance indicators set during the strategic development process. This has an impact on technology development as well, as it requires tracking tools and measurement systems in some areas.

5. Standardisation: A uniform roll-out process that ensures focus areas are targeted where there is the most need for improvement.

6. Employee skill levels: The technical capability of employees is crucially important.

7. Employee empowerment: The empowerment of employees is vital in the drive towards establishing a learning culture that fosters improvement.

8. Systemisation: Regular audits, documentation, standardised work etc. are required to ensure that process stability and sustainability is effected.

9. Communication: This relates to the organisation's communication plan, production, and company data and strategies for improvement.

10. Alignment of finance and HR: The alignment of finance and HR towards the strategic goals of the organisation requires a detailed link to policy development that facilitates and promotes continuous improvement activities.

11. Knowledge management: The organisation can now share its learnings through the evolution of standardised work as empowered employees continuously improve their work methods.

12. Organisational culture: Organisational culture refers to the attitude of the employees within the organisation.

13. Departmental integration: The integration of the various departments is a vital organisational maturity factor.

3 RESEARCH METHODOLOGY

The research has distinct categories, and seeks to establish (through a deductive approach) whether variables are interrelated, and whether the hypotheses presented are accepted or rejected on the basis of the survey results obtained through the research instrument. The quantifiable nature of this research will seek to provide a heightened level of reliability and validity. Organisational maturity factors have been outlined to be specific elements within the organisation's design that have been shown, through the literature reviewed, to establish specified levels of maturity. These maturity levels are also impacted by the various performance improvement programmes, which subsequently will have an impact on performance.

The fundamental approach taken in this research is that it seeks to establish which maturity factors are of the greatest importance to manufacturing firms for their impact on performance improvement selection. It also identifies which performance improvement programme's outcome would have the largest influence in the development of organisational maturity in South Africa.

3.1 Theoretical framework

Figure 2 illustrates the hypothesised interrelationship between maturity factors, performance improvement programmes, and organisational performance factors as studied in the consulted literature sources. The model contends that performance improvement programmes can influence maturity levels - or, conversely, are either favourably or unfavourably influenced by organisational maturity. The research seeks to establish the maturity factors that impact most on this relationship; and this will serve to inform the process of selecting improvement programmes as part of a tool developed through this research. Organisational performance factors are also influenced by organisational maturity.

The final part of the model contends that performance improvement programmes influence organisational performance, which in turn results in organisational performance factors having an influence on the type of performance improvement programme selected.

Implicitly, from Figure 2 of the high level theoretical model, the research can also contend that organisational performance factors (internal quality, equipment availaibility, and output performance) would have an impact on organisational maturity simply through the presumed influence or relationship they have with the selection of performance improvement programme.

3.2 Research instrument

A survey was concluded using a web-based survey tool to collect responses. The research instrument was divided into 10 different sections. Each section was developed to satisfy a research objective, or sets of objectives.

3.3 Sample

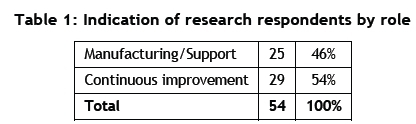

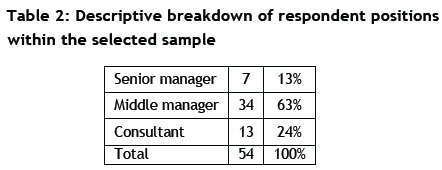

The research sample is considered random in that every respondent had an equal chance of answering. The sample is also stratified, in that various levels within the organisation could respond.

The survey was sent to more than 100 respondents within the Eastern Cape automotive sector.

4 RESULTS

The survey results included 54 respondents from the automotive sector.

4.1 Hypotheses test results

4.1.1 Hypothesis 1

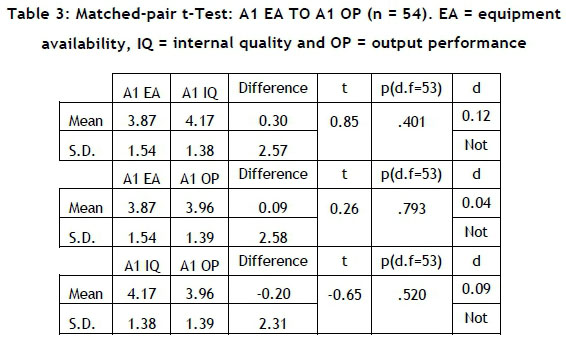

H0: The three components of organisational performance - internal quality, equipment availability, and output performance - make equal contributions towards overall performance within organisations.

H1: The three components of organisational performance - internal quality, equipment availability, and output performance - do not make equal contributions towards overall performance within organisations.

Based on Table 3 above, none of the items was of statistical significance (p greater than 0.025). On this basis, the researcher can reject the alternate hypothesis H1 for hypothesis 1 as all the items were greater than 0.025, which implies statistical insignificance. There is an equal contribution of each component towards overall performance in companies. There was no practical significance for Cohen's d (less than 0.2).

4.1.2 Hypothesis 2

H0: The three performance improvement programmes are equally appropriate for addressing current performance issues within organisations.

H1: The three performance improvement programmes are not equally appropriate for addressing current performance issues within organisations.

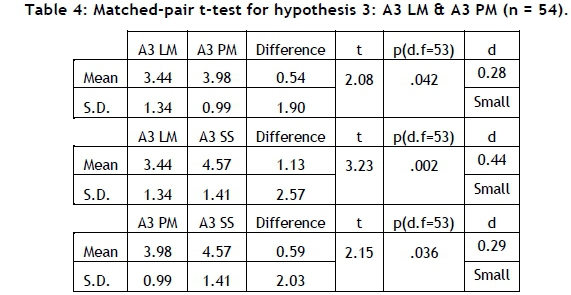

In Table 4 below, lean manufacturing is denoted (LM), total productive maintenance is denoted (PM), and Six Sigma is denoted (SS).

Based on Table 4 above, one of the items was of statistical significance (p- value is greater than 0.025). On this basis, the researcher can accept the alternate hypothesis H1 for hypothesis 2, as the matched pair p-value for item 2 (0.02) in Table 4 was less than 0.025, which implies statistical significance. The three components of performance are therefore not rated equally within organisations. There was practical significance for Cohen's d for all three questions (Cohen's d is greater than 20).

4.1.3 Hypothesis 3

H0: Organisational maturity factors have an equal impact on internal quality, equipment availability, and output performance in an organisation.

H1: Organisational maturity factors do not have an equal impact on internal quality, equipment availability, and output performance in an organisation.

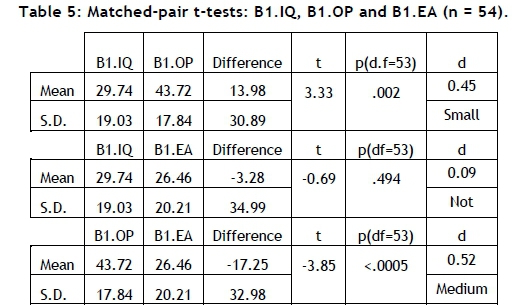

Based on Table 5 above, one of the matched pairs was of statistical significance. On this basis, the researcher can accept the alternate hypothesis H1 for hypothesis 3, as the p-value for item 1 in Table 69 (0.02) was less than 0.025, which implies statistical significance. Organisational maturity factors do not have an equal impact on internal quality, equipment availability, and output performance in an organisation. There was practical significance for Cohen's d recorded for item 2 B1 .IQ versus B1.EA (Cohen's d is greater 20).

4.1.4 Hypothesis 4

H0: The specific performance improvement programmes have a significant impact on organisational maturity development.

H1: The specific performance improvement programmes do not have a significant impact on organisational maturity development.

From the statistical data presented in Table 6, it can be inferred that specific performance improvement programmes have an impact on organisational maturity development (all p values less than 0.05). We can therefore reject the alternate hypothesis for Hypothesis 4.

4.1.5 Hypothesis 5

H0: Organisational maturity factors do not have an equal impact on performance improvement programmes in an organisation.

H1: Organisational maturity factors have an equal impact on performance improvement programmes in an organisation.

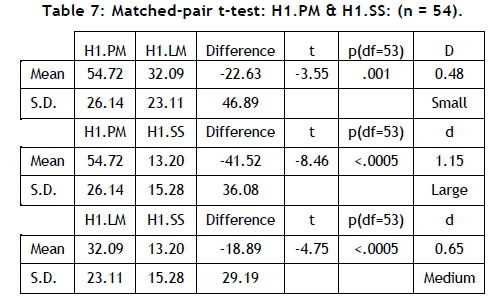

Table 7 indicates p-values (less than 0.025) demonstrating statistical significance for each of the three items. We can therefore reject the alternate hypothesis H1. Organisational maturity factors do not have an equal impact on performance improvement programmes. Cohen's d shows practical significance.

4.1.6 Hypothesis 6

H0: The specific maturity factor does not have an equal impact on each of the three performance improvement programmes.

H1: The specific maturity factor has an equal impact on each of the three performance improvement programmes.

Table 8 shows that there are statically significant differences between the maturity items, and indicates their impacts on the three performance improvement programmes (items H1.5, H1.10, and H1.11 are the only items showing statistical insignificance). On the basis of statistical information, the researcher rejects the alternate hypothesis. Each specific maturity factor has a different impact on each performance improvement programme.

5 CONCLUSION

The research results highlight the influence of the thirteen organisational maturity factors on performance improvement programmes. This two-way role of organisational maturity is vital for programme selection and implementation. The primary research objective - to assess the role of organisational matuirty as a factor in the selection of performance improvement programmes - is satisfied. The research results support the definitive role of organisational maturity in the sustainability of the adopted programme.

Secondary research objective number one aimed to establish the interaction between organisational maturity and organisational performance. From the survey results, it is evident that output performance was influenced the most, with an average of 44 per cent of responses, followed by internal quality with 30 per cent of responses, and lastly equipment availability with 26 per cent. 'Roles and responsibilities' was identified as the maturity factor that influenced output performance significantly. This was closely followed by organisational culture. Internal quality was influenced the most by standardisation, and equipment availability was influenced most by the level of employee technical skills. The research objective is therefore satisfied through the demonstration that organisational maturity factors have an influence on performance.

Secondary research objective number two aimed to establish the dominant performance concerns of Eastern Cape manufacturers. The three factors - internal quality, output performance, and equipment availability - are thus very similar in importance. There is thus no dominant performance concern, as the difference is not significant enough between the three.

Secondary research objective number three aimed to determine the interaction between improvement programme performances and organisational engagement maturity variables.

For lean manufacturing, the following notable results support objective three with its impact on a specified set of maturity variables:

• Labour loading through cycle time establishment enhances standardisation of work and promotes employee ownership

• Just-in-time systems improve communication levels in the organisation and allow performance to be measured more easily.

For Six Sigma, the following notable results support objective three with its impact on a specified set of maturity variables:

• Sophisticated problem-solving approaches support measurement, communication, and learning and development within organisations

• Projects' financial impact assessments align HR and finance. They also serve to improve departmental integration and illuminate the strategic link between the organisation's vision and financial key performance indicators.

• Dedicated improvement teams promote a learning culture, and improve internal communication, training, and departmental integration.

For total productive maintenance, the following notable results support objective three with its impact on a specified set of maturity variables:

• Equipment standards, which form an integral part of TPM, enhance employee skills, empowerment levels, performance measurement, and standardisation.

• Operator-led equipment activities improve measurements, tracking, and employee empowerment, and also enhance specialised training.

• Operator-driven equipment loss measurement enhances performance measurement, promotes employee empowerment, and increases systemisation (when software is used).

Secondary research objective number four aimed to determine the performance improvement programme objective that would have the greatest impact on South African firms, based on the contributing causes of low organisational engagement maturity.The research has shown, through the results of the hypothesis test, that the general set of performance improvement programme tools has the highest influence on developing organisational maturity and, therefore, on performance. However, to service the research objective with a conclusive statement: total productive maintenance was ranked second, followed by lean manufacturing, and lastly by Six Sigma. It can thus be concluded that total productive maintenance would yield the greatest impact for South African manufacturers. Survey responses support this statement where respondents have asserted that equipment availability (linked to total productive maintenance) would yield the greatest impact on performance for their respective organisations.

Secondary research objective number five aimed to establish the defined organisational maturity factors that impact on specific organisational performance measures such as internal quality, output performance, and equipment availability.

From the survey results it can be concluded that the top five maturity factors (in order of importance) influencing each of the performance inputs are as follows:

• Internal quality

1. Standardisation of processes, visual controls, and job instruction

2. Training and development of employees

3. Knowledge-sharing approach from experts to the shop floor

4. Internal shop floor communication

5. Employee empowerment levels

• Output performance

1. Measurement and tracking of performance

2. Support systems (ERP, ISO, production tracking systems, etc.)

3. The link between performance deliverables and strategy

4. Finance and HR policies and practices

5. Roles and responsibilities

• Equipment availability

1. Employee technical skills (maintenance and equipment knowledge)

2. Knowledge-sharing approach from experts to the shop floor

3. Employee empowerment levels

4. Training and development of employees

5. Roles and responsibilities

Secondary research objective number six aimed to establish the contribution of performance improvement programme objectives to organisational performance. The survey analysis results show that each performance improvement programme has a differing level of contribution towards performance, as determined from the sample of respondents. Total productive maintenance is shown to make the greatest contribution to performance, followed by Six Sigma, and lastly by lean manufacturing.

REFERENCES

[1] Leask, G. 2011. Etracc. [Online] Available at: www.etracc.net. Accessed 19 March 2013. [ Links ]

[2] Deloitte. 2013. Enhancing manufacturing competitiveness In South Africa. [Online]. Available at: http://www2.deloitte.com/za/en/pages/manufacturing/articles/mfg-competitiveness. Accessed 19th March 2013. [ Links ]

[3] Bozdogan, K. 2010. Towards an integration of the lean enterprise system, total quality management, six sigma and related enterprise improvement methods, Cambridge, Massachusetts: Massachusetts Institute of Technology. [ Links ]

[4] Fore, S. & Zuze, L. 2010. Improvement in overall equipment effectivess through total productive maintenance. World Academy of Science, Engineering and Technology, 4, pp. 320-328. [ Links ]

[5] Paneerselvam, M.K. 2012. TPM implementation to invigorate manufacturing performance: An Indian industrial rubric. International Journal of Scientific and Engineering Research, 3(6), pp. 1-10. [ Links ]

[6] Ireland, F. & Dale, B.G. 2001, A study of total productive maintenance implementation, Journal of Quality Maintenance Engineering, 7(3), pp. 193-191. [ Links ]

[7] Vidales, P., Jones, G. & Thomas, A. 2012. An integrated approach to TPM and six sigma development in the castings industry. Manufacturing Engineering. Vorne Industries, 2008. [Online] Available at: www.vorne.com. Accessed 19th March 2013. [ Links ]

[8] Wauters, F. & Mathot, J. 2007. ABB. [Online] Available at: www.abb.com. Accessed 19th March 2013. [ Links ]

[9] Kronos, 2007. Kronos. [Online] Available :www.kronos.com/fyo/manufacturing.htm. Accessed 19th March 2013. [ Links ]

[10] Pintelon, L. & Muchiri, P. 2008. Performance measurement using overall equipment effectiveness (OEE). International Journal of Production Research, 46(13), pp. 3517-3535. [ Links ]

[11] Kristiansen, A.G. 2010. TPM, six sigma and lean. Scandinavian Brewers Review, 67(2). [ Links ]

[12] Henderson, B., Larco, A. & Jorge, L. 2000. Lean transformation - How to change your business into a lean enterprise. First ed. Richmond: The Oaklea Press. [ Links ]

[13] Siviy, J., Penn, L. & Stoddard, R. 2007. CMMI & six sigma. USA: Prentice Hall. [ Links ]

[14] Breyfogle, F. 1999. Implementing six sigma. New York: John Wiley and Sons. [ Links ]

[15] Engelund, E.H., Breum, G. & Friis, A. 2009. Optimisation of large scale food production using lean manufacturing principles. Journal of Foodservice, 20(1), pp. 4-14. [ Links ]

[16] Stamm, M.L., Neitzert, T. & Singh, D.P.K. 2009. TQM, TPM, TOC, lean and six sigma - Evolution of manufacturing methodologies under the paradigm shift from Taylorism/Fordism to Toyotism? 16th International Annual EurOMA Conference.Goteborg, Sweden. [ Links ]

[17] Womack, J.J. 1990. The machine that changed the world. New York: Harper-Collins. [ Links ]

[18] Ohno, T. 1988. Toyota Production System: Beyond large-scale production. s.l.: Productivity Press. [ Links ]

[19] Liker, J.K. & Morgan, J.M. 2006. The Toyota way in services: The case for lean product development. The Academy of Management Perspectives, 20, pp. 5-20. [ Links ]

[20] Amin, M. & Karim, M. 2011. A systematic approach to evaluate the process improvement in lean manufacturing organisations. St Petersburg: Queensland University of Technology. [ Links ]

[21] Turesky, E. & Connell, P. 2010. Off the rails: Understanding the derailment of a lean manufacturing initiative. Organisation Management Journal, 7, pp. 110-132. [ Links ]

[22] Wong, Y.C. & Wong, K.Y. 2011. Approaches and practices in lean manufacturing: The case of electrical and electronics companies. African Journal of Business Management, 5(6), pp. 2164-2174. [ Links ]

[23] Abdulmalek, F. & Rajgopal, J. 2007. Analysing the benefits of lean manufacturing and value stream mapping via simulation: A process sector case study. International Journal of Production Economics, 107(1), pp. 223-236. [ Links ]

[24] Lester, D., Parnell, J. & Carraher, S. 1993. Organisational life cycle: A five stage empirical scale. Journal of Organisational Analysis, 11(4), pp. 339-354. [ Links ]

[25] Nave, D. 2002. How to compare six sigma, lean and theory of constraints. Process Improvement, March, pp. 73-78. [ Links ]

[26] Jacob, D., Bergland, S. & Cox, J. 2009. Velocity: Combining 'lean, six sigma and theory of constraints to achieve breakthrough performance. USA: Free Press. [ Links ]

[27] Mazumdar, A. 2012. TPM, lean or Six Sigma. TPM, Lean or Six Sigma, Valcon Management Consultants. January 2012, pp. 1-3. [ Links ]

[28] Womack, J. 2003. How lean compares with six sigma, re-engineering, TOC, TPM etc. Lean Enterprise Institute, July. Available online at http://www.lean.org/womack/DisplayObject.cfm?o=710. Accessed 20 July 2016. [ Links ]

[29] Decarlo, N. 2007. Lean Six Sigma. New York: Penguin Group. [ Links ]

[30] Theisens, D. 2010. How green is your black belt? Systems, Software and Processes, 99(1), pp.257-267. [ Links ]

[31] Curtis, B. & Alden, J. 2006. Bptrends. [Online] Available at: www.bptrends.com. Accessed 19th March 2013. [ Links ]

[32] Pesic, M.A., 2012. Business process management maturity model and six sigma: An integrated approach for easier networking. Serbian Association of Economists Journal, 3-4, pp. 190-198. [ Links ]

Submitted by authors 13 Aug 2015

Accepted for publication 7 Mar 2016

Available online 12 Aug 2016

# Author was enrolled for a DBA at the Nelson Mandela Metropolitan Uniersity, South Africa

* Corresponding author Zahier.Ebrahim@eveready.co.za