Serviços Personalizados

Artigo

Indicadores

Links relacionados

-

Citado por Google

Citado por Google -

Similares em Google

Similares em Google

Compartilhar

South African Journal of Industrial Engineering

versão On-line ISSN 2224-7890

versão impressa ISSN 1012-277X

S. Afr. J. Ind. Eng. vol.24 no.1 Pretoria Jan. 2013

The Toyota Production system's fundamental nature at selected South African organisations - a learning perspective

F.D. NortjeI, 1; D.R. SnaddonII

ISchool of Mechanical, Industrial and Aeronautical Engineering University of the Witwatersrand, South Africa. frans.nortje@theindustrialengineer.com,

IISchool of Mechanical, Industrial and Aeronautical Engineering University of the Witwatersrand, South Africa. drsnaddon@polytechnic.edu.na

ABSTRACT

The Toyota Production System (TPS) has been cited as being the pinnacle of continuous improvement approaches in manufacturing organisations, and many models of the TPS are well known. However, some authors question the effectiveness of established approaches, and propose Bateson's theory of learning [1] to be an effective way to explain phenomena like the TPS. This paper investigates the degree to which TPS elements are found in selected South African organisations. It constructs a model of the TPS using Bateson's theory of learning as a framework. The adoption of TPS elements is investigated through multiple qualitative case studies in seven organisations. The analysis follows a clustering and crosscase approach combined with pattern matching. While elements vary in their use, the selected organisations practise the TPS substantially less than the model advocates, with the model being least practised in low volume job/batch manufacturing. Product-process differences and higher levels of the TPS model may clarify peculiar outcomes.

OPSOMMING

Die Toyota Vervaardigingstelsel (TPS) word deur sommige beskou as die toppunt van volgehoue-verbetering metodes tans in gebruik deur veral vervaardigingsmaatskappye, en teorieë oor die stelsel is welbekend. Sommige kenners reken egter die huidige verstaan van die TPS skiet tekort in sekere aspekte, en stel Bateson se teorie [1] oor hoe mense leer voor as 'n beter manier om 'n fenomeen soos die TPS te verstaan. Hierdie artikel ondersoek die voorkoms van die basiese aard van die TPS by geselekteerde Suid-Afrikaanse organisasies. Bateson se teorie word as 'n raamwerk gebruik om 'n model van die TPS op te stel. Kwalitatiewe gevallestudies, waaraan sewe organisasies deelneem, word gebruik om data in te samel. Die analise volg 'n groepering en kruisondersoek benadering tesame met patroon-ontleding om tot 'n gevolgtrekking te kom. Elemente van die model word wisselend toegepas en aansienlik minder as wat die TPS model voorhou, met die minste toepassing gevind in lae volume / lot-vervaardiging omgewings. Interessante uitkomste word moontlik verduidelik deur produk-proses vergelykings asook die toepassing van die hoër vlakke van die TPS model soos opgestel.

1. INTRODUCTION

Application of 'lean manufacturing', or the Toyota Production System (TPS), has become normative in modern operations management [2]. Given the effort expended in applying these principles, it may be helpful, before embarking on its implementation or when trying to adopt new elements, to understand what the likely adoption of different elements of the TPS would be. This may allow those tasked with its implementation - often industrial engineers - to focus their energy where the greatest likelihood of adoption would be.

Multiple authors have commented on what is required for adoption of the TPS within an organisation. For example:

- Womack and Jones [3] suggest that adoption would be relative to the availability of strong, TPS-capable, senior leadership

- Liker and Hoseus [4] assert that adoption depends upon a sufficient emphasis on Toyota's culture

- Hayes and Wheelwright [5], although not directly commenting on the TPS, suggest that adoption of manufacturing techniques would suit product-process combinations, i.e. high-volume repetitive manufacturing, that would adopt a different set of principles to low volume job-shop environments.

This paper tests the prevalence (or adoption) of the TPS at selected South African organisations through a case study approach. The ingoing hypothesis is that:

The greater the similarity to products and processes of the TPS, the greater the adoption of its operations management principles will be, as in Hayes and Wheelwright's matrix [5].

We do not conclude with definitive outcomes, but rather build towards a theory that may be explored in further research.

2. LITERATURE SURVEY

2.1 Introduction

Many models explain manufacturing systems in general. For example, Cachon and Terwiesch [6] use a basic process view, Wu [7] suggests an object-oriented modelling approach partially based on systems theory, and Cochran et al. [8] separate objectives and means, and associate behaviours with outcomes. Hayes and Wheelwright [5] construct a matrix that explains the interplay between product selection and manufacturing processes and its corresponding strengths and weaknesses in corporate strategy.

There are also many models that may be used to explain the functioning of the TPS. These include the Shingo prize [2], Liker's fourteen management principles of the Toyota Way [9], and Womack and Jones' five lean principles [3], to name a few.

All these models may be applied to understand or specify the TPS. However, Ballé and Régnier [10] and Ohba [11] suggest that a potential shortcoming is the lack of reference to a 'learning' system. Although many authors (e.g. [9,12,13,14]) refer to 'learning' as part of their description of the TPS, they do not specifically refer to the TPS as a learning system.

Ballé et al. [15] and Johnson [16] go further and state that Bateson's theory of learning [1] may be the best known way - albeit currently missing from available discourse - to describe the TPS, as it could capture the element of learning or continuous improvement - a critical part of the TPS - from different perspectives, contexts, and levels.

Proceeding with this suggestion, a study of Bateson's theory of learning was conducted to construct a model of the TPS.

2.2 Bateson's theory of learning

Bateson maintains that a distinction between a class (e.g. a strategy) and its members (e.g. activities linking to that strategy) is necessary when studying behavioural phenomena such as learning, and that the notion of repeatable context is a necessary premise for any theory that defines learning as change. This understanding allows for the definition of levels to describe learning:

- Level Zero is a situation where no learning takes place - i.e. a similar response given similar stimuli.

- Level One is an instance where an entity gives a different response at a future point to the same stimulus in a current situation.

- Level Two takes place when a previous learning, which happened in a specific context, is judged as appropriate and applied in another context.

- Level Three is a correction in the system of the contexts of Level Two.

2.3 Application

To construct a model of the TPS using Bateson, the contemporary application of his theory of learning is first studied. When describing a system, Bateson [1], Bredo [17], and Tosey ([18,19,20,21]) suggest studying the class or context of a lower level, as it informs higher levels of learning. For example, measuring the presence or absence of Level Zero will inform the presence or absence of Level One, as only changes in context enlighten organisational learning. Dilts [22] suggests that, in an organisational system, Level Zero may refer to the environment, behaviours, or capabilities; Level One to the strategy of an organisation; Level Two to its values or beliefs; and Level Three to its greater purpose or vision.

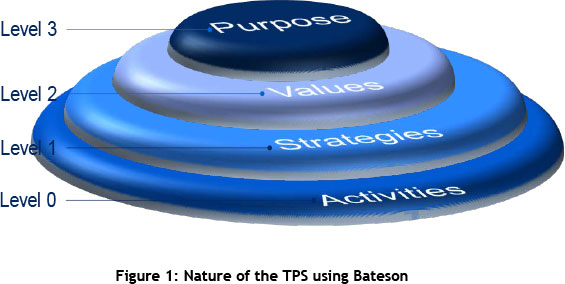

This research describes the TPS on four levels (Zero - activities, One - strategies, Two -values, and Three - purpose), illustrated in Figure 1.

Level One is positioned as a system's fundamental nature, with Level Zero (activities) informing Level One (strategies). Level Two (values) acts as the context in which Level One (strategies) is executed, with Level Three (purpose) providing a meta-context that gives Level Two (values) significance.

From relevant literature about the TPS, and from visits to Toyota South Africa Motors, twelve strategies of the TPS (informed by 48 activities), five values, and four purposes are identified.

Descriptions of each activity of TPS Level Zero are used for later comparisons with selected organisations. These are summarised in Table 1.

Although the main focus of the research is on the fundamental nature of the TPS (strategies), higher levels of the TPS are defined in a similar fashion, as this may potentially inform the outcome of lower levels. The figure below provides a visual representation of the TPS Level One, Two, and Three according to Bateson, with the two inner circles showing Level Two (values) and Level Three (purpose) respectively2.

3. RESEARCH METHODOLOGY

Seven cases3 were selected to test the hypothesis (see Table 2). A number of considerations were balanced in case selection, with participating organisations required to:

- have a formal improvement programme in place, influenced by the TPS;

- be small to medium in size (to allow ease in understanding approach and process); and

- be balanced across the spectrum of Hayes and Wheelwright's matrix [5], i.e. include high and low volume manufacturing.

Service organisations were also included, to allow contrast with high and low volume manufacturing.

The unit of analysis is each selected South African organisation, and the method of gathering data, is through a qualitative multiple case study4.

The analytical strategy relied on the theoretical hypothesis, developed through the literature study, to guide the analysis of the data. To ensure validity, detailed definitions were specified on what the presence of an activity, strategy, value, or purpose constitutes -allowing the researcher to be consistent in analysing evidence gathered (see Table 3 below for one example of definitions used for a particular strategy - 'Increase Customer Value').

Data was gathered through multiple sources of evidence: interactive presentation feedback, interviews, and structured observations, assisted by explicit definitions and the use of matrices. All the information was captured in an electronic database to allow analysis.

- Interactive presentation: each participating organisation was asked to invite a cross-section of their management team to a session where the Bateson-TPS model was presented to their organisation. Participants were asked to record notes on current application on a predesigned template (if practised). The same presentation was repeated/presented to each case.

- Interviews: typically the CEO, a person on a level reporting directly to him or her (e.g. a senior manager), and a person on a level reporting directly to a senior manager (e.g. a mid-level manager) were interviewed on their recent resolution of two problems. This could indicate learning, and reveal some of the strategies used to overcome these problems.

- Structured observations: the twelve strategies of the TPS Level One (with detailed activity definitions guiding observations) were used as a framework during a guided walkabout. Evidence was sought to corroborate claims made during the interviews or presentation of strategies and activities being practised.

Reliability was addressed through a high level of specificity, the use of case-study protocol, and use of a database, as well as using Case One as a pilot case to inform the research design and methodology.

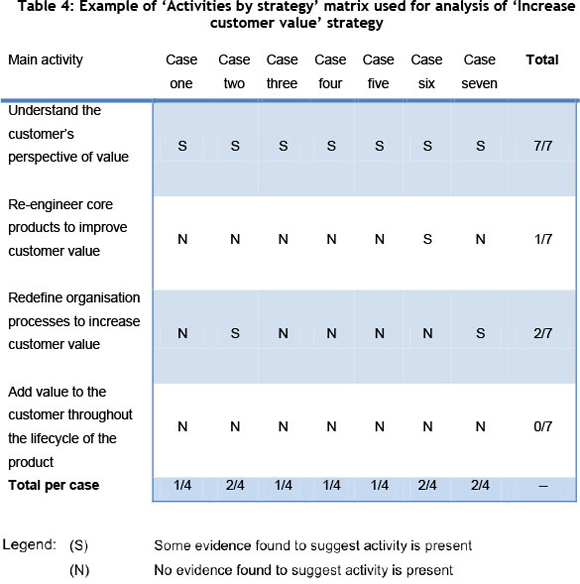

Interpretation was argumentative and thematic, supported by the use of the matrices and database software, working with close to a thousand pieces of evidence gathered. To answer whether a specific TPS Level One strategy was prevalent or practised in any of the cases, a judgement was first made on the TPS Level Zero activities, after which this was used to inform whether or not a strategy was present in a specific case. The research protocol specified that if any of the possible definitions were met, then it was judged as 'some evidence present' for an activity. If none of the possible definitions were present, it was judged as 'no evidence found to suggest activity is present'. This allowed a matrix of activities against cases to be constructed (see Table 4 below), with each definition statement carrying equal weight.

Lastly, to answer the main research question, a meta-matrix clustered the information through an ordered summary tabulation, according to the twelve strategies of the TPS Level One (see Table 5 in the results section). Each activity held equal weight in constructing the matrix.

4. RESEARCH RESULTS

To answer how prevalent the fundamental nature of the TPS is, the total number of activities for which evidence was found was recorded in the table below. As an example, Table 3 shows 'some evidence' found for one of the four activities of 'Increase customer value' for Case One. After repeating this exercise for all seven cases, Table 4 was compiled. Table 4's summary row was then transferred to the meta-matrix below. If all the activities informing strategies are tallied, the maximum score is 48. In addition, each case is listed as HV, LV, or SO, indicating its type according to case selection criteria - i.e. high-volume manufacturer, low-volume manufacturer, or service organisation. An equal weighting was applied to all activities measured. Table 5 shows the results for each case, as well as the average for each strategy.

The outcome shows that the twelve strategies that comprise the fundamental nature of the TPS are found to be practised:

- substantially less by the selected organisations than the Bateson-TPS model propagates;

- to differing degrees;

- the most, and to a similar degree in general, when comparing high-volume manufacturers with service organisations.

4.1 Manufacturing organisations

Results similar to the main hypothesis suggest that the comparison with the Bateson-TPS model may be explained by looking at product-process combinations postulated by Hayes and Wheelwright [5]. The high volume manufacturers show a greater presence of the strategies and tactics of Toyota's improvement model compared with low volume manufacturers, as shown visually in Figure 3.

4.2 Service organisations

A peculiar outcome is the comparatively high prevalence of strategies of the Bateson-TPS model at selected service organisations. A potential explanation was found through applying Bredo [17], and Tosey [20].

- Bredo suggests higher Bateson levels may contain information that explains the lower levels, just as higher order learning informs lower level activities, and the lower level activities help inform higher levels.

- Tosey argues that people will always adjust their ways based on the metacommunication present, as 'different levels of learning are simultaneous and mutually influencing'.

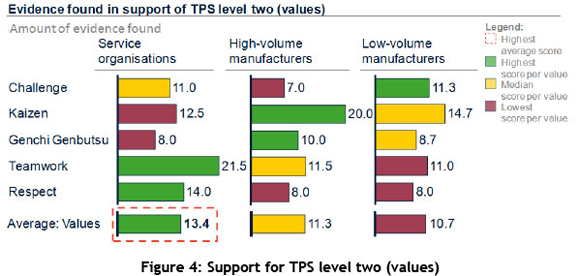

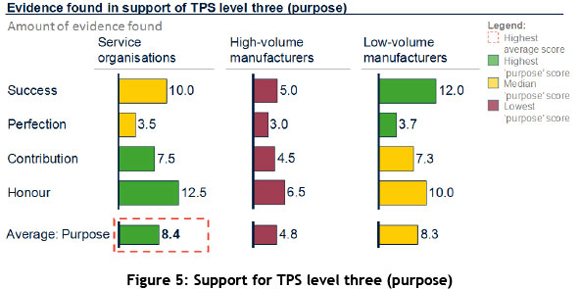

This implies that, should evidence be found for the presence of the higher levels of the TPS model, it might indicate that lower levels will also be present. Figures 4 and 5 show that service organisations did indeed have the most support for the higher levels of the Bateson-TPS model, thus potentially explaining the relatively high presence of lower levels of the Bateson-TPS model shown previously (analysis for higher levels were done using similar definitions and approach as for lower levels5).

5. CONCLUSION AND FURTHER RESEARCH

The nature of case study research does not lend itself to making definitive conclusions. Rather, it allows the researcher to gather evidence in support of a theory6. Two theories are presented that gathered some support through this research:

a) In line with the main hypothesis, adoption of activities and strategies of operations management approaches such as the TPS may be explained to some extent by product-process combinations, as provided by Hayes and Wheelwright's product process matrix [5]

b) Presence of higher dimensions of the TPS model developed (i.e. values and purpose) may be an indicator of the adoption of lower levels (i.e. strategies and tactics)

In other words, the case study results show the benefit of understanding the learning-context in which the TPS operates. Firstly, product-process combinations may indicate the likelihood of adoption of TPS principles, and might guide practitioners in selecting appropriate improvement models. Secondly, the multi-dimensional model developed may have the potential to explain the absence or presence of certain activities and strategies of the TPS not explained by product-process combinations. This may be used to augment existing 'lean' models that do not explicitly focus on the context (both learning and otherwise) in which the TPS operates.

Further research may verify these findings and expand to the general Bateson model proposed, e.g.:

- What are the boundary conditions required for the presence of higher levels of the Bateson-TPS model to predict lower level outcomes?

- What is the correlation between success of implementation (e.g. through measuring change in inventory-turn) compared with the relative position on the product-process matrix or the presence of higher levels of the Bateson-TPS model?

- Are organisations more successful in achieving lean outcomes (e.g. reducing cost of manufacturing, working capital, quality defects, etc.) when they focus on elements of the TPS model that are likely to be adopted by their organisation?

- Can organisations create an environment that is conducive to the adoption of lower levels of the Bateson-TPS model by emphasising higher levels, and, consequently, is there a direct causal relationship between specific higher and lower level elements?

REFERENCES

[1] Bateson, G. (1972). Steps to an ecology of mind - Collected essays in anthropology, psychiatry, evolution, and epistemology. Jason Aronson: London [ Links ]

[2] Shingo Prize. (2010). Shingo Prize for Operational Excellence - Model and application guidelines Version 4. Available from http://www.shingoprize.org/files/uploads/ShingoModelGuidelines.pdf (Accessed 8 March 2011) [ Links ]

[3] Womack, J.P. and Jones, D.T. (2003). Lean thinking. Revised edition. New York: Free Press [ Links ]

[4] Liker, J.K. and Hoseus, M. (2008). Toyota culture, the heart and soul of the Toyota way. New York: McGraw Hill [ Links ]

[5] Hayes, R.H. and Wheelwright, S.C. (1979a). Link manufacturing process and product life cycles, Harvard Business Review (Jan.-Feb.), 133-140 [ Links ]

[6] Cachon, G. and Terwiesch, C. (2009). Matching supply with demand, an introduction to operations management. Second edition. New York: McGraw Hill Irwin [ Links ]

[7] Wu, B. (1994). Manufacturing systems design and analysis. London: Chapman and Hall [ Links ]

[8] Cochran, D.S., Arinez, J.F., Duda, J.W. and Linck, J. (2002). A decomposition approach for manufacturing system design. Journal of Manufacturing Systems, 20(6) [ Links ]

[9] Liker, J.K. (2004). The Toyota way. New York: McGraw Hill [ Links ]

[10] Ballé, M. and Régnier, A. (2007). Lean as a learning system in a hospital ward. Leadership in Health Services, 20(1), 33-41 [ Links ]

[11] Ohba, H. (2002) Communication to the 'Making Things 21C' Conference, Nagoya, March, 7th. Available from: http://www.lean.org/Community/Registered/ ArticleDocuments/the TPS9620evolution.pdf (Accessed 29 March 2009) [ Links ]

[12] Cavaleri, S. (2008). Are learning organizations pragmatic? The Learning Organization, 15(6), 474-485 [ Links ]

[13] Dennis, P. (2007). Lean production simplified. Second edition. New York: Productivity Press [ Links ]

[14] Spear, S.J. and Bowen, H.K (1999). Decoding the DNA of the Toyota Production System. Harvard Business Review, 77(5), 96-106 [ Links ]

[15] Ballé, M., Beauvallet, G., Smalley, A. and Sobek, D. (2006). The thinking production system. Reflections, 7(2),1-12 [ Links ]

[16] Johnson, H.T. (2006). Lean dilemma: Choose system principles or management accounting controls, not both. Available from: http://in2in.org/insights/TomJohnson-LeanDilemma.pdf (Accessed 29 March 2009) [ Links ]

[17] Bredo, E. (1989). Bateson's hierarchical theory of learning and communication. Educational Theory, 39(1) [ Links ]

[18] Tosey, P. (2005). The hunting of the learning organization: A paradoxical journey. Management Learning, 36(3), 335-352 [ Links ]

[19] Tosey, P., Mathison, J. and Michelli, D. (2005). Mapping transformative learning: The potential of neuro-linguistic programming. Journal of Transformative Education, 3 (2), 40-167 [ Links ]

[20] Tosey, P. (2006). Bateson's levels of learning: A framework for transformative learning? Paper presented at the 2006 Universities' Forum for Human Resource Development Conference: University of Tilburg, 22-24 May 2006 [ Links ]

[21] Tosey, P. (2008). Once upon a time... tales of organisational learning. The Learning Organization, 15(6), 454-462 [ Links ]

[22] Dilts, R. (1998). Modelling with NLP. Capitola, CA: Meta Publications [ Links ]

[23] Bicheno, J. (2004). The new lean toolbox - Towards fast flexible flow. Buckingham: Picsie Books [ Links ]

[24] Ballé, F. and Ballé, M. (2005). The Gold Mine. The Lean Enterprise Institute: Cambridge, MA [ Links ]

[25] Hsiao, S.W. and Liu, E. (2005). A structural component-based approach for designing product family. Computers in Industry, 56, 13-28 [ Links ]

[26] Dennis, P. (2006). Getting the right things done. Cambridge, MA: The Lean Enterprise Institute. [ Links ]

[27] Toyota. (2007b). Environmental report. Available from http://www.toyota.co.jp/en/environmental_rep/07/download/ (Accessed 23 March 2009) [ Links ]

[28] TSAM Visit. (2008). A visit to Toyota South Africa Motors during October 2008 to gain insight and information on the Toyota Production System [ Links ]

[29] TSAM Visit (2010). A visit to Toyota South Africa Motors during April 2010 to gain insight and information on the Toyota Production System [ Links ]

[30] Womack, J.P. and Jones, D.T. (2005). Lean solutions: How organisations and customers can create wealth together. New York: Free Press [ Links ]

[31] Ohno, T. (1988). The TPS - Beyond large scale production. Productivity Press: New York, NY [ Links ]

[32] Spear, S.J. (2002). The essence of just-in-time: Embedding diagnostic tests in work-systems to achieve operational excellence. Production Planning and Control, 13(8), 754-767 [ Links ]

[33] Towill, D.R. and Childerhouse, P. (2006). Enabling the seamless supply chain by exploiting the four smooth material flow controls. Production Planning and Control, 17(8), 756-768 [ Links ]

[34] Marchwinski, C. and Shook, J. (2006). Lean lexicon. Third edition. Cambridge, MA: The Lean Enterprise Institute [ Links ]

[35] Toyota. (2009a). Sustainability report. Available from http://www.toyota.co.jp/en/csr/report/09/download/pdf/sustainability_report09.pdf (Accessed 7 November 2009). [ Links ]

[36] Eisenhardt, K.M. (1989). Building theories from case study research. The Academy of Management Review. Vol 14, No. 4, pp. 532-550 [ Links ]

[37] Yin, R.K. (2003). Case Study Research, Design and Methods. Third Edition. Thousand Oaks: Sage. [ Links ]

[38] Leedy, P.D., Newby, T.J. and Ertmer, P.A. (2007). Practical Research, Planning and Design. Sixth Edition. New York: Macmillan [ Links ]

[39] Bell, J. (1999). Doing Your Research Project: a guide for first time researchers in education and social science. Open University Press: Buckingham [ Links ]

1 Author was enrolled for the M.Sc. Eng. (Industrial) degree in the School of Mechanical, Industrial and Aeronautical Engineering, University of the Witwatersrand, South Africa.

2 The intention of the figure is not to indicate a relationship between elements of different levels, only to show that they are on different levels. Refer to Figure 1.

3 Eisenhardt [36] suggests selecting four to ten cases when building theory from case study research, as fewer cases make it difficult to draw conclusions on hypotheses, and more than ten could add too much complexity. This is supported by Yin [37] explaining that the number of cases is not driven by a requirement for a significant sample, but rather to be sufficient to allow replication of results in support of a theory.

4 Leedy [38] advises that when the object of research consists of multiple constructed realities, or if the study is exploratory or interpretive, it is best to use a qualitative approach. Bell [39] and Leedy [38] suggest that a case study approach could be helpful to concentrate on specific instances or elements called by different names or applied in different settings in the object of analysis. Yin [37] says that if it is not possible to select a representative sample of the object of analysis, research can achieve external validity by wisely selecting specific cases, and replicating case results to support a specific theory, e.g. through the use of a case study approach.

5 Evidence was collected to understand the presence or absence of higher levels of the Bateson-TPS model (values and purpose - see Figure 2) during the research. Detailed definitions were specified (similar to those shown for strategies and tactics), which allowed the evidence to be classified, if applicable, in support of one or more of the higher levels. Support was measured based on the amount of evidence found supporting the presence of the higher levels of the TPS, with equal weighting given to each explanation.

6 The objective of case study research is not to work towards a representative sample, but rather to build towards the support of a theory through literal and theoretical replication in support of the hypotheses of the [37].