Servicios Personalizados

Articulo

Indicadores

Links relacionados

-

Citado por Google

Citado por Google -

Similares en Google

Similares en Google

Compartir

Southern African Business Review

versión On-line ISSN 1998-8125

versión impresa ISSN 1561-896X

SABR vol.27 Pretoria 2023

http://dx.doi.org/10.25159/1998-8125/13564

ARTICLE

Financial Performance and Green Supply Chain Management in a South African National Electrical Energy Provider

Irvine LangtonI; Chengedzai MafiniII; Nelson MaotoaweIII

IVaal University of Technology. irvinemakena7@gmail.com. https://orcid.org/0000-0002-9883-3793

IIVaal University of Technology. chengedzaim@vut.ac.za. https://orcid.org/0000-0002-8125-6715

IIIVaal University of Technology. mafin12000@yahoo.com. https://orcid.org/0000-0002-6335-1444

ABSTRACT

INTRODUCTION: The body of literature on green supply chain management (GSCM) in various organisations has increased steadily. However, contextual literature on GSCM is still limited, such as within the electrical energy sector in developing countries such as South Africa.

PURPOSE/OBJECTIVES: The study examined the relationships between internal GSCM (IGSCM), customer monitoring (CM) and -supplier monitoring (SM), customer-supplier collaboration (CC, SC), and financial performance at Eskom Holdings, the national electrical energy provider in South Africa.

DESIGN/ METHODOLOGY: The study employed a quantitative approach design on a sample of 350 supply chain professionals drawn from various Eskom depots nationwide. Hypotheses were tested using structural equation modelling based on the SMART partial least squares (PLS) technique.

FINDINGS: IGSCM positively impacted customer and supplier monitoring and collaboration, linked to higher financial performance. However, IGSCM negatively impacted financial performance.

PRACTICAL IMPLICATIONS: To managers in the electrical energy sector, the study suggests that implementing IGSCM, SM, CM, CC, and SC activities is key in influencing the level of FP. Similarly, it is important to implement IGSCM activities in tandem with customer and supplier monitoring and collaboration if gains in FP are to be realised.

ORIGINALITY/VALUE: This study contributes to GSCM literature as it is one of the few studies that explore IGSCM, customer and supplier monitoring, customer-supplier collaboration, and financial performance within a South African national electrical energy provider.

Keywords: internal green supply chain management; customer monitoring; supplier monitoring; customer collaboration; supplier collaboration; financial performance

Introduction and Background to the Study

In South Africa, the responsibility to provide electrical energy lies under the sole monopolistic mandate of a government-owned national utility, Eskom Holdings, a State-Owned Company Ltd (Act 71 of 2008; Eskom Integrated Report 2021). Eskom was established in 1922 as a national electrical energy provider (National Treasury 2022). Despite its imperative role in the socio-political and economic development, Eskom has been tainted and marred by a myriad of challenges hindering it from performing effectively and efficiently (Niemann et al. 2016:979; Ting and Byrne 2020:4). Some challenges include leadership crises, ineffective cost recovery, and irregular and wasteful expenditure management, among others (Ting and Byrne 2020). The overall result has been the shortage of electrical power in South Africa, with the entire country experiencing load-shedding for several years, with these challenges climaxing in 2022 and 2023.

Sustainability issues manifesting through environmental issues such as pollution have often been cited as another major area of underperformance at Eskom (Kings 2018). Okharedia (2019) posits a general dictum among the public that the lack of environmental sustainability within ESKOM costs the entity in terms of fines that eventually result in financial losses. This is particularly so with Eskom's extensive use of coal, which has led to extensive land degradation, environment, air pollution, and respiratory diseases affecting its employees and communities surrounding Eskom power stations (Gous 2018). Moreover, electricity generation results in waste emissions such as smoke, ash, chemicals, and nuclear waste, thereby negatively affecting the natural environment and human health (Fuzile 2018). As a result, the lack of appropriate 'green electricity generation' practices has been cited as inhibiting Eskom's good reputation, collaboration, efficiency, innovation, and growth (Kings 2018). This has led to an adverse relationship with some of its stakeholders, such as environmentalists' and citizens' movements (Ramabele 2016; Bowman 2020). Other detrimental outcomes to Eskom include the stifling of many business functions and activities, including impeding collaboration amongst business partners, which affects the enterprise' s entire performance (Bowman 2020). The utility has faced severe criticism for failing to be entirely environmentally mindful in its operational activities (Kings 2018; Fuzile 2018). The print media, radio stations, and social media have consistently reported on environmental risks associated with electricity generation activities by Eskom (Kings 2018).

It has been suggested that to overcome its sustainability problems, Eskom faces the task of adopting the use of GSCM technologies such as 'cleaner, greener' solar systems and hydroelectricity generation in the quest to enhance both production and environmental efficiency and effectiveness (Fuzile 2018). It has been recommended that Eskom should become environmentally sentient by embracing and implementing GSCM practices (Ramabele 2016; Bowman 2020). Adopting such initiatives is likely to boost the competitiveness of Eskom, empowering the utility to compete with other electricity-generating entities worldwide (Gous 2018; Bowman 2020).

This article examines the relationship between internal green supply chain management (IGSCM) customer and supplier monitoring, collaboration, and financial performance at Eskom. Current knowledge of applying GSCM and customer-supplier monitoring and integration in State-Owned Enterprises (SOEs) in developing countries is still limited. This has created a need for a greater understanding of the nature of practice between these constructs as increasing stakeholders' outcry puts pressure on the enterprise (Huang et al. 2019). Additionally, the research model being tested in the study is yet to be tested within the context of the electrical power sector in South Africa, implying that the impact of GSCM on supplier and customer relationships, as well as financial performance, remains a grey area in this sector. The study is intended to address these gaps.

Literature Review

An Overview of South African National Electrical Energy Provider (Eskom)

In terms of electricity generation capacity, Eskom ranks among the top 20 utilities in the world (Eskom Integrated Report 2021). It generates approximately 90 per cent of the electricity used in South Africa and approximately 40 per cent of the electricity used in Africa (Department of Public Enterprises 2022). It is one of the critical and strategic contributors to the South African government's goal of ensuring the security of the electricity supply and enabling economic growth and prosperity (Eskom Integrated Report, 2021). Its primary role is not only the generation of electricity but also the transmission, distribution, and sale of electricity, as well as the importation and exportation if need be (National Treasury 2019; Eskom Integrated Report 2019). Although electricity generation is the core function, the company is also active in all elements of the electricity supply chain, including the transmission and distribution to industrial, mining, commercial, agricultural, and residential customers and redistributors (Eskom Report 2022). Eskom's key role is to assist in lowering the cost of doing business in South Africa through the strategic intent statement by the South African Department of Public Enterprises (Department of Public Enterprises 2022). This ensures that Eskom is intended to facilitate economic growth and the security of electricity supply efficiently and sustainably (Eskom Integrated Report 2019). The utility plays a critical role in job creation and poverty reduction. By the end of 2022, the group's employees (including fixed-term contractors) had increased to 47 978 (Eskom Integrated Report 2021).

Green Supply Chain Management (GSCM)

GSCM can be perceived as a set of managerial practices that combines environmental issues with SCM to guarantee environmental compliance and promote the environmental capability of the entire supply chain (Li et al. 2016). It involves integrating environmental practices into SCM, such as product design, material sourcing, and selection manufacturing processes (Rahim et al. 2016). Typical GSCM practices include green procurement, eco-design, green manufacturing, green distribution, reverse logistics, and green training (Li et al. 2020; Samad et al. 2021). The application of GSCM is linked with several paybacks, such as operational and relational efficiency, enhanced corporate image, environmental sustainability, and financial performance, among others (Chinomona and Bikissa-Macongue 2022). Furthermore, GSCM enhances operational efficiency through cost reduction, improved product quality, and faster production lead times (Chinomona and Bikissa-Macongue 2022). Its implementation guarantees environmental compliance and promotes the environmental capability of the entire supply chain for the organisation and value chain participants in delivering the product to the customer and its disposal (Samad et al. 2021).

Internal Green Supply Chain Management (IGSCM)

IGSCM refers to the practices that individual organisations can implement and manage independently to improve environmental performance (Aigbedo 2019). IGSCM, as a practice, reflects the firm's decisions to act in an environmentally friendly way (Laari et al. 2016). The concept aims at attaining the firm's specific internal targets established by the management team or imposed by company policies (Li et al. 2016). It reveals the organisation's capability to adopt a sustainable strategy designed to reduce the undesirable environmental impact of its operations (Almeida et al. 2019). Furthermore, for an organisation to implement GSCM practices, it must ensure commitment and support from the top and mid-level management (Green et al. 2012; Aigbedo 2019).

Customer Monitoring and Collaboration

Customer monitoring (CM) is a fully managed customer experience management process that collates and analyses customer feedback to uncover important themes and trends (Chinomona and Bikissa-Macongue 2021). It is all about tracking the actual behaviours of an organisation's real-life consumers (Eslami and Melander 2019). The process can be achieved using surveys, online communities, social media, live chat platforms and employee feedback, among others in organisations (Feng, Jiang and Xu 2020). Offering excellent CM is essential for retaining customers, encouraging repeat business, and establishing a good brand through word-of-mouth recommendations (Kafouros et al. 2020). Having a system to monitor customers' satisfaction with the service provided by Eskom will help identify the root cause of problems encountered by buyers and provide enterprises with insights on how to improve their products and services best (Chinomona and Bikissa-Macongue 2021). Various studies (Eslami and Melander 2019; Kafouros et al. 2020; Ho et al. 2022) concur that CM cascades into (customer collaboration) CC, and the relationship between the two practices is always positive and significant.

Collaboration is a game-changing trend for future supply chains, emanating mostly from good CM practices (Ho et al. 2022). Thus, CM and collaboration is a recent step in co-design and entails a group of customers taking part in product design and committing to the product purchase (Ho et al. 2022). Collaboration improves product quality and enables organisations to deliver what the customers want (Simatupang and Sridharan 2020). Today's customers demand that products and services be provided without damaging the environment (Ho et al. 2022). Simatupang and Sridharan (2020) recognise that businesses are responsible for many of the current environmental problems, such as global warming and pollution, hence the need to collaborate with suppliers and customers. In addition, collaboration improves customer loyalty and financial performance.

Supplier Monitoring and Collaboration

Supplier monitoring (SM) is a constant evaluation routine of all suppliers participating in an organisation's supply chain (Eslami and Melander 2019). It is a structured process to manage suppliers and improve their impact on the buyer's business (Feng, Jiang, and Xu 2020). It includes managing vendor deliverables, working collaboratively to co-develop new processes, managing compliance, and paying invoices (Eslami and Melander 2019). SM is often achieved by sharing up-to-date and relevant information and has minor variations from one company to another (Statsenko and Zubielqui 2019). This evaluation is generally more focused on the quality of products and delivered services, deadlines, costs and pricing policy, and the practicality of process logistics and material handling (Kafouros et al. 2020).

Furthermore, SM can be achieved through commitment, ease of communication, and degree of innovation, among others. SM, which always complements supplier collaboration (SC) in organisations, is extremely important to businesses (Lee 2015). It helps to mitigate risk, increase service quality, and improve the relationship with providers. In today's business environment, having a good ability to create, monitor and keep alliances is synonymous with competitive advantage (Eslami and Melander 2019).

In GSCM, SC involves selecting suppliers implementing environmental management systems (Loury-Okoumba and Mafini 2021). SC Environmental pressures, social and industry norms, and organisational choices influence SC (Kahkonen et al. 2017; Lee 2015). Within South Africa, firms (e.g., Cummins, Delta, and Checkers) that pursue SM and SC can benefit from integrating suppliers from their initial stages of production (Chinomona and Bikissa-Macongue 2022). Such benefits include improved product quality, operational performance, competitive advantage, and inventory management (Feng et al. 2020). By integrating suppliers into its activities, Eskom tends to benefit in many areas, such as inventory management, improved service delivery, and improved relationships with suppliers.

Financial Performance

Financial performance (FP) is a subset of organisational performance covering operational and financial outcomes (Selvam et al. 2016). It is defined as how efficiently a firm utilises its resources to generate economic outcomes. FP leans towards the ability of the organisation to reduce costs associated with purchased materials, energy consumption, waste treatment, waste discharge and fines for environmental accidents (Zhu, Sarkis and Lai. 2018).

Conceptual Model and Hypotheses

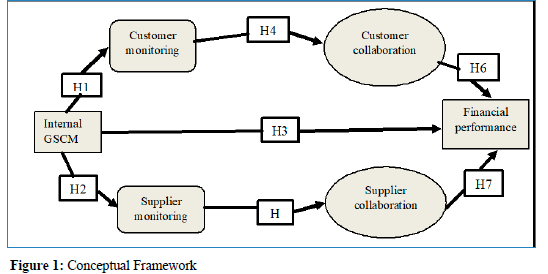

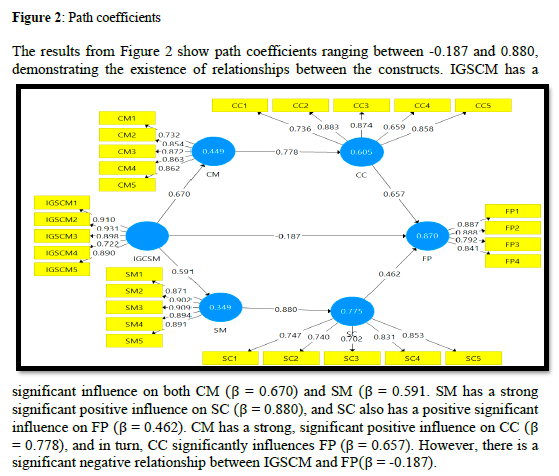

This study is based on the conceptual model presented in Figure 1. In the model, IGSCM is presented as the predictor variable, leading to CM, CC, SM) and SC. The outcome variable is FP.

Internal GSCM and Customer and Supplier Monitoring, Supplier Monitoring

Internal GSCM practices reflect positive communications to the relevant stakeholders about the company and its functions (Li et al. 2020). This assists the business in drawing customers' and media's attention and responsiveness, which in turn transforms consumer insights and purchasing behaviour. Several studies (Ali et al. 2016; Gunasekaran et al. 2015; Laari et al. 2016; Li et al. 2020) establish that internal GSCM practices improve CM and CC. The following hypotheses are thus put forward.

H1: There is a positive and significant relationship between IGSCM and CM.

H2: There is a positive and significant relationship between IGSCM and SM.

Internal GSCM and Financial Performance

Large companies often find IGSCM practices cost-effective and profitable because of their ability to reduce waste (Gunasekaran et al. 2017; Li et al. 2020). At the same time, following the five R's (recycling, reusing, redesigning, refurbishing and reverse logistics) ultimately influences financial performance by minimising production costs (Lee 2015; Li et al. 2016). Besides, implementing GSCM enhances the corporate image, which conveys positive consumer behaviour about the business, resulting in additional revenue and effectiveness (Lee et al. 2012; Lee 2018; Simatupang et al. 2020; Zhu Sarkis and Lai. 2012). This leads to the following hypothesis.

H3: There is a positive and significant relationship between IGSCM and FP.

Customer Monitoring and Customer Collaboration

Ardakani, Soltanmohammadi and Seuring (2022) found CM in business organisations to be the main enabler of a trusting relationship, which leads to a robust CC. The expected result should thus offer an improved integration of operational processes aimed at consistently improving CC and the satisfaction derived from constant monitoring of customer needs, values, and input in the whole supply chain. This leads to the following hypothesis:

H4: There is a positive and significant relationship between CM and CC.

Supplier Monitoring and Supplier Collaboration

Organisations that embrace SM initiatives such as quality monitoring, information sharing, delivery processes management, innovation improvement, and cost and risk monitoring stand a better chance of engaging in strong SC (Feng et al. 2020). Several studies (Ho et al. 2022; Li et al. 2020; Samad et al. 2021) posit that SM positively influences SC between supply chain partners. Therefore, the hypothesis is put forward:

H5: There is a positive and significant relationship between SM and SC.

Customer Collaboration (CC) and Financial performance (FP)

Based on CC within the supply chain, positive FP can be improved by sharing business information, uncertainties, and risks with customers (Son et al. 2016). The relationships between CC and FP have been extensively studied (Li et al. 2020; Shin, Park and Park. 2019; Son, Kocabasoglu-Hillmer and Roden 2016), and the results confirm that CC can be transformed into a competitive advantage, thus contributing to overall positive FP. Furthermore, several studies (Pomponi, Fratocchi and Tafuri 2015; Tsanos & Zografos 2016; Micheli, Cagno, Mustillo and Trianni. 2020; Samad et al. 2021) establish the positive association between CC and FP, demonstrating the existence of a relationship between these two constructs. Therefore, the following hypotheses are presented:

H6: There is a positive and significant relationship between CC and FP.

Supplier Collaboration and Financial Performance

In general, there is much regard for SC because it boosts organisations to increase FP (Mathebula and Masiya 2022; Panahifar, Byrne, Salam and Heavy 2018). Collaboration with suppliers elicited benefits, including supply chain integration, supply chain performance and information sharing, all of which are linked to FP (Peng et al. 2018). Some studies (Panahifar et al. 2015; Panahifar et al. 2018) establish direct positive linkages between SC and FP in organisations. In addition, Ardakani et al. (2022) find that SC results in cost reduction in the whole process of the supply chain. Based on these results, it is hypothesised that:

H7: There is a positive and significant relationship between SC and FP.

Research Methodology

This study adopted a quantitative survey method using a questionnaire for data collection. The study was based on quantitative data collected from 350 supply chain professionals operating within Eskom in various provinces of South Africa. The list of the supply chain professionals was extracted from the employee databases at Eskom. A stratified random sampling method was used to select the respondents to ensure that supply chain professionals.

Existing scales were used to develop the measurement items. Items measuring customer and supplier monitoring were adapted from Ahi and Searcy (2020), while those for internal GSCM were adapted from Zhu et al. (2018). Items measuring customer and supplier collaboration were adapted from Ardakani et al. (2022), and those for environmental performance were obtained from Zhu et al. (2018). Financial performance was measured using items adapted from Green et al. (2012). All measurement scales were validated in previous studies, scoring Cronbach alpha values above 0.7. Each item in the measurement scale was designed for response using a five-point Likert scale in which one corresponds to "strongly disagree" and 5 to "strongly agree." The measures are displayed in Appendix 1. A self-administered online survey questionnaire was used in the data collection process.

Data were analysed using descriptive and inferential statistics. A combination of Statistical Package for the Social Sciences (SPSS version 27.0) and the SMART partial least squares (PLS version 3.0) was employed as tools to achieve the complete analysis of data.

Research Results

Sample Profile

Out of 500 distributed questionnaires, 350 responses were valid for analysis, representing a response rate of 70%. Chi-square tests were executed to evaluate the non-response bias of the respondents and sample for incomplete questionnaires. Gender, income level, ethnicity, education level and age were used as demographic variables, and no significant differences were noted (p > .05). Much of the sample was constituted by black Africans (78%, n = 273). The remaining 22% includes white, Indian, and coloured people. In terms of gender, 70 % (n = 245) and 30 % (n = 105) were male and female, respectively. The majority age group was 33-42 years, representing 62% (n = 217). Regarding income, the majority, 51% (n= 179), stated a monthly income of between R35,000 and R55,000. Concerning education level status, 35% % (n = 123) had a high school certificate (matriculation), whereas the remaining 65% (n =227) possessed a post-high school qualification.

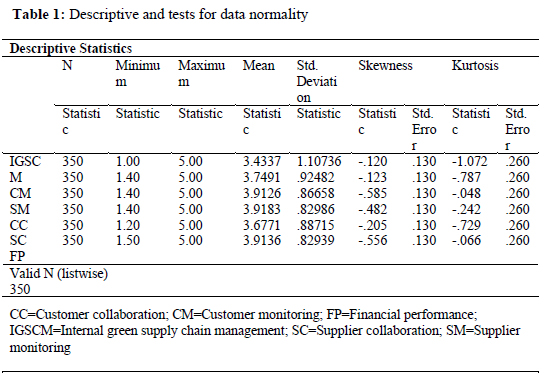

Skewness and kurtosis were applied to assess the distribution of data. To assume that data are satisfactory to demonstrate normal univariate distribution, its skewness must be in the range of -2 to +2, and its kurtosis must be in the range of -3 to +3 (Harrison et al. 2020).

Table 1 shows that the skewness statistics for all scales ranging from -.556 to -0.120 and kurtosis values fell between -1.072 and -0.066 The results indicate a distribution close to normality as the values fall between -2 to +2 and -3 to +3 (recommended by (Kenny 2019). The descriptive statistics analysis for five of the constructs (CM, SM, CC, SC, and FP) shows mean scores of more than 3.500, indicating that the respondents were aware of implementing these activities at Eskom. Only IGSCM scored a mean score of 3,4337, meaning that respondents were inclined to the neutral position on the Likert scale.

Common Method Bias and Scale Accuracy Assessment

Common method variance (CMV) was controlled during questionnaire design, data gathering and analysis. Data were gathered from various Eskom stations around South Africa to avoid context effects, and questionnaire items were concise to counter transient mood states. They were also phrased to avoid replicating social desirability. States and Harman's single factor test was computed, and the overall variance of the un-rotated single factor was 34.52%, which is less than the 50% threshold (Kenny 2019), demonstrating that CMV was not a threat to the validity of the study.

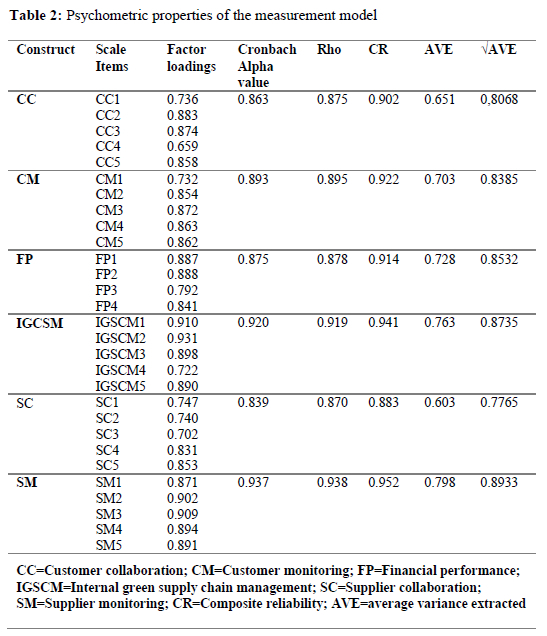

The results of the scale accuracy assessment are indicated in Table 2.

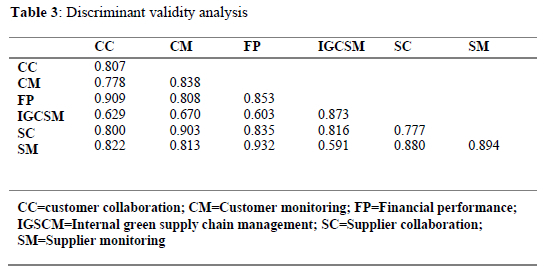

Table 2 indicates the scores for the Cronbach's alpha, Composite Reliability (CR), and Rho A statistics were all above the acceptable cut-off point of 0.70, indicating the attainment of scale reliability (Mitchell and Education 2018). Factor loadings for all measurement items were higher than the recommended minimum threshold of 0.5 (Kenny 2019), signifying the adequacy of convergent validity. To evaluate the discriminant validity of constructs, the Fornel and Larcker criterion was used to compare the square root of each AVE in the diagonal with the correlation coefficients for each construct in the relevant rows and columns (Harrison et al. 2020). As evidenced in Tables 2 and 3, the correlations between constructs do not exceed the value of the square root of the AVE of each construct, indicating the attainment of discriminant validity.

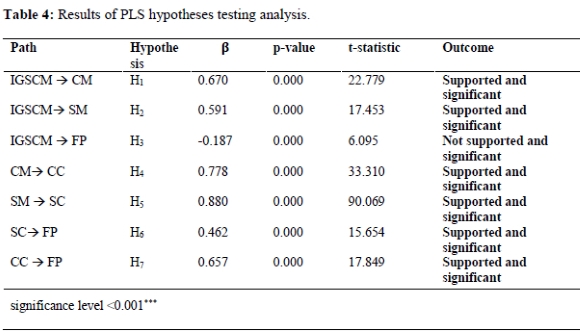

Path Analysis

Path analysis is a form of statistical analysis used to evaluate causal relationships between a set of variables (Crossman 2019). In this study, path analysis was used to test the hypotheses based on the results obtained from PLS analysis. The study utilised the two main criteria under the PLS model to validate and confirm each hypothesis. The first criterion in the application of path analysis included checking the path coefficients, which are represented by a beta (β). For a hypothesis to be supported and significant, the path coefficient must be positive or negative (Hair et al. 2014). The second criterion constitutes the considerable influence of the constructs. The significant influence constitutes three levels, which are represented by stars, also known as p-values. The levels of influence include values with at least three stars (***), which represent p-values less than 0.001; two stars (**) represent p-values less than 0.05, and one star (*) denotes a p-value less than 0.1.

Discussion of Results

The results of the study show that IGSCM has a significant influence on CM (ß = 0.670; p = 0.000; t=22.779). The result indicates a positive relationship between IGSCM and CM. This result is consistent with previous studies (Ho et al., 2022; Li et al., 2020), which showed connections between the two constructs. The study also indicates a positive linkage (ß =0.591; parens between IGSCM and SM. This result is consistent with several previous studies (Epoh & Mafini, 2018; Li et al. 2020); Micheli et al. 2020) where IGSCM was found to be a driver of SM.

These results may indicate the implementation of GSCM practices by Eskom and the awareness by the respondents of this green revolution in their organisation. Although Eskom still uses coal in generating electricity, plans and funding are in place to shift to more environmentally friendly generating units (Ka 'nkosi 2015). Additionally, numerous campaigns on GSCM have been on all sorts of media and have been practiced at Eskom. The use of renewable energies such as solar has gained momentum in the electrical sector in South Africa. This has also improved the expectation that suppliers and customers must comply with sustainability imperatives. Therefore, the electrical energy sector in South Africa is responding to the use of environmentally friendly ways and leading to greater monitoring of both customers and suppliers to promote compliance with green initiatives.

Customer monitoring (CM) was found to have a significant positive influence on CC (ß = 0.778; p = 0.000; t=33.310). A previous study by Haiyun et al. (2021) on innovation strategies for GSCM in the energy industry revealed similar results. The results imply that expediting customer collaboration hinges somewhat on the electrical energy sector's ability to apply CM practices in their organisational processes. The greater the monitoring of suppliers, the stronger the collaborative relationship between the parties involved.

Supplier monitoring (SM) positively and significantly influences SC (ß = 0.880; p =0.000; t=90.069). Field Ho et al. (2022) consistently establish that SM influences SC in their study of opportunities in GSCM in the retail industry. By implication, the stronger the monitoring of suppliers, the better the collaboration between both organisations. In this way, SM practices enable Eskom, and its supply chain partners to commit to each other and increase cooperation efforts. It is then essential for the electrical energy sector to monitor supplier activities to enhance closer ties and cooperation with them.

The results of the study further revealed that CC has a significant positive influence on FP (ß = 0.657; p= 0.000; t=17.849). Likewise, SC also exerts a positive influence on FP (ß = 0.462; p = 0.000; t=15.654). These results support the view that both CC and SC affect the profitability and financial growth of the electrical energy sector. These results confirm the assertions by Habib et al. (2021), who pointed out that monitoring and collaborating with suppliers significantly affects the FP of business organisations. Eskom, as one of the electricity generating companies, has not realised financial growth, with the company depending mainly on government funding. However, the current study advances the view that CC and SC should cascade into the financial growth of Eskom. The CC and SC activities at Eskom require leadership commitment and cooperation among all relevant stakeholders to influence positive financial returns. CC and SC policies may need to be guided by the desire to inspire, motivate and improve FP in the South African electrical energy sector. Overall, the need to improve on CC and SC has become more apparent in the pursuit of achieving FP excellence in the electrical energy sector in South Africa.

An interesting result is the negative influence of IGSCM on FP (ß = -0.187; p = 0.000; t=6.095). The result indicates that the implementation of IGSCM is linked to declining FP. It is also generally acknowledged that implementing the GSCM practices is an expensive exercise that affects FP negatively (Blanchard 2021). Typical IGSCM activities such as environmentally friendly product innovation, process innovation, and technological innovations require the use of financial resources, thereby affecting the FP of an organisation negatively. As such, for the electrical energy sector to push for IGSCM initiatives, a substantial budget from the profits should be in place. Therefore, green SCM activities are an extra cost to an organisation, though necessary in this new era.

Conclusions

This study aimed to investigate the relationship between IGSCM, customer and supplier monitoring and engagement, and FP at Eskom, which is the largest corporation in the electrical energy sector in South Africa. The study confirms the view that the implementation of IGSCM activities positively contributes to SM and CM in the South African electrical energy sector. The study concludes that SM and CM positively impact SC and CC, respectively. Moreover, both CC and SC are essential for the improvement of FP. However, the implementation of IGSCM has a negative effect on the FP of the sector.

The results of this study have important implications for understanding the interactions between IGSCM, supplier and customer relationships, and financial performance and how they can be employed to resuscitate the ailing South African electrical energy sector. In addition, these outcomes, which show significant relationships, provide critical empirical evidence for GSCM, customer and supplier relationship research. The study also validates similar research outcomes from other environments to the South African electrical energy sector. The study, therefore, is a reference work for future researchers on IGSCM and FP in comparable environments elsewhere.

To managers in the electrical energy sector, the study suggests that implementing IGSCM, SM, CM, CC, and SC activities is key in influencing the level of FP. Similarly, it is important to implement IGSCM activities in tandem with customer and supplier monitoring and collaboration if gains in FP are to be realised. As the results of the study show, an inconsiderate approach to IGSCM could diminish rather than improve the available financial resources.

To enhance the execution of IGSCM practices, modern technological resolutions should be considered. Using such technology resolutions may provide several benefits, such as a reduction in paperwork, the accuracy of information, easy integration with other functions and data access, which enables improved sustainability. Reductions in packaging costs using renewable electrical energy sources in place of carbon and coal could lead to a decline in carbon production, making Eskom more ecologically pleasant. The periodic maintenance of electricity generating plants and units, as well as production equipment, is likely to improve their cost-effectiveness through reductions in the use of coal and emissions. Training and development programs focusing on GSCM should be offered to all the staff to raise awareness within the sector. Eskom should provide a budget for implementing the GSCM initiatives so that funds can be supplied when required. Customer and supplier integration should be established and strengthened as these can lead to more effective relationships.

The study limited its scope to Eskom as the major player in the electrical energy sector in South Africa. This could be a drawback, given that this sector is broad and has numerous players whose views cannot be disregarded. Extending the study to two or three more companies could have yielded more expansive results. The study is limited to a quantitative approach, which has its own inherent weaknesses.

References

Ahi, P. and C. Searcy. 2020. "A Comparative Literature Analysis of Definitions for Green and Sustainable Supply Chain Management". Journal of Cleaner Production 5 (2): 329-341. https://doi.org/10.1016/jjclepro.2013.02.018 [ Links ]

Aigbedo, H. 2019. "Assessment of the Effect of Location and Financial Variables on Environmental Management Performance for Industrial Goods Supply Chains". Journal of Environmental Management 236: 254-268. https://doi.org/10.1016/j.jenvman.2018.11.066 [ Links ]

Ali, A., Y. Bentley, and G. Cao. 2016. "The Influence of Supplier Collaboration on Green Supply Chain Management Practices and Sustainable Firm Performance in UK Food Supply Chain SMEs". Logistics Research Network Conference, Chartered Institute of Logistics and Transport UK. [ Links ]

Ali, N., A. Ahmed, L. Anum, T. M. Ghazal, S. Abbas, M. A. Khan, H. M. Alzoubi, and M. Ahmad. 2021. "Modelling Supply Chain Information Collaboration Empowered with Machine Learning Technique". Intelligent Automation & Soft Computing 30 (1): 243-257. https://doi.org/10.32604/iasc.2021.018983 [ Links ]

Almeida, A., R. Alvarenga, L. Sartor, and F. Simioni. 2019. "Mitigating Environmental Impacts using Life Cycle Assessment in Brazilian Companies: A Stakeholders' Perspective". Journal of Environmental Management 236: 291-300. https://doi.org/10.1016/jjenvman.2019.01.094 [ Links ]

Ardakani, D. A., A. Soltanmohammadi, and S. Seuring. 2022. "The Impact of Customer and Supplier Collaboration on Green Supply Chain Performance". Benchmarking: An International Journal 6 (4): 21 -3. [ Links ]

Blanchard, D. 2021. Supply Chain Management Best Practices. John Wiley & Sons. https://doi.org/10.1002/9781119738275 [ Links ]

Bowman, A. 2020. "Parastatals and Economic Transformation in South Africa: The Political Economy of the Eskom Crisis". African Affairs 119 (476): 395-431. https://doi.org/10.1093/afraf/adaa013 [ Links ]

Chinomona, E. and M. B. Bikissa-Macongue. 2021. "The Drivers of Customer Collaboration in E-Business: A Case of Food Retailers in Southern Gauteng". Journal of Contemporary Management 18 (1): 1 -22. [ Links ]

Chinomona, E. C., and M. B. Bikissa-Macongue. 2022. "The Impact of Green Supply-Chain Management on Logistics Performance in the Construction Sector in South Africa". Journal of Transport and Supply Chain Management 16: 752. https://doi.org/10.4102/jtscm.v16i0.752 [ Links ]

Department of Public Enterprises. 2022. "Annual Report South Africa". Department of Public Enterprises, September 2022. http://www.dpe.gov.za/resourcecentre/publications/Annual%20Reports/DPE%20Annual%20Report%202016-17.pdf [ Links ]

Epoh, L. R. and C. Mafini. 2018. "Green Supply Chain Management in Small and Medium Enterprises: Further Empirical Thoughts from South Africa". Journal of Transport and Supply Chain Management 12 (0): 1-12. https://doi.org/10.4102/jtscm.v12i0.393 [ Links ]

Eskom Integrated Report. 2019. "Powering your World - Eskom Holdings Limited". Eskom, 31 March 2019. www.eskom.co.za. [ Links ]

Eskom Integrated Report. 2021. "Eskom's Procurement and Supply Chain Management Policy". Eskom, 21 September 2021. http://www.eskom.co.za/Tenders/EskomPurchasingPolicies/Documents/EskSupplyChainManagementProcedure.pdf. [ Links ]

Eslami, M. H. and L. Melander. 2019. "Exploring Uncertainties in Collaborative Product Development: Managing Customer-Supplier Collaborations". Journal of Engineering and Technology Management 53: 49-62. https://doi.org/10.1016/jjengtecman2019.05.003 [ Links ]

Feng, T., Y. Jiang, and D. Xu. 2020. "The Dual Process Between Green Supplier Collaboration and Firm Performance: A Behavioural Perspective". Journal of Cleaner Production 1 -21. https://doi.org/10.1016/jjclepro.2020.m073 [ Links ]

Fuzile, B. 2018. "Red Flags after Eskom Posts Annual Results". Sunday Times, 28 July 2018. https://www.timeslive.co.za/sunday-times/business/2018-07-23-red-flags-after-eskom-posts-annual-results/ [ Links ]

Gous, N. 2018. "Eskom wants to keep polluting." Sunday Times, 19 March 2018. https://www.timeslive.co.za/news/south-africa/2018-03-19-eskom-wants-permission-to-keep-on-polluting/ [ Links ]

Green Jr, K. W., P. J. Zelbst, J. Meacham, and V. S. Bhadauria. 2012. "Green Supply Chain Management Practices: Impact on Performance. Supply Chain Management": An International Journal 17 (3): 290-305. https://doi.org/10.1108/13598541211227126 [ Links ]

Gunasekaran, A., T. Papadopoulos, R. Dubey, S. F. Wamba, S. J. Childe, B. Hazen, and S. Akter. 2017. "Big Data and Predictive Analytics for Supply Chain and Organizational Performance". Journal of Business Research 70: 308-317. https://doi.org/10.1016/jjbusres.2016.08.004 [ Links ]

Gunasekaran, A., N. Subramanian, and S. Rahman. 2015. "Green Supply Chain Collaboration and Incentives: Current Trends and Future Directions". Transportation Research Part E: Logistics and Transportation Review 7 (4): 1-10. https://doi.org/10.1016/j.tre.2015.01.002 [ Links ]

Habib, M. A., Y. Bao, N. Nabi, M. Dulal, A. A. Asha, and M. Islam. 2021. "Impact of Strategic Orientations on the Implementation of Green Supply Chain Management Practices and Sustainable Firm Performance". Sustainability 13 (1): 340. https://doi.org/10.3390/su13010340 [ Links ]

Haiyun, C., H. Zhixiong, S. Yüksel, and H. Dinçer. 2021. "Analysis of the Innovation Strategies for Green Supply Chain Management in the Energy Industry Using the QFD-Based Hybrid Interval Valued Intuitionistic Fuzzy Decision Approach". Renewable and Sustainable Energy Reviews 143: 110844. https://doi.org/10.1016/j.rser.2021.110844 [ Links ]

Harrison, R. L., T. M. Reilly, and J. W. Creswell. 2020. "Methodological Rigor in Mixed Methods: An Application in Management Studies". Journal of Mixed Methods Research 14 (4): 473-495. https://doi.org/10.1177/1558689819900585 [ Links ]

Ho, J. C., M. K. Shalishali, T. L. B. Tseng, and D. S. Ang. 2022. "Opportunities in Green Supply Chain Management". The Coastal Business Journal 8 (1): 2. [ Links ]

Huang, X., B. L. Tan, X. Ding, and D. Bennett. 2019. "An Exploratory Survey of Green Supply Chain Management in Chinese Manufacturing Small and Medium-Sized Enterprises: Pressures and Drivers". Journal of Manufacturing Technology Management 26 (1):1-12. https://doi.org/10.1108/JMTM-05-2012-0053 [ Links ]

Ka'Nkosi, S. 2015. "What is up with SA's parastatals? Business Report". IOL, 27 July 2015. www.iol.co.za/business/news/what-s-up-with-sa-s-parastatals-1.1890886. [ Links ]

Kafouros, M., J. H. Love, P. Ganotakis, and P. Konara. 2020. "Experience in R&D Collaborations, Innovative Performance, and the Moderating Effect of Different Dimensions of Absorptive Capacity". Technological Forecasting and Social Change 150: 1-16. https://doi.org/10.1016/j.techfore.2019.119757 [ Links ]

Kahkonen, A., K. Lintukangas, P. Ritala, and J. Hallikas. 2017. "Supplier Collaboration Practices: Implications for Focal Firm Innovation Performance". European Business Review 29 (4): 402-418. https://doi.org/10.1108/EBR-04-2016-0058 [ Links ]

Kenny, D. A. 2019. "Enhancing Validity in Psychological Research". American Psychologist 74 (9): 1018. https://doi.org/10.1037/amp0000531 [ Links ]

Kings, S. 2018. "Eskom is not coughing up for the pollution it causes". Mail & Guardian, 1 May 2014. https://mg.co.za/article/2014-05-01-eskom-is-not-coughing-up-for-the-pollution-it-causes. [ Links ]

Laari, S., J. Töyli, T. Solakivi, and L. Ojala. 2016. "Firm Performance and Customer-Driven Green Supply Chain Management". Journal of cleaner production 11 (2): 1960-1970. https://doi.org/10.1016/jjclepro.2015.06.150 [ Links ]

Lee, C. 2018. "Green Suppliers with Environmental Performance in the Supply Chain Perspective." Asia Pacific Management Review 13 (4): 731 -745. [ Links ]

Lee, S. M., S. Tae Kim, and D. Choi. 2012. "Green Supply Chain Management and Organizational Performance". Industrial Management & Data Systems 112 (8):1148-1180. https://doi.org/10.1108/02635571211264609 [ Links ]

Lee, S. Y. 2015. "The Effects of Green Supply Chain Management on the Supplier's Performance Through Social Capital Accumulation. Supply Chain Management". An International Journal 20 (1): 42-55. https://doi.org/10.1108/SCM-01-2014-0009 [ Links ]

Li, G., L. Li, T. M. Choi, and S. P. Sethi. 2020. "Green Supply Chain Management in Chinese Firms: Innovative Measures and the Moderating Role of Quick Response Technology". Journal of Operations Management 66 (7-8): 958-988. https://doi.org/10.1002/joom.1061 [ Links ]

Li, S., V. Jayaraman, A. Paulraj, and K. Shang. 2016. "Proactive Environmental Strategies and Performance: Role of Green Supply Chain Processes and Green Product Design in the Chinese High-Tech Industry". International Journal of Production Research, 54 (7): 2136-2151. https://doi.org/10.1080/00207543.2015.1111532 [ Links ]

Loury-Okoumba, W. V., and C. Mafini. 2021. "Supply Chain Management Antecedents of Performance in Small to Medium Scale Enterprises". South African Journal of Economic and Management Sciences 24 (1): 1-13. https://doi.org/10.4102/sajems.v24i1.3661 [ Links ]

Mafini, C., and W.V. Loury-Okoumba. 2018. "Extending Green Supply Chain Management Activities to Manufacturing Small and Medium Enterprises in a Developing Economy". South African Journal of Economic and Management Sciences 21 (1): 1-12. https://doi.org/10.4102/sajems.v21i1.1996 [ Links ]

Mathebula, N. E., and T. Masiya. 2022. "Governance Issues and State Capture at Eskom and Transnet: A Kingdon's Multiple Streams Theory for Policy Studies". African Journal of Governance & Development 11 (1.1.): 146-163. [ Links ]

Micheli, G. J., E. Cagno, G. Mustillo, and A. Trianni. 2020. "Green Supply Chain Management Drivers, Practices, and Performance: A Comprehensive Study on the Moderators". Journal of Cleaner Production 259: 121024. https://doi.org/10.1016/jjclepro.2020.121024 [ Links ]

Mitchell, A., and A.E. Education. 2018. A review of mixed methods, pragmatism, and abduction techniques. Proceedings of the European Conference on Research Methods for Business & Management Studies. [ Links ]

National Treasury. 2019. "Medium Term: Budget Policy Statement". National Treasury, 30 October 2019. http//www.treasury.gov.za. [ Links ]

National Treasury. 2022. "Medium Term: Budget Policy Statement". National Treasury, 26 October 2022. http//www.treasury.gov.za [ Links ]

Niemann, W., T. Kotzé, and F. Adamo. 2016. "Drivers and Barriers of Green Supply Chain Management Implementation in the Mozambican Manufacturing Industry". Journal of Contemporary Management 13: 977-1013. [ Links ]

Okharedia, A. A. (2019) "A Conceptual Framework in Promoting Knowledge Management in Electricity Industry in South Africa: The Case Of ESKOM". Journal of Business and Retail Management Research (JBRMR) 13 (3): 269-281. https://doi.org/10.24052/JBRMR/V13IS03/ART-24 [ Links ]

Panahifar, F., P. J. Byrne, M. A. Salam, and C. Heavy. 2018. "Supply Chain Collaboration and Firm's Performance: The Critical Role of Information Sharing and Trust". Journal of Enterprise Information Management 31 (3): 358-379. https://doi.org/10.1108/JEIM-08-2017-0114 [ Links ]

Peng, B., Y. Tu, and G. Wei. 2018. "Governance of Electronic Waste Recycling Based on Social Capital Embeddedness Theory". Journal of Clean Production 187: 29-36. https://doi.org/10.1016/jjclepro.2018.02.265 [ Links ]

Pomponi, F., L. Fratocchi, S. R. Tafuri, and S. Rossi Tafuri. 2015. "Trust Development and Horizontal Collaboration in Logistics: A Theory Based Evolutionary Framework". Supply Chain Management. An International Journal 20: 83-97. https://doi.org/10.1108/SCM-02-2014-0078 [ Links ]

Rahim, S. A., Y. Fernando, and R. Saad. 2016." Sustainable Green Supply Chain Management and Impact on Organisations". Journal of Emerging Trends in Economics and Management Sciences (JETEMS) 7 (3):147-155. [ Links ]

Ramabele, B.A. 2016. "Assessing Corporate Responsibility on Sustainable Development at Eskom: A Case of Camden and Grootvlei Power Stations". University of South Africa, September 2016. http://hdl.handle.net/10500/21920. [ Links ]

Samad, S., M. Nilashi, A. Almulihi, M. Alrizq, , A. Alghamdi, S. Mohd, H. Ahmadi, and S. N. F. S. Azhar. 2021. "Green Supply Chain Management Practices and Impact on Firm Performance: The Moderating Effect of Collaborative Capability". Technology in Society 67: 101766. https://doi.org/10.1016Zj.techsoc.2021.101766 [ Links ]

Selvam, M., J. Gayathri, V. Vasanth, K. Lingaraja, and S. Marxiaoli. 2016. "Determinants of Firm Performance: A Subjective Model". International Journal of Social Science Studies 4 (7): 90-100. https://doi.org/10.11114/ijsss.v4i7.1662 [ Links ]

Shin, P., S. H. Park, and S. Park. 2019. "Partnership-Based Supply Chain Collaboration: Impact on Commitment, Innovation, and Firm Performance". Sustainability 11 (44): 1-19 https://doi.org/10.3390/su11020449 [ Links ]

Simatupang, T. M., A. C. Wright, and R. Sridharan. 2020. "The Knowledge of Coordination for Supply Chain Integration". Business Process Management Journal 8 (3): 289-308. https://doi.org/10.1108/14637150210428989 [ Links ]

Son, B.G., C. Kocabasoglu-Hillmer, and S. Roden. 2016. "A Dyadic Perspective on Retailer-Supplier Relationships Through the Lens of Social Capital". International Journal of Production Economics 178: 120-131. https://doi.org/10.1016/jijpe.2016.05.005 [ Links ]

Statsenko, L. and G.C. Zubielqui. 2019. "Customer Collaboration, Service Firms' Diversification and Innovation Performance". Industrial Marketing Management 1-18. https://doi.org/10.1016/j.indmarman.2019.09.013 [ Links ]

Ting, M. B., and R. Byrne. 2020. "Eskom and the Rise of Renewables: Regime-Resistance, Crisis and the Strategy of Incumbency in South Africa's Electricity System". Energy Research & Social Science 60: 101333. https://doi.org/10.1016/j.erss.2019.101333 [ Links ]

Tobi, H., and J.K. Kampen. 2018. "Research Design: The Methodology for Interdisciplinary Research Framework". Quality & quantity 52 (3): 1209-1225. https://doi.org/10.1007/s11135-017-0513-8 [ Links ]

Tsanos, C.S. and K.G. Zografos. 2016. "The Effects of Behavioural Supply Chain Relationship Antecedents on Integration and Performance". Supply Chain Management. International Journal 21: 678-693. https://doi.org/10.1108/SCM-06-2016-0211 [ Links ]

Zhu, Q., J. Sarkis, and K. H. Lai. 2012. "Examining the Effects of Green Supply Chain Management Practices and Their Mediations on Performance Improvements". International Journal of Production Research 50 (5): 1377-1394. https://doi.org/10.1080/00207543.2011.571937 [ Links ]

Zhu, Q., J. Sarkis, and K. H. Lai. 2018. "Confirmation of a Measurement Model for Green Supply Chain Management Practices Implementation". International Journal of Production Economics 111 (2): 261-273. https://doi.org/10.1016/j.ijpe.2006.11.029 [ Links ]