Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

Water SA

On-line version ISSN 1816-7950

Print version ISSN 0378-4738

Water SA vol.49 n.1 Pretoria Jan. 2023

http://dx.doi.org/10.17159/wsa/2023.v49.i1.3952

RESEARCH PAPER

Application of biopolymer in turbidity removal and sludge settling behaviour of travertine-processing wastewater: Performance optimization using response surface methodology (RSM)

Ebru TasI; Emmanuel Ikechukwu UgwuII; Eyüp SabahI; Zeyni ArsoyI

IDepartment of Mining Engineering, Faculty, Faculty of Engineering, Afyon Kocatepe University, 03200 Afyonkarahisar, Turkey

IIDepartment of Civil Engineering, College of Engineering and Engineering Technology, Michael Okpara University of Agriculture Umudike, P.M.B. 7267, Umuahia Abia State, Nigeria

ABSTRACT

A flocculation process was performed to treat travertine-processing effluents with a high concentration of suspended solids using an eco-friendly biopolymer. The experiments were conducted through a standard jar test procedure to optimize the process parameters for sludge volume index (SVI) and turbidity removal. The effects of mixing time, suspension pH, and polymer dosage on treatment efficiency were investigated using central composite design, a standard technique in response surface methodology. The constructed response model was tested using the analysis of variance (ANOVA). Using the Design-Expert tool, the coefficients of regression models were computed. The Fischer value (F-value) was used to evaluate the significance and validity of the predicted model, while the coefficient of determination (R2) was applied to estimate the model significance by comparing the predicted data with the measured data. The optimized parameters obtained were polymer dose of 276.20 mg/L, suspension pH of 8.60, and mixing time of 4.20 min. The optimal SVI and turbidity values obtained were 1.36 mL/g and 2.99 NTU, respectively. Additionally, R2 values for SVI and turbidity were determined as 0.9337 and 0.8654, respectively. Also, the difference between adjusted R2 values and predicted R2 was less than 0.2. Validation tests showed that the response surface methodology is an effective method for optimizing the flocculation mechanism.

Keywords: biopolymer, central composite design, travertine-processing wastewater, sludge volume index, turbidity

INTRODUCTION

Natural stone processing/mining plants, such as for granite, travertine, marble, etc., generate a considerable amount of wastewater during cutting, washing, sizing, and polishing processes, which contains a high number of negatively charged colloidal-sized particles. Such effluents of high turbidity and low solids content are not easily removed by the pre-treatment process, constituting a severe environmental issue. Therefore, solid-liquid separation of wastewater across the natural stone processing industries is significant in terms of economic and ecological considerations.

The machines used in the natural stone processing stages have different speeds and water consumption depending on the manufacturer and model. Furthermore, the speeds at which the same machine is applied to stones with different physical properties vary. However, Mutlutürk (2017) observed that the amount of water used is always approximately the same regardless of the size and properties of the stone. It was further reported by Mutlutürk (2017) that the average amount of water consumed in gang saws used for cutting natural stones from dimension stone quarry is 2 650 L/m2. Furthermore, S/T installed in tile lines, machines used for caliber, honing, polishing, plate and tile slim, splitting machines, bridge cutting and sizing machines, and alternative surface treatments (brushing, sandblasting, hammering, edge-corner breaking) consume approximately 875, 6 300, 480, 390, and 5 L/m2 of process water, respectively. That equates to 10 700 L of water per m2 of natural stone. The processed/treated water is used to provide this large volume of water consumed in stone processing plants. There are two output parameters used in evaluating the treatment of travertine-processing wastewater. The first output parameter is the turbidity of water obtained from the upper flow of a thickener. The removal of suspended colloidal particles from the recycled water is necessary to avert their possible detrimental effects on life as well as the efficiencies of cutting and polishing equipment in the production of tiles or slabs and to prevent clogging of water pipes and pumps, etc. (Çelik and Sabah, 2008). The second output parameter used is the settled sludge volume of flocculated particles. Water content or solid concentration strongly affects the cost of sludge treatment (the filtration step followed by dewatering) and disposal operations.

Wastewater treatment is a process of treating sewage or wastewater to remove suspended solids and convert them into effluent that can be safely discharged into the environment. The coagulation/ flocculation process is a type of physicochemical wastewater treatment method to reduce colloidal turbidity and suspended solids. It is a simple, efficient, and cost-effective method for natural stone processing wastewater treatment where inorganic salts of multivalent metals are mainly used as coagulants. In contrast, anionic or long-chain nonionic polymers are commonly used as flocculants. However, applying metal coagulants could constitute some significant environmental issues, such as the production of toxic sludge (large volumes of metal hydroxide). This causes an increase in concentrations of metals such as aluminum in the treated water as well as disposal problems, which may pose adverse health effects to humans (Rad et al., 2014; Okolo et al., 2017; Irfan et al., 2017).

The polymeric flocculants are non-biodegradable; thus, their degraded products are toxic due to the emission of minute concentrations of monomeric acrylamide in water, which could permeate the food chain, causing cancer (Singh et al., 2010; Huppertsberg et al., 2020). Researchers worldwide are working toward developing biopolymer-based flocculants from natural sources that can substitute for synthetic polymeric flocculants, because of their accessibility, safety, and biodegradability, which have put them in high demand (Lee et al., 2014).

Although there are many publications on coagulation/flocculation of travertine-processing wastewater using inorganic coagulants and polymeric flocculants such as polyaluminum chloride, iron salts, alum, and anionic polyacrylamides (Alptekin, 2006; Ersoy et al., 2009; Sabah and Aciksoz, 2012; Tasdemir and Kurama, 2013; Onen et al., 2018) there is still a lack of data on the settling characteristics of the sludge of suspended travertine fines and the residual turbidity of water treated using environment-friendly biopolymers devoid of acrylamide monomers. This biopolymer is associated with an inorganic coagulant to form a new hybrid polymer that is non-toxic and biodegradable, making its application in wastewater treatment a promising possibility (Lee et al., 2012).

The main objective of the present study was to investigate the flocculation efficiency of an eco-friendly hybrid polymer consisting of biopolymer/inorganic metal salt, and the interactive effects of polymer dosage, mixing time, and pH, for minimizing sludge volume index (SVI) and turbidity. Central composite design (CCD), a response surface methodology (RSM)-based technique, was used to optimize the selected process parameters, which were aimed at obtaining the required responses.

MATERIALS AND METHODS

Sampling

The travertine-processing wastewater was used as the effluent, and was collected in suspension form according to TSE 5667-10 (2002). The effluent sample was collected from the outlet of the travertine-processing wastewater plant located in Afyonkarahisar, Turkey. The sample was transported to the laboratory in 100 L barrels, stored in a 200 L capacity stirring tank, and analysed within 48 h of collection. The samples were mixed to obtain a homogenous mixture before the characterization/flocculation test was carried out.

Chemicals

The biopolymer used in this study is a blended biopolymer and polyaluminum chloride formulation free of acrylamide monomer (BHR-P50), supplied by Dober Chemical Company, USA. It is a whitish-yellowish-coloured opaque liquid with a viscosity and specific gravity of 500-1 300 cp and 0.95-1.15 cP, respectively. The suspension pH was adjusted using sodium hydroxide and hydrochloric acid (Merck grade) solutions.

Preparation of solution

One mL liquid biopolymer was dissolved in distilled water of 100 mL volume (EC 0.2 S/cm) to make a primary stock solution of the polymer with a concentration of10 000 mg/L. Before injecting the stock solution into the system for the flocculation tests, it was diluted with deionized water to achieve the desired concentrations of 50, 100, 200, and 400 mg/L standard biopolymer solutions.

Experimental procedure

The flocculation experiments were carried out using a VELP Scientifica Srl (Velp JLT4) speed-controlled jar test. Firstly, 500 mL of travertine suspension of 1.0% w/w solids was put in a 600 mL glass beaker, which was vigorously agitated at 300 r/min for a period of 3 min, to achieve maximum dispersion as well as to regulate the preset pH values of 6.0-10.0 by introducing sodium hydroxide/ hydrochloric acid as required. The required quantities of the flocculant were injected into the travertine suspension and subjected to agitation for an extra 1 to 5 min at 200 r/min before being reduced to 30 r/min to allow the floc to mature at 4 min preset time.

After a 15 min settling period, 25 mL volume of supernatant sample was taken at 3 cm preset distance underneath the interface between air and liquid, using a unique framework consisting of a syringe with a pipe and a scale, which helped in preventing the turbidity measurements from being disrupted by the settled flocs.

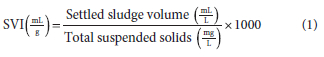

Physical, mineralogical, and physicochemical analysis

The travertine fines' particle size distribution (PSD) was determined using the Malvern Mastersizer 2000 laser diffraction technique. X-ray diffraction (XRD) was used to determine the mineral constituents of the travertine (Shimadzu XRD-6000). The conductivity and pH of the effluent samples were determined with the aid of a pH meter (WTW InoLab Multi 720), whereas turbidity was determined using a turbidimeter (WTW Turb 550) based on a nephelometric turbidity unit (NTU) for the supernatant of all samples, including samples with and without the biopolymer. Total suspended solids (TSS) and total solids (TS) concentrations were measured according to the Standard Methods for the Examination of Water and Wastewater, 2540 (APHA, 2005). The total dissolved solids (TDS) were determined as the difference between the TSS and TS. Titration with a chelating agent, ethylene diamine tetraacetic acid (EDTA), was used to determine the ions and hardness in water Mg2+(aq) and (Ca2+(aq). SVI is an indicator of the settling behaviour of sludge. To experimentally determine SVI, 1 L of wastewater is poured into a graduated cylinder of 1 000 mL volume (Imhoff cone); after waiting 30 min for settling of solids, the volume occupied by the sludge is reported in milliliters. The SVI is calculated by dividing the result of the settling test in mL/L by the TSS concentration in mg/L, as shown in Eq. 1.

Experimental design

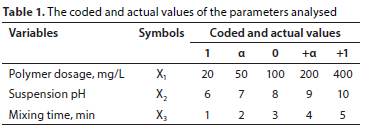

In optimizing process parameters for turbidity removal and sludge settling behaviour of travertine-processing wastewater, the central composite design (CCD), based on the conventional response surface methodology (RSM), was chosen. Since various parameters are often represented in multiple units and also have different levels of variance, the relevance of their influence on responses could only be correlated after they had been coded. The parameters were coded, as can be seen in Eq. 2, for statistical analysis.

where Xi is the un-coded function of the ith variable, X0 is the Xi value at the center of the field under investigation, while ΔΧ is the phase shift. Three parameters in the optimization technique were selected as X1, X2, and X3 for polymer dosage, suspension pH, and mixing time, respectively. The range and levels of the coded and actual values are presented in Table 1.

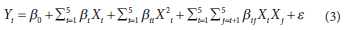

The responses were identified as turbidity and SVI. A polynomial function was used to connect the dependent with the independent variables, as seen in Eq. 3.

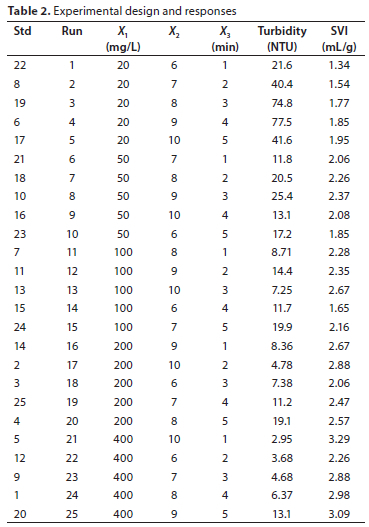

where Y represents the dependent variable (turbidity and SVI), Xi and Xj are the independent variables influencing y; and β0, βy, βii, and βij are the offset terms, the ith linear coefficient, the iith quadratic coefficient, the ijth interaction coefficient, and ε the error term, respectively (Onukwuli et al., 2021; Nnaji et al., 2022). The experimental design of this study and the responses are presented in Table 2.

Using the Design-Expert Tool 13 free trial version, the coefficients of regression models were computed. The Fischer value (F-value) was used to evaluate the significance and validity of the predicted model (Kumar et al., 2009), while the coefficient of determination (R2) was applied to estimate the model significance by comparing the predicted data with the measured data (Anilkumar et al., 2016).

RESULTS AND DISCUSSION

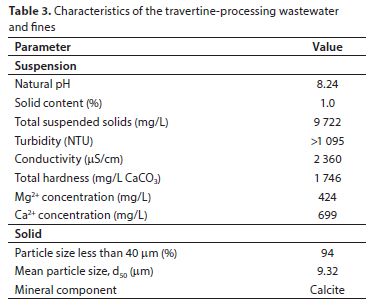

Characterization of travertine fines and suspensions

Powder X-ray diffraction (XRD) of travertine fines in wastewater showed that they were composed of calcite. Their particle size and distributions determined by laser light scattering are closely related to the settling characteristics of the travertine-processing wastewater. As Table 3 indicates, almost 94% of travertine fines are less than 40 μm, with a mean particle size d50 of 9.32 μm. So travertine-processing wastewater has both the properties of a suspension and the nature of a colloid. Therefore, it is challenging to clarify naturally. Furthermore, Brownian motion is significant to maintain the travertine fines in a dispersed phase because of high (to 94%) content of finely dispersed (less than 40 μm) fractions of travertine fines, fairly low (1.0%) solid ratio of the suspension, very high TSS (9.722 mg/L) and turbidity (>1 085 NTU) at natural pH, and weak electronegativity on the surface of particles caused by high-valence cations like Ca2+ and Mg2+. This suggests that the effect of particle-particle interactions in travertine suspension was insignificant and. therefore, zeta potential would not be expected to influence sedimentation stability significantly.

Travertine-processing wastewater with an alkaline nature (8.24) contains high amounts of various inorganic substances such as Mg2+ and Ca2+, at 424 mg/L and 699 mg/L, respectively, which leads to high water hardness with 1 746 mg/L CaCO3 (= 175°F). This is well above the proposed limiting value and falls within the class of very hard waters. Besides, the high bivalent ion concentration of the wastewater seems to decrease the specific resistance and increase the conductivity. The conductivity of the wastewater, which contained travertine fines and was measured at a natural pH, was high (2 360 μS/cm). Changes in the composition and ionic strength of water, together with the colloidal behaviour of solid particles in wastewater, significantly affect the flocculation process and the floc structure. The presence of cationic compounds alters the interactions between the colloidal particles and the polymer molecules, which causes a more coiled form of the polymer chain. This implies that not only an inferior settling rate but also increased turbidity is observed (Sabah and Erkan, 2006).

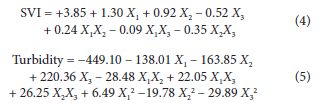

Regression models for SVI and turbidity

Statistical identification of the relationship between the operational and settling parameters and turbidity for the travertine-processing wastewater experiment is described in Table 2. The regression equations for SVI and turbidity are shown as Eqs 4 and 5:

where X1, X2, and X3 are polymer dosage, suspension pH, and mixing time, respectively. The effect of a single variable is defined by the coefficient of one factor, while the interaction between the two variables and the quadratic effect is defined by the coefficient of two factors and those with a second-order term. A positive sign before the words indicates a synergistic effect, while a negative sign indicates an antagonistic effect (Kim, 2016).

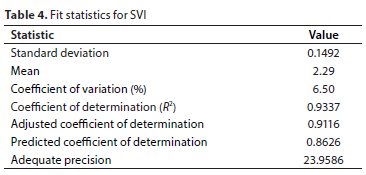

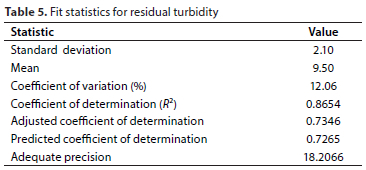

Fit statistics for SVI and turbidity

The fit statistics for SVI are shown in Table 4, while that for turbidity is shown in Table 5. The values obtained for the coefficients of determination (R2 of 0.9337 and 0.8654 for SVI and turbidity, respectively) are indications that the empirical model could only account for 10.2% of the overall variation (Ahamad et al., 2005). Moreover, the variation between the adjusted R2 values and the predicted R2 was less than 0.2 (Tables 4 and 5). This confirms that the adjusted R2 values are consistent with the R2 values predicted. Considering the two responses, the predicted values for SVI are the nearest to the values observed in the experiment, with a coefficient of determination of 0.9337 and the lowest standard deviation of 0.1492 (Table 4). This means that the experimental values are well-adjusted to the developed models. The model is best if the value of the coefficient of determination is close to 1. The standard deviation, as well as the coefficient of variation (CV) obtained, are both low, implying that the models could be replicated (Tables 4 and 5). The results of adequate precision (Tables 4 and 5) are much higher than the optimal value of 4, indicating that the model is well-fitted (Das, 2017). The obtained values of adequate precision demonstrate an appropriate fit that shows the model's ability to navigate the design space (Design-Expert, 2018).

Analysis of variance (ANOVA) for SVI and turbidity

At 95% confidence level, the models for the responses were checked for validity, as presented in Tables 6 and 7. In ANOVA, the model and parameters are significant when p < 0.05; therefore, the models were statistically significant, as shown by p values of <0.05 (Aravind et al., 2015). The findings also revealed F-values of 42.23 and 5.44 for SVI and turbidity (Tables 6 and 7). The F-value is a metric that indicates how well empirical models are suited to describing the statistical variance. The lower the value of p and the higher the value of F, the higher the level of significance of the coefficient terms and the model's ability to explain data variation (Chowdhury, 2013). All the individual terms for SVI and turbidity were significant in the models. In the case of interaction terms, X1X2 and X2X3 were substantial in the models for SVI and turbidity, while X1X3 was not important in the models (Tables 6 and 7). The quadratic terms X22 (p = 0.0350) and X32 (p = 0.0032) for turbidity were significant in the model, whereas X12 (p = 0.4950) was not significant (significance is determined by comparing the F-value and p-value results) (Table 7). The lack of fit was ineffective in any of the scenarios, confirming the accuracy of the developed models (Mondal et al., 2020). The polymer dosage (X1) had the most significant impact on SVI (Table 6), whereas the mixing time (X3) had the most significant effect on turbidity removal (Table 7), according to the F values.

Effect of process parameters on SVI and turbidity

The plots showing the response surface for SVI are presented in Fig. 1. The result indicated that the SVI increased as the suspension pH and polymer dosage increased (Fig. 1a). Fig. 1b shows that the SVI is at the lowest when the polymer dosage decreases, irrespective of the mixing time value. In the case of mixing time and suspension pH, as the suspension pH increased and the mixing time decreased, SVI increased (Fig. 1c). SVI is guided by three variables in the coagulation-flocculation technique, i.e, hydration, high polymer, and osmotic pressure effects (Ives, 1978). The hybrid polymer used in this study was a blended biopolymer and polyaluminum chloride (PAC) formulation carrying highly positive polymer charges. When the polymer was positively charged, the osmotic effect could be reduced, and the high polymer effect could be ignored (Wang et al., 2007). Therefore, a hybrid polymer with cationic nature was favourable for minimizing the SVI under neutral and slightly acidic conditions.

The plots showing the response surface for turbidity are presented in Fig. 2. The significant decrease in the response surface plots suggests that the best conditions were precisely within the model boundaries (Fig. 2). The effect of mixing time and suspension pH indicates that as the mixing time increased and the suspension pH decreased, the turbidity removal increased (Fig. 2a). The optimal conditions were found in the region where the mixing time increased from 1 to 5 min while the polymer dosage decreased from 400 to 20 mg/L on the response surface plot for mixing time versus polymer dosage (Fig. 2b). Conversely, the polymer dosage, suspension pH, and mixing time all had noticeable interactive effects on residual turbidity. This is due to the internal interactions of the variables. The destabilization capacity of mono-component travertine-processing wastewater increases in alkaline and neutral media due to charge neutralization between Al species contained in the hybrid polymer and negatively charged travertine-processing wastewater fines (Sabah and Aciksoz, 2012). Also, more mixing time is required to ensure adequate contact between the polymer molecules and colloidal particles to create stable flocs, in the case of low polymer concentrations. The optimal conditions were found in the zone where the polymer dosage increased from 200 to 400 mg/L while the pH decreased from 10.0 to 6.0, according to the response surface plot for mixing time versus suspension pH (Fig. 2c). The sphere-like shape, with the highest response at the central curvature (Fig. 2c) implies that polymer dosage, as well as suspension pH, had a strong effect on turbidity removal (Wang et al., 2007).

Optimization of SVI and turbidity

For model validation, the experiments were performed with the predicted values. The process optimization solution was chosen on the basis of its proximity to one of the highest desirability (Araromi et al., 2017). The target for optimization of SVI and turbidity was set at the minimum for all the operating conditions studied. The following were the optimal conditions for SVI and turbidity: polymer dosage of 276.20 mg/L, suspension pH of 8.60, and mixing time of 4.20 min, with the minimum turbidity and SVI determined to be 2.99 NTU and 1.36 mL/g, respectively, within the optimal conditions (Table 8). Based on the results obtained, the experimental values of turbidity, as well as SVI, were very close to the predicted values. This implies that the RSM method was very efficient in optimizing the coagulation-flocculation technique (Wang et al., 2007).

CONCLUSIONS

Considering the high volume of wastewater containing a large amount of suspended solids generated from natural stone mining/ processing plants (marble, travertine, granite, etc.), the practical and economical treatment of travertine-processing wastewater to meet water quality objectives for wastewater reclamation and reuse and to protect public health is an important topic. Obtaining treated travertine-processing wastewater with low turbidity and low SVI is the essential objective to be achieved through the flocculation process using an eco-friendly biopolymer derived from chitosan and plants. In this study, the flocculation technique was applied in turbidity removal and sludge settling behaviour of travertine-processing wastewater using a biopolymer as a flocculant. A total of 20 CCD-based experimental runs were generated to optimize the polymer dosage, suspension pH, and mixing time. A desirability function technique was used to obtain equilibrium between the different responses of SVI and turbidity. The optimization study was aimed at minimizing SVI and turbidity, and the results indicated that the optimum values of mixing time, suspension pH, and polymer dosage to achieve the minimum SVI, as well as turbidity, were 276.20 mg/L, 8.60, and 4.20 min, respectively. The optimal SVI and turbidity values obtained were 1.36 mL/g and 2.99 NTU. The RSM approach was found to be efficient in optimizing the flocculation process in validation experiments.

AUTHOR CONTRIBUTIONS

Mr Sabah supervised the investigation; Mrs Tas applied the experiments; Mr Ugwu developed the methodology; Mr Arsoy prepared the tables; Mrs Tas, Mr Ugwu, Mr Sabah and Mr Arsoy discussed the method and the main text.

ORCID

Eyüp Sabah: http://orcid.org/0000-0002-5225-0891

REFERENCES

AHAMAD AL, ISMAIL S and BHATIA S (2005) Optimization of coagulation-flocculation process for palm oil mill effluent using response surface methodology. Environ. Sci. Technol. 39 2828-2834. https://doi.org/10.1021/es0498080 [ Links ]

ALPTEKlN AM (2006) Purification of natural stone wastewaters with flocculation/coagulation method. Master' Thesis, Afyon Kocatepe University (in Turkish). [ Links ]

ANILKUMAR B, CHITTI NB and KAVITHA G (2016) Biosorption of zinc on to gracilariacorticata (red algae) powder and optimization using central composite design. J. Appl. Sci. Eng. Method. 2 (3) 412-425. [ Links ]

APHA (2005) Standard Methods for the Examination of Water and Wastewater. American Public Health Association, American Water Works Association, Water Environment Federation, Washington. [ Links ]

ARAROMI DO, ALADE AO, BELLO MO, BAKARE T, AKINWANDE BA, JAMEEL AT and ADEGBOLA SA (2017) Optimization of oil extraction from pitanga (Eugenia uniflora l) leaves using simplex centroid design (SCD). Sep. Sci. Technol. 52 (8) 341-1349. https://doi.org/10.1080/01496395.2017.1287199 [ Links ]

ARAVIND J, LENIN C, NANCYFLAVIA C, RASHIKA P and SARAVANAN S (2015) Response surface methodology optimization of nickel (II) removal using pigeon pea pod biosorbent. Int. J. Environ. Sci. Technol. 12 105-114. https://doi.org/10.1007/s13762-013-0391-0 [ Links ]

CHOWDHURY ZC (2013) Preparation, characterization and adsorption studies of heavy metals onto activated adsorbent materials derived from agricultural residues. PhD thesis, University of Malaya. [ Links ]

ÇELIK MY and SABAH E (2008) Geological and technical characterization of Iscehisar (Afyon-Turkey) marble deposits and the impact of marble waste on environmental pollution. J. Environ. Manage. 87 (1) 106-116. https://doi.org/10.1016/j.jenvman.2007.01.004 [ Links ]

DAS B (2017) Response Surface Modeling of Copper (II) adsorption from aqueous solution onto neem (Azadirachta indica) bark powder: Central composite design approach. J. Mater. Environ. Sci. 8 (7) 2442-2454. [ Links ]

DESIGN-EXPERT (2018) Design-Expert software. Version 11.0.3, Stat-Ease Inc., Minneapolis. [ Links ]

ERSOY B, TOSUN I, GÜNAY A and DIKMEN S (2009) Turbidity removal from wastewaters of natural stone processing by coagulation/flocculation methods. Clean Soil Air Water 37 (3) 225-232. https://doi.org/10.1002/clen.200800209 [ Links ]

HUPPERTSBERG S, ZAHN D, PAUELSEN F, REEMTSMA T and KNEPPER TP (2020) Making waves: Water-soluble polymers in the aquatic environment: An overlooked class of synthetic polymers? Water Res. 181 115931. https://doi.org/10.1016/j.watres.2020.115931 [ Links ]

IRFAN M, BUTT T, IMTIAZ N, ABBAS N, AHMAD R and SHAFIQUE A (2017) The removal of COD, TSS and colour of black liquor by coagulation-flocculation process at optimized pH, settling and dosing rate. Arab. J. Chem. 10 2307-2318. https://doi.org/10.1016/j.arabjc.2013.08.007 [ Links ]

IVES KJ (1978) Rate theories. In: Ives KJ (ed.) The Scientific Basis of Flocculation. Springer, The Netherlands. [ Links ]

KIM SC (2016) Application of response surface method as an experimental design to optimize coagulation-flocculation process for pre-treating paper wastewater. J. Ind. Eng. Chem. 38 93-102. https://doi.org/10.1016/j.jiec.2016.04.010 [ Links ]

KUMAR R, SINGH R, KUMAR N, BISHNOI K and BISHNOI NR (2009) Response surface methodology approach for optimization of biosorption process for removal of Cr(VI), Ni(II) and Zn(II) ions by immobilized bacterial biomass sp. bacillus brevis. Chem. Eng. J. 146 401-407. https://doi.org/10.1016/jxej.2008.06.020 [ Links ]

LEE CS, ROBINSON J and CHONG MF (2014) A Review on application of flocculants in wastewater treatment. Process. Saf. Environ. 92 (6) 489-508. https://doi.org/10.1016/j.psep.2014.04.010 [ Links ]

LEE KE, MORAD N, TENG TT and POH BT (2012) Development, characterization and the application of hybrid materials in coagulation/flocculation of wastewater: A review. Chem. Eng. J. 203 370-386. https://doi.org/10.1016/j.cej.2012.06.109 [ Links ]

MONDAL M and RAY AK (2020) Removal of As(V) Using low cost adsorbents: Aerocrete and vermiculite modified with iron oxy-hydroxide. Adsorption 26 387-396. https://doi.org/10.1007/s10450-020-00201-y [ Links ]

MUTLUTÜRK M (2017) Natural stone production and water interaction. In: 9th International Marble and Natural Stones Congress and Exhibition of Turkey, Belek-Antalya, Turkey, 13-15 December 2017. 481-488. [ Links ]

NNAJI PC, ANADEBE VC, ONUKWULL OD, OKOYE CC and UDE AJ (2022) Multifactor optimization for treatment of textile wastewater using complex salt-Lufa cylindrical seed extract (CSLCSE) as coagulant: response surface methodology (RSM) and artificial intelligence algorithm (ANN-ANFIS). Chem. Pap. 76 2125-2144. https://doi.org/10.1007/s11696-021-01971-7 [ Links ]

ONEN V, BEYAZYUZ P and YEL E (2018) Removal of turbidity from travertine processing wastewaters by coagulants, flocculants and natural materials. Mine Water Environ. 37 (3) 482-492. https://doi.org/10.1007/s10230-017-0499-4 [ Links ]

RAD HD, ATARI L, BABAEI AA and GOUDARZI G (2014) Analysis of heavy metal contents by using poly aluminum chloride water treatment residuals and their implications for land application. Asian J. Chem. 22 7651-7656. https://doi.org/10.14233/ajchem.2014.17483 [ Links ]

OKOLO BI, NNAJI PC, OKE EO, ADEKUNLE KF, UME CS and ONUKWULI OD (2017) Optimizing bio-coagulants for brewery wastewater treatment using response surface methodology. Niger. J. Technol. 36 (4) 1104-1113. https://doi.org/10.4314/njt.v36i4.16 [ Links ]

ONUKWULI OD, NNAJl PC, MENKITI MC, ANADEBE VC, OKE EO, UDE CN and UDE CJ (2021) Dual-purpose optimization of dye-polluted wastewater decontamination using bio-coagulants from multiple processing techniques via neural intelligence algorithm and response surface methodology. J. Taiwan Inst. Chem. Eng. 125 372-386. https://doi.org/10.1016/j.jtice.2021.06.030 [ Links ]

SABAH E and ACIKSOZ C (2012) Flocculation performance of fine particles in travertine slime suspension. Physicochem. Probl. Miner. Process. 48 (2) 555-566. https://doi.org/10.5277/ppmp120219 [ Links ]

SINGH RP, KARMAKAR GP, RATH SK, KARMAKAR NC, PANDEY SR, TRIPATHY T, PANDA J, KANAN K, JAIN SK and LAN NT (2000) Biodegradable drag-reducing agents and flocculants based on polysaccharides: materials and applications. Polym. Eng. Sci. 40 46-60. https://doi.org/10.1002/pen.11138 [ Links ]

TAÇDEMlR T and KURAMA H (2013) Fine particle removal from natural stone processing effluent by flocculation. Environ. Prog. Sustain. Energ. 32 (2) 317-324. https://doi.org/10.1002/ep.11634 [ Links ]

TSE 5667-10 (2002) Water quality - Sampling - Part 10: Guidance on sampling of waste waters. Turkish Standards Institution (TSE), Ankara [ Links ]

WANG J, CHEN Y, GE X and YU H (2007) Optimization of coagulation-flocculation process for a paper-recycling wastewater treatment using response surface methodology. Colloids Surf. A. 302 204-210. https://doi.org/10.1016/j.colsurfa.2007.02.023 [ Links ]

ZAINUDIN NF, LEE KT, KAMARUDDIN KT, BHATIA S and MOHAMED AR (2005) Study of adsorbent prepared from oil palm ash (OPA) for flue gas desulfurization. Sep. Purif. Technol. 45 50-60. https://doi.org/10.1016/j.seppur.2005.02.008 [ Links ]

Correspondence:

Correspondence:

Eyüp Sabah

Email: esabah@aku.edu.tr

Received: 14 October 2021

Accepted: 14 November 2022