Serviços Personalizados

Artigo

Indicadores

Links relacionados

-

Citado por Google

Citado por Google -

Similares em Google

Similares em Google

Compartilhar

Journal of Contemporary Management

versão On-line ISSN 1815-7440

JCMAN vol.10 no.1 Meyerton 2013

RESEARCH ARTICLES

A perspective on the criteria used by SMEs in Pietermaritzburg to select suppliers

MJ Naude

University of KwaZulu-Natal

ABSTRACT

The purpose of this article is to provide a perspective on (1) the criteria that small and medium enterprises (SMEs) in Pietermaritzburg use to select their suppliers, and (2) the supply challenges they face. The selection of suppliers is an important task of the procurement professional, who is responsible for managing a firm's supply base - a critical role in all sectors of the economy - and thus protecting and defending the cost structure of the SME. This study presents a cross-case analysis of eleven case studies compiled by postgraduate students at the University of KwaZulu-Natal. Purposive sampling was used to select the cases reviewed. The results reveal that the majority of participants have a formal procurement policy in place.

The main criteria used to select suppliers include pricing, quality, on-time delivery and reputation/reliability. Challenges identified by participants include late deliveries and uncertain availability of stock from suppliers. The main limitation of this study is that only eleven SMEs were included. Therefore, the stated supplier selection criteria and procurement challenges faced are not exhaustive. However, insights from this study could assist parties in procurement to focus their attention on supplier-related challenges that may be within their control, and if solved could lead to cost savings, and improved quality and service delivery.

Key phrases: assessment criteria; procurement; procurement challenges; small and medium enterprises (SMEs)

1 INTRODUCTION

Globally, small and medium enterprises (SMEs) form the backbone of the economy (Hugo & Badenhorst-Weiss 2011:284). This same situation applies to South Africa, where the government has placed significant focus on developing the SME sector in order to promote economic growth and create employment.

Resource dependence theory (RDT) confirms that enterprises operate within a network of exchange relationships, and its main focus is on how some enterprises become dependent on other enterprises for survival (Pfeffer & Salancik 1978:3). Every enterprise, whether in the public or private sector, is dependent on materials and services supplied by other enterprises. As no enterprise is self-sufficient, it can be concluded that sound relationships within the supply chain are vital and that suppliers must be carefully selected. The selection of suppliers is an important task of the procurement professional, who is responsible for managing the firm's supply base, which is a critical role in all sectors of the economy.

The objectives of the procurement department are to source goods and services of the right quality from the right supplier at the right price in the right quantity delivered to the right place at the right time using the right supply chain (Hugo & Badenhorst-Weiss 2011:76; Lysons & Farington 2006:6). Of these objectives, the crucial one is selecting the right supplier. By carefully managing suppliers, the procurement professional safeguards the cost structure of an enterprise. In addition, choosing the right supplier has proved to provide a competitive advantage (Agarwal, Sahia, Mishra, Bag & Singh 2011:801). Hugo and Badenhorst-Weiss (2011:77) are of the opinion that the main key performance indicators of supplier assessment are cost, quality, delivery and environmental issues. These criteria are not exhaustive but can also include, among others, time, flexibility, service, financial status and location (Agarwal et al. 2011:801). Therefore the importance of supplier selection is clear and this should be viewed as a crucial strategic activity in the procurement sector. There is potential for it to improve an enterprise's supply chain management practices, which would result in costs savings and improvements in quality and service delivery.

Given this background, the aim of this article is to try to determine the criteria that SMEs in Pietermaritzburg use to select their suppliers, and the supply challenges they face. This article presents a cross-case analysis of case studies compiled by postgraduate students at the University of KwaZulu-Natal. Purposive sampling was used to select the cases reviewed. The findings reveal that seven out of eleven participants have a formal procurement policy in place. The key criteria used to select suppliers include pricing, quality, timeous delivery and reputation/reliability. Supply challenges that have been identified include aspects such as availability of stock from suppliers, incorrect pricing, poor forecasting methods and late deliveries.

The research study is original in that it provides a perspective on the criteria used by SMEs in Pietermaritzburg to select suppliers. The results of this study could assist parties in procurement to focus their attention on supplier-related challenges that may be within their control, and if solved could lead to cost savings, improved quality and service delivery. The study is descriptive and exploratory in nature, and is based on existing literature reviews, press reports and eleven case studies conducted in Pietermaritzburg at various SMEs.

2 LITERATURE REVIEW

This section classifies SMEs according to the National Small Business Act 102 of 2003 (as amended), provides an overview of procurement and outlines the importance of supplier selection criteria.

2.1 SMEs in South Africa

SMEs play a vital role in the economies of many countries and it is therefore appropriate that governments throughout the world focus on the development of the SME sector to promote economic growth. The role of SMEs in South Africa is no exception. Olawale and Garwe (2010:729) report that SMEs contribute 56% of private sector employment and 36% of the gross domestic product of the country.

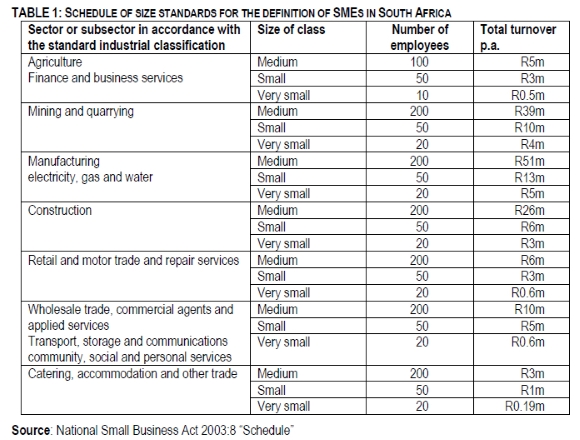

Nieman (2006:4) comments that SMEs in South Africa can be defined in terms of qualitative and quantitative criteria. The qualitative criteria relate to the ownership structure of the enterprise in that it must be a separate and distinct business entity, it cannot be part of a group companies, its subsidiaries and branches must be included when measuring its size and it should be managed by its owners (Hugo & Badenhorst-Weiss 2011:285; Nieman 2006:5; Olawale & Garwe 2010:730). The quantitative definitions of SMEs, according to industry sector or subsector, and in accordance with the Standard Industrial Classification, are presented in Table 1. These definitions are based on the National Small Business Act 26 of 2003.

2.2 Procurement

Business enterprises, whether they are large businesses or SMEs, cannot exist in isolation, as they are located within a network of relationships with individuals, customers and suppliers (Nieman 2006:253). Procurement is widely recognised as an important activity of an enterprise. Some authors observe that this function is regarded as a strategic weapon as it is able to create collaborative relationships and thus meet the challenges of a competitive and dynamic environment (Lawson, Cousins, Handfield & Peterson 2009:2650). In the current business environment the efficiency and effectiveness of an enterprise is strongly determined by procurement. It is estimated that for the majority of enterprises, the cost of purchased goods and services accounts for 50-70% of total costs. According to Gadde, Håkanssan and Persson (2010:6), procurement is strategically significant not only because of these cost factors, but also because of the important relationships with suppliers who represent technical capabilities through their specialised resourcing.

Procurement can be defined as the business function responsible for acquiring the goods and/or services needed by an enterprise. It is the link between an enterprise and its suppliers, and comprises of related activities that organise the flow of goods and services from suppliers into an enterprise (Monczka, Handfield, Giunipero, Patterson & Waters 2010:10; Sanders 2012:153; Van Weele 2010:8). One of the tasks of procurement is the management of the supply base, which includes the identification and selection of suppliers, and measuring supplier performance, in order to ensure that materials and services are procured in the right quality and the right quantity, from the right supplier, delivered at the right place at the right price. In light of the above and because the focus of this article is on supplier selection, the next section deals with supplier selection criteria.

2.3 Supplier selection criteria

The selection of suppliers is an important facet of procurement and supply chain management. The first step in supplier selection is defining the right criteria for potential suppliers. Both qualitative and qualitative approaches may be considered when considering supplier selection and evaluation (Alvandi, Fazli & Memarzade, 2011:19; Zarbini-Sydani, Karbasi & Atef-Yekta 2011:1322).

The impact of global competition has forced suppliers at all levels of the supply chain to improve their services to customers (Simchi-Levi, Kaminsky & Simchi-Levi, 2003:1). The cost of raw materials and components comprises the main cost of a product and a considerable amount of sales revenue is spent on procuring these. There are various supplier selection criteria but the main criteria are cost, quality, delivery and environmental issues (Alvandi et al. 2011:19; Monczka et al. 2010:170; Zarbini-Sydani et al. 2011:1333).

Even though cost, quality and delivery are the main criteria for supplier selection for non-critical and low-value purchases, many successful enterprises base their operational experience on the main objectives of operations management - namely, quality, speed, reliability, flexibility and cost - and these often form the foundation for the selection of suppliers (Hugo & Badenhorst-Weiss 2011:77). The following is a more definitive list of criteria that can be used to select suppliers. They will vary from item to item, from enterprise to enterprise and from industry to industry.

2.3.1 Price/cost competitiveness

One of the primary functions of a procurement officer is to defend the cost structure of the enterprise at the right quality. As indicated in Hugo and Badenhorst-Weiss (2011:77), as suppliers achieve higher productivity levels and reduce their own input costs, they will be in a position to offer lower prices than their competitors. This will lower the input costs of the procuring enterprise and could enable them to reduce their selling prices, thereby achieving a competitive advantage.

2.3.2 Product quality and quality accreditations

A product or service must conform to specifications and must be reliable or durable. Product quality influences the productivity of the enterprise, such as fewer operational interruptions, the quality of the final product, better customer service and ultimately the competitive advantage of an enterprise (Chopra & Meindl 2007:428; Hugo & Badenhorst-Weiss 2011:78; Leenders, Johnson, Flynn & Fearon 2006:263). Many enterprises also require their suppliers to be ISO 9000 / ISO 14001 accredited.

2.3.3 Delivery performance/reliability

On-time delivery is vital in the current business climate as more and more enterprises move towards a demand-pull for manufactured products and services. There is pressure to reduce inventory and suppliers are often required to make smaller deliveries. Late deliveries can have a negative impact on a manufacturing enterprise, the worst-case scenario being that the production line can come to a standstill (Chopra & Meindl 2007:429; Hugo & Badenhorst-Weiss 2011:77).

2.3.4 Service performance

On-time delivery and exchange of goods and service that meet the required specifications of the buyer are critical. Ng (2010:154) notes that in addition to meeting the required specifications, a supplier can satisfy a customer's expectations through delivery at the right place, by providing superior sales support, by dealing with customer complaints timeously, and by providing after-sales service such as maintenance, repair, training and spares. The level of service offered is essential as extensive support can lower operational costs and improve efficiency.

2.3.5 Flexibility

A supplier can be flexible with regard to volume, variety and mix. The business environment is continually changing and suppliers have to be able to adapt quickly with regard to different needs and developing new products (Hugo & Badenhorst-Weiss 2011:78). Chopra and Meindl (2007:429) observe that when dealing with a supplier who is not flexible, order quantities will vary, which will affect the level of buffer stock the SME carries.

2.3.6 Financial status

The financial status of a supplier is important as the financial health of the supplier reduces the risk of uninterrupted supply of a product or service and its ability to meet the requirements of the customer (Hugo & Badenhorst-Weiss 2011:79; Leenders et al. 2006:264).

2.3.7 Engineering and manufacturing technical competence

Areas that need to be considered are whether the supplier's equipment and processes, technological abilities and design capability will be able to meet the required specifications and whether the supplier has the available capacity to meet future demands (Hugo & Badenhorst-Weiss 2011:79). Handfield, Moncza, Guinipero and Patterson (2009:214) concur and further elaborate that the time required to design and develop new products can be reduced by using suppliers that have the relevant skills and capacity.

2.3.8 Broad-based black economic empo wermen t

BBBEE is a core requirement of the South African business environment that enterprises must deal with. The Broad-Based Black Economic Empowerment Act 53 of 2003 was promulgated in January 2004. Prior to 2003, steps taken by government to promote procurement programmes that benefited those who were previously disadvantaged affected only "organs of the state." Since 2004, various business sectors have joined forces and developed their own specific charter - in accordance with the BBBEE Act - that outlines the sector's plans for transformation and the implementation of the BBBEE Act (Hugo & Badenhorst-Weiss 2011:288).

2.3.9 Management capability

Assessing the management capability of a potential supplier is important but is complex. Different aspects of this criterion include the morale of staff, relationships between employer and employee, the responsiveness of the supplier and the overall professional ability and experience of management and staff (Handfield et al. 2009:214; Hugo & Badenhorst-Weiss 2011: 81).

2.3.10 Environmental regulation compliance

Enterprises are becoming more and more aware of the importance of protecting the environment from unnecessary harm. Most countries have laws for controlling environmental contamination, for example air pollution, and for disposing of, reducing and recycling waste.

Procurement officers have to be aware of the level of compliance of the suppliers they purchase from, as they do not want to be associated with businesses that have a record of environmental damage (Monczka et al. 2010:173). For example, the Body Shop, a business renowned for its environmental concerns, include in their packaging specifications a consideration of the need to reduce packaging, to decrease the number of different types of plastics used and to facilitate recycling (Baily, Farmer, Crocker, Jessop & Jones 2008:212).

2.3.11 Geographic location

The distance between the buying and selling enterprises is also a criterion for selection. The location of a supplier can have an impact on the timeous delivery of goods, transportation and logistical costs, flexibility with regard to the frequency of deliveries, and service levels.

There may be sound economic reasons for preferring local suppliers as opposed to more distant ones, particularly in just-in-time production systems, when closeness to the suppliers is vital (Leenders et al. 2006:272; Ng 2010:154).

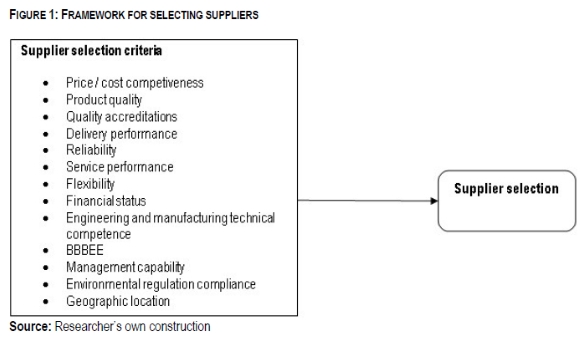

Based on the supplier selection criteria discussed in the literature, the following framework (Figure 1) for selecting suppliers can be developed.

It can be concluded from the literature that although quality, delivery, reliability and cost are common determinants for the selection of suppliers, the list of criteria for selecting suppliers dealt with in this article is not exhaustive and will depend on each particular circumstance, i.e. where the purchase item is located or whether the purchase item is a routine, leverage, bottleneck or critical item.

3 METHODOLOGY

This article presents a case study where 43 postgraduate students at the University of KwaZulu-Natal were engaged in an external group project whereby they had to describe and critically evaluate the supplier selection process of an SME of their choice. Purposive sampling was used to select the cases.

3.1 Problem statement

The purpose of this article is to provide a perspective on what criteria SMEs in Pietermaritzburg use to select their suppliers and to provide a perspective on the challenges they face in their procurement department. Therefore the aim is then to answer the following research questions:

• What criteria do SMEs in Pietermaritzburg use to select their suppliers?

• What supply challenges do SMEs face?

3.2 Research objectives

The objectives of the study derive from the research questions and are as follows:

• To present a perspective on what criteria SMEs use to select their suppliers in Pietermaritzburg.

• To identify supply challenges faced by SMEs.

• To determine the reasons for these challenges.

3.3 Research methodology

The empirical study that forms the basis of this article is descriptive and exploratory. The nature of the problem statement, the purpose of the research study and the proposed methodology pointed the research strategy in the direction of quantitative research. As indicated by Cooper and Schindler (2006:716), "non-quantitative data collection is used to increase understanding of the topic". A cross-case analysis of case studies was adopted, as the focus of this study was on eleven SMEs in Pietermaritzburg. Purposive sampling was used to select the cases reviewed. Purposive sampling is explained in Saunders, Lewis and Thornhill (2009:598) as a non-probability sampling procedure in which the judgment of the researcher is used to select the cases that make up the sample. The SMEs included in this study meet the qualitative and quantitative definitions of an SME as prescribed by the National Small Business Act 26 of 2003.

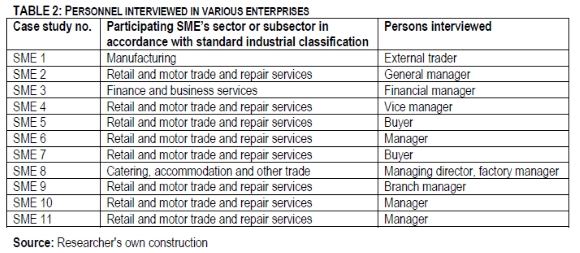

Secondary data was gathered by way of a literature review. Primary research was conducted through informal semi-structured interviews with participants at eleven SMEs in Pietermaritzburg, listed in Table 2. The aim of these interviews was (1) to determine the criteria used by SMEs when selecting suppliers and (2) to identify possible supply challenges that these entities face.

The case studies were conducted by Supply Chain Management students, who are registered for the Postgraduate Diploma in Management. This diploma is an evening programme, which is offered to part-time students at the University of KwaZulu-Natal. The majority of these students are working either in the public or private sector.

This assignment was part of a group project that required students to describe, illustrate and critically evaluate the process used by an SME of their choice to select a supplier. The students were provided with a technical guideline, a permission letter to conduct the research, an informed consent form that participants signed and a semi-structured interview guide. The interview guide consisted of open-ended questions dealing with supplier selection and possible supply challenges facing participants. The main aim of these interviews was to extract qualitative data to ensure that the research questions were answered.

3.4 Data analysis

Each interview was transcribed in a report format, after which it became possible to review, compare and combine the findings of each participant. The students were required to submit all raw data with their completed project. The transcripts were checked for accuracy and correctness by comparing them in some cases to digital recordings. Only the case studies where accuracy and reliability could be determined were included in this study. Out of a sample of 22 cases, only eleven were included.

4 ANALYSIS AND DISCUSSION OF THE FINDINGS

A total of eleven case studies of SMEs were reviewed. The findings revealed that seven of the participating SMEs had a procurement policy in place. The participating SMEs indicated that they mostly purchased from domestic suppliers, and only purchased from international suppliers when necessary.

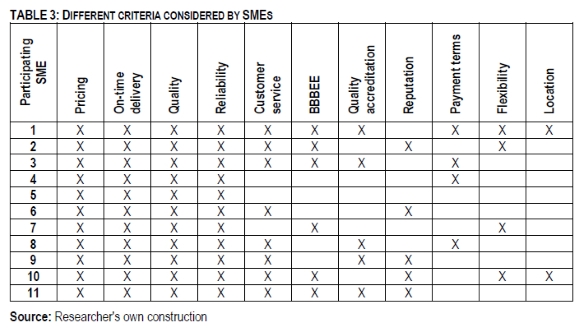

Table 3 lists the criteria identified from the empirical study which the participants consider the basic and important ones for the selection of suppliers for core products - critical or leverage items.

4.1 Different criteria considered by SMEs

Procuring from the 'right supplier' can lead to a decrease in costs, an increase in profit, an improvement in quality and a guarantee of on-time delivery. One way of finding the 'right supplier' is by choosing the 'right' selection criteria. The findings reveal that this research supports 7 of the 13 criteria considered when selecting suppliers, identified from the literature study and listed in Figure 1.

The results confirm that the main criteria for supplier selection by all eleven participating SMEs are pricing, quality, on-time delivery and reliability. From the literature reviewed, the main criteria identified by Alvandi et al. (2011:19), Monczka et al. (2010:170) and Zarbini-Sydani et al. (2011:1333) for supplier selection are cost, quality, flexibility, reliability and environmental issues; therefore, it can be concluded that the findings support the literature review.

However, it is clear from Table 3 that none of the participants included environmental issues as one of the supplier selection criteria. This criterion for supplier selection listed in the literature review is for all enterprises and not specifically for SMEs. Therefore, it could be explained that as eight out of the eleven participating SMEs operate in the retail sector and purchase goods for reselling to consumers, they may not be as aware of the impact of products and processes on the environment as large manufacturing firms. The results confirm the following additional criteria for supplier selection.

4.1.1 Customer service

Eight out of eleven participating SMEs included customer service as one of the criteria for supplier selection. These SMEs indicated that the after-sales services and timely service support provided by suppliers is important. The after sales service of suppliers is carefully monitored through reports containing the time taken to repair defective goods or money refunded for damaged goods.

4.1.2 BBBEE

Six of the SMEs supported the BBBEE initiative. One participant indicated that his employers intended to tidy up their supply database by refining the selection of the suppliers according to BBBEE criteria and making inactive those that were not suitable. Another remarked that his employers were committed to having a supply base that closely reflects its diversity of customers and employees.

4.1.3 Quality accreditation

Five SMEs required their suppliers to be officially quality accredited. The accreditations ranged from SABS approval to food and safety accreditation. In the case of small suppliers who do not have the relevant accreditation, some of the participating SMEs were able to conduct their own evaluation and audit, thereby saving the supplier the cost and stress of trying to obtain official accreditation.

4.1.4 Flexibility

Four participating SMEs expected their suppliers to be flexible with regard to varying the volume, variety and mix required, and to being able to deliver at different times.

4.1.5 Location

Two of the participating SMEs indicated that local suppliers are preferred, as sourcing goods and services locally results in lower transport costs, reduced delivery times and improved communication. It was also found that direct delivery to retail stores is preferable as this avoids unnecessary warehousing costs. The following two criteria identified are not listed in the literature review. These are the reputation of a supplier and the payment terms that are offered by the supplier.

4.1.6 Reputation of a supplier

Five out of eleven participating SMEs indicated that the reputation of a supplier should be examined to determine (1) whether the supplier conducts business honestly and fairly, and (2) whether the supplier can be depended on to deliver goods on time. One participant believed that "a good reputation ensures a buyer's trust".

4.1.7 Paymen t terms

Four participating SMEs indicated that reasonable payment terms from suppliers are important, as SMEs do not have the available capital and overdraft facilities that larger manufacturing enterprises do.

4.2 Supply challenges

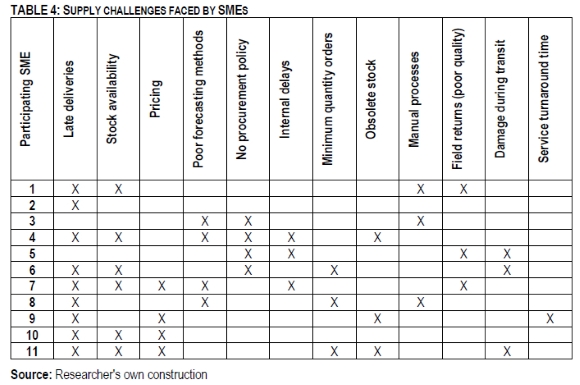

The interview guide included a section dealing with supply challenges. The reasons for including this section were to determine what some of the supply challenges that face SMEs are, and to determine the reasons for such challenges. Table 4 lists the supply challenges that the participants face.

4.2.1 Late deliveries

Nine participants noted that late deliveries are a major problem for them. For economic reasons, the suppliers' policy states that a full truckload should always leave the depot. For example, if a supplier is based in the Gauteng area and an SME has not ordered a full truckload, the supplier will wait until it has filled a truck before dispatching it to deliver the product. This results in the SME not receiving orders on time or holding extra stock in order to prevent "stock outs". Another reason for late deliveries noted by one participating SME is a disturbing number of accidents and truck breakdowns during transit.

4.2.2 Stock availability

Six participants indicated that suppliers sometimes run out of stock, as at times there is only one supplier for a particular product. One participating SME explained that either the price of the product is too high and it is available, or the price of the product is low and it is unavailable. Procuring products at the optimal price in the retail sector is vital, as the SME needs to purchase the product at a reasonably low price in order to make a profit.

4.2.3 Pricing

Four participating SMEs observed that the industry they were in was very competitive and that it was becoming more and more difficult to maintain or grow market share. In the audio/visual and appliance sector, prices of products are constantly dropping. Therefore, if a retailer's pricing is too high, consumers will purchase the appliance elsewhere as low prices increase product appeal. One SME indicated that it did not have the purchase clout of its larger counterparts, who are able to purchase appliances in bulk and receive "kickbacks" by selling their products. This impacted negatively on the SME's sales.

4.2.4 Poor forecasting methods

A key difficulty for four participating SMEs is forecasting the demand for products required. These SMEs rely on historical data in forecasting their requirements, which can result in their being out of stock at certain times and having to place rush orders.

4.2.5 No procurement policy

Four SMEs do not have a formalised, documented procurement policy. The SMEs' participants believed this to be a significant deficiency as procurement professionals are in a position to select suppliers that they may prefer to deal with, rather than the most suitable suppliers.

4.2.6 Internal delays

Three participating SMEs indicated that at times staff members did not communicate requirements on time, resulting in the placing of rush orders. This at times poses a challenge in that goods will be received late.

4.2.7 Minimum quantity orders

Some of the suppliers to SMEs require a minimum order quantity in order for the SME to qualify for a discount. The SME is often in no position to place a larger order due to financial constraints. In order for the SME to increase its profit, it needs to decrease its costs. This poses a challenge for the SME as it is unable to take advantage of bulk discounts.

4.2.8 Obsolete stock

Three SMEs in the retail sector indicated that they face the problem of obsolete and non-selling stock. Technology is continuously changing and new products are being developed continually. Hence, these SMEs sometimes hold stock that is becoming obsolete and is priced higher than the new products that replace the existing products at a lower price. The only way to get rid of non-selling stock is to mark it down well below cost in order to sell it. This has a negative impact on the SMEs' profits.

4.2.9 Manual processes

Three SMEs use manual processes for ordering goods. The total quantities of materials to be ordered are loaded onto Excel and a purchase requisition is generated. It was noted that this is time-consuming and is subject to human error.

4.2.10 Field returns (poor quality)

Three SMEs indicated the challenge of faulty consignments and the rejection thereof. The faulty consignments could be the result of poor communication. The handling of faulty consignments can lead to serious tension and, at worst, even litigation. Faulty consignments are returned to the supplier.

4.2.11 Damage during transit

Three SMEs lamented that at times goods were damaged during transit, resulting in goods being returned to the supplier and the SME facing stock-outs.

4.2.12 Service turnaround time

One SME in the retail industry noted that service turnaround time is compromised when dealing with returns from customers. When faulty goods are returned, a product has to be evaluated and checked first before it is repaired. Repairs have to be completed within a certain period. However, most customers have to wait longer for their products as suppliers delay the process.

5 CONCLUSION

The South African government recognises that economic growth and employment creation can be achieved by developing the SME sector. SMEs are dependent on materials and services supplied by other businesses, namely suppliers. One of the important facets of procurement is the identification and selection of suppliers. Considering the importance of supplier selection, the aim of this article was to provide (1) a perspective on what criteria SMEs in Pietermaritzburg use to select their suppliers, and (2) insight into the supply challenges they face.

The research findings indicate that the main criteria for selecting suppliers by SMEs are: pricing, on-time delivery, quantity and reputation/reliability. The findings reveal that this research supports the main criteria identified in the literature reviewed. The main supply challenges faced by SMEs that have been identified are related to late deliveries and stock availability. These challenges are attributed to accidents and truck breakdowns during transit, and suppliers' only delivering full truckloads for economic reasons - SMEs have to wait until the supplier has a full truckload for delivery.

The main limitation of this study is that only eleven SMEs were included. Therefore the supplier selection criteria identified from the findings are not exhaustive. It was also not part of this study to rank the criteria in the selection of suppliers from the most important to the least important. Neither was it possible to identify all supply-related challenges and the findings can therefore not be generalised.

However, the findings of this study pave the way for further research. From the identified criteria a questionnaire can be designed in order to test these criteria: (1) rank them from most to least important and provide the reason for selecting the criteria; and (2) identify other criteria for supplier selection. This questionnaire could be sent to a larger sample of SMEs in the greater Pietermaritzburg and Durban area.

In conclusion, this article makes a contribution in addressing the dearth of published research on the topic from an SME perspective. Insights from this study could assist parties in procurement to focus their attention on supplier-related challenges that are within their control and, if handled correctly, could improve SMEs' supply chain management practices, which would in turn lead to cost savings and improved quality and service delivery.

REFERENCES

AGARWAL P, SAHIA M, MISHRA V, BAG M & SINGH V. 2011. A review of multi-criteria decision making techniques for supplier evaluation and selection. International Journal of Industrial Engineering Computations, 2(4): 801-810. [ Links ]

ALVANDI M, FAZLI S & MEMARZADE M. 2011. Novel MCDM method for supplier selection in E-SCM. European Journal of Scientific Research, 67(1): 16-44. [ Links ]

BAILY P, FARMER D, CROCKER B, JESSOP D & JONES D. 2008. Procurement principles and management. 10th edition. Harlow, England: Prentice-Hall. [ Links ]

CHOPRA S & MEINDL P. 2007. Supply chain management: strategy, planning and operations. 3rd edition. New Jersey: Pearson Education. [ Links ]

COOPER DR & SCHINDLER PS. 2006. Business research methods. 9th edition. Boston: McGraw-Hill. [ Links ]

GADDE LE, HÀKANSSAN H & PERSSON G. 2010. Supply network strategies. 2nd edition. Wiltshire: Wiley. [ Links ]

HANDFIELD RB, MONCZKA RM, GIUNIPERO LC & PATTERSON JL. 2009. Sourcing and supply chain management. 4th edition. Mason, OH: South-Western, Cengage Learning. [ Links ]

HUGO WMJ & BADENHORST-WEISS JA. 2011. Purchasing and supply management. 6th edition. Pretoria: Van Schaik. [ Links ]

LAWSON B, COUSINS PD, HANDFIELD RB & PETERSON KJ. 2009. Strategic purchasing, supply management practices and buyer performance improvement: an empirical study of UK manufacturing organisations. International Journal of Production Research, 47(10): 2649-2667. [ Links ]

LEENDERS MR, JOHNSON PF, FLYNN AE & FEARON HE. 2006. Purchasing and supply management. 13th edition. Boston: McGraw-Hill. [ Links ]

LYSONS K & FARRINGTON B. 2006. Purchasing and supply chain management. 7th edition. Harlow: Prentice Hall Financial Times. [ Links ]

MONCZKA RM, HANDFIELD RB, GIUNIPERO LC, PATTERSON JL & WATERS D. 2010. Purchasing and supply chain management. Hampshire, UK: South-Western Cengage Learning. [ Links ]

NATIONAL SMALL BUSINESS ACT, 2003. Act No. 26, 2003. Government Gazette No. 25763, 26 November 2003. [Internet: www.info.gov.za/view/DownloadFileAction?id=68002; downloaded on 2012-06-08] [ Links ]

NG E. 2010. Understanding B2B supplier selection relationships: the case of Taiwan agribusinesses. Journal of Business-to-Business Marketing, 17: 149-172. [ Links ]

NIEMAN G. 2006 Small business management: a South African approach. Pretoria: Van Schaik. [ Links ]

OLAWALE F & GARWE D. 2010. Obstacles to the growth of new SMEs in South Africa: A principal component analysis approach. African Journal of Business Management, 4(5): 929-738. [ Links ]

PFEFFER J & SALANCIK GR. 1978. The external control of organizations. New York: Harper & Row. [ Links ]

SANDERS NR. 2012. Supply chain management: a global perspective. New Jersey: Wiley. [ Links ]

SAUNDERS M, LEWIS P & THORNHILL A. 2009. Research methods for business students. 5th edition. Harlow, England: Prentice Hall: [ Links ]

SIMCHI-LEVI D, KAMINSKY P & SIMCHI-LEVI E. 2003. Designing and managing the supply chain: concepts, strategies and case studies. 2nd edition. Boston: Irwin McGraw-Hill. [ Links ]

VAN WEELE AJ. 2010. Purchasing and supply chain management. 5th edition. Sydney: Cengage Learning. [ Links ]

ZARBINI-SYDANI A, KARBASI A & ATEF-YEKTA E. 2011. Evaluating and selecting suppliers in the textile industry using hierarchical fuzzy TOPSIS. Indian Journal of Science and Technology, 4(10): 1322-1334. [ Links ]