Servicios Personalizados

Articulo

Indicadores

Links relacionados

-

Citado por Google

Citado por Google -

Similares en Google

Similares en Google

Compartir

Journal of Energy in Southern Africa

versión On-line ISSN 2413-3051

versión impresa ISSN 1021-447X

J. energy South. Afr. vol.33 no.4 Cape Town dic. 2022

http://dx.doi.org/10.17159/2413-3051/2022/v33i4a13116

ARTICLES

Commercialization of green hydrogen production from kraal manure in the Eastern Cape, South Africa: A review

N. Dyanti*; T. Ncanywa

Faculty of Education, Walter Sisulu University Butterworth, South Africa

ABSTRACT

Renewable Energy Independent Power Producer Procurement launched in 2011 contracts renewable energy producers to supplement the national electricity grid. No preferred bidders produce energy using hydrogen fuel cells, particularly Proton Exchange Membrane Fuel Cell (PEMFC), possibly due to technicalities associated with qualifying hydrogen and fuel cells as renewable. The study explores processes to be followed in South Africa to commercialise green hydrogen production for PEMFC from kraal manure. The paper employed an integrative literature review methodology. There are different stages in product commercialization such as basic research, disclosure of invention and intellectual property protection, feasibility testing, trials and demonstrations, and business development. The discussions indicate a huge amount of hydrogen that can be produced from sheep and cattle kraal manure that is in abundance in the Eastern Cape. Commercialization of hydrogen production can address global economic goals such as waste management, fighting poverty, reducing unemployment, and addressing energy challenges.

Keywords: Renewable energy, PEMFC, green hydrogen, kraal manure, commercialization

Introduction

The high rate of population growth and urbanisation have substantially increased energy demand. Most of the energy consumed is generated from fossil fuels that are depleting and also contribute to environmental issues such as greenhouse gas (GHG) emissions. More than 80% of South African GHG emissions come from the energy sector due to electricity generation from coal (Department of Environment, Agriculture, Forestry and Fisheries (DEAFF), 2019). Therefore, the energy sector is the major driver of reducing GHG emissions for South Africa to meet set targets. As far as this literature survey extends, Eskom, the national electricity producer and supplier in South Africa, does not have in-house measures that effectively reduce GHG emissions (Tyler & Hochstetler, 2021). On the other hand, the South African government started decarbonisation initiatives in 2006/7 by creating climate institutions administered by the DEAFF. The institutions include but are not limited to Inter-Government Climate Change Committee (IGCCC), National Energy Regulator South Africa (NERSA), and Independent Power Producer Office (IPPO) however their effectiveness is heavily affected by politics and the lack of enabling policies in place (Tyler & Hochstetler, 2021). The DEAFF pledged a net-zero carbon emission target by 2050 on its Low Emission Development Strategy (DEAFF, 2019). The strategy has qualitative and quantitative Sectoral Emission Targets (SET) set under the climate change bill that will be reviewed every 5 years. The strategy is still at the research and analysis stage whereby information is collected to guide the SETs (DEAFF, 2019).

In addition to the SET initiative, Renewable Energy Independent Power Producer Procurement (REIPPP) launched in 2011 contracts renewable energy producers to supplement the national electricity grid (DEAFF, 2019). The producers are scored on cost, contribution to economic transformation through local content used job creation, ownership of shares by black South Africans, and other benefits for local communities (Tyler & Hochstetler, 2021). However, there are very few black South African-owned renewable energy producers, hence the REIPPP contribution to the net-zero carbon emission target is insignificant. This observation may be attributed to several factors such as lack of capital, technical skills, and business acumen (Uhunamure & Shale, 2021). The country is supposedly transitioning from a resource-based to a knowledge-based economy despite the evident shortage of skills and no clear roadmap to achieve such. For instance, South Africa is growing its research, development and innovation contribution whereby new products and services that are essential in decarbonisation are founded on paper (Maestro et al., 2021). The discoveries remain on paper due to lack of commercialisation, a key skill in economic development that is overlooked particularly by institutions of higher learning and skilled labourers that are at a better standing of discovering methods/systems that efficiently reduce greenhouse gas emissions (Gachie et al., 2017). It is worth mentioning that the unclear relationship between institutions of higher learning, industry and funders also inhibits the commercialisation of research products and innovations (Hart et al., 2021). Nonetheless, the REIPPP project has identified 25 energy producers that add 2583 MW of renewable energy to the national grid on Bid Window 5 which was finalized in 2021 (ESI Africa, 2021). The preferred bidders are 49.2% South African with 34.7% being black-owned and 2 out of the 25 from Eastern Cape who produce energy from wind and solar. No preferred bidders produce energy using hydrogen fuel cells, particularly Proton Exchange Membrane Fuel Cell (PEMFC), possibly due to technicalities associated with qualifying hydrogen and fuel cells as renewable. Hence, it is imperative to explore what can be done in South Africa to commercialise green hydrogen production from renewable resources for PEMFC. One of the renewable resources that are locally available in the Eastern Cape is kraal manure found in cattle and sheep farming (Waldner et al., 2017).

PEMFC shown in Error! Reference source not found, converts chemical energy from a catalyst-facilitated reaction of hydrogen and oxygen into electrical energy (Bose et al., 2011). Catalysts used in PEMFC are predominantly platinum group metals, more than 70% of the worlds platinum comes from South Africa. Hydrogen is the most abundant element on earth, but it is highly reactive so rarely found in its elemental form as H2, very light meaning it requires large spaces to store minimum quantities, and highly flammable making it dangerous to store and transport. The catalyst layer requires pure hydrogen as it is prone to poisoning by gases such as carbon monoxide/dioxide (CO/CO2) or sulphur (S) commonly found in hydrogen gases. Oxygen can be supplied to the PEMFC as pure O2 or as air from the environment in self-breathing cells (Bose et al., 2011). There are two simultaneous chemical reactions taking place in PEMFC, as shown in Error! Reference source not found., one at the anode catalyst where hydrogen (H2) is oxidized into hydrogen proton (H+) to release electrons (e") and the other at the cathode side where the oxygen (O2) is reduced by the electron from hydrogen into oxide ion (02") (Bose et al., 2011, Xiong et al., 2021). The flow of electrons from the anode to the cathode is resulting in electrical energy while the reaction between the oxide ion and the hydrogen proton from water (H2O). The overall reaction is exothermic, therefore releases heat (Xiong et al., 2021).

As illustrated in Error! Reference source not found., PEMFC only emits deoxygenated air, heat, and water vapour as a by-product with zero greenhouse gas emissions. Additional advantages of PEMFC are that it continues to generate electricity for as long as there is hydrogen supply, requires short recharging time for mobile applications, and operates silently with no moving parts (Larminie & Dicks, 2003). The compatibility of the PEMFC allows customization of power output according to the application, ranging from portable charging power banks to powering teaching equipment in classrooms, household appliances, leisure vehicles (boats and golf carts) and automobiles. The by-products can be useful depending on the system powered by the PEMFC. For instance, heat from PEMFC in boats is used to warm water, water collected for other uses and deoxygenated air to retard fire on jet fuel (Renouard-Vallet et al, 2010). Contrary to wind and solar energy, the capability of PEMFC to generate electricity is neither dependent on weather nor location. Incorporation of the PEMFC into the existing technologies will ensure an uninterrupted supply of electricity. PEMFC are widely used in developed countries such as China, the USA, Canada and European countries for mobile (cars, boats, etc.), aeronautic, and stationary (households) applications (Adamson, 2017). Unlike the developed countries, South Africas primary objective is to use PEMFC for stationary applications as in households, clinics, schools, and others, as an alternative and supplementary energy source. Hence, South Africa has a Hydrogen South Africa (HySA) program that facilitates the implementation of hydrogen and fuel cell economy through product development, demonstration, and prototyping (Pollet et al, 2014).

South Africa has more than 75% of the worlds platinum reserve and two-thirds cost of the PEMFC system is attributed to the platinum group metal catalyst. HySA program addresses the lack of speciality skills in PEMFC manufacturing and roll-out. Some of the roll-out projects include a PEMFC-powered generator, scooter, forklift, golf cart, University of the Western Capes nature reserve and a rural village in Gauteng (Fuel Cells Bulletin, 2014; Nice, 2020). In the Eastern Cape, the PEMFC system was initially installed at a rural school in 2015 and recently at a Science Centre (Nice, 2020). All the reported applications are evidence of the feasibility of the PEMFC technology in South Africa. As it stands, there are no hydrogen production sites or refuelling stations in most of South Africa, including the Eastern Cape. Availability and accessibility of hydrogen will strengthen the roll-out of the PEMFC system that alleviates pressure from the conventional energy supply system. With the arising need, there comes the responsibility to produce hydrogen from renewable and sustainable sources to fully qualify the PEMFC technology as environmentally friendly. Hence, the need to explore processes to commercialize green hydrogen production in South Africa. The paper explores the commercialisation of green hydrogen production by employing an integrative literature review methodology. The methodology is advantageous because of its strength in showing a conceptual paper to inform social policy (rngreen & Levinsen, 2017; Snyder, 2019). The integrative review methodology is useful when knowledge base and critical review are applied. This methodology contains elements of re-conceptualisation and expansion of theoretical foundation and is relevant for contextualisation modelling of hydrogen gas from kraal manure (Snyder, 2019).

Conceptual framework

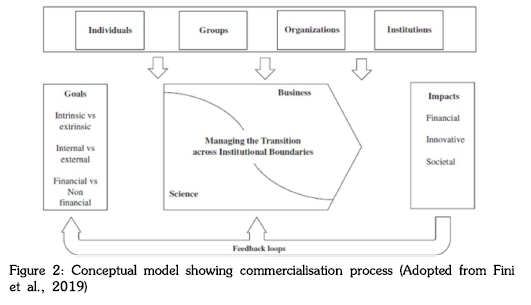

The concept of commercialization of work from research is documented in literature as a complex and multi-stakeholder process (Fini et al., 2019; Hess & Rothaermel, 2011). The theoretical aspects of commercialisation are more driven by empirical studies that show concepts and stages of the commercialisation process, as illustrated in Figure 2. Therefore, the commercialisation of scientific research is relevant to development, especially in the context where Universities need to respond to social needs. The different stakeholders namely, individuals, groups, organization and institutions shown in Figure 2 set goals to form businesses. In the commercialisation process, the stakeholders should manage institutional boundaries encountered during transitions from scientific findings to business ventures across (Fin et al, 2019). There is a desired need for commercialisation from research outputs in South African universities. Theories in this regard include knowledge of activities of commercialisation, the collaboration between industry and universities, and the process of entrepreneurship in academia (Fin et al, 2019; Spinuzzi, 2015). Commercialising the production of hydrogen from kraal manure can drive innovation, and the key is knowledge of this research to develop businesses that have a unique competitive advantage (Figure 2). Commercialising hydrogen production can create jobs and improve knowledge and values in the societies where the businesses are active/located (Spinuzzi, 2015).

Stages of commercialization

The paper reviews the stages of commercialization such as basic research, disclosure of invention and intellectual property (IP) protection, prototype development and feasibility testing, trials and demonstrations, and business development (Gross et al., 2018, Lucchese et al., 2019). The basic research stage entails testing hypotheses, research market needs, and commercialization possibilities. The following stage is whereby a researcher discloses an invention for IP protection assessment whether it is a patent, trade secret, or copyright. Depending on the positive outcome of IP assessment, the invention is tested for feasibility by redesigning, conducting product development testing and collecting market research data. The improved product/service is then produced on a small scale for trials, market samples, and demonstrators for customer feedback on quality and satisfaction. The last stage of commercialization is business development which entails compiling a business plan for the new spin-off company or existing business (Perkins & Love, 2010).

Basic research

In this study, commercialisation is contextualised from the point where academic knowledge from academic research is transferred to businesses that benefits society (Perkmann et al, 2012). The concept of commercialising energy sources came from taking the product into markets and linking companies that produce fuel cells with companies that generate hydrogen through the kraal manure collection (Xiong et al., 2020). Xiong et al., 2020 alluded that there should be a practical process of taking knowledge into solving real community problems. Also, as Universities are transforming to be entrepreneurial and innovative, there is a need to have research on the concept of commercialization of products and services produced by universities, and the need to understand the process and expected outcomes (Perkmann et al., 2012).

The basic research stage starts with identifying a problem or gap that could potentially be addressed through a dedicated investigation of relevant mediation strategies (Kishuk et al., 2021). The identified problem or gap is formulated into a testable hypothesis or research question that will be answered based on the research finding. The market research stage is incorporated into the basic research step whereby the inventor discovers or improves a new product/service in the laboratory using a research funding grant and tests whether the product has a market and/or ability to generate revenue (Farrell et al., 2022). It is at this stage that the invention identifies whether it can solve local or international societal problems and must clearly state its contribution to the economy of the institutions community. In the case of producing green hydrogen from kraal manure, research findings revealed that hydrogen can be extracted from kraal manure and the process will be qualified as green by using renewable energy sources such as wind turbines and capturing the by-product carbon dioxide for further processing to avoid GHG emissions to the environment (Karaeva, 2021; Yilmazel & Duran, 2021). The social impact of the process is mostly job creation for locals who will be collecting and delivering the manure while internationally contributing to reducing GHG.

Disclosure of invention and IP protection

To encourage invention disclosure for IP protection, research output should be recognized and rewarded by remunerating researchers during the commercialization process (Kichuk et al., 2021). Invention disclosure can be concertises by hosting awareness programmes or incorporating entrepreneurship education into mainstream teaching and learning whereby researchers and inventors are exposed to the stages of commercialisation. The awareness campaigns equip researchers with knowledge on handling privacy issues, ownership divisions and disclosure policies so that they engage in the process with confidence (Aziz & Nasir, 2021). In so doing, the level of participation in commercialisation of research improves since the IP process includes some steps in the commercialization ranging from IP audit, incubation of new ideas, reduction of ideas to the practical form, protection of the idea and exploiting the idea (Downie, 2005; Ncube, 2013). The IP protection involves disclosure of inventions, ownership of patents, licensing and registering companies (Delgado et al., 2019). The IP audit stage allows the researcher to keep records. These records state the patent, trademark, copyright, trade secrets and confidential information (Aziz & Nasir, 2021; Ncube, 2013). For instance, the process of converting kraal manure to a high yield of green hydrogen is protected as either patent or trade secret. Patent holders experience barriers when it comes to equity, commercialization knowledge, and protecting their ideas from others who can steal the idea and run with it as their own. Universities need to up the game on implementing policies and overcome strict regulatory processes of commercialization (Aziz & Nasir, 2021). Awareness and clarity on the process is a mutually beneficial strategy for both the researchers and the university as this process can generate socially impactful research that is economical (Delgado et al., 2019).

Feasibility testing

The feasibility stage involves increasing production scale at the laboratory, testing repeatability, reproducibility, and improving the yield of pure hydrogen while minimising production time and use of resources. This stage evaluates and improves the process of getting kraal manure into the processing plant to ensure that it is time and cost-effective (Adamson, 2017). It is at this stage that the inventor selects the most efficient hydrogen production methods based on the quality of manure collected and available sustainable reagents and chemicals (Pollet et al, 2014). Therefore, the feasibility testing stage is discussed under the following sections: Process of hydrogen production and Hydrogen from kraal manure.

Process of hydrogen production

Hydrogen can be produced from various methods that are categorised based on the cleanliness of the process in terms of GHG emissions and handling. Grey/brown hydrogen produced from fossil fuels emits most GHG, although it is widely used to produce more than 90% of the worlds hydrogen due to its cost competitiveness (The International Energy Agency, 2019). Blue hydrogen incorporates carbon capture and storage in fossil fuels-based production to minimise GHG emissions to the environment. Green hydrogen is produced from renewable sources using renewable energy with zero GHG emissions. Green hydrogen is the most suitable to curb environmental impact compared to blue hydrogen; however, it is not yet cost-effective (Dawood et al., 2020). There are requirements such as the source of raw materials/feedstock, energy supply, point of use, and handling of by-products that must be met for the produced hydrogen to qualify as green. On the other hand, there is no standard definition of what green hydrogen is and it seems to be geographically dependent (Abad et al., 2020). According to the review conducted by Abad et al. (2020), green hydrogen is hydrogen produced from renewable sources with transparency on the production process used, air pollution, low emission GHG intensity factors, point of use and energy security (Abad et al, 2020; Dawood et al., 2020). A common aspect of green hydrogen is that the source must be renewable, which consequently informs the choice of the following production methods as qualified: Electrolysis of water using renewable energy like wind or solar, steam reforming of biomethane, pyro-reforming of glycerine; and by-product of biodiesel production.

Despite the above methods, Dawood et al., 2020 argued that existing hydrogen production pathways cannot be verified for cleanliness due to a lack of universal benchmarking standards. PEMFC requires 99.99% pure hydrogen to prevent catalyst layer poisoning by gases such as carbon monoxides or sulfides. Pure hydrogen can only be achieved from water electrolysis (Bareiss et al., 2019; Kumar & Himabindu, 2019). However, the process is neither renewable nor sustainable, since commonly used energy to power the electrolyser is generated from fossil fuels. The use of renewable energy sources, such as photovoltaic cells to power electrolysers, reduces greenhouse gas emissions by 75%, but at a high cost (Bareiss et al., 2019). The high cost makes the method less attractive and unsustainable. The choice of the production method is a trade-off between available feedstock, environmental implications, quality of hydrogen and the cost. The water electrolysis method uses water as feedstock. Water scarcity is another threat to humankind globally, hence Clean Water and Sanitation is one of the United Nations Sustainable Development Goals (United Nations, 2015). Therefore, water electrolysis cannot be classified as sustainable even though it is a green source of hydrogen.

Additionally, hydrogen produced from waste (food, wood, agricultural) and manure using renewable energy is also classified as green. The processes of producing hydrogen from waste are essential as the Waste to Energy initiative addresses two global issues of waste management and energy scarcity (Khan, 2020). Different methods used to produce hydrogen from waste are photosynthesis, wet sludge pyrolysis, dark fermentation, or anaerobic digestion to optimise yield and a multigenerational plant system that gasifies waste before subjecting it to Brayton and Stirling cycles (Han et al, 2015; Luo et al., 2016; Materazzi et al., 2019).

Photosynthesis and wet sludge pyrolysis are not energy friendly due to the required lighting. Brayton and Stirlings cycles applied in multigenerational plant system are thermodynamic cycles that use hydraulics, internal combustion chambers and heat exchangers (Maretazzi et al., 2019; Toro et al., 2017). The cycles require intense knowledge of the system, reactor design and special engineering, thereby making it difficult to implement, especially in developing countries with a limited highly skilled workforce. The low caloric value, high moisture content and organic components in waste require a pre-treatment stage (gasification), hence the need to have a multigenerational plant.

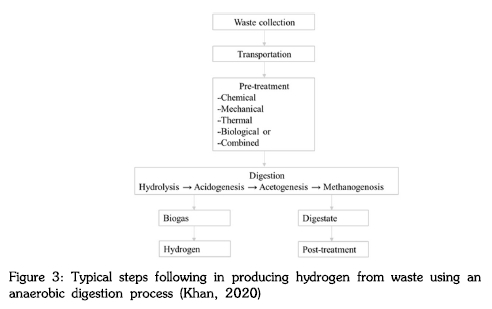

Anaerobic digestion is the process where biomass is broken down by microorganisms in the absence of oxygen (Khan, 2020). Biomass is an organic matter which includes agricultural crop residues, forest residues, crops specifically grown for energy use (switchgrass), municipal solid waste (wastewater treatment plants biosolids) and animal wastes (kraal manure). Anaerobic digestion is similar to dark fermentation in the sense that oxygen is omitted in the former while light in the latter. Waste and manure have high moisture content and organic components making them unsuitable for self-combustion (Khan, 2020). Studies further revealed that pre-treating waste and manure using thermochemical process or removing toxic heavy metals like lead (Pb) can increase the yield and selectivity of hydrogen (Bala et al., 2019; Rafieenia et al., 2017; Sharma et al., 2018). Khan et al., eloquently demonstrated the step commonly followed for anaerobic digestion in Figure 3 where hydrogen production from manure would include a collection of manure from kraals and farms, transportation, pre-treatment, digestion to extract biogas that is further treated to separate hydrogen and formation of digestate as a by-product (Khan, 2020). The pre-treatment stage shown in Figure 3 uses either mechanical, chemical, biological, thermal, or combined approach. As alluded to above, the combination of thermal and biological is a preferred approach. The treated manure sludge is digested through hydrolysis, acidogenesis, acetogenesis and methanogenesis (Khan, 2020).

Dark fermentation is a biological method of producing hydrogen by treating biomass with heterogenous microorganisms in the absence of light (Han et al., 2015). Dark fermentation occurs at four different temperature ranges, namely mesophilic (25-40 C), thermophilic (40-65 C), extremely thermophilic (6580 C) or hyperthermophilic (80 C) conditions. Advantages of the higher temperature of hyperthermophilic conditions are yielding higher hydrogen production compared to mesophilic, increased hydrolysis rate, stabilize waste, lowering the risk of contamination by hydrogen consuming methanogens, stabilising reactor operations by increasing tolerance to high hydrogen partial pressure (Han et al., 2015; Pawar & van Niel, 2013). Caldicellulosiruptor becii (C becii) is the widely used thermophile due to its ability to degrade non-pretreated plant biomass and to simultaneously metabolize multiple sugars (Yilmazel & Duran, 2021). One of the limitations of dark fermentation is the sourcing of mixed culture microorganisms that must be grown and stored in specific conditions (Han et al., 2015). The cost of plant growth and transportation makes use of plant biomass unfavourable for hydrogen production while manure is an inexpensive readily available renewable source.

Hydrogen from kraal manure

Kraal manure is a by-product of cattle feeding that is high in nitrogen and phosphorus. Nitrogen and phosphorus from kraal manure pollute water bodies while methane emissions pollute the air and cause foul odour (Yimazel & Duran 2021). Processing of kraal manure to produce hydrogen addresses environmental issues while recovering valuable gas that has numerous uses. In addition to the extraction of gases, the potassium and phosphorus by-products can be extracted and used in producing fertilizers (Hussain et al., 2021). The by-products can be commercialized by selling them to companies that manufacture fertilizers.

Several studies have been conducted to study and optimize the extraction of hydrogen from manure (Karaeva, 2021; Karlsson et al., 2008; Xin et al., 2018; Yilmazel & Duran, 2021). The studies prove that hydrogen production from kraal manure is viable. As far as this literature survey extends, there are no commercial hydrogen production facilities in the Eastern Cape, South Africa (Ayodele et al., 2021). Particularly, from kraal manure despite the large farming of cattle and sheep in the province as depicted in Figure 4 (Waldner et al., 2017). Figure 4 indicates presence of sheep (yellow colour) and cattle (pink colour) farming in the Eastern Cape Province, which in turn shows availability of sizeable amount of kraal manure. Table 1 seeks to contextualise hydrogen production from kraal manure with data on hydrogen yield based on manure extracted from Yilmazel and Duran for the study conducted in Turkey (Yilmazel & Duran, 2020). This study is aware of geographical and socioeconomic differences between Tukey and South Africa, their implications on the end results are part of the feasibility stage and all the associated costs incurred are documented in the business plan which falls under the business development stage. The results in Table 1 assumed that the wet manure has 15% total solids and that hydrogen will be produced using dark fermentation.

The Turkey case study presented in Table 1 can be used as a baseline in establishing hydrogen production in the Eastern Cape, particularly on quantifying the number of cattle in the province and optimizing the dark fermentation process to improve yield or incorporate the mixed cultures in anaerobic digestion. The conversion efficiency of hydrogen into electrical energy ranges between 50 and 70% (Handwerker et al., 2021). The energy density of hydrogen is 3.33 kWh of usable energy per kilogram and that equates to 0.8 Nm3 of hydrogen required to produce 1 kWh (Handwerker et al., 2021; Air Liquide, 2022). Therefore, the 76 million m3 of hydrogen contained in Table 1 can produce more than 60 million kWh in a year under ideal conditions. In the case of South Africa and its geographical landscape, the production can be optimised by having multiple processing plants closer to the wind turbine energy source and the kraal manure collection points. The reproducibility tests carried out during the feasibility stage will ensure process duplication at the various plants.

Trials, market samples and demonstrations

The trial stage includes prototype development for deployment to target clients in the form of trials, market samples and demonstrations. This stage aims to strengthen market formation whereby clients get to learn about the new product, provide feedback on the value of the new product compared to existing ones and establish a niche market (Gross et al., 2018). The feedback obtained during this stage is essential for testing whether there is a need for re-designing or improving the product and an opportunity for consumers to resolve their uncertainties about the product. The positive reception of the product by consumer facilitates early commercialisation to a wider market (Gross et al., 2018).

Green hydrogen would be more appealing to environmentally conscious consumers as the price might be steep at the beginning of the commercialisation (Bala et al, 2019). The target niche market is government through policymakers and municipalities. The policymakers can devise policies on incentives for users of green hydrogen while municipalities have a responsibility to supply uninterrupted electricity to the public (DEAFF, 2019). The demonstration of green hydrogen showcases the conversion of kraal manure into hydrogen using portable solar panels, lighting as an artificial sun for indoor exhibitions, the pure hydrogen fed into the fuel cell, and power output as an indicator of the hydrogen purity since the presence of impurities will damage the fuel cell. The production process and application of green hydrogen will be exhibited at events such as Science Expo, Mining Indaba and any other event that might have potential investors, government officials and policymakers.

Business development stage

The business development stage focuses on exploring market knowledge in the business (Burgers et al, 2008; Farrell, 2022). In the market knowledge phase, there is enough information about customer preferences and strategies to attract potential customers. This is the stage where purchasing of the product follows a learning-by-doing strategy (Burgers et al, 2008). In the learning-by-doing strategy, the business can be self-sustained based on customer feedback and attained distribution channels (Gross et al., 2018). It is at this stage that action and participation research can be conducted on customer analysis and marketing strategies.

In the business development stage, lessons are learnt from evaluating company documents such as business plans and minutes of meetings (Virtanen & Pellikka, 2018). Analysis of minutes of meetings can inform businesses on best marketing strategies and SWOT (strengths, weaknesses, opportunities, threats) analysis (Zulkarnain et al, 2018). The business formulates a plan that integrate development with commercialisation by indicating how opportunities are identified. The sustainable business plan shows opportunity identification based on societal problems with solutions that can be transformed into businesses (Burgers et al., 2008; Virtanen & Pellikka, 2018; Camacho et al., 2019). The business plan displays value creation chain and integrates goals, activities and output in the business development process. Additionally, there are time frames, costs and risks involved at the development stage, and these are mentioned in the business plan. For instance, Camacho et al. (2019) stipulated that the time frames cater for the time taken during the production phase to the availability of the product to the market and the processes of producing the good can be lengthy. Based on Sustainable Development Goal number 7 (Affordable and Clean Energy) and efforts to minimise carbon footprints, the process of commercializing hydrogen production should be environmentally friendly and follow energy efficient production process (United Nations, 2015; Wang et al, 2018). However, as the hydrogen production process that feeds the fuel cell technology is new in the energy production space, there are risks involved such as regulatory barriers and financial risk (Baeyens et al, 2020). On the regulation side, there might be market penetration as this market is controlled by different ministries in South Africa like Energy Department, municipalities, DEAFF and others.

The financial risk in the commercialization process is explained by the costs involved. Commercialization of hydrogen production needs to be less costly, fully functional and be reliable to the end-user. As much as the raw material is coming from abundant kraal manure in the Eastern Cape, the process of production needs to reach a stage of maintenance and repair after distribution which is very costly. Furthermore, the product readiness stage involves steps that are repeated; and these must reliable (assessing reliability is costly) and consistent (Baeyens et al., 2020). Furthermore, scaling of hydrogen production can be costly. The solution to these risks has been alluded to by Baeyens et al. (2020) that prioritizing the source of hydrogen production from waste by the government can be key to mitigating the risk. In addition, government policies can open doors and provide finances for these kinds of exercises to the needy. Moreover, it is anticipated that use of manure as feedstock can save a lot of raw material costs as the province is in an abundance of villages and farms with cattle and sheep (see Figure 4). The cost can be contained by devising an effective manure collection strategy that involves community members. A project like the hydrogen production from kraal manure can be successfully spined out at universities for resource support (Campbell, 2005). For instance, universities have laboratories and informed researchers to develop the process of hydrogen production. In addition, it is easier for universities to get facilities and technology within its focused environment, and attract investors, funding and incentive systems in organisations such as National Research Fund, Technology Innovation Agency and others (ESI Africa, 2021). It has been shown in Campbell (2005) that companies funded within universities are more stable and progressive than those that are externally funded. Furthermore, several benefits from the commercialization project of hydrogen production are education transformation that link knowledge produced by universities into markets, influence socio-economic indicators like increased employability, minimising crime, addressing inequality, and environmental factors (Assembly, 2015; Franco-Giraldo & Gentilin, 2021) Many countries including South Africa are challenged with commercialisation of products, especially those that come from postgraduate research (Kim et al., 2020; Thurbon et al., 2021). However, lessons can be learnt from Korea on promoting hydrogen production from environmental factors and a push by policymakers through their development strategies and ambitions on traditional developments (Haslam et al., 2012). The Korean government committed to investing in hydrogen and fuel-cell R&D programs. By 2007, public-private investment exceeded US$110 million p/a (see Haslam et al., 2012). There are legislative plans on energy development and climate change in Korea. By 2005, Korea was just 25 years behind the technology level of Japan and the US.

Conclusions and recommendation

The study aimed to explore processes involved in the commercialization of hydrogen production from kraal manure in the Eastern Cape Province in South Africa. The study is motivated by the lack of green hydrogen for PEMFC despite the roll-out of the technology as an energy supplement. The integrative literature methodology was employed to achieve the set objective. Various green hydrogen production methods were reviewed whereby advantages and disadvantages were highlighted. For instance, water electrolysis produces 99.9% pure hydrogen, but water is a scarce resource while dark fermentation qualifies uses renewable sources (biomass) but required mixed culture microorganisms that are difficult to source and store. Consequently, anaerobic digestion was a favoured method based on its high yields of hydrogen due to the pre-treatment stage. The production of hydrogen from manure employing the anaerobic digestion method includes different stages such as a collection of manure from kraals and farms, transportation, liquidation treatment, digestion to extract biogas that is further treated to separate hydrogen and formation of digestate. The strategy for collecting and transporting kraal manure must be time and cost effective to minimise overheads costs.

This study showed the feasibility of hydrogen production from manure by reporting on several studies that have successfully produced hydrogen and attempted to improve its yield. The feasibility and deployment stages will validate whether the purity of the produced hydrogen meets PEMFC standard of 99.99% pure H2. The cattle and sheep farming, lack of hydrogen production, port availability and fuel cell systems in the Eastern Cape suggest the need to commercialize hydrogen production. Furthermore, the commercialization of hydrogen production might yield jobs from the different stages. The collection of kraal manure might attract labour from general workers who do not have specialized skills. Factories of hydrogen production from different municipalities might offer jobs to skilled chemistry or chemical engineering student recruited from surrounding Higher Education Institutions. Therefore, the commercialization of hydrogen production has a potential to address global economic goals such as fighting poverty, reducing unemployment and addressing energy and waste handling challenges.

References

Abad, A.V. and Dodds, P.E. 2020. Green hydrogen characterisation initiatives: Definitions, standards, guarantees of origin, and challenges. Energy Policy 138, pp.111300. [ Links ]

Adamson K-A. 2017. Fuel cells and hydrogen emerging market Series special report e China 2016-2026. 4th Energy Wave. [ Links ]

Air Liquide. 2022. Fuel Cells, https://energies.airliquide.com/resources-planet-hydrogen/fuel-cell accessed on 08 June 2022. [ Links ]

Assembly, G., 2015. Sustainable development goals. SDGs Transform Our World, 2030. [ Links ]

Ayodele, T.R., Mosetlhe, T.C., Yusuff, A.A. and Ogunjuyigbe, A.S.O. 2021. Off-grid hybrid renewable energy system with hydrogen storage for South African rural community health clinic. International Journal of Hydrogen Energy, 46(38), pp.19871-19885. [ Links ]

Baeyens, J., Zhang, H., Nie, J., Appels, L., Dewil, R., Ansart, R. and Deng, Y. 2020. Reviewing the potential of bio-hydrogen production by fermentation. Renewable and Sustainable Energy Reviews, 131, pp.110023. [ Links ]

Bala R., Gautam V. and Mondai M.K. 2019. Improved biogas yield from the organic fraction of municipal solid waste as a preliminary step for fuel cell technology and hydrogen generation. International Journal of Hydrogen Energy, 44, pp.164-173. [ Links ]

Barei, K., de la Rua, C, M ckl, M. and Harnacher, T. 2019. Life cycle assessment of hydrogen from proton exchange membrane water electrolysis in future energy systems. Applied Energy, 237, pp.862-872. [ Links ]

Bose, S., Kuila, T., Nguyen, T.X.H., Kim, N.H., Lau, K.T. and Lee, J.H. 2011. Polymer membranes for high-temperature proton exchange membrane fuel cell: recent advances and challenges. Progress in Polymer Science, 36(6), pp.813-843. [ Links ]

Burgers, J.H., Van Den Bosch, F.A. and Volberda, H.W., 2008. Why new business development projects fail: coping with the differences of technological versus market knowledge. Long range planning, 41(1), pp.55-73. [ Links ]

Camacho, F., Macedo, A. and Malcata, F. 2019. Potential industrial applications and commercialization of microalgae in the functional food and feed industries: A short review. Marine drugs, 17(6), pp.312. [ Links ]

Campbell, A.F., 2005. The evolving concept of value add in university commercialisation. Journal of Commercial Biotechnology, 11(4), pp.337-345. [ Links ]

Dawood, F., Anda, M. and ShafiuUah, G.M. 2020. Hydrogen production for energy: An overview. International Journal of Hydrogen Energy, 45(7), pp.3847-3869. [ Links ]

Department of Environmental Affairs, Forestry and Fishers (DEAFF), 2019. Unpublished dataset of institutional capacity 20002019. [ Links ]

ESI Africa, 2021. Successful energy projects for bid window 5 announced, https://www.esi-africa.com/southern-africa/successful-energy-projects-for-bid-window-5-announced/. Accessed on 01 January 2022. [ Links ]

Farrell, A., Mapanga, W., Chitha, N., Ashton, J. and Joffe, M., 2022. Characteristics, enablers and barriers affecting entrepreneurial behaviour for academics in low-and middle-income countries: A scoping review. Development Southern Africa, pp.1-15. [ Links ]

Fini, R., Rasmussen, E., Wiklund, J. and Wright, M. 2019. Theories from the lab: How research on science commercialization can contribute to management studies. Journal of Management Studies, 56(5), pp.865-894. [ Links ]

Franco-Giraldo, L. and Gentilin, M., 2021. Factors affecting the commercialisation of new knowledge: a roadmap proposal. International Journal of Business Innovation and Research, 25(1), pp. 19-34. [ Links ]

Fuel Cells Bulletin. SA government, HySA launch a prototype fuel cell generator solution. Fuel Cells Bulletin 2014, 12, pp.5-6. [ Links ]

Fuel cells and hydrogen 2 joint undertaking programme review report. 2018. [ Links ]

Gachie, W. and Govender, D.W., 2017. Commercialization of higher education institutions research within the National System of Innovation. African Journal of Science, Technology, Innovation and Development, 9(4), pp.387-397. [ Links ]

Gross, R., Hanna, R., Gambhir, A., Heptonstall, P. and Speirs, J. 2018. How long does innovation and commercialisation in the energy sectors take? Historical case studies of the timescale from invention to widespread commercialisation in energy supply and end-use technology. Energy Policy, 123, pp.682-699. [ Links ]

Han, W., Ye M., Zhu A.J., Zhao H.T. and Li Y.F. 2015. Batch dark fermentation from enzymatically hydrolyzed food waste for hydrogen production. Bioresource Technology 191, pp.24-29. [ Links ]

Handwerker, M., Wellnitz, J. and Marzbani, H., 2021. Comparison of hydrogen powertrains with the battery powered electric vehicle and investigation of small-scale local hydrogen production using renewable energy. Hydrogen, 2(1), pp.76-100. [ Links ]

Hart, K., An, S., Edwards, A.M., Mahadevan, R., Master, E.R. and Edwards, E.A., 2021. Could open science stimulate industry partnerships in chemical engineering university research?. The Canadian Journal of Chemical Engineering, 99(10), pp.2186-2194. [ Links ]

Hess, A.M. and Rothaermel, F.T. 2011. When are assets complementary? Star scientists, strategic alliances, and innovation in the pharmaceutical industry. Strategic Management Journal, 32(8), pp.895-909. [ Links ]

Hussain, F., Shah, S.Z., Ahmad, H., Abubshait, S.A., Abubshait, H.A., Laref, A., Manikandan, A., Kusuma, H.S. and Iqbal, M. 2021. Microalgae an ecofriendly and sustainable wastewater treatment option: Biomass application in biofuel and bio-fertilizer production. A review. Renewable and Sustainable Energy Reviews, 137, pp.110603. [ Links ]

Karaeva, J.V. 2021. Hydrogen production at centralized utilization of agricultural waste. International Journal of Hydrogen Energy, 46(69), pp.34089-34096. [ Links ]

Karlsson, A., Vallin, L. and Ejlertsson, J. 2008. Effects of temperature, hydraulic retention time and hydrogen extraction rate on hydrogen production from the fermentation of food industry residues and manure. International Journal of Hydrogen Energy, 33(3), pp.953-962. [ Links ]

Khan, I. 2020. Waste to biogas through anaerobic digestion: hydrogen production potential in the developing world-a case of Bangladesh. International Journal of Hydrogen Energy, 45(32), pp. 15951-15962. [ Links ]

Kichuk, Y., Kunchenko-Kharchenko, V., Hrushchynska, N., Zhukova, Y., Yarishe, O., 2021. Intellectual Capital of Institutions of Higher Education in the Knowledge Economy. Journal of Optimization in Industrial Engineering, Special issue, pp.159-166. [ Links ]

Kim, M., Yoon, S.U. and Kim, H.M. 2020. A Study on the Hydrogen Economic Law for the Realization of Hydrogen Society in Korea, 46, pp. 1-30. [ Links ]

Kumar, S.S. and Himabindu, V. 2019. Hydrogen production by PEM water electrolysisA review. Materials Science for Energy Technologies, 2(3), pp.442-454. [ Links ]

Carmine, J, Dicks A. 2003. Fuel Cell Systems Explained. 2nd ed. England: John Wiley & Sons Ltd; [ Links ]

Lototskyy, M.V., Tolj, I., Parsons, A., Smith, F., Sita, C. and Linkov, V. 2016. Performance of electric forklift with low-temperature polymer exchange membrane fuel cell power module and metal hydride hydrogen storage extension tank. Journal of power sources, 316, pp.239-250. [ Links ]

Lucchese, P., Ohira, E. and Leaver, J. 2019. IEA Hydrogen Technology Collaboration Program (TCP) End of Term Report 2015-2020 and Strategic Plan 2020-2025. [ Links ]

Luo, S. and Feng, Y. 2016. The production of hydrogen-rich gas by wet sludge pyrolysis using waste heat from blast-furnace slag. Energy 113, pp.845-851. [ Links ]

Maestre, V.M., Ortiz, A. and Ortiz, I. 2021. Challenges and prospects of renewable hydrogen-based strategies for full decarbonization of stationary power applications. Renewable and Sustainable Energy Reviews, 152, pp.111628. [ Links ]

Materazzi, M., Taylor R. and Cairns-Terry M. 2019. Production of biohydrogen from gasification of waste fuels: pilot plant results and deployment prospects. Waste Management, 94, pp.95-106. [ Links ]

Nice, J.A. 2020. Appropriate renewable energy for education infrastructure in rural South Africa: The Cofimvaba science centre model. Unpublished. [ Links ]

mgreen, R. and Levinsen, K. 2017. Workshops as a Research Methodology. Electronic Journal of E-learning, 15(1), pp.70-81. [ Links ]

Pawar, S.S. and van Niel Ed WJ. 2013. Thermophilic biohydrogen production: how far are we? Appl Microbiol Biotechnol, 97, pp.79998009. [ Links ]

Perkmann, M., Tartari, V., McKelvey, M., Autio, E., Brostr m, A., Deste, P., Fini, R., Geuna, A., Grimaldi, R., Hughes, A. and Krabel, S. 2013. Academic engagement and commercialisation: A review of the literature on university-industry relations. Research Policy, 42(2), pp.423-442. [ Links ]

Perkins, G. and Love, G. 2010. The commercialisation of underground coal gasification. Chemeca 2010: Engineering at the Edge; 26-29 September 2010, Hilton Adelaide, South Australia, pp.399. [ Links ]

Pollet, B.G., Pasupathi, S., Swart, G., Mouton, K., Lototskyy, M., Williams, M., Bujlo, P., Ji, S., Bladergroen, B.J. and Linkov, V. 2014. Hydrogen South Africa (HySA) Systems Competence Centre: Mission, objectives, technological achievements and breakthroughs 5. international journal of hydrogen energy, 39(3577), pp.3596. [ Links ]

Rafieenia, R., Girotto, F., Peng, W., Cossu, R., Pivato, A., Raga, R., et al. 2017. Effect of aerobic pre-treatment on hydrogen and methane production in a two-stage anaerobic digestion process using food waste with different compositions. Waste Management, 59, pp. 194-1999. [ Links ]

Renouard-Vallet, G., Saballus, M., Schmithals, G., Schirmer, J., Kallo, J. and Friedrich, K.A. 2010. Improving the environmental impact of civil aircraft by fuel cell technology: concepts and technological progress. Energy & Environmental Science, 3(10), pp. 1458-1468. [ Links ]

Sharma, P. and Melkania, U. 2018. Impact of heavy metals on hydrogen production from the organic fraction of municipal solid waste using co-culture of Enterobacter aerogenes and E. Coli. Waste Management, 75, pp.89-96. [ Links ]

Snyder, H. 2019. Literature review as a research methodology: An overview and guidelines. Journal of business research, 104, pp.333-339. [ Links ]

Spinuzzi, C, Pogue, G., Nelson, R.S., Thomson, K.S., Lorenzini, F., French, R.A., Burback, S.D. and Momberger, J. 2015, July. How do entrepreneurs hone their pitches? Analyzing how to pitch presentations develop in a technology commercialization competition. In Proceedings of the 33rd annual international conference on the design of communication (pp. 1-11). [ Links ]

The International Energy Agency. The Future of Hydrogen: seizing todays opportunities. 2019. https://www.iea.org/reports/the-future-of-hydrogen [ Links ]

Thurbon, E., Kim, S.Y., Mathews, J.A. and Tan, H. 2021. More Creative Than Destructive? Synthesizing Schumpeterian and Developmental State Perspectives to Explain Mixed Results in Koreas Clean Energy Shift. The Journal of Environment & Development, pp.10704965211013491. [ Links ]

Toro, C. and Lior, N. 2017. Analysis and comparison of solar-heat driven Stirling, Brayton and Rankine cycles for space power generation. Energy, 120, pp.549-564. [ Links ]

Tyler, E. and Hochstetler, K. 2021. Institutionalising decarbonisation in South Africa: navigating climate mitigation and socio-economic transformation. Environmental Politics, 30(supl), pp. 184-205. [ Links ]

Uhunamure, S.E. and Shale, K. 2021. A SWOT Analysis Approach for a Sustainable Transition to Renewable Energy in South Africa. Sustainability, 13(7), pp.3933. [ Links ]

United Nations Organisation. 2015. #Envision2030: 17 goals to transform the world for persons with disabilities, at https://www.un.org/development/desa/disabilities/envision2030.html accessed on 03 January 2022 [ Links ]

U.S. Department of Energy. 2017. State of the states: fuel cells in America. [ Links ]

Virtanen, M. and Pellikka, J., 2018. Integrating the opportunity development and commercialisation process. International Journal of Business and Globalisation, 20(4), pp.479-496. [ Links ]

Waldner F., Hansen M.C., Potapov P.V., L w F., Newby T., Ferreira S, et al. 2017. National-scale cropland mapping based on spectral-temporal features and outdated land cover information. PLoS ONE 12(8), pp.181911. [ Links ]

Wang, J., Wang, H. and Fan, Y. 2018. Techno-economic challenges of fuel cell commercialization. Engineering, 4(3), pp.352-360. [ Links ]

Xin, Y., Wang, D., Li, X.Q., Yuan, Q. and Cao, H. 2018. Influence of moisture content on cattle manure char properties and its potential for hydrogen-rich gas production. Journal of analytical and applied pyrolysis, 130, pp.224-232. [ Links ]

Xiong, K., Wu, W., Wang, S. and Zhang, L. 2021. Modelling, design, materials and fabrication of bipolar plates for proton exchange membrane fuel cell: A review. Applied Energy, 301, pp.117443. [ Links ]

Xiong, S., Ji, J. and Ma, X. 2020. An environmental and economic evaluation of remanufacturing lithium-ion batteries from electric vehicles. Waste Management, 102, pp.579-586. [ Links ]

Yilmazel, Y.D. and Duran, M. 2021. Biohydrogen production from cattle manure and its mixtures with renewable feedstock by hyperthermophilic Caldicellulosiruptor bescii. Journal of Cleaner Production, 292, pp.125969. [ Links ]

Zulkarnain, A., Wahyuningtias, D. and Putranto, T.S., 2018, March. Analysis of IFE, EFE and QSPM matrix on business development strategy. In IOP Conference Series: Earth and Environmental Science (Vol. 126, No. 1, p. 012062). IOP Publishing. [ Links ]

* Corresponding author: Email: nodyantyi@wsu.ac.za