Serviços Personalizados

Artigo

Indicadores

Links relacionados

-

Citado por Google

Citado por Google -

Similares em Google

Similares em Google

Compartilhar

Journal of Energy in Southern Africa

versão On-line ISSN 2413-3051

versão impressa ISSN 1021-447X

J. energy South. Afr. vol.33 no.3 Cape Town Ago. 2022

http://dx.doi.org/10.17159/2413-3051/2022/v33i3a12543

ARTICLES

An overview of the socio-economic impacts of the green hydrogen value chain in Southern Africa

Simeon Shiweda HamukoshiI, *; Neliswa MamaI, *; Panduleni Penipawa ShimandaII; Natangue Heita ShafudahIII

IDepartment of Chemistry, Nelson Mandela University, Port Elizabeth, South Africa

IICentre for Research and Development, and Clara Barton School of Nursing, Welwitchia Health Training Centre, Windhoek, Namibia

IIIDepartment of Physics, Chemistry and Materials Science, Faculty of Agriculture, Engineering and Natural Sciences, University of Namibia, Windhoek, Namibia

ABSTRACT

The green hydrogen economy offers synthetic green energy with significant impacts and is environmentally friendly compared to current fossil-based fuels. Exploration of green hydrogen energy in Southern Africa is still in the initial stages in many low-resourced settings aiming to benefit from sustainable green energy. At this early stage, potential benefits to society are yet to be understood. That is why the socio-economic impact of green hydrogen energy must be explored. This paper reviews the current literatures to describe the potential socio-economic effects in the Southern African Development Community (SADC). The review supports the view that green hydrogen will be beneficial and have great potential to revolutionise agricultural and industrial sectors, with advanced sustainable changes for both production and processing. This paper also examines how sustainable green hydrogen energy production in Southern Africa will provide economic value in the energy export sector around the world and support climate change initiatives. Further, it discusses the impacts of the green hydrogen value addition chain and the creation of green jobs, as well as the need for corresponding investments and policy reforms. It is also noted that the green hydrogen economy can contribute to job losses in fossil fuel-based industries, so that the workforce there may need re-skilling to take up green jobs. Such exchanges may deter efforts towards poverty alleviation and economic growth in SADC.

Keywords: green jobs, SADC, sustainable fuel

1. Introduction

In recent years, there has been much interest in the green hydrogen economy, with green hydrogen as a synthetic fuel and energy carrier. Green hydrogen has a significant role in the future of transport and industrial sectors, as observed in countries with fully established hydrogen infrastructures, such as Japan and Australia (Jensterle et al., 2019). There is much potential to produce green hydrogen in Southern Africa, yet no country there is currently involved in green hydrogen production and usage, to the best of our knowledge. However, attention to the development of infrastructure for green hydrogen in parts of Southern Africa has been observed. Many Southern African countries are endowed with abundant natural resources such as wind, sun, and long coastlines, that would allow them to produce and deliver green hydrogen (Custers and Matthysen, 2009). Many of these renewable energy resources are still not clearly defined statutorily, but are rather inserted in frameworks of competition and regulations within the energy sector, which makes it hard to make hydrogen production a priority (Imasiku et al. , 2021). A high percentage of electricity in Southern Africa is generated in coal-burning plants, which makes the region one of the worst emitters of greenhouse gases in the world (Akinbami, Oke and Bodunrin, 2021). Green hydrogen energy has the potential to meet energy demand in the region, transform the economy through energy exports, and create both direct and indirect green jobs that will improve livelihood and social standards (AbouSeada and Hatem, 2022). However, exploration into establishing a green hydrogen economy in the Southern African Development Community (SADC) is yet to begin. On the positive side, there is a new interest in this area, especially in Namibia and South Africa.

There are several ways to produce green hydrogen, but several authors see it as prudent to generate hydrogen from water electrolysis (Wang, Lu and Zhong, 2021). Currently, when electrolysis is compared to other green hydrogen technology methods, such as photolysis, the commercial stage to scale-up the production of green hydrogen has been curbed by various factors. For example, the semiconductors applied in the typical Honda-Fujishima photolysis set-up, such as Titania, have large bandgaps limited in the UV region (Kang et al., 2019). The normal sunlight has only 5% of UV light and that means using Titania as a photocatalyst would be inefficient to produce large quantity of hydrogen. The research on bandgap engineering to shift the bandgap of various semiconductors with noble metals such as silver has been proposed but is still at initial stage (Barone et al., 2014). In the case of electrolysis, using electricity to split water into hydrogen and oxygen by using renewable energy has been scaled-up for industrial application. The main issue that contributes to the cost of green hydrogen from electrolysis is the cost of renewable energy and the cost of electrolys-ers (IRENA, 2020). Recently, the cost of electrolysis components has been dropping due to advanced materials development. The cost of renewable energy must be a very important factor to consider. Thus, a good wind capacity factor, high sun irradi-ance, and hydro power are favourable to producing green hydrogen more cheaply. For this reason, many developers are interested in Southern Africa as a potential hub of green hydrogen production, because of its renewable energy resource. Additionally, it is important that the water used in the elec-trolyser is desalinated using renewable energy, to make the product green. This whole process has, therefore, advantages over other methods such as steam-methane reforming, which emits carbon dioxide into the atmosphere (Boppella et al., 2021; Burton et al. , 2021). Even though various innovative methods have been proposed to capture carbon emitted from processes such as steam reforming methane and coal burning, the equipment designed for storing the carbon captured (blue hydrogen) has been seen as increase the price of hydrogen (Atilhan et al. , 2021; Navas-Anguita et al. , 2021). Therefore, the preferred method of producing clean, or green hydrogen, considering all aspects, is water electrolysis powered by renewable energy.

Applications for green hydrogen in daily life range from powering large haulage automotive and small to large industrial applications (by utilising fuel cells or hydrogen engines). Additionally, large amounts of the hydrogen produced today is consumed in ammonia plants. Ammonia is an essential fertiliser in agricultural production and a storage medium for hydrogen due to its easy and safe handling (Brightling, 2018).

This paper reviews the current literature to describe the potential socio-economic impact of the hydrogen economy in the SADC. It presents the commonly known methods of producing hydrogen and unpacks the production of green hydrogen and potential storage and utilisation mediums; finally, it offers a summary of potential socio-economic benefits.

2. Production of hydrogen, utilisation, and storage

Hydrogen is still amongst the least produced chemical elements found in an impure state, although production dates back as early as the 18th century (OECD Nuclear Energy Agency., 2010). Hydrogen can be produced through electrolysis, a process that involves passing an electric current through the water to split the hydrogen bond from oxygen bonds (Hilliard, 2016). The electrical energy used to power the electrolysis process is significant, especially in low-middle resourced countries. Producing hydrogen using renewable energy sources (see Figure 1) is preferable, because it is environmentally friendly in terms of carbon emission - and hence referred to as green (Noussan et al., 2021). Hydrogen can also be produced from non-renewable energy sources, such as fossil fuel and natural gas, to give grey and blue hydrogen respectively. These two approaches are not considered environmentally friendly, especially the grey method, which releases carbon dioxide to the atmosphere, whereas carbon dioxide is captured during the blue hydrogen production, which also makes the process more costly (Atilhan et al., 2021; Navas-Anguita et al., 2021).

The production of green hydrogen is expected to prevail in the coming years, with many ongoing and planned projects in mining industries and various technological spaces pointing in this direction (Fúnez Guerra et al. , 2020; Li, Shi and Phoumin, 2021). Hydrogen from renewable power is technically viable today and is quickly approaching economic competitiveness. The rising interest in this supply option is driven by the falling costs of renewable energy and systems integration challenges due to rising shares of variable renewable power supply.

2.1 Water electrolysis

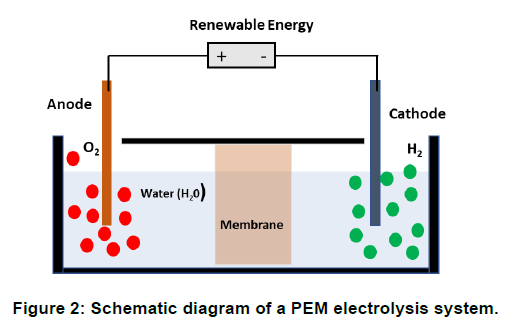

Water splitting represents the low-cost, clean, sustainable, and most efficient method of generating hydrogen and oxygen via the cathodic hydrogen and anodic oxygen evolution reactions (Huang and Wang, 2020; Wang, Lu and Zhong, 2021). It is, however, essential to note that although the electrochemical process represents the critical enabling technology, the high capital cost of electrolysers remain a significant barrier, though significant improvement has been made thus far on the reducing this cost (Bertuccioli et al., 2014). There are three well known types of electrolysis system: alkaline electrolysis; proton exchange membrane (PEM) electrolysis; and solid oxide (SO) electrolysis. Figure 2 illustrates how hydrogen is produced and its subsequent chemical reaction by the PEM electrolysis system. The solid polymer electrolyte that conducts proton ion is sandwiched between two electrodes to construct a membrane electrode assembly. The H2O reacts at the anode to form O2 and positively charged hydrogen ions (protons), as in Equation 1.

The electrons flow through an external circuit and hydrogen ions selectively moves across the PEM to the cathode. At the cathode, hydrogen ions combine with electrons from external circuit to form hydrogen gas, as per Equation 2.

As stated above, the main contributing factor to the high cost of electrolysers is producing the functional components, specifically the electrodes and membranes. Various metals, metal oxides, metal carbides, etc., have been studied and applied in electrochemical water splitting. There is currently intensified research in the fabrication of thin films of these various materials and their subsequent applications in water splitting to lower the cost of the materials (Gaillard et al., 2013; Yu et al., 2019). Apart from saving natural resources, thin films as electrodes could considerably advantage industrial-scale electrochemical water splitting and improved performance under strict industrial conditions. With recent improvement in material development and technology such as nano thin films components, the cost of electrolysers is expected to drop significantly in the next few years.

2.2 Hydrogen fuel cells for mobility and power generation applications

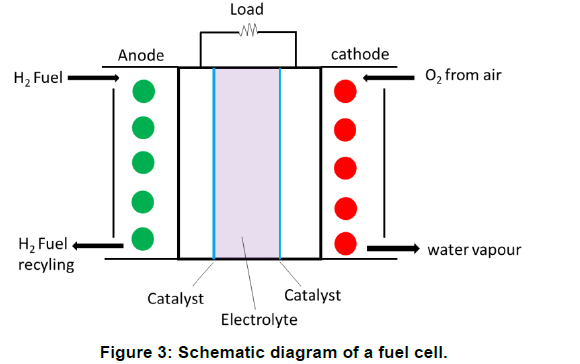

The fuel cell that uses hydrogen as an energy source has emerged as a promising alternative to traditional combustion engines used in automobiles and industrial applications (Samuelsen, 2017). The chemical energy is directly converted to electrical power without a complicated combustion process. The fuel cell operation design is illustrated in Figure 3, where the hydrogen fuel and oxygen enter through the anode and the cathode respectively. The overall reaction produces water instead of the carbon dioxide produced by combustion engines that uses fossil fuels like petrol and diesel (Robertson and Shaffer, 2014). In comparison to fossil fuel, fuel cell technology of-fers an essential solution in the future of hydrogen fuel economy and contributes to decarbonising the world.

The primary components of the fuel cell are an ionic conducting electrolyte, a cathode, and an anode material. We have recently fabricated several functional thin films that could be suitable as components for the fuel cell. For example, a recent paper (Shafudah, Nagai and Sato, 2021) reports on manufacturing a cubic zirconia thin film that could be suitable for a solid electrolyte in solid oxide fuel cells. An advantage of this is that most of the basic materials for the fuel cell can be sourced locally in SADC (e.g., South Africa is known for its abundance of platinum, which is a critical anodic and cathodic material).

2.3 Production of green chemicals/reagents

Hydrogen is an essential reagent in many organic chemical reactions to produce chemicals, reacting with other molecules or substances. These products have important biological, chemical, and industrial applications. It should also be noted that hydrogen occurs as a diatomic molecule in these reactions, presenting it with two hydrogen atoms (H2). This is because hydrogen alone is unstable in a pure state; combined with another hydrogen atom it attains the chemistry octet properties or stability. Hydrogen reacts with compounds such as aldehydes, carboxylic acids, and esters to form alcohols (see Figure 4). Many of the alcohols, such as the aliphatic alcohols, are easily synthesised both biologically and chemically. They can also be used to power internal combustion engines (Smith, 2020). Hydrogen can also be reacted with nitrogen and nitrites to produce ammonia fertilisers and amines. Green hydrogen can be used as a precursor to produce green chemicals and reagents instead of hydrogen coming come from non- renewable energy sources.

SADC is endowed with forestry with invader species, which could provide biomass as feedstock to give sustainable carbon. Green hydrogen is viewed as a precursor for different types of green synthetic fuels and chemical such as power-to-liquid fuels (kerosene, gasoline, diesel, methanol), and power-to-gasoline (methane) or power-to-chemicals (e.g., ammonia). It is important that the input carbon materials should be sourced in a climate-neutral manner and that the resulting products should be used mainly for hard-to-abate sectors of industry and transport, those which cannot easily be de-fossilised by directly using renewable electricity and batteries.

2.4 Production of green steel and green iron

Steel provides crucial materials for the building and construction sector, such as reinforcing steel bars, beams, and pipes. A large part of carbon dioxide emissions comes from steel and iron production (see Figure 5). However, these industries are looking to make these processes more environmentally friendly by establishing new technologies (Kim et al., 2022). The use of hydrogen as the iron ore reducing agent is one of the prominent techniques in direct reduction plants (Heidari et al., 2021). Green hydrogen as a reducing agent in such plants can have great economic and environmental impacts. Southern African countries such as Zambia, Zimbabwe and South Africa are home to iron ore deposits that are often extracted and shipped out for processing (Fessehaie and Rustomjee, 2018). Zambia is looking into sponge iron production through the direct deduction of iron technique (Atilhan et al., 2021; Navas-An-guita et al., 2021). The expected green hydrogen from SADC can then be used as a reducing agent in both direct and indirect iron oxide reduction approaches. Green hydrogen can be used as source of fuel to power furnaces and other machinery for green steel production. These new industries are expected to create green jobs and improve the entire Southern Africa economy through steel exports and other value-added products

Steel can also be produced through the recycling of steel scrap (Oh and Park, 2021). Steel does not lose quality, so steel waste products are recycled repeatedly without loss of property. Scrap as an iron source does not require reducing agents as compared to the previously discussed methods. However, it requires enough energy to melt the scrap steel or sponge iron to be moulded into other types of steel. The heat required for these processes results from arc furnaces powered by energy sources such as coals, fuels, and even hydrogen (Ohnuki et al., 1994). Currently, the production of steel in Southern Africa is through ferrous scraps as raw material (Chansa et al. , 2019; Schoeman, Oberholster and Somerset, 2021).

2.5 Green ammonia as a valuable commodity in the hydrogen industry

A large proportion of the ammonia (NH3) produced is for agricultural fertilisers. It is also produced for applications for purifiying water, refrigerant gas, and manufacturing plastics, pesticides, dyes, and chemicals (Grossel, 2002). Ammonia is generally produced when natural gas, liquefied petroleum gas, or petroleum naphtha put into gaseous hydrogen then reacted with nitrogen to yield either gaseous or liquid ammonia, as indicated in Figure 6. The common method of producing ammonia is the Haber-Bosch process, in which ammonia is obtained under higher temperatures (Kyriakou et al., 2020). Green Hydrogen can be used in the Haber-Bosch processes to produce green ammonia for the previously listed applications. Catalysts such as iron are often employed to speed up the rate of the reaction and the iron as catalytic materials could potentially be sourced or manufactured in SADC.

Ammonia is highly valued as a potential hydrogen storage option as it has a high hydrogen density of about 17.8 wt%. Additionally, ammonia has increased flexibility in its utilisation, including mobile and stationary applications (Ikáheimo et al., 2018).

3. National economic and social impacts

3.1Food security

Agriculture is essential for both economic development and food security and is central to most coun-tries'economies, providing employment and helping with sustaining life and land (Koroma and You, 2016). Agriculture contributes a large part of the GDP of many Southern African countries through goods for profit. The Namibian government has recently constructed the large Neckartal Dam to supply water for agricultural activities in the southern part of the country and beyond (Lillie and Steyn, 2017). There is no doubt as to the government's interest in boosting food production. Other means of improving food security and the country's economy through food production continue to be explored. Modern agriculture is carbon-intensive and relies heavily on fossil fuels. The green hydrogen economy has the potential to increase production and eliminate problems associated with fossil fuel use in food production. There could be great advantages in using green hydrogen for farming equipment such as tractors; it could be an ideal alternative to fossil fuels for many farmers (Kleperis et al., 2021).

3.2Automobile industry

Vehicles that use gasoline as a contribute to GHG production (Manojkumar et al., 2021). Governments and environmental agencies worldwide have been enacting laws to impose high fines and taxes on companies that manufacture cars that release GHG into the atmosphere (Karl and Felix, 2007). Companies such as Tesla have already started manufacturing cars that are powered by electricity from renewable energy sources (Wang, Lu and Zhong, 2021). In addition, major car companies such as Nissan, Toyota and Ford have built prototype vehicles using fuel cells with or without auxiliary batteries and either fuelled by pure (gaseous or liquid) hydrogen (Handwerker, Wellnitz and Marzbani, 2021).

However, the lack of hydrogen infrastructure remains a severe challenge. Even though some manufacturers made commitments to introduce fuel cell vehicles to the market, these vehicles will likely make their debut within fleet operations to minimise fuelling and maintenance issues. That is why the production of green hydrogen in Southern Africa could lead to hydrogen exports to countries who wish to decarbonise as part of the Paris Agreement, a route toward carbon neutrality. Southern African companies and mines can also benefit from the sale and value addition of the materials that may be needed in the green hydrogen industry. For example, the sale of platinum and certain other metals from SADC could be expected to go up due to their utilisation in fuel cells and electrolysis systems.

3.3Environmental impacts

It is well known that soil nutrients are usually removed from the soil by the crops during harvesting. Farmers then apply fertilisers to retain soil fertility, to allow for adequate plant growth. Effective fertilizers are characterised by a high nitrogen content, which is an essential element and a vital source of nutrition for growing plants (Sikora et al., 2020). Ammonia fertilisers have the highest nitrogen content and are therefore the most used and commercially available. Without the addition of fertilisers, yields and agricultural productivity would be significantly reduced. As the world population grows, so does the demand for fertiliser. Fertiliser manufacturing is responsible for about one-third of global GHGs annually (Gilbert, 2012). The production of ammonia in southern Africa may have a significant impact on food security. On the other hand, it is important that the production of green ammonia is environmentally safe and that environmentally friendly methods of producing fertilisers are used.

The GHGs released mainly from the burning of fossil fuels absorb solar energy, which keeps the heat close to the earth's surface rather than the environment with the potential to change the carbon dioxide concentrations, increase temperature, and obliterate precipitation patterns. The burning of hydrogen for heat or in fuel cells results in water vapour as the only by-product of the atmosphere. Even though this by-product is also considered a GHG, it is short-lived, and it is somehow always kept in balance by the hydraulic cycle. Also, excessive amounts of water vapour always return to the ground by precipitation (Beswick, Oliveira and Yan, 2021).

3.4Geopolitical issues

The use of hydrogen to fuel cars poses a serious threat to the gasoline industry, which is predicted to reach its peak in the next 20 years (Norouzi, Fani and Ziarani, 2020). Currently, the petroleum industry generates billions of dollars in revenue, with the United States, Saudi Arabia and Russia dominating the industry (Mitchell, Marcel and Mitchell, 2012).

There are also major oil reserves in the SADC, with Angola the leading producer of crude oil, with reserves of 69.1 million metric tons (UNCTAD, 2012). South Africa holds around 15 million barrels of oil reserves, ranking it 85th in the world (Ash, Pailman and Ilunga, 2022). Namibia has also reported potential offshore crude oil reserves with potential to drill in years to come (Heim, 2020). Recently, there have also been reports of possible oil reserves in the Okavango Delta, in north-eastern Namibia, by a Canadian oil firm (Heim, 2020).

Private companies and states all over the world continue to invest in the exploration and application of crude oil because of the revenue and its role in development and people's livelihoods. This suggests that using green hydrogen to replace crude oil will have major implications for economic, social, and political stability. Therefore, careful assessment is needed by governments interested in green hydrogen production to understand the advantages and disadvantages that would come with the new fuel industry.

3.5 Green hydrogen enabling policy formulation and regulation in SADC

The existing renewable energy policies in SADC countries do not incorporate hydrogen in their framework. Policy reform to accommodate green hydrogen can help to establish sustainable markets for a green hydrogen economy and to enhance de-carbonisation. These may also foster investments by energy suppliers, energy distributors, and users in both private and public sectors. Renewable energy policies in SADC should focus on establishing the role of hydrogen within long-term energy strategies which would allow industries to align their goals with this technology. Supporting research and development should also be included, as this plays a pivotal role for the hydrogen production and supply chain network, given the critical role of production costs in business (Imasiku et al., 2021). In addition, all the unnecessary regulatory conditions that may delay hydrogen energy project developers obtaining licences through unclear requirements and regulations should be eliminated, because of their potential to slow down the transition to hydrogen energy-based economies. Lastly, all policy reform should focus on establishing opportunities to enhance future hydrogen development progress. This can be achieved by building on current policies, infrastructure, and skills, enhanced investor confidence, and lower costs, allowing Southern African countries to transform existing industrial seaports into hubs for lower-cost, and lower-carbon hydrogen and to also use the existing natural gas/coal infrastructure to accommodate green hydrogen energy supplies.

4. Conclusion

This review supports the view that there are enough renewable energy resources to sustain the green hydrogen economy in Southern Africa. Green hydrogen policy formulation and regulation will be an important factor in fostering economic growth through a green economy in SADC. A return on both direct and indirect investments is projected to come through transformation of agricultural and industrial sectors, and value chain additions through producing, processing, and supplying green hydrogen energy. Economic benefits will have a crucial role in improving social welfare and infrastructure in the region. While trade-offs are to be made on how to invest in and explore this economy, the availability of natural resources and renewable solar energy in the region will be significant for cost reduction. However, initial trade-off decisions will not be easy as they could come at an expense of improving current social welfare, especially given that the required electrical power is costly. Possible job losses in fossil fuel sectors can be another adverse outcome of a green hydrogen economy, but this will be compensated for by reskilling of workers in the existing industries and creating new green jobs.

Author contributions

NHS conceptualised the study and then designed it in collaboration with SSH, and PPS. SSH performed the literature review and drafted the paper, and NHS, and PPS contributed actively. NM reviewed the paper and supported the interpretations and presentation of the findings. All authors read and approved the final manuscript.

References

AbouSeada, N. and Hatem, T.M. (2022) Climate action: Prospects of green hydrogen in Africa, Energy Reports, 8, pp. 3873-3890. Available at: https://doi.org/10.1016AJ.EGYR.2022.02.225. [ Links ]

Akinbami, O.M., Oke, S.R. and Bodunrin, M.O. (2021) The state of renewable energy development in South Africa: An overview, Alexandria Engineering Journal, 60(6), pp. 5077-5093. Available at: https://doi.org/10.1016AJ.AEJ.2021.03.065. [ Links ]

Ash, M., Pailman, K. and Ilunga, K. (2022) ICLG - Oil & Gas Laws and Regulations South Africa 2022. Global Legal Group. Available at: https://iclg.com/practice-areas/oil-and-gas-laws-and-regulations/south-africa (Accessed: August 15, 2022). [ Links ]

Atilhan, S. et al. (2021) Green hydrogen as an alternative fuel for the shipping industry, Current Opinion in Chemical Engineering, 31, p. 100668. Available at: https://doi.org/10.1016AJ.COCHE.2020.100668. [ Links ]

Barone, P. et al. (2014) Study of band gap of silver nanoparticles - Titanium dioxide nanocomposites, Journal of Chemistry, 2014. Available at: https://doi.org/10.1155/2014/589707. [ Links ]

Bengal, W. (2017) Alternative synthesis of ammonia, International Journal of Research and Analytical Reviews (IJRAR), 4(1), pp. 725-728. [ Links ]

Bertuccioli, L. et al. (2014) Study on development of water electrolysis in the EU. [ Links ]

Beswick, R.R., Oliveira, A.M. and Yan, Y. (2021) Does the Green Hydrogen Economy Have a Water Problem?, ACS Energy Letters, 6(9), pp. 3167-3169. Available at: https://doi.org/10.1021/ACSENERGYLETT.1C01375/AS-SET/IMAGES/LARGE/NZ1C01375_0001.JPEG. [ Links ]

Boppella, R. et al. (2021) Anion-mediated transition metal electrocatalysts for efficient water electrolysis: Recent advances and future perspectives, Coordination Chemistry Reviews, 427, p. 213552. Available at: https://doi.org/10.1016/J.CCR.2020.213552. [ Links ]

Brightling, J. (2018) Ammonia and the fertiliser industry: The development of ammonia at Billingham, Johnson Mat-they Technology Review, 62(1), pp. 32-47. Available at: https://doi.org/10.1595/205651318X696341. [ Links ]

Burton, N.A. et al. (2021) Increasing the efficiency of hydrogen production from solar powered water electrolysis, Renewable and Sustainable Energy Reviews, 135, p. 110255. Available at: https://doi.org/10.1016/J.RSER.2020.110255. [ Links ]

Chansa, F. et al. (2019) Industrial Growth and Policy in Zambia: Lessons from South Korea, African Journal of Economic Review, 7(2), pp. 1-26. Available at: https://www.ajol.info/index.php/ajer/article/view/188391 (Accessed: August 15, 2022). [ Links ]

Crompton, R. et al. (2020) Petrol price regulation in South Africa: Is it meeting its intended objectives? Helsinki: The United Nations University World Institute for Development Economics Research (UNU-WIDER). Available at: https://doi.org/10.35188/UNU-WIDER/2020/897-9. [ Links ]

Custers, R. and Matthysen, K. (2009) Africa's natural resources in a global context. [ Links ]

Fessehaie, J. and Rustomjee, Z. (2018) Resource-based industrialisation in Southern Africa: Domestic policies, corporate strategies and regional dynamics, Development Southern Africa, 35(3), pp. 404-418. Available at: https://doi.org/10.1080/0376835X.2018.1464901. [ Links ]

Fúnez Guerra, C. et al. (2020) Viability analysis of underground mining machinery using green hydrogen as a fuel, International Journal of Hydrogen Energy, 45(8), pp. 5112-5121. Available at: https://doi.org/10.1016/J.IJHYDENE.2019.07.250. [ Links ]

Gaillard, N. et al. (2013) A nanocomposite photoelectrode made of 2.2 eV band gap copper tungstate (CuWO4) and multi-wall carbon nanotubes for solar-assisted water splitting, International Journal of Hydrogen Energy, 38(8), pp. 3166-3176. Available at: https://doi.org/10.1016/J.IJHYDENE.2012.12.104. [ Links ]

Gilbert, N. (2012) One-third of our greenhouse gas emissions come from agriculture, Nature [Preprint]. Available at: https://doi.org/10.1038/NATURE.2012.11708. [ Links ]

Grossel, S.S. (2002) Hazardous Chemicals Handbook, in Journal of Loss Prevention in the Process Industries. 2nd edn. Oxford: Elsevier, pp. 403-404. Available at: https://doi.org/10.1016/S0950-4230(02)00025-6. [ Links ]

Handwerker, M., Wellnitz, J. and Marzbani, H. (2021) Comparison of Hydrogen Powertrains with the Battery Powered Electric Vehicle and Investigation of Small-Scale Local Hydrogen Production Using Renewable Energy, Hydrogen 2021, Vol. 2, Pages 76-100, 2(1), pp. 76-100. Available at: https://doi.org/10.3390/HYDROGEN2010005. [ Links ]

Heidari, A. et al. (2021) A Review on the Kinetics of Iron Ore Reduction by Hydrogen, Materials, 14(24). Available at: https://doi.org/10.3390/MA14247540. [ Links ]

Heim, M. (2020) Elephant in Namibia: Kavango Basin Research Report. Frankfurt. [ Links ]

Hilliard, S. (2016) Water splitting photoelectrocatalysis: the conception and construction of a photoelectrocatalytic water splitting cell. Université Pierre et Marie Curie. Available at: https://tel.archives-ouvertes.fr/tel-01358735. [ Links ]

Huang, J. and Wang, Y. (2020) Efficient Renewable-to-Hydrogen Conversion via Decoupled Electrochemical Water Splitting, Cell Reports Physical Science, 1(8), p. 100138. Available at: https://doi.org/10.1016/J.XCRP.2020.100138. [ Links ]

Ikãheimo, J. et al. (2018) Power-to-ammonia in future North European 100% renewable power and heat system, International Journal of Hydrogen Energy, 43(36), pp. 17295-17308. Available at: https://doi.org/10.1016AJ.IJHYDENE.2018.06.121. [ Links ]

Imasiku, K. et al. (2021) A Policy Review of Green Hydrogen Economy in Southern Africa, Sustainability 2021, Vol. 13, Page 13240, 13(23), p. 13240. Available at: https://doi.org/10.3390/SU132313240. [ Links ]

IRENA (2020) Green Hydrogen Cost Reduction: Scaling Up Electrolysers to Meet the 1.5°C Climate Goal. Abu Dhabi. Available at: www.irena.org/publications. [ Links ]

Jensterle, M. et al. (2019) The role of clean hydrogen in the future energy systems of Japan and Germany. Berlin. [ Links ]

Kang, X. et al. (2019) Titanium Dioxide: From Engineering to Applications, Catalysts 2019, Vol. 9, Page 191, 9(2), p. 191. Available at: https://doi.org/10.3390/CATAL9020191. [ Links ]

Karl, G. and Felix, K. (2007) The automotive industry and climate change: Framework and dynamics of the CO2 (r)evolution. Stuttgart. [ Links ]

Kim, J. et al. (2022) Decarbonizing the iron and steel industry: A systematic review of sociotechnical systems, technological innovations, and policy options, Energy Research & Social Science, 89, p. 102565. Available at: https://doi.org/10.1016/J.ERSS.2022.102565. [ Links ]

Kleperis, J. et al. (2021) Hydrogen supported bioconversion of biogas CO2 to upgrade biomethane in fuel for vehicles: Recent findings in farmers survey, Engineering for Rural Development, 20, pp. 1774-1780. Available at: https://doi.org/10.22616/ERDEV.2021.20.TF390. [ Links ]

Koroma, S. and You, N. (2016) Namibia's foreign policy and the role of agriculture in poverty eradication. Available at: www.fao.org/publications. [ Links ]

Kyriakou, V. et al. (2020) An Electrochemical Haber-Bosch Process, Joule, 4(1), pp. 142-158. Available at: https://doi.org/10.1016/J.JOULE.2019.10.006. [ Links ]

Li, Y., Shi, X. and Phoumin, H. (2021) A strategic roadmap for large-scale green hydrogen demonstration and commercialisation in China: A review and survey analysis, International Journal of Hydrogen Energy [Preprint]. Available at: https://doi.org/10.1016/j.ijhydene.2021.10.077. [ Links ]

Lillie, E. and Steyn, G. (2017) The design and construction of Neckartal Dam. [ Links ]

Manojkumar, R. et al. (2021) I.C. Engine emission reduction using catalytic converter by replacing the noble catalyst and using copper oxide as the catalyst, Materials Today: Proceedings, 45, pp. 769-773. Available at: https://doi.org/10.1016/J.MATPR.2020.02.804. [ Links ]

Mitchell, J., Marcel, V. and Mitchell, B. (2012) What Next for the Oil and Gas Industry? [ Links ]

Navas-Anguita, Z. et al. (2021) Revisiting the role of steam methane reforming with CO2 capture and storage for longterm hydrogen production, Science of The Total Environment, 771, p. 145432. Available at: https://doi.org/10.1016/J.SCITOTENV.2021.145432. [ Links ]

Norouzi, N., Fani, M. and Ziarani, Z.K. (2020) The fall of oil Age:A scenario planning approach over the last peak oil of human history by 2040, Journal of Petroleum Science and Engineering, 188, p. 106827. Available at: https://doi.org/10.1016/J.PETROL.2019.106827. [ Links ]

Noussan, M. et al. (2021) The role of green and blue hydrogen in the energy transition-a technological and geopolitical perspective, Sustainability (Switzerland), 13(298), pp. 1-26. Available at: https://doi.org/10.3390/su13010298. [ Links ]

OECD Nuclear Energy Agency. (2010) Nuclear production of hydrogen : Fourth Information Exchange Meeting, Oak-brook, Illinois, United States, 13-16 April 2009., p. 464. Available at: https://www.oecd-nea.org/jcms/pl_14468/nu-clear-production-of-hydrogen?details=true (Accessed: August 15, 2022). [ Links ]

Oh, M.K. and Park, J.H. (2021) Effect of Industrial Waste Fluxes (Red Mud and White Mud) on Dephosphorization and Refractory Corrosion: Applications to Electric Arc Furnace Process Using Direct Reduced Iron, Metallurgical and Materials Transactions B: Process Metallurgy and Materials Processing Science, 52(6), pp. 3583-3595. Available at: https://doi.org/10.1007/S11663-021-02313-4. [ Links ]

Ohnuki, K. et al. (1994) Developmemt of Steel Scrapp Melting Process, NIPPON Steel Technical Report, (61), pp. 52-57. [ Links ]

Robertson, A.D. and Shaffer, P.S. (2014) 'Combustion always produces carbon dioxide and water': a discussion of university chemistry students' use of rules in place of principles, Chemistry Education Research and Practice, 15(4), pp. 763-776. Available at: https://doi.org/10.1039/C4RP00089G. [ Links ]

Samuelsen, S. (2017) The automotive future belongs to fuel cells range, adaptability, and refueling time will ultimately put hydrogen fuel cells ahead of batteries, IEEE Spectrum, 54(2), pp. 38-43. Available at: https://doi.org/10.1109/MSPEC.2017.7833504. [ Links ]

Schoeman, Y., Oberholster, P. and Somerset, V. (2021) A decision-support framework for industrial waste management in the iron and steel industry: A case study in Southern Africa, Case Studies in Chemical and Environmental Engineering, 3, p. 100097. Available at: https://doi.org/10.1016/J.CSCEE.2021.100097. [ Links ]

Shafudah, N.H., Nagai, H. and Sato, M. (2021) Selective formation of cubic or tetragonal zirconia thin films of transparent, with no use of metal ion stabilizer by heating molecular precursor films under mild conditions, Functional Materials Letters, 14(2). Available at: https://doi.org/10.1142/S1793604721510127. [ Links ]

Sikora, J. et al. (2020) Assessment of the Efficiency of Nitrogen Slow-Release Fertilizers in Integrated Production of Carrot Depending on Fertilization Strategy, Sustainability 2020, Vol. 12, Page 1982, 12(5), p. 1982. Available at: https://doi.org/10.3390/SU12051982. [ Links ]

Smith, M. (2020) March's advanced organic chemistry: Reactions, Mechanisms, and Structure. 8th edn. Wiley. Available at: https://www.wiley.com/en-us/March%27s+Advanced+Organic+Chemistry%3A+Reactions%2C+Mecha-nisms%2C+and+Structure%2C+8th+Edition-p-9781119371809 (Accessed: August 15, 2022) [ Links ]

UNCTAD (2012) World Investment Report 2012: Towards a New Generation of Investment Policies. [ Links ]

Wang, S., Lu, A. and Zhong, C.J. (2021) Hydrogen production from water electrolysis: role of catalysts, Nano Convergence, 8(4). Available at: https://doi.org/10.1186/s40580-021-00254-x. [ Links ]

Worrell, E., Price, L. and Martin, N. (2001) '"Energy efficiency and carbon dioxide emissions reduction opportunities in the US iron and steel sector, Energy, 26(5), pp. 513-536. Available at: https://doi.org/10.1016/S0360-5442(01)00017-2. [ Links ]

Yu, J. et al. (2019) Recent Advances and Prospective in Ruthenium-Based Materials for Electrochemical Water Splitting, ACS Catalysis, 9(11), pp. 9973-10011. Available at: https://doi.org/10.1021/ACSCATAL.9B02457/AS-SET/IMAGES/MEDIUM/CS9B02457_0023.GIF. [ Links ]

* Corresponding author: Email: s218169809@mandela.ac.za