Servicios Personalizados

Articulo

Indicadores

Links relacionados

-

Citado por Google

Citado por Google -

Similares en Google

Similares en Google

Compartir

Journal of Energy in Southern Africa

versión On-line ISSN 2413-3051

versión impresa ISSN 1021-447X

J. energy South. Afr. vol.33 no.1 Cape Town feb. 2022

http://dx.doi.org/10.17159/2413-3051/2022/v33i1a8362

ARTICLES

https://dx.doi.org/10.17159/2413-3051/2022/v33i1a8362

Integration of waste heat in thermal desalination technologies: A review

Deepti CharitarI,*; Amos MadhlopaII

ICentre for Higher Education Development, University of Cape Town, South Africa

IIPhysics Department, University of Malawi, Malawi (At the time of writing this paper, both authors were affiliated with the Energy Research Centre, University of Cape Town, South Africa)

ABSTRACT

Desalination is increasingly becoming a crucial method for providing fresh water globally. However, most of the desalination technologies are energy-intensive and driven by fossil fuels that are contributing to climate change and other environmental problems. In this vein, renewable energy and energy efficiency are promising pillars of sustainable energy production and consumption, and the recovery of waste heat helps to augment the energy efficiency of a system. Based on the temperature (T) of the heat source, waste heat can be classified into three categories: low temperature (T<100°C), medium temperature (100°C<T<300°Q and high temperature (T>300°C). There is scarcity of review work on the integration of waste heat in desalination technologies. In this study, the progress in the utilisation of waste heat to drive thermal desalination processes has been investigated. It is found that 63% of waste heat streams are of low grade, which is still satisfactory for thermal desalination technologies that run on low-temperature heat sources. As of 2018, there was only one known thermal desalination plant driven by waste heat. Lack of data on waste heat, especially in developing countries, has been identified as a major challenge to the advancement of desalination technologies driven by this source of thermal energy. Other constraints are presented and discussed in this paper.

Keywords: condensation; energy intensiveness; evaporation; thermodynamics

1. Introduction

Anthropogenic activities are contributing to the pollution of freshwater resources, thereby reducing the quantity of available water that meets acceptable standards. Over 1.8 billion people globally use a source of drinking water which is contaminated with faecal matter (World Health Organisation, 2015), and 33 countries will be under extreme water stress by 2040 (World Resources Institute, 2 015). One way of increasing the quantity of drinking water is through desalination - a process in which saline or brackish water is converted into potable water. Desalination is an important method of providing fresh water. Nevertheless, conventional desalination processes are energy-intensive (Kumar et al., 2012; Gude, 2016) and most often the energy is obtained from the combustion of fossil fuels. This results in the emission of greenhouse gases into the atmosphere, thus leading to climate change and other environmental problems. Moreover, energy production from fossil fuels and water consumption are inevitably linked, because water is required for the production of energy and energy, in turn, is needed for the treatment of water (Sparks et al., 2014). Consequently, it is essential to exploit sustainable sources of energy in the desalination process.

Renewable energy and energy efficiency are promising pillars of sustainable energy production and consumption, and the recovery of waste heat helps to increase the energy efficiency of a system. The most commonly used renewable energy sources for desalination are solar, wind and geothermal (Sharon & Reddy, 2015). Significant research has been done on desalination processes driven by renewable energy sources, namely: (i) solar energy (Badran et al., 2005; Abdel-Rehim & Lasheen, 2007; Abdallah & Badran, 2008; Abdallah, Badran & Abu-Khader, 2008; Tanaka, 2009; Khalifa & Ibrahim, 2010; Dwivedi & Tiwari, 2010; Arunkumar et al., 2010; Tanaka, 2011; Singh et al., 2013; Omara, Kabeel & Younes, 2013; Rajaseen-ivasan, Raja & Srithar, 2014; Morad, El-Maghawry & Wasfy, 2015; Chaichan & Kazem, 2015; Matrawy, Alosaimy & Mahrous, 2015; Appadurai & Velmurugan, 2015; Srithar et al., 2016) (ii) wind energy (Kiranoudis, Voros & Maroulis, 1997; Liu et al., 2002; Miranda & Infield, 2003; Koklas & Papathanassiou, 2006; Forstmeier et al., 2007; Dehmas et al., 2011; Cendoya, Toccaceli & Bat-taiotto, 2014) and (iii) geothermal energy (Mohamed & El-Minshawy, 2009; Mahmoudi et al., 2010; Sarbatly & Chiam, 2013; Manenti et al., 2013; Loutatidou & Arafat, 2015; Bundschuh et al., 2015), with many review articles on this subject (García-Rodríguez, 2002; Charcosset, 2009; Eltawil, Zhengming & Yuan 2009; Gude, Nirmalakhandan & Deng, 2010; Shatat, Worall & Riffat, 2013; Li, Goswami & Stefanakos, 2013; Ghaffour et al., 2015; Sharon & Reddy, 2015). It is also clear from literature that exploitation of waste heat in the desalination processes has also attracted research attention. Nonetheless, information is scarce on the progress in the use of waste heat for thermal desalination. In this study, a detailed review of desalination pro-cesses driven by waste heat is presented, as well as the barriers limiting the integration of this source of heat in these processes.

2. Desalination technologies

2.1 Classification of desalination technologies

Desalination technologies can generally be categorised into membrane and thermal types, as shown in Figure 1. The membrane type of desalination systems does not entail a phase change of water, and such desalination systems are reported in detail elsewhere (Charcosset, 2009; Subrami & Jacangelo, 2015). In thermal technologies, the water undergoes phase change. This study focuses on thermal technologies, and therefore only these types of systems will be reviewed.

2.2 Thermal processes

2.2.1 Multi-effect distillation

A multi-effect distillation (MED) system consists of several vessels called effects, arranged in series, with decreasing pressure maintained in each subsequent vessel (American Water Works Association, 2011). An external heat source is used to increase the temperature of the feedwater in the first effect to bring about the evaporation process, subsequently generating water vapour, which then moves to the second effect and this process repeats itself such that the heat generated in one effect is used in the next effect, and so on (Al-Karaghouli & Kazmerski, 2013), as illustrated in Figure 2.

2.2.2 Multi-stage flash

A multi-stage flash (MSF) system comprises three major components, namely the brine heater, and the heat recovery and rejection units (Bandi, Uppaluri & Kumar, 2016), as depicted in Figure 3. The brine heater is used to increase the temperature of the feedwater, which then goes through a series of stages that are kept at successively lower temperatures and pressures. In each stage, some of the hot feedwater is allowed to flash, resulting in the generation of water vapour that condenses on the outer surface of the condenser and gets collected on a tray, while the rest of the feedwater flows to the subsequent stages (American Water Works Association, 2011).

2.2.3 Vapour compression

The working principle of the vapour compression (VC) desalination technology is as follows: (i) an external heat source is used to increase the temperature of the feedwater; (ii) the heated feedwater is allowed to flash; (iii) the generated water vapour is compressed and used as heat input to the same stage where it was produced or to other stages (Sharon & Reddy, 2015). There are two types of VC systems, namely: thermal vapour compression (TVC), and mechanical vapour compression (MVC), respectively employing high pressure steam and electricity for the vapour compression process (American Water Works Association, 2011). A MVC unit is illustrated in Figure 4.

2.2.4 Humidification-dehumid ifica tion

The working principle of a humidification-dehumidification (HDH) system is as follows: (i) the temperature of dry air is increased by means of a heater; (ii) this warm air is then made to pass through a humidifier where water vapour is generated; (iii) the water vapour leaves the humidifier and is condensed in a dehumidifier by exchanging heat with the incoming seawater which gets preheated before going into the humidifier; (iv) the condensed water vapour leaving the dehumidifier is collected as the distillate, while excess brine is discharged from the humidifier (Bourouni, Chaibi & Tadrist, 2001), as illustrated in Figure 5.

2.2.5 Freeze desalination

A basic freeze desalination (FD) system comprises a crystalliser, a separator and a melter, as shown in Figure 6. FD is a process in which seawater is cooled below its freezing point, leading to the formation of pure ice crystals in the crystalliser (Sharon & Reddy, 2015). The ice crystals are then separated from the brine in the separator. Thereafter, the ice crystals go into a melter, which melts them into freshwater. Although the FD desalination method has a low energy usage and a high concentrating factor, its use has been limited to laboratory and pilot studies due to the predominance of other conventional thermal and membrane technologies in the desalination industry (Williams et al., 2015).

2.2.6 Adsorption desalination

In an adsorption desalination (AD) unit (Figure 7), saline water is fed into an evaporator and vaporises and then flows to the adsorption bed (kept at a low temperature by circulation of cold water), where an adsorbent is used for adsorption of the vapour. The vapour is recovered in the desorption bed by circulating hot water and then condensed in the condenser, giving freshwater (Sharon & Reddy, 2015).

2.2.7 Solar stills

A conventional solar still comprises a thin layer of saline water in a basin which is fitted in an insulated box with a transparent cover. Solar radiation is transmitted through the transparent cover and captured by the basin liner in the form of thermal energy, which in turn heats the water in the basin. As the temperature of the water increases, evaporation occurs and water vapour is produced. Convection currents are subsequently induced between the water surface and the transparent cover surface, since the air-vapour mixture has a higher temperature and a lower density at the water surface than the air-vapour mixture at the internal surface of the transparent cover. Due to this temperature and density difference, the air-vapour mixture at the water surface rises and, as it comes into contact with the surface of the glass cover, vapour condenses. The distillate then flows along the lower side of the transparent cover and is subsequently collected in the freshwater tank (Elango, Gunasekaran & Sampathkumar, 2015).

2.2.8 Vacuum desalination

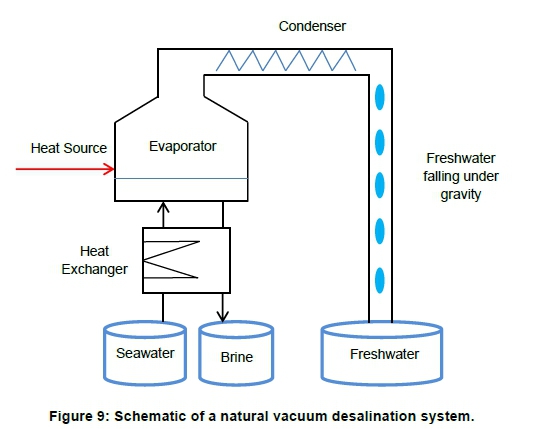

In vacuum desalination (VD), seawater is made to evaporate at a lower temperature than usual by using a vacuum to decrease its boiling point (Tay, Low & Jeyaseelan, 1996). The main components of a VD system include an evaporator, a condenser, and a vacuum pump. The pump consumes electrical energy and can be eliminated by creating a vacuum naturally in the evaporator by allowing the water to fall under the force of gravity (Sharon & Reddy, 2015), as illustrated in Figure 9.

2.3 Energy requirements for driving thermal desalination processes

Due to the energy-intensiveness of desalination processes, most desalination plants around the world are in regions where energy is abundantly available at low cost. It is estimated that only 1% of the total water obtained from desalination is derived from renewable energy sources (IRENA, 2012). Table 1 gives the thermal and electrical energy requirements for thermal desalination processes.

The values given in Table 1 depict the general energy needs of thermal desalination processes. As can be observed from Table 1, natural VD has the highest thermal energy requirements, followed by HDH, MED, MSF and TVC. In terms of electrical energy requirements, FD and MVC have the highest requirements and natural VD has the lowest requirement.

It has been claimed that, since the MSF process can be driven by waste heat or by-product heat, the cogeneration of heat, power and water in the same plant would represent an energy efficient and cost-effective method of satisfying the water and energy needs of the Middle East and Northern Africa (IRENA, 2012). It is further reported that AD is an evolving desalination process which can be driven by low-grade heat sources (Alsaman, et al., 2016).

The integration of waste heat into solar stills can also represent an effective means of providing additional heat to the system in order to enhance the rate of evaporation, leading to a higher yield of fresh water.

3. Use of waste heat in thermal desalination

3.1 Potential of waste heat

Waste heat is the energy that is released to the environment when primary energy sources are converted to final energy, and it can be classified into three categories: low temperature (T<100 °C), medium temperature (100 °C<T<300 °C) and high temperature (T>300 °C) (Forman et al., 2016). Examples of waste heat sources include hot combustion gases released to the environment, hot products being discharged from industrial processes, and heat from the hot surfaces of equipment (United States Department of Energy, 2008). A study conducted on the global waste heat potential revealed that (i) 72% of global primary energy consumption is lost after conversion; (ii) 63% of waste heat streams are at temperatures below 100 °C; and (iii) the electricity generation sector has the largest share of low temperature waste heat (Forman et al., 2016). This category of waste heat has the potential to drive low-temperature thermal processes such as AD, HDH, MED, VD and solar stills. Figure 10 shows the maximum value of the industrial waste heat potential which has been reported for various countries. It can be observed that Canada has the highest waste heat potential at 2300 PJ, followed by the United States of America with a waste maximum heat potential of 1583 PJ.

It has been claimed that one of the most effective methods for minimising the costs associated with desalination is the integration of waste heat to desalination systems (Breschi, 1999). Studies have been made of desalination technologies driven by waste heat sources - for instance, waste heat from power plants, generators, process industries, and exhaust gas of combustion engines, and these are reviewed in the following sections.

3.2 Thermodynamic performance of desalination processes driven by waste heat

Thermodynamics is defined as the study of energy, its change from one form to another, and its relation to states of matter (ASHRAE, 2001). It involves the principles of the: a) transitivity of the equilibrium state of systems; b) conservation of energy in a system; c) quality of energy, and the maximum useful work in a process (exergy); and d) change in the entropy of a system (Okoroigwe & Madhlopa, 2016). These principles play a vital role in the analysis of desalination and other thermal processes. Thermodynamic analyses of thermal desalination units have been reviewed in previous work (Hamed et al., 1996; Tay, Low & Jeyaseelan, 1996; Kaushal & Varun, 2010; Sampathkumar et al., 2010; Ranjan & Kaushik, 2013; Palenzuela et al., 2014).

Sodha, Kumar and Tiwari (1981) performed a numerical analysis on the performance of a solar still by introducing a flow of waste hot water from thermal power plants through the solar still, both at a constant rate and once daily. The waste hot water was available from Badarpur thermal power station waste heat temperature of 44 °C. Shih and Shih (2007) carried out a study to assess the feasibility of using waste heat from a sulphuric acid production plant of 1000 tonnes per day capacity to drive desalination processes. They investigated numerically four different scenarios: (i) MED with plate heat exchangers (MED PHE); (ii) MED-TVC with heat recovery system (MED-TVC HRS); (iii) MSF with PHE and (iv) MSF with HRS. The results showed that 3400, 5680, 1150 and 1170 m3 of desalinated water can be produced daily by the MED PHE, MED-TVC with HRS, MSF PHE and MSF with HRS, respectively. Sommarva (2008) discussed various process configurations of MSF and MED desalination plants to optimise production and performance ratios by using waste heat from power plants. The waste heat sources included the steam condensate from the MSF and flue gas streams from combined cycle gas turbines.

Sada and Jassim (2009) performed a numerical investigation by developing a model integrating a steam power plant with an MED system, making use of the waste heat from the power plant to drive the desalination process. Their results showed that the amount of distilled water produced was 41 667 to 625 000 kgh1 at waste heat temperatures ranging from 160 to 250 °C.

Tanaka and Park (2010) conducted a theoretical investigation on the effect of integrating the waste heat from a portable electric generator into a solar still with wicks. Their numerical analysis revealed that 20 kg of distilled water could be produced in three, five and nine hours at waste gas flow rates of 40, 20 and 10 m3 per hour respectively, and they stated that this amount of distillate corresponds to the experimental value of the maximum daily productivity of solar stills. The waste gas was at a temperature of 250 °C. Ammar et al. (2013) investigated theoretically the performance of a desalination system by using waste heat (at temperatures ranging from 47 to 109 °C) from a paper mill company located in a British coastal area. They conducted two case studies, one in which the waste heat was fed directly to a HDH system, another where a heat pump was used to upgrade the waste heat before being fed to an MED system. Their results showed that for the first scenario the maximum rate of water production was 2.258 kg/s. For the second scenario, the water production rates for 8, 9 and 10 MED stages were 6.54, 6.85 and 6.99 kg/s respectively.

Park et al. (2015) designed and built a multi-effect diffusion basin type solar still, using waste heat from the exhaust gas of a portable electric generator as a back-up heat source. Their experimental results showed that the two-effect diffusion solar still could achieve a productivity between 17.1 and 19.6 kg/m2 per day at a waste heat temperature of 283 °C.

Maheswari, Murugavel and Esakkimuthu (2015) carried out an experimental investigation on a thermal desalination system using the waste heat from the exhaust gas of an internal combustion engine. Their results showed that 3 L per hour of saline water could be desalinated by using the waste heat (at a temperature of 410 °C) from the exhaust gas of the internal combustion engine. Elminshawy, Siddiqui and Sultan (2015) performed an experimental investigation on a desalination system using solar energy and waste heat from flue gases of thermal power stations under the climatic conditions of Al-Qassim in Saudi Arabia. Their model was made up of evacuated tube solar collectors, a storage tank, an evaporator, a condenser, an air blower, and electric heaters. They found that the daily production of water, from 9 am to 5 pm, was approximately 50 litres, at a global solar radiation on a horizontal surface in the range of 15 to 29 MJ/m2 per day, with the useful waste heat ranging from 130 to 180 MJ/day.

Park et al. (2016) performed experimental investigations on a solar still incorporating a waste heat supply under the climatic conditions of the Republic of Korea. The source of the waste heat was derived from the exhaust gas of an electric generator with an AC power rating of 5.6 KVA. Their results revealed that water production increases linearly with increasing heat input. Moreover, it was found that the productivity of this type of solar still can be up to 18.02 kg/m2 at a waste heat input of 22.37 MJ/day. The temperature of the exhaust gas ranged from 280 to 350 °C.

Thu et al. (2016) conducted a theoretical analysis on an AD system driven by waste heat at a temperature of 85 °C. Results showed that potable water could be produced at a rate of 6.5 m3 per ton of silica gel (used as the adsorbent) per day. He et al. (2016) carried out a theoretical investigation on an HDH system driven by the exhaust gas from a furnace. The temperature of the exhaust gas was 130 °C and the water production level ranged from 12.5 to 70.8 kg per hour.

He et al. (2017) conducted a theoretical investigation on an HDH system powered by exhaust gas at 110 °C. Their system consisted of four main components, namely, the direct contact humidifier, dehumidifier, the plate waste heat collector, and the recuperator. A maximum water productivity of 105.26 kgh-1 was obtained in their simulation. Chunhua et al. (2017) carried out a theoretical analysis on an MED system, with a production capacity of 10 000 m3 per day, using waste hot water from petrochemical industry at temperatures ranging from 90 to 98 °C. Their results showed that for every 1 °C increase in feed-water temperature, the production of freshwater increased by approximately 438 m3 per day. Zhang et al. (2017) investigated theoretically and experimentally the effects of using cooling water waste heat (at a temperature ranging from 71 to 85 °C), from a diesel generator to drive an MED system with a freshwater capacity of 60 tons per day.

Khalilzadeh and Nezhad (2018) investigated theoretically an MED system in which the required steam is generated by using waste heat from a high-capacity wind turbine. They found that in the areas with an average wind speed of 11 ms1, the waste heat in a 7580 kW wind turbine is 231 kW at a temperature of 140 °C, resulting in a water production level of 45.069 m3 per day. Table 2 gives a summary of the thermodynamic performance of the studies done on thermal desalination processes driven by waste heat.

As can be observed from Table 2, most of the studies have been theoretical only while a few of them have been experimental only and some comprised both theoretical and experimental prongs. Experimental studies were predominantly carried out on solar stills, which are usually easy to construct on a small-scale and, as such, are feasible for such testing. Moreover, solar stills can be operated by using low-grade heat. The types of waste heat that were explored in previous studies on solar stills included waste hot water from thermal power plants and exhaust gas from generators. It is noted that there is wide variation in the distillate production levels among the different studies. This variation is attributed to the use of different designs and operating and environmental parameters in the various studies. Nevertheless, these findings provide useful insights about the potential of exploiting waste heat in the desalination industry.

3.3 Economic performance

The cost of water is an important factor in making decisions about investing in a given desalination project. Even if the technical performance of the desalination technology is satisfactory, its competitiveness in the mix of water treatment technologies is predominantly influenced by the cost of the desalinated water. It is also known that the cost of energy in the desalination process influences the costs of operation and maintenance of the desalination plant (Kavvadias & Khamis, 2014). Clearly, this indicates the economic benefit of using a cheap source of energy such as waste heat. It is therefore not surprising that some researchers have investigated the economic performance of desalination technologies driven by waste heat. Table 3 shows the economic assessment of thermal desalination systems driven by waste heat. It can be observed that most of the studies have focused on the thermodynamic aspect, paying little or no attention to the cost-effectiveness of the system and the environmental benefit that could be achieved by integrating waste heat into the system instead of the heat being purged into the atmosphere. Various costs of water were obtained in the studies, ranging from 0.91 USD/m3 of desalinated waster obtained from an MED system integrated with waste heat from a sulphuric acid production plant (Shih & Shih, 2007), to 14 USD/m3 of desalinated water obtained from a thermal desalination unit coupled with solar collectors, electric heater, air blower, evaporator and condenser, using waste heat from the exhaust gas of a combined cycle gas turbine (Elminshawy, Siddiqui & Sultan, 2015), to 16.676 USD/m3 of desalinated water generated by an MED system using waste heat from a wind turbine (Khalilzadeh & Nezhad, 2018).

3.4 Environmental performance

The exploitation of fossil fuels to drive desalination processes contributes to GHG emissions and climate change. According to the IPCC (2012), the median lifecycle emissions of fossil fuels varies from 0.469 to 1.001 kg CO2eq/kWh. With regards to the environmental benefit of using waste heat in thermal desalination systems, only one study quantified the reduction in the global warming potential that could be achieved by so doing. This study revealed that the global warming potential of natural gas- and coal-fired desalination could decrease by 65% and 90% respectively if an MED system coupled to a heat pump and driven by waste heat is used instead (Ammar et al., 2013).

4. Discussion

Many previous studies have investigated the thermodynamic performance of different thermal desalination technologies using waste heat. The most commonly used waste heat sources were found to be the waste gas or waste hot water from power stations. The temperatures of the waste heat sources investigated in previous studies ranged from 15 to 410 °C, with the majority of them higher than 50 °C. Although it is estimated that nearly 2050% of industrial energy consumption is eventually discharged as waste heat (United States Department of Energy, 2008), it can be noted that there is only one known thermal desalination system which is actually being driven by waste heat: the MED pilot plant on Guishan Island, Guangdong, China, which is driven by the waste heat of a diesel engine (Zhang et al., 2017). This indicates a possible existence of some barriers to the integration of waste heat in thermal desalination systems and these limitations are discussed in this section.

4.1 Lack of data on waste heat

The development of a desalination technology involves designing and testing the system. Seemingly, advances in desalination systems are resulting in complex configurations that require appropriate computational tools for designing and performance appraisal. In this regard, simulation of desalination systems is gaining acceptance as a suitable tool. One of the most important input variables to such a design tool is energy. Thus, it is important to know the quantity and grade of the available waste heat in order to develop a suitable thermal desalination technology.

It has been stated that waste heat is rarely measured and reported because it is a by-product and therefore not lucrative (Brueckner et al., 2014). Companies are also often ignorant about how waste heat can be utilised and to whom it can be sold, and this in turn creates additional research costs for them (Pehnt et al, 2011). This is particularly an issue in developing countries where there is often a lack of data on waste heat. As can be observed from Figure 10, the waste heat potential is commonly quantified in developed countries like USA, Canada, Japan and many European countries, but very rarely quantified in developing countries such as those in Latin America, Africa and Asia. The lack of information on waste heat is therefore a major challenge to the development of waste heat-based desalination plants, particularly for developing countries, which often face the dual challenges of climate change and water shortage.

4.2 Geographical barriers

Heat exchangers play an important role in desalination systems driven by waste heat. In most of the relevant studies, the temperature of the heat source was less than 250 °C, which can be considered as low-grade heat. Therefore, as reported in literature, it is better to use heat pipes in the context of low-grade heat as they perform better than conventional heat exchangers, but one disadvantage is that they are also more expensive than conventional heat exchangers (Ammar et al., 2012). Consequently, if there is no demand for heat in the region where waste heat production occurs, profitability is substantially lowered because additional long heat pipes are needed for heat transport to the desired location (Pehnt et al, 2011). This is particularly a hindrance for existing desalination plants as they are most often situated close to available water resources, such as the ocean, in order to minimise costs associated with pumping and transporting water. There might not always be existing waste heat sources near to these desalination plants and this can lead to an increase in costs due to additional heat pipes being required. Therefore, integration of waste heat in existing desalination plants might not be economically viable for both the waste heat generating company and the desalination plant, as the former would have to invest in heat transfer pipes and the latter might find it cheaper to use other energy sources readily available. Nonetheless, new desalination plants could be constructed near the generation points of waste heat streams depending on the availability of water resources and space. They can then make use of the waste heat and contribute to energy efficiency and reduce the harmful impact on the environment.

4.3 Fluctuation in the reliability, supply and composition of waste heat

The viability of waste heat recovery is dependent on the stream to which the waste heat will be transferred and on various parameters of the waste heat itself, such as the temperature, quantity of waste heat available, and composition of the waste heat stream (United States Department of Energy, 2008). However, these factors keep varying. The fluctuations in the reliability and supply of waste heat occur due to changes in industrial production and gap between demand and supply (Lu, Price & Zhang, 2016). Consequently, it is not always feasible to use waste heat as an energy source in the desalination systems because water supply needs to be continuous, while the supply of energy from the waste heat source is not always constant. To overcome this challenge, desalination systems driven by waste heat could also include a back-up energy source. Unpredictability in demand and supply of waste heat can also be overcome by using thermal storage. In waste heat recovery systems, a water tank is most commonly used for thermal storage as it is economically feasible for large-scale applications and water can act as both the heat-transfer medium and thermal storage medium due to its excellent thermal-physical properties (Xu, Wang & Yang, 2019). Thus, when there are fluctuations in the supply of waste heat, either a back-up energy source or thermal storage could be used to ensure a continuous desalination process for a reliable water supply.

4.4 Lack of information on the cost-effectiveness and environmental benefit of desalination processes driven by waste heat

As observed in Sections 3.3 and 3.4, few studies have examined the economic and environmental performance of thermal desalination systems driven by waste heat. Therefore, industries might not always be keen to invest in thermal desalination technologies driven by waste heat, as there will be an element of financial risk and, also, they might not have any incentive to use this waste heat because negligible data is available on the environmental benefits of using waste heat-based desalination technologies.

5. Conclusion

Progress in the integration of waste heat in thermal desalination processes has been reviewed. It was found that 63% of waste heat streams are of low grade that has the potential to drive low-temperature thermal desalination processes. Findings also show that there is very limited progress in the development of thermal desalination plants that run on waste heat, which is ascribed to: a) the lack of sufficient data on waste heat, especially in developing countries; b) geographical barriers that lead to high costs associated with heat recovery and transport; c) fluctuation in the reliability, supply and composition of waste heat; and d) lack of information on the cost-effectiveness and environmental benefit of waste heat driven thermal desalination processes. Consequently, further research is required in the following areas:

a) mapping the waste heat recovery potential in developing countries;

b) techno-economic feasibility of thermal desalination plants close to the sources of waste heat;

c) the integration of an energy storage system for waste heat-driven thermal desalination processes; and

d) environmental analysis of thermal desalination units powered by waste heat.

Acknowledgement

The authors are grateful to the National Research Foundation (in South Africa) for the financial support provided through grant number 95689.

Author roles

Deepti Charitar: Carried out the literature review, collected and processed data, and drafted the initial manuscript.

Amos Madhlopa: Conceptualised the research idea, edited the manuscript, and provided general guidance.

References

Abdallah, S and Badran, O.O. 2008. Sun tracking system for productivity enhancement of solar still. Desalination 220 (1-3): 669-676. [ Links ]

Abdallah, S., Badran, O. and Abu-Khader, M.M. 2008. Performance evaluation of a modified design of a single slope solar still. Desalination 219 (1-3): 222-230. [ Links ]

Abdel-Rehim, Z.S and Lasheen, A. 2007. Experimental and theoretical study of a solar desalination system located in Cairo, Egypt. Desalination 217 (1-3): 52-64. [ Links ]

Al-Karaghouli, A. and Kazmerski, L. 2013. Energy consumption and water production cost of conventional and renewable-energy-powered desalination processes. Renewable and Sustainable Energy Reviews 24: 343-356. [ Links ]

Alsaman, A.S., Askalany, A.A., Harby, K. and Ahmed, M.S. 2016. A state of the art of hybrid adsorption desalination - cooling systems. Renewable and Sustainable Energy Reviews 58: 692-703. [ Links ]

Ammar, Y., Joyce, S., Norman, R., Wang, Y. and Roskilly, A.P. 2012. Low grade thermal energy sources and uses from the process industry in the UK. Applied Energy 89 (1): 3-20. [ Links ]

Ammar, Y., Li, H., Walsh, C., Thornley, P., Sharifi, V. and Roskilly, A.P. 2013. Reprint of 'Desalination using low grade heat in the process industry: Challenges and perspectives'. Applied Thermal Engineering 53 (2): 234-245. [ Links ]

Appadurai, M. and Velmurugan, V. 2015. Performance analysis of fin type solar still integrated with fin type mini solar pond. Sustainable Energy Technologies and Assessments 9: 30-36. [ Links ]

Arunkumar, T., Jayaprakash, R., Perumal, K. and Kumar, S. 2010. Desalination Process of single slope solar still coupled with crescent absorber. Journal of Environmental Research and Development 5 (1): 23-33. [ Links ]

ASHRAE [American Society of Heating, Refrigerating and Air-Conditioning Engineers]. 2001. Fundamentals handbook. Atlanta: American Society of Heating, Refrigerating and Air-Conditioning Engineers. [ Links ]

Badran, A.A., A1-Hallaq, A.A., Salman, I.A.E. and Odat, M.Z. 2005. A solar still augmented with a flat-plate collector. Desalination 172 (3): 227-234. [ Links ]

Bandi, C.S., Uppaluri, R. and Kumar, A. 2016. Global optimization of MSF seawater desalination processes. Desalination 394: 30-43. [ Links ]

Bourouni, K., Chaibi, M.T. and Tadrist, L. 2001. Water desalination by humidification and dehumidification of air: state of the art. Desalination 137 (1-3): 167-176. [ Links ]

Breschi, D. 1999. Seawater distillation from low-temperature streams: a case history. Desalination 122 (2-3): 247-254. [ Links ]

Brueckner, S., Miró, L., Cabeza, L.F., Pehnt, M. and Laevemann, E. 2014. Methods to estimate the industrial waste heat potential of regions - A categorization and literature review. Renewable and Sustainable Energy Reviews 38: 164-171. [ Links ]

Bundschuh, J., Ghaffour, N., Mahmoudi, H., Goosen, M., Mushtaq, S. and Hoinkis, J. 2015. Low-cost low-enthalpy geothermal heat for freshwater production: Innovative applications using thermal desalination processes. Renewable and Sustainable Energy Reviews 43: 196-206. [ Links ]

Cendoya, M.G., Toccaceli, G.M. and Battaiotto, P.E. 2014. Wind generation applied to water desalination and H2 production in remote areas with weak networks. International Journal of Hydrogen Energy 39 (16): 8827-8832. [ Links ]

Chaichan, M.T. and Kazem, H.A. 2015. Water solar distiller productivity enhancement using concentrating solar water heater and phase change material (PCM). Case Studies in Thermal Engineering 5: 151-159. [ Links ]

Charcosset, C. 2009. A review of membrane processes and renewable energies for desalination. Desalination 245 (1-3): 214-231. [ Links ]

Chunhua, Q., Hongqing, Lv., Houjun, F., Qingchun, Lv. and Yulei, X. 2017. Performance and economic analysis of the distilled seawater desalination process using low-temperature waste hot water. Applied Thermal Engineering 122: 712-722. [ Links ]

Dehmas, D.A., Kherba, N., Hacene, F.B., Merzouk, N.K., Merzouk, M., Mahmoudi, H. and Goosen, M.F.A. 2011. On the use of wind energy to power reverse osmosis desalination plant: A case study from Ténés (Algeria). Renewable and Sustainable Energy Reviews 15 (2): 956-963. [ Links ]

American Water Works Association. 2011. Desalination of seawater - Manual of water supply practices M61. [ Links ]

Dwivedi, V.K. and Tiwari, G.N. 2010. Experimental validation of thermal model of a double slope active solar still under natural circulation mode. Desalination 250 (1): 49-55. [ Links ]

Elango, C., Gunasekaran, N. and Sampathkumar, K. 2015. Thermal models of solar still - A comprehensive review. Renewable and Sustainable Energy Reviews 47: 856-911. [ Links ]

Elminshawy, N.A.S., Siddiqui, F.R. and Sultan, G.I. 2015. Development of a desalination system driven by solar energy and low grade waste heat. Energy Conversion and Management 103: 28-35. [ Links ]

Eltawil, M.A., Zhengming, Z. and Yuan, L. 2009. A review of renewable energy technologies integrated with desalination systems. Renewable and Sustainable Energy Reviews 13 (9): 2245-2262. [ Links ]

Forman, C., Muritala, I.K., Pardemann, R. and Meyer, B. 2016. Estimating the global waste heat potential. Renewable and Sustainable Energy Reviews 57: 1568-1579. [ Links ]

Forstmeier, M., Mannerheim, F., D'Amato, F., Shah, M., Liu, Y., Baldea, M. and Stella, A. 2007. Feasibility study on wind-powered desalination. Desalination 203 (1-3): 463-470. [ Links ]

García-Rodríguez, L. 2002. Seawater desalination driven by renewable energies: a review. Desalination 143 (2): 103113. [ Links ]

Ghaffour, N., Bundschuh, J., Mahmoudi, H. and Goosen, M.F.A. 2015. Renewable energy-driven desalination technologies: A comprehensive review on challenges and potential applications of integrated systems. Desalination 356: 94-114. [ Links ]

Gude, V.G. 2016. Desalination and sustainability - An appraisal and current perspective. Water Research 89: 87-106. [ Links ]

Gude, V.G., Nirmalakhandan, N. and Deng, S. 2010. Renewable and sustainable approaches for desalination. Renewable and Sustainable Energy Reviews 14 (9): 2641-2654. [ Links ]

Gude, V.G., Nirmalakhandan, N., Deng, S. and Maganti, A. 2012. Feasibility study of a new two-stage low temperature desalination process. Energy Conversion and Management 56: 192-198. [ Links ]

Hamed, O.A., Zamamiri, A.M., Aly, S. and Lior, N. 1996. Thermal performance and exergy analysis of a thermal vapour compression desalination system. Energy Conversion and Management 37: 379-387. [ Links ]

He, W.F., Han, D., Huang, L., Zhang, Y.K. and Wu, Y.K. 2017. Energy and cost analysis of a humidification dehumidification desalination system driven by low grade waste heat. Energy Procedia 142: 2354-2360. [ Links ]

He, W.F., Xu, L.N., Han, D. and Gao, L. 2016. Performance analysis of an air-heated humidification-dehumidification desalination plant powered by low grade waste heat. Energy Conversion and Management 118: 12-20. [ Links ]

IPCC [Intergovernmental Panel on Climate Change]. 2012. Renewable energy sources and climate change mitigation: Special report of the Intergovernmental Panel on Climate Change. [ Links ]

IRENA [International Renewable Energy Agency]. 2012. Water desalination using renewable energy. Available: https://www.irena.org/DocumentDownloads/Publications/IRENA-ETSAP%20Tech%20Brief%20I12%20Water-Desalination.pdf. [ Links ]

Kaushal, A. and Varun. 2010. Solar stills: A review. Renewable and Sustainable Energy Reviews 14: 446-453. [ Links ]

Kavvadias, K.C. and Khamis, I. 2014. Sensitivity analysis and probabilistic assessment of seawater desalination costs fuelled by nuclear and fossil fuel. Energy Policy 74: S24-S30. [ Links ]

Khalifa, A.J.N. and Ibrahim, H.A. 2010. Effect of inclination of the external reflector of simple solar still in winter: An experimental investigation for different cover angles. Desalination 264 (1-2): 129-133. [ Links ]

Khalilzadeh, S. and Nezhad, A.H. 2018. Utilization of waste heat of a high-capacity wind turbine in multi effect distillation desalination: Energy, exergy and thermoeconomic analysis. Desalination 439: 119-137. [ Links ]

Kiranoudis, C.T., Voros, N.G. and Maroulis, Z.B. 1997. Wind energy exploitation for reverse osmosis desalination plants. Desalination 109 (2): 195-209. [ Links ]

Koklas, P.A. and Papathanassiou, S.A. 2006. Component sizing for an autonomous wind-driven desalination plant. Renewable Energy 31: 2122-2139. [ Links ]

Kumar, P.V, Kaviti, A.K., Prakash O. and Reddy, K.S. 2012. Optimisation of design and operating parameters on the year round performance of a multi-stage evacuated solar desalination system using transient mathematical analysis. International Journal of Energy and Environment 3 (3): 409-434. [ Links ]

Kumar, P.V., Kumar, A., Prakash, O. and Kaviti, A.K. 2015. Solar stills system design: A review. Renewable and Sustainable Energy Reviews 51: 153-181. [ Links ]

Kumar, R.S., Mani, A. and Kumaraswamy, S. 2005. Analysis of a jet-pump-assisted vacuum desalination system using power plant waste heat. Desalination 179 (1-3): 345-354. [ Links ]

Li, C., Goswami, Y. and Stefanakos, E. 2013. Solar assisted sea water desalination: A review. Renewable and Sustainable Energy Reviews 19: 136-163. [ Links ]

Liu, C.C.K., Jae-Woo, P., Migita, R. and Gang, Q. 2002. Experiments of a prototype wind-driven reverse osmosis desalination system with feedback control. Desalination 150 (3): 277-287. [ Links ]

Loutatidou, S. and Arafat, H.A. 2015. Techno-economic analysis of MED and RO desalination powered by low-enthalpy geothermal energy. Desalination 365: 277-292. [ Links ]

Lu, H., Price, L. and Zhang, Q. 2016. Capturing the invisible resource: Analysis of waste heat potential in Chinese industry. Applied Energy 161: 497-511. [ Links ]

Maheswari, K.S., Murugavel, K.K. and Esakkimuthu, G. 2015. Thermal desalination using diesel engine exhaust waste heat - An experimental analysis. Desalination 358: 94-100. [ Links ]

Mahmoudi, H., Spahis, N., Goosen, M.F., Ghaffour, N., Drouiche, N. and Ouagued, A. 2010. Application of geothermal energy for heating and fresh water production in a brackish water greenhouse desalination unit: A case study from Algeria. Renewable and Sustainable Energy Reviews 14 (1): 512-517. [ Links ]

Manenti, F., Masi, M., Santucci, G., and Manenti, G. 2013. Parametric simulation and economic assessment of a heat integrated geothermal desalination plant. Desalination 317: 193-205. [ Links ]

Matrawy, K.K., Alosaimy, A.S. and Mahrous, A.F. 2015. Modeling and experimental study of a corrugated wick type solar still: Comparative study with a simple basin type. Energy Conversion and Management 105: 1261-1268. [ Links ]

Miranda, M.S. and Infield, D. 2003. A wind-powered seawater reverse-osmosis system without batteries. Desalination 153 (1-3): 9-16. [ Links ]

Miró, L., Brückner, S. and Cabeza, L.F. 2015. Mapping and discussing industrial waste heat (IWH) potentials for different countries. Renewable and Sustainable Energy Reviews 51: 847-855. [ Links ]

Mohamed, A.M.I. and El-Minshawy, N.A.S. 2009. Humidification-dehumidification desalination system driven by geothermal energy. Desalination 249 (2): 602-608. [ Links ]

Morad, M.M., El-Maghawry, H.A.M. and Wasfy, K.I. 2015. Improving the double slope solar still performance by using flat-plate solar collector and cooling glass cover. Desalination 373: 1-9. [ Links ]

Okoroigwe, E. and Madhlopa, A. 2016. An integrated combined cycle system driven by a solar tower: A review. Renewable and Sustainable Energy Reviews 57: 337-350. [ Links ]

Omara, Z.M. and Eltawil, M.A. 2013. Hybrid of solar dish concentrator, new boiler and simple solar collector for brackish water desalination. Desalination 326: 62-68. [ Links ]

Omara, Z.M., Kabeel, A.E. and Younes, M.M. 2013. Enhancing the stepped solar still performance using internal reflectors. Desalination 314: 67-72. [ Links ]

Palenzuela, P., Hassan, A.S., Zaragoza, G. & Alarcón-Padilla, D.C. 2014. Steady state model for multi-effect distillation case study: Plataforma Solar de Almería MED pilot plant. Desalination 337: 31-42. [ Links ]

Park, C.D., Lim, B.J., Chung, K.Y., Lee, S.S. and Kim, Y.M. 2016. Experimental evaluation of hybrid solar still using waste heat. Desalination 379: 1-9. [ Links ]

Park, C.D., Lim, B.J., Noh, Y.D., Lee, S.S. and Chung, K.Y. 2015. Parametric performance test of distiller utilizing solar and waste heat. Desalination and Water Treatment 55 (12): 3303-3309. [ Links ]

Pehnt, M., Bödeker, J., Arens, M., Jochem, E. and Idrissova, F. Industrial waste heat - tapping into a neglected efficiency potential. In: Proceedings of the ECEEE 2011 Summer Study - Energy efficiency first: The foundation of a low-carbon society; 2011. p. 691-700. [ Links ]

Pugsley, A., Zacharopoulos, A., Mondol, J.D. and Smyth, M. 2016. Global applicability of solar desalination. Renewable Energy 88: 200-219. [ Links ]

Rajaseenivasan, T., Raja, P.N. and Srithar, K. 2014. An experimental investigation on a solar still with an integrated flat plate collector. Desalination 347: 131-137. [ Links ]

Ranjan, K.R. and Kaushik, S.C. 2013. Energy, exergy and thermo-economic analysis of solar distillation systems: A review. Renewable and Sustainable Energy Reviews 27: 709-723. [ Links ]

Sada, G.K. and Jassim, L.I. 2009. Utilization of exhaust waste heat from power plants for sea water desalination. Journal of Engineering and Development 13 (4): 58-68. [ Links ]

Sampathkumar, K., Arjunan, T.V., Pitchandi, P. and Senthilkumar, P. 2010. Active solar distillation - A detailed review. Renewable and Sustainable Energy Reviews 14: 1503-1526. [ Links ]

Sarbatly, R. and Chiam, C.K. 2013. Evaluation of geothermal energy in desalination by vacuum membrane distillation. Applied Energy 112: 737-746. [ Links ]

Sharon, H. and Reddy, K.S. 2015. A review of solar energy driven desalination technologies. Renewable and Sustainable Energy Reviews 41: 1080-1118. [ Links ]

Shatat, M., Worall, M. and Riffat, S. 2013. Opportunities for solar water desalination worldwide: Review. Sustainable Cities and Society 9: 67-80. [ Links ]

Shih, H and Shih, T. 2007. Utilization of waste heat in the desalination process. Desalination 204 (1-3): 464-470. [ Links ]

Singh, R.V., Kumar, S., Hasan, M.M., Khan, M.E. and Tiwari, G.N. 2013. Performance of a solar still integrated with evacuated tube collector in natural mode. Desalination 318: 25-33. [ Links ]

Sodha, M.S., Kumar, A. and Tiwari, G.N. 1981. Utilisation of waste hot water for distillation. Desalination 37 (3): 325342. [ Links ]

Sommarva, C. 2008. Utilisation of power plant waste heat steams to enhance efficiency in thermal desalination. Desalination 222 (1-3): 592-595. [ Links ]

Sparks, D., Madhlopa, A., Keen, S., Moorlach, M., Dane, A., Krog, P. and Dlamini, T. 2014. Renewable energy choices and their water requirements in South Africa. Journal of Energy in Southern Africa 25 (4): 80-92. [ Links ]

Srithar, K., Rajaseenivasan, T., Karthik, N., Periyannan, M. and Gowtham, M. 2016. Stand alone triple basin solar desalination system with cover cooling and parabolic dish concentrator. Renewable Energy 90: 157-165. [ Links ]

Subrami, A. and Jacangelo, J.G. 2015. Emerging desalination technologies for water treatment: A critical review. Water Research 75: 164-187. [ Links ]

Tanaka, H. 2009. Experimental study of a basin type solar still with internal and external reflectors in winter. Desalination 249 (1): 130-134. [ Links ]

Tanaka, H. 2011. A theoretical analysis of basin type solar still with flat plate external bottom reflector. Desalination 279 (1-3): 243-251. [ Links ]

Tanaka, H. and Park, C.D. 2010. Distillation utilizing waste heat from a portable electric generator. Desalination 258 (1-3): 136-142. [ Links ]

Tay, J.H., Low, S.C. and Jeyaseelan, S. 1996. Vacuum desalination for water purification using waste heat. Desalination 106 (1-3): 131-135. [ Links ]

Thu, K., Saha, B.B., Chua, K.J. and Ng, K.C. 2016. Performance investigation of a waste heat-driven 3-bed 2-evaporator adsorption cycle for cooling and desalination. International Journal of Heat and Mass Transfer 101: 1111-1122. [ Links ]

United States Department of Energy. Waste heat recovery: Technology and opportunities in U.S. industry. 2008. Available: http://www1.eere.energy.gov/manufacturing/intensiveprocesses/pdfs/waste_heat_recovery.pdf. [ Links ]

Williams, P.M., Ahmad, M., Connolly, B.S. and Oatley-Radcliffe, D.L. 2015. Technology for freeze concentration in the desalination industry. Desalination 356: 314-327. [ Links ]

World Health Organisation. 2015. Drinking water. Available: http://www.who.int/mediacentre/factsheets/fs391/en/. [ Links ]

World Resources Institute. 2015. Ranking the world's most water-stressed countries in 2040. Available: http://www.wri.org/blog/2015/08/ranking-world%E2%80%99s-most-water-stressed-countries-2040. [ Links ]

Xu, Z.Y., Wang, R.Z. and Yang, C. 2019. Perspectives for low-temperature waste heat recovery. Energy. 176: 1037-1043. [ Links ]

Youssef, P.G., Al-Dadah, R.K. and Mahmoud, S.M. 2014. Comparative analysis of desalination technologies. Energy Procedia 61: 2604-2607. [ Links ]

Zhang, F., Xu, S., Feng, D., Chen, S., Du, R., Su, C. and Shen, B. 2017. A low-temperature multi-effect desalination system powered by the cooling water of a diesel engine. Desalination 404: 112-120. [ Links ]

* Corresponding author: Tel.: +44 (0)1274383943