Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

Journal of Energy in Southern Africa

On-line version ISSN 2413-3051

Print version ISSN 1021-447X

J. energy South. Afr. vol.30 n.2 Cape Town May. 2019

http://dx.doi.org/10.17159/2413-3051/2019/v30i2a5337

ARTICLES

doi: http://dx.doi.org/10.17159/2413-3051/2019/v30i2a5337

The effect of cetane number and oxygen content in the performance and emissions characteristics of a diesel engine using biodiesel blends

Semakula MaroaI; Freddie InambaoII

IDiscipline of Mechanical Engineering, University of KwaZulu-Natal Howard College, Mazisi Kunene Road, Durban 4041, South Africa. https://orcid.org/0000-0002-4777-7197

IIDiscipline of Mechanical Engineering, University of KwaZulu-Natal Howard College, Mazisi Kunene Road, Durban 4041, South Africa. https://orcid.org/0000-0001-9922-5434

ABSTRACT

The growth in demand for power generation and energy from alternative fuels at low cost and friendly to the natural environment is increasing. This study used waste plastic pyrolysis oil (WPPO) and ethanol to apply direct blending of conventional diesel, WPPO and ethanol with 2-ethyl hexyl nitrate (EHN). The purpose was to improve the combustion and performance characteristics of the WPPO blends. The EHN has the potential to reduce emissions of carbon dioxide, carbon monoxide, unburnt hydrocarbon, oxides of nitrogen and particulate matter. Ethanol improves viscosity, miscibility, and the oxygen content of WPPO. Five mixing ratios were selected. The mixing ratio with EHN was based on total quantity of blended fuel at 0.01%. At 50% engine load, the brake specific fuel consumption was 0.043 g/kWh compared with CD at 0.04 g/kWh. The blend 90/WPPO5/E5 had the highest value of 14% for brake thermal efficiency, while on NOX emissions three blends 90/WPPO5/E5, 80/WPPO10/E10, 70/WPPO15/E15, had the lowest values of 384 ppm, 395 ppm, 414 ppm, compared with CD fuel at 424 ppm. The implication was that ethanol and WPPO blends can be used in diesel engine power generators as an alternative fuel with modification, as their respective densities of 792 kg/m3 and 825 kg/m3 are close to CD fuel's at 845 kg/m3. Additionally, these combinations with EHN reduced emissions more than earlier thought and improved engine performance, equalling that of conventional diesel fuel.

Keywords: 2-ethyl hexyl nitrate; ethanol; oxygen content; ignition quality; waste plastic pyrolysis oil; cetane index

1. Introduction

The increased use of private automobiles has significantly increased the demand for energy, especially primary sources of energy. Alternative solutions to meeting this increasing energy demand associated with modern day developmental needs must, therefore, be increased. Diesel engines, since their discovery by Rudolph Diesel in 1893, have proved superior, more power efficient and more economic with fuel than gasoline engines (Shrinivasa, 2012). Diesel engines, however, emit high levels of carbon dioxide, unburnt hydrocarbon, oxides of nitrogen and particulate matter and smoke. These emissions have been shown to affect human health and environment (Börjesson et al., 2014). Diesel exhaust is now classified as carcinogenic to humans (Benbrahim-Tallaa et al., 2012), with exposure linked to increased risk of lung cancer and cardiovascular diseases (Giles et al., 2012). Diesel exhaust emissions are considered the primary source of providing ground-level ozone (Innes, 1981), sick building syndrome (Hester and Harrison, 2009), acid rain (Mills and Elouali, 2015) and smog (Ou et al., 2016). The need to find alternative sources of fuel energies with the more desirable characteristics of petroleum-based fossil fuels can, therefore, not be overemphasised (Damodharan et al., 2018).

In the last two decades there has been a growing interest in higher-level alcohols because of their high energy levels, higher cetane numbers, better blend stability, less hygroscopic tendencies, increased carbon chain length and improved ignition quality of the alcohol fuel molecules (Koivisto et al., 2015), compared with the lower alcohols such as ethanol and methanol. Alcohols are classified under oxygenated fuels with a hydroxyl group. This inherent oxygen in their molecular structure enables alcohols to reduce smoke emissions during combustion in diesel engines, particularly during high engine loads as reported by (Lapuerta et al., 2010b). The reduction in smoke emissions and opacity is directly linked to the oxygen content of the blends of diesel and alcohol produced (Ren et al., 2008). Through research collaborations with various biotechnology research groups, there have been improvements in the yield of higher-level alcohols through processing cellulose by modern fermentation processes such as using clostridium species (Gaida et al., 2016); and biosynthesis from glucose using genetically-engineered micro-organisms like Escherichia coli (Desai et al., 2015), cyanobacteria (Formighieri, 2015) and saccha-romyces cerevisiae (Ofuonye et al., 2013).

The research community has been constrained by the growing concern over fossil fuel depletion, oil price fluctuations, escalating energy demands and stringent emission regulation and control to continuously search for better alternative renewable energy resources to serve as replacements and sources of primary energy (Kumar and Saravanan, 2016b). Early developments of alternatives in fuel energy studies utilised food-based sources as alternatives to petroleum fuels, but this faced opposition and arguments from all sectors, including bodies such as the Food and Agriculture Organization and the United Nations Commission on Human Rights because of poor food security in low- and middle-income countries. The first-generation food-based biodiesels lead to cultivation of large swathes of land for commercial purposes, eventually supress-ing the edible food crop acreage. This increased food insecurity leads to increased food prices and economic inflation (Kumar and Saravanan, 2016b).

Research on waste plastic pyrolysis oil (WPPO) showed that using the pyrolysis technique to extract liquid fuel from plastic waste material is a viable alternative to diesel fuel production and is sustainable (Demirbas, 2004; Scheirs, 2006; Xue, 2015; Mani, 2009). This is true especially when waste plastic oil is used with fuel additives (Damodharan et al., 2017). Statistics show that, as of 2016, only a paltry 9% world wide of waste plastic has been recycled with almost 80% going to landfills to continue degrading the natural environment, since plastics are non-biodegradable (Geyer et al., 2017). This is poor response and alarming as the gap between generation and recycling continues to increase, thus requiring bridging. Plastic pyrolysis can also be done using catalytic pyrolysis and other thermal processes. The catalytic method uses low levels of temperature to cause plastic degradation and decomposition than the thermal technique, which requires high temperature to produce high and greater liquid fuel. This has helped in recycling waste into energy, a development that captivated and motivated associated research (Zhang et al., 2008; Cann and Liao, 2010; Dekishima et al., 2011).

Extensive research has used fuel-additives on WPPO biodiesel and other biodiesels (Rakopoulos et al., 2010; Li et al., 2015; Campos-Fernández et al., 2012; Lapuerta et al., 2010b; Jin et al., 2011; Zhu et al., 2011; Mani et al., 2011; Zhang et al., 2012; Park et al., 2012; Wang et al., 2012; Chen et al., 2013a; Campos-Fernandez et al., 2013; Soloiu et al., 2013; Chen et al., 2013b; Wei et al., 2014; Kumar et al., 2013; Saravanan, 2015; Devaraj et al., 2015; Kumar and Sankaranarayanan, 2016; Kumar and Saravanan, 2016a). (Xiaoyan et al., 2008) studied the use of biodiesel-ethanol (BE) blends to reduce the emissions of nitrogen oxides (NOX) and particulate matter (PM) in a diesel engine utilising both ethanol and selective catalytic reduction over catalyst Ag/Al2O3. This study found increased unburnt hydrocarbons (UHC), carbon monoxide (CO) and PM emissions of 14% caused by an increase in the soluble organic fractions in the PM emissions, as well as a 60 % to 80% reduction in Bosch smoke number, based on the European Steady-state Cycle standard. The NOX emissions were, consequently, reduced significantly, by 73%, leading to a conclusion that a combination of BE and a selective catalytic reduction arrangement could provide a good platform for NOX and PM reduction and control.

In another study by (Aydin and Ogüt, 2017) the authors presented the relationship of these fuels to torque, brake thermal efficiency, brake-specific fuel consumption (BSFC) and emission characteristics in diesel engines. Because of this research work in the last decade, new rules and regulation have emerged. For example, developed and emerging countries in Europe and America require fuel manufacturers and distributors to add 1-5% biofuel to most commercially available diesel fuels. In the United States of America, the renewable fuel standard programme now requires blending of advanced biofuels in an increasing amount. This rule is in line with the quantity of fossil fuel used in transportation. The government has been targeting to achieve an annual projection growth escalation of 136 billion litres by 2022 (Lawyer et al., 2013).

There are two reasons ethanol is considered as an additive to WPPO blends. Firstly, ethanol is produced from raw material of plant or plant waste origin, qualifying as alternative renewable source of energy and, secondly, its high oxygen content and solubility in WPPO blends (Lapuerta et al., 2008; Shahir et al., 2014; Kwanchareon et al., 2007; Fernando and Hanna, 2004; Li et al., 2005). Several studies have, however, shown that an increase in the ethanol fraction decreases the auto-ignition properties of diesel because of its low propensity to auto-ignite (Chacartegui et al., 2007; Tutak et al., 2015; Hansen et al., 2005;Kwanchareon et al., 2007; Kim and Choi, 2008; Moon et al., 2013; Can et al., 2004; Rakopoulos et al., 2008; Yilmaz et al., 2014; Kuszewski et al., 2017). The cetane number-value of the blends with diesel decreases as the fraction of ethanol increases (Chacartegui et al., 2007; Hansen et al., 2005; Can et al., 2004; Kuszewski et al., 2017). Reduced cetane numbers (CN) fuel values are undesirable because of their nature to prolong ignition delay, which causes increased engine peak cylinder combustion pressures (Baczewski et al., 2015; Yanowitz et al., 2017), increased engine combustion noise and wear in addition to increased NOX emissions. This impact resulting from alteration of CN has been extensively studied (Kidoguchi et al., 2000; [Ikingür and Altiparmak, 2003; Takahashi et al., 2011; Szybist and Bunting, 2005; Kurtz and Polonowski, 2017; Watanabe et al., 1998; Catalufia and Da Silva, 2012; Chaichan and Ahmed, 2012; Chukwuezie et al., 2017; Reijnders et al., 2016; Tat, 2011). Plastics have substantial stored potential energy of hydrocarbons inherent in their molecular structure (Mani et al., 2011). They are readily available as waste in municipal solid waste management sites where they threaten the environment (Geyer et al., 2017). Altering them through modern methods of decomposition, plastic waste can be converted to liquid fuels and used as biodiesels (Zhou, 2014).

The present study examines fuels that are derived from renewable feedstock sources such as municipal solid waste (MSW) disposed plastics through blending. Waste was converted into energy to contribute to energy sustainability studies through the use of ethanol to increase the oxygen content and 2-ethyhexyl nitrate, which improves the cetane number and reduces emissions of CO, CO2 and NOX.

2. Experimental setup

The blending of WPPO, whose n-alkenes are 25% lower for auto-ignition, was compared with diesel fuel, which contains adequate n-alkenes for auto-ignition. The aromatics, which affect PM emissions, are low in WPPO blends. The WPPO consists of about 27%, 25% and 9% iso-alkanes, n-alkanes and olefins respectively, with over 30% content being undefined because of complicated and complex chemical bond structures (API, 2010), (Harley and Kean, 2004). However, aromatics cyclo-alka-nes (naphthalene) and others poor in auto-ignition were also found to be 40% by (Ghosh et al., 2006). Blending was, firstly, preferred to improve the low pour point of WPPO to improve cold starting characteristics. Secondly, blending was used to improve the fuel spray characteristics by using ethanol, which is soluble and miscible in WPPO blends. Thirdly, blending contributed in the reduction of the viscosity of WPPO biodiesel, thus aiding and improving spray characteristics.

2.1Engine tests

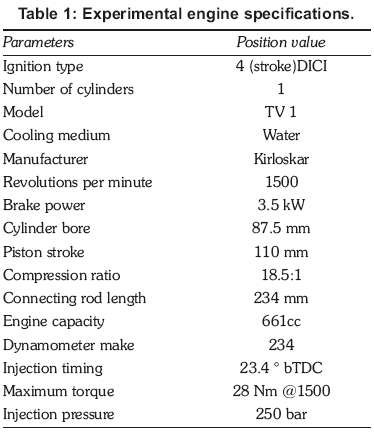

The experiment was conducted at the at the Mechanical Engineering Department Laboratory (29°52'09.9"S 30°58'37.9"E), University of KwaZulu-Natal, Durban, South Africa. The experiment used a test rig of a naturally aspirated single-cylinder diesel engine power generator, water cooled, direct injection and Kirloskar TV1. Figure 1 shows a schematic of the engine test setup and Table 1 presents the details of the engine and specifications.

2.2Physicochemical property analysis

The WPPO by pyrolysis was obtained from a commercial plant whose flow chart is shown in Figure 3. Ethanol, conventional diesel and 2-ethyl hexyl nitrate (EHN) were purchased from local outlets. Blending used a homogeniser for five minutes at 3000 rpm. The properties of all samples were measured in the Chemical Engineering Laboratory, University of KwaZulu-Natal, and Durban. Table 2 shows the physicochemical properties of the fuels before blending and Table 3 shows physicochemical properties of blended mixture-fuels and their determined fuel properties after blending. Figure 2 is a photograph of the sample distillates of WPPO obtained from pyrolysis.

3. Results and discussion

3.1 Brake specific fuel consumption

Figure 4 shows a variation of BSFC with engine load. The BSFC is compared to engine load in Figure 1. This graph reveals that, as the load increases, there is an equal increase for fuel consumed by the test engine. The values obtained at full engine load for the blends of 90/WPPO5/E5, 80/WPPO10/E10, 70/WPPO15/E15, 60/WPPO20/ E20, 50/WPPO25/E25 and CD were 0.04g/kW.h, 0.041g/kW.h, 0.042 g/kW.h, 0.043 g/kW.h and 0.035g/kW.h respectively.

At high engine loads, the conversion of heat energy to mechanical energy increases with increase in combustion temperature. This leads to increased BSFC for the biodiesel, the increase proportional to the difference in their heating values (GVC) in Tables 2 and 3, which is identical to the findings of (Lapuerta et al., 2010a). These blends of WPPO compare well to conventional diesel fuel and other biodiesel blends with comparative differences in the heating values.

As the blend ratio increased, there was a decrease in the BSFC across all the test fuels, although the values for all WPPO blends were higher than the conventional diesel (CD) test-fuel. The closeness of the values and the packed graph reveal a close resemblance and identical BSFC characteristics of WPPO, ethanol and EHN compared to CD fuel. For example, at 50% engine load the blend of 80/WPPO10/E10 had a value of 0.043 g/kW.h compared to the full engine load with 0.041g/kW.h; this value being higher than the CD test-fuel, with 0.04g/kW.h at 50 % engine load and 0.035g/kW.h at full engine load.

3.2 Brake thermal efficiency

The brake thermal efficiency (BTE) variations with engine load are shown in Figure 5. The graphs show that, as the load increased, there was increase in the BTE across all the test-fuel blends of WPPO and CD. At 50% engine load the values for blends 90/WPPO5/E5, 80/WPPO10/E10, 70/WPPO15/E15, 60/WPPO20/E20, 50/WPPO25/E25 and CD were 22%, 21%, 20%, 18%, 16.5% and 22.5% respectively. As the blend ratio and engine load increased, there was increase in BTE across the blends of WPPO but with a decrease in the BTE within the blends. At 25% engine load, 90/WPPO5/E5 had values of 14%, 22%, 26.5% and 25% compared with 70/WPPO15/E15 with 12.5%, 20.0%, 22.5% and 23.0% respectively.

The highest BTE value was recorded by blend 90/WPPO5/E5 at 25% engine load compared with any other blend of WPPO, ethanol and addition of EHN. The density, which is closer to CD and the effect of blending, which improved this blends physicochemical properties, could cause this. Figure 5 shows values of 24.8%, 23%, 21% and 19% respectively for blends 80/WPPO10/E10, 70/WPPO15/E15, 60/WPPO20/E20 and 50/WPPO25/E25. Blend 50/WPPO25/E25, however, reported the lowest values than other blends. At 25%, engine load the BTE value was 9.5% compared with full load at 19%, this being the lowest values of BTE as shown in Figure 5 for all the blends tested.

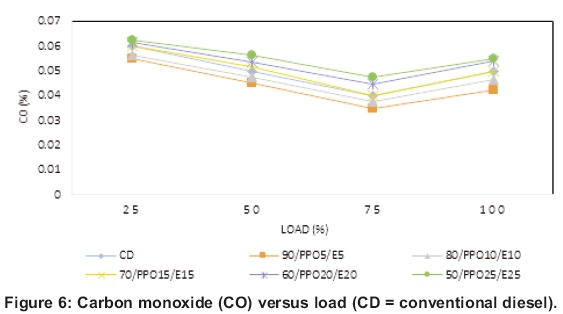

3.3 Carbon monoxide

Figure 6 shows a variation of carbon monoxide with engine load. As the engine load and the blend ratio increased, the values of blends 90/WPPO5/E5, 80/WPPO10/E10, 70/WPPO15/E15, 60/WPPO20/ E20, and 50/WPPO25/E25 gave carbon monoxide emissions decreases of up to 75% of engine load. The blends subsequently recorded a continuous increase as the engine load approached full load. At 25% engine load, the blends of 90/WPPO5/E5, 80/WPPO10/E10, 70/WPPO15/E15, 60/WPPO20/ E20, 50/WPPO25/E25 recorded values of 0.0550%, 0.0565%, 0.0600%, 0.0615% and 0.0625% respectively.

As the load is increased to 75%, the values were0.035%, 0.0375%, 0.0445% and 0.0475% respectively. At full load, all the test fuels showed increased CO emissions, with blends 90/WPPO5/E5 and 80/WPPO10/E10 reporting the lowest emissions among the test blends across all the engine load conditions. At 50%, the blends recorded values of 0.0445% and 0.0475% compared to full load at 0.0425% and 0.0465% respectively. The increased CO emissions, though lower as compared to diesel fuel, can be attributed to partial combustion (Rahman et al., 2014), as the load increased and the presence of ethanol shortened ignition delay, thus increasing CO emissions.

As the engine load and the blend ratio increased, an increase in the carbon monoxide emission across all engine loads and within the blends and CD, test-fuel was experienced. At 50% engine load, the values of the blends and CD recorded 0.045%, 0.0475%, 0.0515%, 0.0535%, 0.0565% and 0.05% for 90/WPPO5/E5, 80/WPPO10/E10, 70/WPPO15/E15, 60/WPPO20/ E20, 50/WPPO25/E25 and CD respectively. These values from Figure 4 imply a reduction of CO emissions across all test fuels, irrespective of blend ratio and type of fuel, except at high engine loads exceeding 75% and up to to full engine load. This was followed by a steady increase in the emissions of CO.

The CO emissions are a direct result of poor oxidation of the hydrocarbon fuels in the combustion chamber and are determined by the local fuel/air equivalence ratio. Compared with CD, all the biodiesels tested showed decreased CO emissions, because of the high oxygen content in the test biodiesels and the addition of EHN, which greatly increased the CN, corroborating the results of Ìçingür et al. (2003) and Wu et al. (2009). However, as the engine load increased from 75% towards full load, there was an observed increase in CO emissions, despite the oxygen content of the biodiesel and increased CN of the blends of WPPO, ethanol and EHN. This deviation of results was attributed to differences in CN for the different biodiesel test fuel blends used. The increment in CN as the blend ratio increased, led to an increase in fuel quantity burnt during diffusive combustion, hence increased CO emissions as the quality of combustion decreased.

3.4 Exhaust gas temperature

The trend of exhaust gas temperature (EGT) and the engine load in Figure 7 increased significantly, as the load increased, especially for the blends. At 25% engine load, the blends 90/WPPO5/E5, 80/WPPO10/E10, 70/WPPO15/E15, 60/WPPO20/ E20, 50/WPPO25/E25 recorded values of 165 °C, 195 °C, 226 °C and 256 °C than the CD with 155 °C, 175 °C, 205 °C and 240 °C for all engine load conditions.

As the engine load increased from 25% to full load, the graph curves tended toward unitary and similar to the values of CD. The blends of WPPO, ethanol and fuel additives, consequently, have identical temperature characteristics to those of the CD test-fuel, especially as the engine load reaches 75% heading to 100% (full load). This was attributed to the presence of ethanol, which decreased ignition delay, thus lowering the combustion temperature.

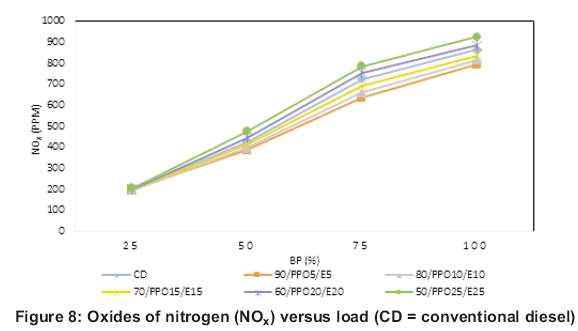

3.5 Oxides of nitrogen

The variation of engine load with NOX emissions is given in Figure 8, showing that NOX emissions increased with increasing engine load, irrespective of fuel, blend ratio or EHN. However, the value of NOX emissions from the blends 90/WPPO5/E5, 80/WPPO10/E10, and 70/WPPO15/E15 recorded lower values compared with CD fuel. For example, at 50% the value of the blends were 385 ppm, 396 ppm and 415 ppm, compared with CD fuel at 425 ppm.

Blend 60/WPPO20/E20 and 50/WPPO25/E25 yielded the highest NOX emissions compared with the other blends of 90/WPPO5/E5, 80/ WPPO10/E10, and 70/WPPO15/E15 across all the engine load conditions tested. At 25% engine load, the two blends emitted 205 ppm and 200 ppm NOx respectively. However, at full engine load the NOX emissions increased to 925 ppm and 885 ppm compared with blend 90/WPPO5/E5 at the same load with 197 ppm and at full load at 792 ppm. Figure 8 shows that, as the blend ratio increased the NOX increased in direct proportion across all the blended test-fuels. However, blend 90/WPPO5/E5 registered the lowest values of NOX of all the experimental blends.

The formation of NOX in biodiesel combustion strongly depends on the combustion temperatures and oxygen concentration in the combustion zone. However, with high blend ratios of 70/WPPO15/E15, 60/WPPO20/E20 and 50/ WPPO25/E25, the combustion process contracted, subsequently failing to provide enough cooling effect to decrease peak combustion temperatures, leading to increased NOX. These findings imply that there is a correlation between the alcohol content in the fuel and peak flame temperatures, nitrogen content and oxygen availability (Heywood, 1988). Increased NOX emissions can be attributed to the presence of nitrogen from the cetane number-improver ENH and other contaminants from the WPPO composition, as well as to the generation of hydrocarbon radicals through molecular unsatura-tion (Benjumea et al., 2010; Altun, 2014). The NOX levels are still low, however, which is attributed to high CN numbers of the tested biodiesels (see Table 3) and increase in the CN and blend ratios (i.e., oxygen content). These findings are identical to the findings of Zhu et al. (2016).

3.6 Unburnt hydrocarbons

Figure 9 shows a variation of UHC emission with engine load, where emissions increased with an increase in engine load. The increase was specifically substantial at engine loads ranging from intermediate (75%) to full. For an example, a 50% engine load yielded respectively 22 ppm, 21 ppm, 20 ppm, 18 ppm and 15 ppm UHC from blends 90/WPPO5/E5, 80/WPPO10/E10, 70/WPPO15 /E15, 60/WPPO20/E20 and 50/WPPO25/E25, compared with full load that yielded 35 ppm, 34 ppm, 32 ppm, 29 ppm and 26 ppm UHC. An inference here is that at high engine loads the values of UHC emissions are significantly high for all the blends of WPPO, ethanol and EHN, although lower than for the CD fuel.

Figure 9 shows that higher UHC emissions from blends 90/WPPO5/E5 and 80/WPPO10/E10 were recorded, but still lower than the values of the CD test-fuel. The general trend shown in the graph in Figure 9, however, was that as the blend ratio increased, there was significant reduction in the UHC emissions, observed across all the test-fuels irrespective of the engine load condition, for all the blends tested, when compared with CD fuel.

Hydrogen radicals in the diesel-ethanol-WPPO-EHN blends likely caused the higher hydrocarbon emissions. The high fraction of ethanol in blends 70/WPPO15/E15, 60/WPPO20/E20, and 50/ WPPO25/E25 contributed to increase in the emissions of UHC. This compared well with Tutak et al. (2015) and Lujaji et al. (2011), and results in SI engine cylinder walls, crevices and quenched cylinder walls, especially when richer air-alcohol mixtures were introduced.

3.5 Carbon dioxide

Figure 10 represents the variation of CO2 with engine load, where CO2 emissions increased as the blend ratio and engine load increased, but these emissions remained lower and almost identical when compared with CD. At 50% engine load, the values of CD; and the blends of 90/WPPO5/E5, 80/WPPO10/E10, 70/WPPO15/E15, 60/WPPO20/ E20 and 50/WPPO25/E25 emitted 3.58%, 3.35%, and 2.95%, 2.6%, 2.55% and 2.25% respectively.

Figure 10 also reveals that, as the load increased there was a significant increase in the CO2 emissions across all test fuels, although with lower values as the blend ratio increased. For example, CD fuel corresponded with 2%, 3.85%, 5.95% and 8.95% CO2 for respective engine loads of 25%, 50%, 75% and 100%, while blend 80/WPPO10/E10 corresponded with 1.8%, 2.95%, 4.85% and 8.55% for similar loads. The blend with the lowest CO2 emissions was 50/WPPO25/E25, with values of 1.62%, 2.25%, 3.65% and 7.35% for engine loads of 25 %, 50 %, 75 % and 100 % respectively.

4. Conclusions

• Lower blend ratios 90/WPPO5/E5 and 80/WPPO10/E10 exhibit identical brake-specific fuel consumption (BSFC) of conventional diesel test fuel compared to the other blends. This blends show lowest BSFC values compared to the others.

• The brake thermal efficiency of blend 90/WPPO5/E5 (90 % conventional diesel, waste plastic pyrolysis oil 5 % an ethanol 5 % by volume ) showed values, which were very close to the values of conventional diesel fuel values. This was attributed to close density values and the gross calorific values of waste plastic pyrolysis oil (WPPO) blends, which showed marginal differences. This case was apparent especially at lower blend ratios of all the mixtures and blends tested.

• There was a reduction of unburnt hydrocarbons (UHC) emissions with the use of WPPO blends, ethanol and 2-ethyl hexyl nitrate (EHN), with a notable reduction in oxides of nitrogen emissions especially for the blend 90/WPPO5/E (90% conventional diesel, waste plastic pyroly-sis oil 5%, and ethanol 5 % by volume). This was a clear indication that this blend performed well when compared with petroleum conventional diesel.

• Although there was indicated increase in the emissions of CO, CO2 NOX and UHC, for all the blends of WPPO, ethanol and EHN. There was a clear indication that the emission levels were notably lower than the emission levels of conventional petroleum diesel, based on the ASTM measurements used in this study. However, when the overall value of emissions is compared with other emissions standards, the WPPO blend performed well on emission level tested.

• The blends of WPPO, ethanol and EHN have identical temperature characteristics to those of the conventional diesel test fuel especially as the engine load hits 75% heading to full load.

This was attributed to the presence of ethanol responsible for decreased ignition delay. The presence of high oxygen enrichment was a factor of decreased CO emission for the tested biodiesels compared with conventional diesel fuel, although there was increase in CO emissions as fuel CN and blend ratio was increased. This was attributed to deterioration of the combustion characteristics, as the cetane numbers (CN) and the alcohol blend ratio increases. The biodiesels with extremely high CN in the tested fuel need further investigation as a fuel improver.

This study thus makes a strong case for alternative fuels to replace petroleum-based fossil fuels like diesel commonly used as the primary propulsion fuel in transport and power generation.

Author roles

Semakula Maroa: data collection, concept write-up, research formulation and all the analytical discussions pertaining to this research paper.

Freddie Inambao: editing, supervision and technical support.

References

ALTUN, Ş. 2014. Effect of the degree of unsaturation of biodiesel fuels on the exhaust emissions of a diesel power generator. Fuel, 117, 450-457.

API 2010. HPVTesting Group Kerosene/jet fuel category assessment document. Submitted to the US EPA, by The American Petroleum Institute, Consortium Registration, 1100997. [ Links ]

AYDiN, F & OGUT, H. 2017. Effects of using ethanol-biodiesel-diesel fuel in single cylinder diesel engine to engine performance and emissions. Renewable Energy, 103, 688-694. [ Links ]

BACZEWSKI, K., SZCZAWIDSKI, P & KAMIDSKA, M. 2015. Experimental testing of influence of commercial depressants on diesel fuels low temperature properties. Journal of KONES, 22, 7-14. [ Links ]

BENBRAHIM-TALLAA, L., BAAN, R. A., GROSSE, Y., LAUBY-SECRETAN, B., EL GHISSASSI, F, BOUVARD, V, GUHA, N., LOOMIS, D., STRAIF, K. & GROUP I. A. F R. O. C. M. W. 2012. Carcinogenicity of diesel-engine and gasoline-engine exhausts and some nitroarenes. Elsevier. [ Links ]

BENJUMEA, P, AGUDELO, J. R. & AGUDELO, A. F 2010. Effect of the degree of unsaturation of biodiesel fuels on engine performance, combustion characteristics, and emissions. Energy & Fuels, 25, 77-85. [ Links ]

BÖRJESSON, M., AHLGREN, E. O., LUNDMARK, R. & ATHANASSIADIS, D. 2014. Biofuel futures in road transport-A modeling analysis for Sweden. Transportation Research Part D: Transport and Environment, 32, 239-252. [ Links ]

CAMPOS-FERNÁNDEZ, J., ARNAL, J. M., GÓMEZ, J. & DORADO, M. P 2012. A comparison of performance of higher alcohols/diesel fuel blends in a diesel engine. Applied energy, 95, 267-275. [ Links ]

CAMPOS-FERNANDEZ, J., ARNAL, J. M., GOMEZ, J., LACALLE, N. & DORADO, M. P 2013. Performance tests of a diesel engine fueled with pentanol/diesel fuel blends. Fuel, 107, 866-872. [ Links ]

CAN, O., CELIKTEN, I. & USTA, N. 2004. Effects of ethanol addition on performance and emissions of a tur-bocharged indirect injection Diesel engine running at different injection pressures. Energy conversion and Management, 45, 2429-2440. [ Links ]

CANN, A. F. & LIAO, J. C. 2010. Pentanol isomer synthesis in engineered microorganisms. Applied microbiology and biotechnology, 85, 893-899. [ Links ]

CATALUNA, R. & DA SILVA, R. 2012. Effect of cetane number on specific fuel consumption and particulate matter and unburned hydrocarbon emissions from diesel engines. Journal of Combustion, 2012. [ Links ]

CHACARTEGUI, C., LOPEZ, J., ALFONSO, F, AAKKO, P, HAMELINCK, C., VOSSEN, G. & KATTENWINKEL, H. 2007. Blending ethanol in diesel. Final report for Lot 3b of the Biodiesel Improvement On Standards, Coordination of Producers and Ethanol Studies (Bioscopes) project. [ Links ]

CHAICHAN, M. T. & AHMED, S. T. 2012. Effect of fuel cetane number on multi-cylinders direct injection diesel engine performance and exhaust emissions. Al-Khwarizmi Engineering Journal, 8, 65-75. [ Links ]

CHEN, Z., LIU, J., HAN, Z., DU, B., LIU, Y. & LEE, C. 2013a. Study on performance and emissions of a passenger-car diesel engine fueled with butanol-diesel blends. Energy, 55, 638-646. [ Links ]

CHEN, Z., LIU, J., WU, Z. & LEE, C. 2013b. Effects of port fuel injection (PFI) of n-butanol and EGR on combustion and emissions of a direct injection diesel engine. Energy conversion and management, 76, 725-731. [ Links ]

CHUKWUEZIE, O., NWAKUBA, N., ASOEGWU, S. & NWAIGWE, K. 2017. Cetane Number Effect on Engine Performance and Gas Emission: A Review. Am J Eng Res, 6, 56-67. [ Links ]

DAMODHARAN, D., SATHIYAGNANAM, A., RANA, D., KUMAR, B. R. & SARAVANAN, S. 2017. Extraction and characterization of waste plastic oil (WPO) with the effect of n-butanol addition on the performance and emissions of a DI diesel engine fueled with WPO/diesel blends. Energy conversion and management, 131, 117-126. [ Links ]

DAMODHARAN, D., SATHIYAGNANAM, A. P, KUMAR, B. R. & GANESH, K. C. 2018. Cleaner emissions from a DI diesel engine fueled with waste plastic oil derived from municipal solid waste under the influence of n-pentanol addition, cold EGR, and injection timing. Environmental Science and Pollution Research, 1-15. [ Links ]

DEKISHIMA, Y., LAN, E. I., SHEN, C. R., CHO, K. M. & LIAO, J. C. 2011. Extending carbon chain length of 1-butanol pathway for 1-hexanol synthesis from glucose by engineered Escherichia coli. Journal of the American Chemical Society, 133, 11399-11401. [ Links ]

DEMIRBAS, A. 2004. Pyrolysis of municipal plastic wastes for recovery of gasoline-range hydrocarbons. Journal of Analytical and Applied Pyrolysis, 72, 97-102. [ Links ]

DESAI, S. H., RABINOVITCH-DEERE, C. A., FAN, Z. & ATSUMI, S. 2015. Isobutanol production from cellobionic acid in Escherichia coli. Microbial cell factories, 14, 52. [ Links ]

DEVARAJ, J., ROBINSON, Y. & GANAPATHI, P 2015. Experimental investigation of performance, emission and combustion characteristics of waste plastic pyrolysis oil blended with diethyl ether used as fuel for diesel engine. Energy, 85, 304-309. [ Links ]

FERNANDO, S. & HANNA, M. 2004. Development of a novel biofuel blend using ethanol- biodiesel- diesel microemulsions: EB-diesel. Energy & Fuels, 18, 1695-1703. [ Links ]

FORMIGHIERI, C. 2015. Cyanobacteria as a platform for direct photosynthesis-to-fuel conversion. Solar-to-fuel conversion in algae and cyanobacteria. Springer. [ Links ]

GAIDA, S. M., LIEDTKE, A., JENTGES, A. H. W., ENGELS, B. & JENNEWEIN, S. 2016. Metabolic engineering of Clostridium cellulolyticum for the production of n-butanol from crystalline cellulose. Microbial cell factories, 15, 6. [ Links ]

GEYER, R., JAMBECK, J. R. & LAW, K. L. 2017. Production, use, and fate of all plastics ever made. Science advances, 3, e1700782. [ Links ]

GHOSH, P., HICKEY, K. J. & JAFFE, S. B. 2006. Development of a detailed gasoline composition-based octane model. Industrial & engineering chemistry research, 45, 337-345. [ Links ]

GILES, L. V., CARLSTEN, C. & KOEHLE, M. S. 2012. The effect of pre-exercise diesel exhaust exposure on cycling performance and cardio-respiratory variables. Inhalation toxicology, 24, 783-789. [ Links ]

HANSEN, A. C., ZHANG, Q. & LYNE, P W. 2005. Ethanol-diesel fuel blends-a review. Bioresource technology, 96, 277-285. [ Links ]

HARLEY, R. A. & KEAN, A. J. 2004. Chemical composition of vehicle-related volatile organic compound emission in central carlifonia. USA: Departmeent of Civil and Environmental Engeneering, University of Carlifonia. [ Links ]

HESTER, R. E. & HARRISON, R. M. 2009. Air quality in urban environments, Royal Society of Chemistry. [ Links ]

HEYWOOD, J. B. 1988. Internal combustion engine fundamentals, New York, Mcgraw-Hill. [ Links ]

IÇiNGÜR, Y., Y. & ALTIPARMAK, D. 2003. Effect of fuel cetane number and injection pressure on a DI Diesel engine performance and emissions. Energy conversion and management, 44, 389-397. [ Links ]

INNES, W. B. 1981. Effect of nitrogen oxide emissions on ozone levels in metropolitan regions. Environmental science & technology, 15, 904-912. [ Links ]

JIN, C., YAO, M., LIU, H., CHIA-FON, F L. & JI, J. 2011. Progress in the production and application of n-butanol as a biofuel. Renewable and Sustainable Energy Reviews, 15, 4080-4106. [ Links ]

KIDOGUCHI, Y., YANG, C., KATO, R. & MIWA, K. 2000. Effects of fuel cetane number and aromatics on combustion process and emissions of a direct-injection diesel engine. JSAE review, 21, 469-475. [ Links ]

KIM, H. & CHOI, B. 2008. Effect of ethanol-diesel blend fuels on emission and particle size distribution in a common-rail direct injection diesel engine with warm-up catalytic converter. Renewable Energy, 33, 2222-2228. [ Links ]

KOIVISTO, E., LADOMMATOS, N. & GOLD, M. 2015. Systematic study of the effect of the hydroxyl functional group in alcohol molecules on compression ignition and exhaust gas emissions. Fuel, 153, 650-663. [ Links ]

KUMAR, B. R. & SARAVANAN, S. 2016a. Effects of iso-butanol/diesel and n-pentanol/diesel blends on performance and emissions of a DI diesel engine under premixed LTC (low temperature combustion) mode. Fuel, 170, 49-59. [ Links ]

KUMAR, B. R. & SARAVANAN, S. 2016b. Use of higher alcohol biofuels in diesel engines: A review. Renewable and Sustainable Energy Reviews, 60, 84-115. [ Links ]

KUMAR, G., SRINIVAS, G. & CH, A. K. 2013. Experimental Investigations on Diesel Engine Fueled With Tyre Pyrolysis Oil and Diesel Blends. International Journal of Emerging Trends in Engineering and Development, 1. [ Links ]

KUMAR, P S. & SANKARANARAYANAN, G. 2016. Investigation on environmental factors of waste plastics into oil and its emulsion to control the emission in DI diesel engine. Ecotoxicology and environmental safety, 134, 440-444. [ Links ]

KURTZ, E. & POLONOWSKI, C. J. 2017. The Influence of Fuel Cetane Number on Catalyst Light-Off Operation in a Modern Diesel Engine. SAE International Journal of Fuels and Lubricants, 10. [ Links ]

KUSZEWSKI, H., JAWORSKI, A. & USTRZYCKI, A. 2017. Lubricity of ethanol-diesel blends-Study with the HFRR method. Fuel, 208, 491-498. [ Links ]

KWANCHAREON, P, LUENGNARUEMITCHAI, A. & JAI-IN, S. 2007. Solubility of a diesel-biodiesel-ethanol blend, its fuel properties, and its emission characteristics from diesel engine. Fuel, 86, 1053-1061. [ Links ]

LAPUERTA, M., ARMAS, O., HERNANDEZ, J. J. & TSOLAKIS, A. 2010a. Potential for reducing emissions in a diesel engine by fuelling with conventional biodiesel and Fischer-Tropsch diesel. Fuel, 89, 3106-3113. [ Links ]

LAPUERTA, M., ARMAS, O. & RODRIGUEZ-FERNANDEZ, J. 2008. Effect of biodiesel fuels on diesel engine emissions. Progress in energy and combustion science, 34, 198-223. [ Links ]

LAPUERTA, M., GARCIA-CONTRERAS, R., CAMPOS-FERNANDEZ, J. & DORADO, M. P 2010b. Stability, lubricity, viscosity, and cold-flow properties of alcohol- diesel blends. Energy & fuels, 24, 4497-4502. [ Links ]

LAWYER, K., ICKES, A., WALLNER, T., ERTL, D., WILLIAMSON, R., MIERS, S. & NABER, J. 2013. Blend Ratio Optimization of Fuels Containing Gasoline Blendstock, Ethanol, and Higher Alcohols (C3-C6): Part I-Methodology and Scenario Definition. SAE Technical Paper. [ Links ]

LI, D.-G., ZHEN, H., XINGCAI, L., WU-GAO, Z. & JIAN-GUANG, Y. 2005. Physico-chemical properties of ethanol-diesel blend fuel and its effect on performance and emissions of diesel engines. Renewable energy, 30, 967-976. [ Links ]

LI, L., WANG, J., WANG, Z. & XIAO, J. 2015. Combustion and emission characteristics of diesel engine fueled with diesel/biodiesel/pentanol fuel blends. Fuel, 156, 211-218. [ Links ]

MANI, M., & NAGARAJAN, G, 2009. Influence of injection timing on performance, emission and combustion characteristics of a DI diesel engine running on waste plastic oil. Energy, 34, 1617-1623. [ Links ]

MANI, M., NAGARAJAN, G. & SAMPATH, S. 2011. Characterisation and effect of using waste plastic oil and diesel fuel blends in compression ignition engine. Energy, 36, 212-219. [ Links ]

MILLS, A. & ELOUALI, S. 2015. The nitric oxide ISO photocatalytic reactor system: measurement of NOx removal activity and capacity. Journal of Photochemistry and Photobiology A: Chemistry, 305, 29-36. [ Links ]

MOON, S., TSUJIMURA, T., OGUMA, M., CHEN, Z., HUANG, Z. & SAITOU, T. 2013. Mixture condition, combustion and sooting characteristics of ethanol-diesel blends in diffusion flames under various injection and ambient conditions. Fuel, 113, 128-139. [ Links ]

OFUONYE, E., KUTIN, K. & STUART, D. T. 2013. Engineering Saccharomyces cerevisiae fermentative pathways for the production of isobutanol. Biofuels, 4, 185-201. [ Links ]

OU, J., YUAN, Z., ZHENG, J., HUANG, Z., SHAO, M., LI, Z., HUANG, X., GUO, H. & LOUIE, P K. 2016. Ambient ozone control in a photochemically active region: short-term despiking or long-term attainment? Environmental science & technology, 50, 5720-5728. [ Links ]

PARK, S. H., CHA, J., KIM, H. J. & LEE, C. S. 2012. Effect of early injection strategy on spray atomization and emission reduction characteristics in bioethanol blended diesel fueled engine. Energy, 39, 375-387. [ Links ]

RAHMAN, M. M., HASSAN, M. H., KALAM, M. A., ATABANI, A. E., MEMON, L. A. & RAHMAN, S. A. 2014. Performance and emission analysis of Jatropha curcas and Moringa oleifera methyl ester fuel blends in a multi-cylinder diesel engine. Journal of Cleaner Production, 65, 304-310. [ Links ]

RAKOPOULOS, C. D., DIMARATOS, A. M., GIAKOUMIS, E. G. & RAKOPOULOS, D. C. 2010. Investigating the emissions during acceleration of a turbocharged diesel engine operating with bio-diesel or n-butanol diesel fuel blends. Energy, 35, 5173-5184. [ Links ]

RAKOPOULOS, D., RAKOPOULOS, C., KAKARAS, E. & GIAKOUMIS, E. 2008. Effects of ethanol-diesel fuel blends on the performance and exhaust emissions of heavy duty DI diesel engine. Energy Conversion and Management, 49, 3155-3162. [ Links ]

REIJNDERS, J., BOOT, M. & DE GOEY, P 2016. Impact of aromaticity and cetane number on the soot-NOx tradeoff in conventional and low temperature combustion. Fuel, 186, 24-34. [ Links ]

REN, Y., HUANG, Z., MIAO, H., DI, Y., JIANG, D., ZENG, K., LIU, B. & WANG, X. 2008. Combustion and emissions of a DI diesel engine fuelled with diesel-oxygenate blends. Fuel, 87, 2691-2697. [ Links ]

SARAVANAN, S. 2015. Effect of exhaust gas recirculation (EGR) on performance and emissions of a constant speed DI diesel engine fueled with pentanol/diesel blends. Fuel, 160, 217-226. [ Links ]

SCHEIRS, J., & KAMINSKY W, 2006. Feedstock recycling and pyrolysis of waste plastics, Chichester, UK, John Wiley & Sons. [ Links ]

SHAHIR, S., MASJUKI, H., KALAM, M., IMRAN, A., FATTAH, I. R. & SANJID, A. 2014. Feasibility of diesel- biodiesel-ethanol/bioethanol blend as existing CI engine fuel: An assessment of properties, material compatibility, safety and combustion. Renewable and Sustainable Energy Reviews, 32, 379-395. [ Links ]

SHRINIVASA, U. 2012. The evolution of diesel engines. Resonance, 17, 365-377. [ Links ]

SOLOIU, V., DUGGAN, M., HARP, S., VLCEK, B. & WILLIAMS, D. 2013. PFI (port fuel injection) of n-butanol and direct injection of biodiesel to attain LTC (low-temperature combustion) for low-emissions idling in a compression engine. Energy, 52, 143-154. [ Links ]

SZYBIST, J. P & BUNTING, B. G. 2005. Cetane number and engine speed effects on diesel HCCI performance and emissions. SAE Technical Paper. [ Links ]

TAKAHASHI, K., SEKIMOTO, M., WATANABE, H., SAITO, T., AOKI, R., SAKURAI, Y., FURUSE, T. & IMAI, S. Effects of cetane number and chemical components on diesel emissions and vehicle performance. 20th World Petroleum Congress, 2011. World Petroleum Congress. [ Links ]

TAT, M. E. 2011. Cetane number effect on the energetic and exergetic efficiency of a diesel engine fuelled with biodiesel. Fuel Processing Technology, 92, 1311-1321. [ Links ]

TUTAK, W., LUKÁCS, K., SZWAJA, S. & BERECZKY Á. 2015. Alcohol-diesel fuel combustion in the compression ignition engine. Fuel, 154, 196-206. [ Links ]

WANG, X., CHEUNG, C., DI, Y. & HUANG, Z. 2012. Diesel engine gaseous and particle emissions fueled with diesel-oxygenate blends. Fuel, 94, 317-323. [ Links ]

WATANABE, H., TAHARA, T., TAMANOUCHI, M. & IIDA, J. 1998. Study of the effects on exhaust emissions in direct injection diesel engines: Effects of fuel injection system, distillation properties and cetane number. JSAE review, 19, 21-26. [ Links ]

WEI, L., CHEUNG, C. & HUANG, Z. 2014. Effect of n-pentanol addition on the combustion, performance and emission characteristics of a direct-injection diesel engine. Energy, 70, 172-180. [ Links ]

XIAOYAN, S., YUNBO, Y., HONG, H., SHUAI, S., HONGYI, D. & RULONG, L. 2008. Combination of biodiesel-ethanol-diesel fuel blend and SCR catalyst assembly to reduce emissions from a heavy-duty diesel engine. Journal of Environmental Sciences, 20, 177-182. [ Links ]

XUE, Y., ZHOU, S., BROWN, R. C., KELKAR, A., & BAI, X, 2015. Fast pyrolysis of biomass and waste plastic in a fluidized bed reactor. Fuel, 156. [ Links ]

YANOWITZ, J., RATCLIFF M. A., MCCORMICK, R. L., TAYLOR, J. D. & MURPHY, M. J. 2017. Compendium of experimental cetane numbers. National Renewable Energy Lab.(NREL), Golden, CO (United States). [ Links ]

YILMAZ, N., VIGIL, F M., DONALDSON, A. B. & DARABSEH, T. 2014. Investigation of CI engine emissions in biodiesel-ethanol-diesel blends as a function of ethanol concentration. Fuel, 115, 790-793. [ Links ]

ZHANG, K., SAWAYA, M. R., EISENBERG, D. S. & LIAO, J. C. 2008. Expanding metabolism for biosynthesis of nonnatural alcohols. Proceedings of the National Academy of Sciences, 105, 20653-20658. [ Links ]

ZHANG, Q., YAO, M., ZHENG, Z., LIU, H. & XU, J. 2012. Experimental study of n-butanol addition on performance and emissions with diesel low temperature combustion. Energy, 47, 515-521. [ Links ]

ZHOU, C., FANG, W., XU, W., CAO, A., & WANG, R, 2014. Characteristics and the recovery potential of plastic wastes obtained from landfill mining. Journal of cleaner production, 80, 80-86. [ Links ]

ZHU, L., CHEUNG, C., ZHANG, W. & HUANG, Z. 2011. Combustion, performance and emission characteristics of a DI diesel engine fueled with ethanol-biodiesel blends. Fuel, 90, 1743-1750. [ Links ]

* Corresponding author: Tel.:+27 (0)78 418 2602 Email: ssemakulamaroa@gmail.com