Servicios Personalizados

Articulo

Indicadores

Links relacionados

-

Citado por Google

Citado por Google -

Similares en Google

Similares en Google

Compartir

Journal of Energy in Southern Africa

versión On-line ISSN 2413-3051

versión impresa ISSN 1021-447X

J. energy South. Afr. vol.26 no.4 Cape Town nov. 2015

Influence of fire-ignition methods and stove ventilation rates on gaseous and particle emissions from residential coal braziers

Tafadzwa MakoneseI, *; Daniel M MasekameniII; Harold J AnnegarnIII; Patricia B C ForbesIV

ISeTAR Centre, Faculty of Engineering & the Built Environment, University of Johannesburg, Bunting Road Campus, Johannesburg, South Africa

IIDepartment of Environmental Health, University of Johannesburg, Doornfontein Campus, Johannesburg, South Africa

IIIEnergy Institute, Cape Peninsula University of Technology, Cape Town, South Africa

IVLaboratory for Separation Science, Department of Chemistry, University of Pretoria, South Africa

ABSTRACT

Despite extensive electrification of low-income residential areas on the South African Highveld, extensive use is still made of wood and coal as domestic fuels, particularly for winter space heating. In informal settlements characterised by poverty and lacking electrification, coal is combusted in non-standardised, inefficient and polluting metal braziers, colloquially known as imbaulas. Copious emissions from domestic coal fires result in elevated household and ambient air pollution levels well above national air quality limits. Despite the severity of this pollution as a public health issue, emissions data from residential coal-burning braziers are still scarce. Consequently, there is a need to evaluate the emission characteristics of these devices. In this paper, we report on controlled combustion experiments carried out to investigate systematically influences of fire-ignition methods and stove ventilation rates on gaseous and condensed matter (smoke) emissions from informal residential coal combustion braziers. Two methods of stove ignition-conventional bottom-lit updraft (BLUD) and the top-lit updraft (TLUD) (colloquially known as the Basa njengo Magogo) were investigated. Emission factors (EFs) were found to be dependent on fire ignition method and stove ventilation rates. The top-lit ignition method reduces PM10/PM2.5 by 76% to 80% compared to the BLUD method. Carbon monoxide emissions do not change significantly with the ignition method. Pollutant emissions from normal combustion in high ventilation conditions were low compared to pollutants emitted when an oxygen deficient atmosphere was created under low ventilation conditions. High stove ventilation rates resulted in a 50% reduction in PM10/PM2.5 emissions compared to the low ventilation rates. Emissions of gaseous and particulate matter from incomplete combustion can be minimised by design optimisation of the braziers. Ideally, the emissions of condensed matter particles (which form the bulk of emitted particles in residential coal fires) can be reduced through good mixing of emitted gases and air, and by ensuring a long residence time in the high temperature oxygen rich post combustion zone, to allow for complete oxidation. This study is significant in that it presents the first systematic and comprehensive study of factors affecting emissions from coal braziers.

Keywords: household air pollution, residential coal combustion, emission factors, braziers, imbaula, improved stoves

1. Introduction

Household air pollution, primarily from cooking and heating stoves, has been identified as a major global cause of morbidity and mortality from non-communicable diseases (Lim et al. 2012). Potentially harmful combustion emissions include carbon monoxide (CO), particulate matter (PM), organic carbon (OC), elemental carbon (EC), and polycyclic aromatic hydrocarbons (PAHs) (Shen et al., 2013). Specifically, fine and ultrafine particulate matter emissions from coal combustion are receiving significant attention from regulatory authorities and environmental scientists, due to their adverse health effects (Makonese et al., 2014; Bai et al., 2011; Teramae & Takarada, 2009; Nelson, 2007; Yi et al., 2008; Bockhorn, 2000). Hence, fine particulate formation mechanisms and gas/particle partitioning, and influencing factors need to be studied in detail to develop novel combustion technologies that are less polluting (Bai et al., 2011).

Starting in the early 1980's, the large-scale electrification of the apartheid government-designated Black residential areas was regarded, at the time, as the solution to the pervasive air pollution problems associated with the use of coal and wood as domestic heating and cooking fuels. While access to electricity was welcomed as a contribution to improved quality of life and increased modernity, the hoped for coincident improvement in ambient air quality did not take place due to several reasons. The dominant reason was economic - for heating, coal is more economical than electricity, by at least a factor of two (Kimemia & Annegarn, 2011a).

In South Africa, coal fuel will continue to be a major industrial and domestic source of energy for several decades. This energy carrier will continue to be used as a primary source of energy for generation of electricity, industrialisation and for the enhancement of standard of living for the increasing population (Finkelman et al., 2002; IRP 2013). In burgeoning non-electrified informal settlements on the interior plateau of South Africa, commonly known as the Highveld, continued combustion of wood and coal in hand-fabricated braziers provides the primary domestic energy source. These braziers (colloquially known as imbaulas) are typically fabricated by punching holes in the sides of discarded metal paint drums and fitting a crude wire grid (Makonese, 2011; Kimemia et al., 2011; Le Roux, et al., 2009; Standish et al., 2007). These devices are used extensively for space heating during the winter (May-August) (Makonese, 2011; Kimemia et al., 2011b; Annegarn & Sithole, 1999). In the absence of any design optimisation, these braziers generate copious quantities of dense white smoke, composed primarily of condensed semi-volatile hydrocarbons from the pyrolysis and incomplete combustion of coal and wood. Source-apportionment studies have identified residential coal burn-ing as the greatest single source of airborne aerosols among other pollutants in South Africa's coal-burning townships (Mdluli, 2007; Scorgie et al., 2001; Annegarn et al., 1998). The levels of combustion particles are particularly high on cold, clear nights with calm winds, especially when low-lying inversion layers reduce vertical exchange of air (Bolling et al., 2012; Namork et al., 2004).

There are, to date, a dearth of reports on emission factors (EFs) from residential coal combustion, leading to uncertainties and bias in most emission inventories and predictive models (Shen et al., 2013). A compilation of EFs for residential coal combustion varied by a factor ten (Scorgie et al., 2004). The variability arises in part from the variety of parameters that influence combustion. For example, combustion technology and operational practice of appliances have a major influence on the physico-chemical properties of the emitted particles (Uski, 2014; Bølling et al., 2012; Tissari et al., 2008). Emission factors reported in the literature vary due to differences in fuel properties (e.g. moisture and volatile matter content), stove design, fire ignition methods (BLUD versus TLUD), fire management and ventilation (e.g. air supply amount and fuel-air mixing conditions) and even experimental methods (e.g. laboratory chamber, simulated stove/open burning, and field measurement) (Shen et al., 2013; Chen et al., 2012; Jetter et al., 2012; Johnson et al., 2010; Jetter & Kariher, 2009).

The aim of this paper is to report on a systematic study of some of the factors that influence emission factors from packed-bed residential coal-burning devices, namely influences of fire ignition methods and stove ventilation rates. Emission factors of PM2.5/PM10, CO, CO2, NOx, SO2 and H2S were measured for bottom-lit updraft (BLUD) and top-lit updraft (TLUD) ignition methods and for three stove ventilation rates from informal braziers. The significance of the work lies in conducting experimental procedures that confirms no-cost or low-cost interventions to reduce exposure to household air pollution (HAP) as an interim measure until implementation of universal clean sustainable energy for all (se4all, 2015).

2 Experimental methods

2.1 Experimental stoves

Emissions were measured from coal fires set in a set of three representative artisan-manufactured bra-ziers/imbaulas, purchased from users in residential areas of Johannesburg (Figure 1). Tests were conducted under laboratory conditions at the SeTAR Centre laboratory, University of Johannesburg.

Imbaula (brazier type) stoves are hand-made out of round metal drums with perforations of varying sizes around the sides, and a wire grate across the middle of the container to support the solid fuel. The imbaulas are found in three characteristic sizes, determined by three commonly available metal drums: 20 L metal paint drums- for domestic use; 70 L metal dustbins, or sectioned 200 L oil drums -for commercial purposes and typically used in street-side restaurants. In our experiments, only 20 L drums were used.

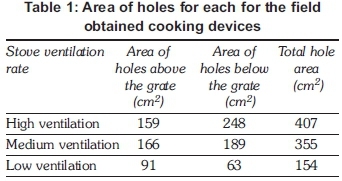

The devices for testing were selected with hole-sizes and densities to represent low, medium and high stove ventilation rates (taken as the total are of the holes). The fuel grate was kept at the same height for all three braziers. Further optimisation in terms of the location and density of holes below and above the grid was not considered at this stage of the investigation. The stove ventilation rates (hole areas) for the three field obtained braziers are given in Table 1.

2.2 Fuel analysis

Sufficiently large batches of coal were purchased to conduct a range of comparative tests, and were characterised for thermal content, elemental (proximate) analysis, moisture and ash content in third party laboratories using standard methods. The fuel samples were analysed on an air dry basis. Results for the proximate and ultimate analysis for the D-grade coal used in this study are presented in Table 1.

Prior to the experiments, the coal was crushed and sieved. Coal pieces in the range 20 mm<D<40 mm were used to minimise variability due to changes in air flow resistance in the packed bed resulting from non-uniform coal sizes. Prior to use, the fuel was stored in airtight containers. Each fuel batch was analysed for moisture content shortly before the commencement of each set of experiments.

2.3 Fire ignition methods

Two methods of igniting the coal fires were compared to the traditional bottom-lit updraft (BLUD) method, and the top-lit updraft (TLUD) method. The latter is colloquially known as the Basa njengo Magogo (BnM; it means 'to make fire like the old lady/grandmother'), and elsewhere as the Scotch fire ignition method. In the BLUD method the order of laying a fire is as follows: a few lumps of coal were added onto the grate, followed by paper, wood kindling, and then ignition, after which the bulk of the coal was added at an appropriate time after the wood fire is established. In our experiments, ~1 000 g of coal was placed onto a grate at the bottom of the brazier followed by 36 g of rolled paper and 360 g of pine wood chips. After ignition, about 2 000 g of coal was added on top of the already burning kindling (Makonese et al., 2014).

In the TLUD method, the order of laying the fire is reversed - first the bulk of coal was placed onto the fire grate followed by paper, and then wood kindling, with a few lumps of coal added on top of the already burning kindling at an appropriate time. As such, 2 000 g of coal was added to the bottom of the brazier onto the fuel grate followed by 36 g of paper and 360 g of kindling. After lighting the kindling, about 1 000 g of coal was added to the brazier above the kindling (Makonese et al., 2014).

2.4 Experimental set-up

An adaptation of the hood method (Ahuja et al., 1987) was used for evaluating emissions from coal-burning braziers. Since the experimental stoves did not have a flue, the stoves were placed under a collection hood attached to the dilution system which was responsible for the ducting and dilution of exhaust emissions (Figure 2). Since a high forced extraction flowrate may influence the combustion characteristics of the stove (Bhattacharya et al., 2002), an extractor fan was not used for drawing air through the hood and duct. The hood method can be used simultaneously with measurements for the determination of thermal parameters. This has the added advantage of enabling simultaneous meas-urements of emissions and thermal parameters in a systematic and standard manner (Zhang et al., 1999).

The sampling configuration for gases included, in sequence, a stainless steel tubing, a filter holder, and a flue gas analyser (Testo® 350XL/454) for the undiluted flue gas channel. For the diluted channel, the sampling configuration included, in sequence, the dilution system, Teflon tubing, and a second Testo® flue gas analyser. The Testo® measured CO2, CO, NOx, H2, H2S, SO2and O2. The monitor is equipped with standard measurement modules for O2, CO, and NOx. In addition to this, measurement modules for CxHy, NOlow, COlow, SO2, H2S or CO2 by infrared absorption are optionally available. The monitor uses electrochemical cells for H2S and NOx gas measurements, whilst CO2 is determined using a non-dispersive infrared cell and an oxygen balance is used for the calculation of excess air.

The sampling configuration for particulate matter included, in sequence, the SeTAR dilution system, Teflon tubing, and a particulate monitor (DustTrak DRX 8533 aerosol monitor). The DustTrak aerosol measures number-size fractions of the sampled aerosol by laser scattering. The instrument measures simultaneously in real time size-segregated fractions PM1, PM2.5, PM4, PM10, and Total Particle Mass -TPM, over a wide concentration range (0.001-150 mg m-3).

2.5 Calculations

2.5.1 Determination of fuel moisture content

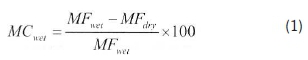

To determine the moisture content (MC) in the fuel, a small sample (~ 50 g) of the coal was weighed on a calibrated scale with 0.1 g resolution and dried in an oven at 100° C for about 24 hours. The sample was taken out and weighed again a day after the initial 24 hrs had lapsed. To check that the coal fuel had attained dry mass, the exercise was repeated every 3 hours until a steady mass was attained. The percentage moisture content was calculated using the following equation:

where MFwetis the mass of the wet fuel and MFdry is the mass of the dry fuel.

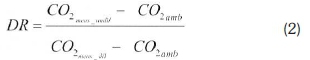

2.5.2 Determination of the dilution ratio

Carbon dioxide mixing ratios of the diluted and undiluted exhaust were measured to determine the dilution ratio. This eliminates the need for a venturi flow meter on the inlet, which has been shown to incur particle loss (Lipsky and Robinson, 2005; Hildeman et al., 1989). For the purposes of this study, dilution ratio (DR) is defined by Equation 2: where C02meas_undil is the C02 measured from the undiluted exhaust, CO2meas_dillis the CO2 concentration measured from the diluted exhaust, and CO2ambis the CO2 concentration of the ambient environment. The CO2 concentration of the undiluted exhaust is measured at the sample inlet whilst the diluted exhaust CO2 concentration is monitored at the end of the tunnel after the sample is well mixed. Separate CO2 monitors and sensors were used in the dilution channel to continuously monitor the dilution ratio of the system. Variations in the CO2 concentration of the dilution air (CO2amb) were negligible and did not impact the calculation of dilution levels based on Equation 2 (Lipsky & Robinson, 2005), which can thus be simplified to:

2.5.3 Calculating the volume of emissions

Based on the chemistry of the burned fuel (raw fuel corrected for remaining materials) the stoichiomet-ric volume of the combustion products was estimated. A gas sample was drawn from the emission stream and analysed for O2, CO2, CO, NOx, H2, SO2 and H2S content using Testo gas analysers. The volumetric concentration of each gas is multiplied by X (refers to the total air demand) to derive a total number of moles from which a total mass of each gas is calculated. The SeTAR data calculation sheet uses a chemical mass balance approach for the determination of Excess Air (EA). EA is the amount of air used in excess of the amount required for complete (stoichiometric) combustion of the fuel and is represented by Equation 4:

where O2measis the measured O2; O2measoxid is the O2required to complete the oxidation of incompletely burned gases and O2detis the total O2 in all detected gases. The determination of the total volume of emissions from the fire is affected by the volume of diluting air in the sample. The calculation of the total air demand (ʎ) is made in the following manner:

This method reflected in Equations 4 and 5 can determine the total air demand ʎ even when a water gas shift reaction is taking place in the fire.

2.5.4 Determination of emission factors

The characteristics and quantities of gaseous and particulate emissions from residential coal combustion in typical braziers were determined and emission factors reported in an extensive experimental study. A large number of gaseous and particulate components were studied for the experimental fuels and devices with systematic variations in fuel characteristics (e.g. quality and moisture content), appliance and operational properties. Special focus was on detailed characterization of the emissions of CO, CO2, NOx, H2S, SO2 and particulate matter. Statistical analyses were used to determine if there were significant differences in emission factors due to varying parameters. A two-tailed student T-test at the 95% confidence level was used for statistical evaluation of the thermal and PM data.

For the determination of gaseous emission factors, the SeTAR heterogeneous stove testing protocol relies on the carbon mass balance method, which has been previously employed for sampling open biomass combustion sources (Ward et al., 1996) and biofuels (Bertschi et al., 2003). This method relies on the ratio between pollutants and a fuel proxy (e.g. CO plus CO2) in the exhaust gas to determine an emission factor (Roden et al., 2008; 2006). This approach requires a representative sample, so either multiple points in the plume must be sampled equally, or the entire plume must be collected and well mixed before sampling (Roden et al., 2008). For our experiments, exhaust gas samples from the braziers were extracted from the exit duct above the capture hood ~ 1.0 m above the fire into Teflon tubes. This approach allows for into a Teflon tube taken initial dilution through natural plume rise and entrainment.

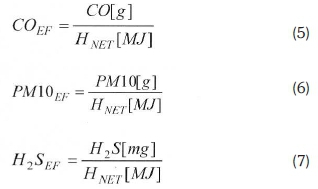

For this study, the term emission factor is defined as concentration of a gas or particulate matter emitted by the stove, expressed in parts per million volume (ppmv), normalised to 0% excess air (oxygen). This provides the concentrations in undiluted air equivalent (i.e. sufficient air to provide stoichiometric combustion). For simplicity in representing the results of the mass balance of all emissions from complete and partial combustion of the fuel, we have chosen zero per cent excess air as a reference value for emission factor reporting. It is possible to convert emissions in ppmv to other units such as [g MJ-1 or mg MJ-1] of fuel. First, there is a need to determine the net heat gained (HNET) from the fuel. This variable is the heat retained by a cooking vessel during a burn cycle and is expressed in units of Mega Joules [MJ]. It includes the heating of the pot and its contents plus the heat of evaporation of water, but excludes other heat flows through the pot, specifically radiative and convective losses from the pot sides and top.

The mass of detected PM2.5 or PM10 is first multiplied by any dilution factor applied by the equipment, then multiplied by □ to derive the total mass emitted. This method is able to track and correctly determine the performance of the stove in real time while burning fuels in an inhomogeneous manner, as is often the case with biomass and coal fuels. At a minimum, the standard reporting metrics for the particle mass concentration include mass of PM emitted per net MJ of energy delivered into the pot, or mass of PM emitted per net MJ of energy delivered from the fire. For example, the mass of CO2, CO, PM2.5 and PM10 in grams; NOx, H2S, and SO2 in milligrams emitted during a burn cycle are determined and divided by the net heat gained HNET, yielding emission factors with units of mass of emissions per net MJ [g MJ-1 or mg MJ-1]. For example:

2.5.5 Statistical analysis

An F-Test for the null hypothesis that two normal populations have the same variance was used in our data analyses. This test can be used in practice, with care, particularly where a quick check is required, and subject to associated diagnostic checking. We used large alpha levels (at least 0.05) and balanced layouts as the F-Test is relatively robust. The F-Test is used to determine the type of T-test to use (i.e. T-test: Two sample assuming equal variances or T-test: Two sample assuming unequal variances). A p-value >0.05 indicates the compared values are the same, while a p-value <0.05 indicates that the compared values differ with a 95% confidence.

The two-tailed student T-test at the 95% confidence level was applied for statistical evaluation of the emissions results from tests of the two ignition methods, and of the three stove ventilation rates.

3. Results and discussion

3.1 Effect of ignition method

Gas emission factors for the field-designed stoves, using D-grade coal, for top-lit and bottom-lit methods are presented in Table 3, together with a statistical comparison of the differences. The emission factors are based on integration over the combustion cycle, from ignition until three hours had elapsed, or fuel burnout occurred, whichever was the soonest.

When comparing the TLUD and BLUD ignition methods, there are no statistically significant differences (p>0.05) in CO emission factors at high and medium ventilation rates. However, there was found to be a significant difference (p<0.05) in CO emission factors between the fire-ignition methods at low ventilation rates (Table 3) - there was a 20% increase in CO when using the TLUD method. This result is rather counterintuitive - it is expected that CO emissions will increase with poor stove ventilation rates (typical of BLUD fires). In the absence of sufficient oxygen, CO formed by oxysorption on the surface of the char is unable to further oxidise to CO2and as result high CO emissions are detected in the flue gas. Thus, a lack of oxygen results in smouldering combustion conditions which favour the emission of products of incomplete combustion, including CO. Further detailed explanations need to be sought to explain this anomaly.

CO2emissions do not show significant differences with a change in the ignition method. This is because CO2 emissions are dependent on the carbon content of the coal, and since the fuel was taken from the same batch, little to no change in total CO2emissions is expected. CO is influenced by poor combustion conditions during initial phases of pyrolization, but the majority of CO arises during coking combustion (Figure 3).

Emission factors of NOx, SO2and H2S show statistically significant differences between ignition methods. The use of the TLUD method resulted in a 13% decrease in NOx emissions and an average 65% and 90% reduction in SO2 and H2S emissions, respectively (Table 3). SO2emissions from the BLUD method were three-fold higher compared to the TLUD method, whereas H2S EFs were ten-fold higher in the BLUD compared to the TLUD method. This indicates that the TLUD ignition method has potential to reduce the amount of SO2and H2S emitted to the atmosphere during residential coal combustion. Different results to the ones reported in this study on the dependence of H2S and SO2emission on the fire-ignition method have been reported in the literature. Le Roux et al. (2009) found that the ignition method does not have an influence on SO2emissions.

Our results for NOx, SO2and H2S emissions are counterintuitive, for which further explanation has to be sought. It is expected that NOx, SO2and H2S emissions do not vary significantly with the ignition method, when other parameters are held constant. Total sulphur emissions (SO2+ H2S) are a constant that is dependent on the sulphur content of the coal and, based on mass conservation, ought not to vary significantly if the coal is taken from the same batch and combusted to completion. However, the ratio of SO2 and H2S could vary, depending on combustion conditions. H2S formation is enhanced in the restricted oxygen environment of the BLUD ignition method (i.e. with the rising column of hot gases including N2, CO2, H2O, H2 and CO during coal pyrolysis, sulphur competes with hydrogen for available oxygen, and may combine with H+ to form H2S). The resultant total emission factors should indicate an enhancement of H2S with a corresponding decrease in SO2 emissions, and vice versa for the respective ignition methods. However, results presented here show that the sum of H2S and SO2 gases do not show S mass conservation, indicating possible systematic errors in the analysis or processing of obtained data. The total S recovered is 2% to 6% of the S as analysed in the fuel (See Section 2.2 for results on fuel analysis) for the BLUD and the TLUD ignition methods, respective-ly. Based on principles of conservation of mass, the total S recovered from the analysis should be similar to the S as analysed in the elemental content of the fuel. There is a need to analyse the remaining ash for S content to see how much of it remained in the ash especially for TLUD fires. A reason for this anomaly could be that no attempt was made in this study to homogenise the received fuel samples (about 1 000 kg of fuel) and this could have resulted in significant variations in the resultant emission factors. In future evaluations, one could first homogenise the received fuel sample and store it under a dry nitrogen atmosphere.

During the combustion experiments, we noticed that emissions of SO2and H2S were released early in the combustion cycle, with a single peak emission rate for each gas during the first hour of combustion. This is in contrast to CO and PM emissions that showed were released in varying amounts throughout the burn cycle, Figure 4 shows an emissions time graph of H2S and SO2-indicating that H2S forms during the pyrolization phase and is low during coking phase. During the coking phase, when sufficient O2 is available, SO2 dominates the low residual S emissions. The emission of these pollutants decreased gradually after their emission peaks, indicating H2S and SO2 may be the dominant precursors/catalysts for the formation of organic condensation particles during the ignition phase (Wang et al., 2012).

Particle emission factors for the laboratory designed stoves, using D-grade coal, for TLUD and BLUD ignition methods are presented in Table 4, together with a statistical evaluation of the differences. The emission factors, expressed as particulate mass per MJ of energy in the combusted fuel, are based on integration over the combustion cycle from ignition until three hours had elapsed, or fuel burnout, whichever was the soonest.

From Table 4, it can be seen that PM2.5 emissions constitute more than 90% of PM10 emissions. There are statistically significant differences (p<0.05) in PM emission factors between the fire-ignition methods. The top-lit ignition method reduces PM10/PM2.5 by 76% to 80% compared to the BLUD method. This result is similar to assertions made by Le Roux et al. (2009) who found a reduction in particulate emissions of between 78% and 92% when using the TLUD ignition method. However, Le Roux et al. (2009) do not specify ventilation rate of their single tested device, nor on coal moisture and coal lump size.

3.2 Effects of ventilation rates

The effect of ventilation rates on the emissions of CO, CO2, SO2 and H2S were investigated. Three stoves with different ventilation rates were used for each ignition method, with moisture content and other parameters held constant. The results of these experiments for three field-acquired braziers are presented in Table 5.

When comparing the high and medium ventilation rates, results show that there is a significant difference (p<0.05) in CO emissions, but not for CO2, SO2 and H2S emissions. When comparing medium and low ventilation rates, there are no significant differences (p>0.05) between the respective emissions of CO, CO2, SO2 and H2S. When comparing the high and low ventilation rates, results show that there is a significant difference (p<0.05) in CO emissions, but not for CO2, SO2 and H2S emissions. This shows that ventilation rates of the tested devices influence CO emissions, but may not affect the combustion characteristics of CO2, SO2 and H2S.

The effect of ventilation rates on the emissions of PM10 is investigated. Three stoves with different ventilation rates were evaluated for each ignition method, with moisture content and other parameters held constant. The results of the experiments for the lab-designed braziers are presented in Table 6.

When comparing high and medium stove ventilation rates, results show that there are significant differences (p<0.05) in PM10 emissions for both ignition methods. However, when comparing medium and low ventilation rates, results show that there are no significant differences (p>0.05) in PM10 emissions for either ignition method. For the high and low stove ventilation rates, results show that there are significant differences (p<0.05) in PM10 emissions for both ignition methods. The trends are that the more air holes there are in a brazier, the less the particulate emissions. A change from low to high stove ventilation rates result in a 50% reduction of particulate emissions. However, the reduction due to increased ventilation is not as great as the reduction due the switch to the top-lit ignition method. A well ventilated brazier when used in conjunction with the TLUD ignition method has the potential to have the maximum reduction of PM emissions from coal fires in informal braziers. It should be noted that the range of ventilation hole areas as defined in this study, were based on representative samples collected from field observations and as such, these potential reductions can be applied in estimating benefits that could be obtained in implementation campaigns.

The performance of the braziers can be improved by increasing ventilation through the fuel bed. An increase in the oxygen content allows for improved combustion conditions and increased combustion temperatures that can lead to improved heat transfer. If excess air is limited, inefficient combustion results with consequent increased emissions of products of incomplete combustion including soot (black carbon), smoke, and carbon monoxide. Conversely, relatively high excess air can lower the combustion efficiency-excessive airflow rates/ high ventilation rates may increase the convective cooling of the fire, thereby affecting the mixing and local concentration of fuel/oxidant in the gas stream. In addition, air velocity rates may directly affect the reaction rate of the condensed phase. As such, a balance should be found between providing the optimal amount of excess air. The most important issue in combustion research is the improvement of combustion efficiency to minimise the emission of harmful pollutants. Increased ventilation in a stove may also be achieved by using forced draft/ ventilation, as in some wood pellet and biomass burning gasifiers. However, this option is not viable on brazier stoves. The target market for these stoves remains the low-income (energy poor) households situated on the Highveld region of South Africa.

The significant effect of stove ventilation rates and fire-ignition methods on the gaseous and condensed matter (smoke) emission factors observed in this study highlights the vital role of these parameters in the performance evaluation. For future tests and performance evaluation exercises, testing protocols should specify or restrict stove ventilation rates and ignition methods to be used, to avoid any bias that may emanate from different stove ventilation rates and fire-ignition methods. For example, prediction models are used to estimate the amount of pollutant emissions in a given geographical location, and the estimates are based on emission factors from actual stove tests. As such, it is recommended that stove ventilation rates and the ignition methods employed should be evaluated through extensive field surveys in the estimation of pollutant emission factors to be used in the models.

4 Conclusion

In this study, the impacts of fire ignition methods and ventilation rates on the emissions of gaseous and condensed matter (smoke) particles were investigated. Measured gaseous and PM emission factors were significantly different with changes in the ignition method and stove ventilation rates. Emissions of gaseous and particulate matter from incomplete combustion can be minimised by design optimisation of the braziers. Ideally, the emissions of condensed matter particles (which form the bulk of emitted particles in residential coal fires) can be reduced by allowing for good mixing between the volatile gas from the fuel bed and the air supply and by ensuring a long residence time in the high temperature oxygen rich post combustor zone to allow for complete oxidation. Thus a brazier/imbaula with high ventilation rates has a potential to reduce emissions of CO and PM. However, results presented herein provide useful information on the important role of ignition method and ventilation rates in the performance evaluation of cookstoves, and how the emission factors obtained from these evaluations may be used in accurate prediction of total emissions.

Further studies are needed to understand the influences of other combustion parameters on emission performance of fixed-bed residential coal burning devices. Reported low, medium and high ventilation rates were based on the empirical observations of stoves in use. Future improvements could explore additional factors that include varying the size of ventilation holes, and location density above or below the fuel bed, and the median size and size distribution of the fuel. We kept the fuel median size and size distribution constant between 20 mm and 40 mm throughout the course of this study. There is a need to investigate the effect of hole density pattern on ventilation rates by clustering primary air holes below the fuel grate and a limited number of secondary air holes above the level of the packed fuel bed. Repeats of experiments are needed to determine whether anomalies found in this study are reproducible or not and to determine the range of emission factors when repeating experiments under the same operating conditions.

Acknowledgements

This work was supported financially by the University of Johannesburg through a URC/Faculty of Science grant to the SeTAR Centre, and in part from a grant from the Global Alliance for Clean Cookstoves (GACC) to the SeTAR Centre as a Regional Stove Testing and Development Centre. The authors thank Thokozile Sithole and David Kimemia for their assistance with the combustion experiments and Crispin Pemberton-Pigott for part analysis of the data.

References

Ahuja, D. R., Veena, J., Smith, K. R., and Venkataraman, C. (1987). Thermal performance and emission characteristics of unvented biomass-burning cook-stoves: A proposed standard method for evaluation, Biomass, 12:247-270. [ Links ]

Annegarn, H. J., Grant, M. R., Kneen, M. A., and Scorgie, Y. (1998). Direct source apportionment of particulate pollution within a township. Low-Smoke Coal Programme: Draft of final report. Report No. AER98.117DME, Department of Minerals and Energy, Pretoria. [ Links ]

Annegarn, H. J., and Sithole, J. S. (1999). Soweto Air Monitoring Project (SAM). Quarterly Report to the Department of Minerals and Energy, Report No. AER 20.001 Q-SAM, University of Witwatersrand, Johannesburg. [ Links ]

Bai, H., Ma, Y., Ai, X., Li, H., Liu, P, and Cang, D. (2011). Chemical and morphological properties of particulate matter generated from coal-fired circulating fluidized bed boiler, Third International Conference on Measuring Technology and Mechatronics Automation, IEEE computer society; doi:10.1109/ICMTMA.2011.179. [ Links ]

Bertschi, I. T., Yokelson, R. J., Ward, D. E., Christian, T. J., and Hao, W. M. (2003). Trace gas emissions from the production and use of domestic biofuels in Zambia measured by open-path Fourier transform infrared spectroscopy, Journal of Geophysical Research-Atmospheres, 108; doi:10.1029/2002JD002158. [ Links ]

Bhattacharya, S. C., Albina, D. O., and Salam, P A. (2002). Emission factors of wood and charcoal-fired cookstoves, Biomass and Bioenergy, 23:453-469. [ Links ]

Bockhorn, H. (2000). Ultrafine particles from combustion sources: Approaches to what we want to know, Mathematical, Physical and Engineering Sciences, 358:2659-2672. [ Links ]

B0lling, A. K., Totlandsdal, A. I., Sallsten, G. et al. (2012). Wood smoke particles from different combustion phases induce similar pro-inflammatory effects in a co-culture of monocyte and pneumocyte cell lines, Particle & Fibre Toxicology, 9:45; doi:10.1186/1743-8977-9-45. [ Links ]

Chen, L. W. A., Verburg, P., Shackeelford, A. et al. (2010). Moisture effects on carbon and nitrogen emission from burning of wildland biomass, Atmospheric Chemistry & Physics, 10(14):6617-6625. [ Links ]

Chen, Y. J., Roden, C. A., and Bond, T. C. (2012). Characterizing biofuel combustion with patterns of real-time emission data (PaRTED), Environmental Science & Technology, 46(11):6110-6117. [ Links ]

Finkelman, R. B., Orem, W., Castranova, V. et al. (2002). Health Impacts of Coal and Coal Use: Possible Solution, International Journal of Coal Geology, 50:425-443. [ Links ]

Hildeman, L. M., Cass, G. R., and Markowski, G. R. (1989). A dilution stack sampler for collection of organic aerosol emissions: design, characterization and field tests, Aerosol Science & Technology, 10:193-204. [ Links ]

IRP (2013). Integrated Resource Plan For Electricity (IRP) 2010-2030 Update Report 2Ú13, Department of Energy, Pretoria. http://www.doe-irp.co.za (Accessed 27 May 2015). [ Links ]

Jetter, J. J., and Kariher, P (2009). Solid-fuel household cook stoves: Characterisation of performance and emissions, Biomass and Bioenergy, 33:294-305. [ Links ]

Jetter, J., Zhao, Y., Smith, K. R., Khan, B., Yelverton, T., DeCarlo, P, and Hays, M. D. (2012). Pollutant emissions and energy efficiency under controlled conditions for household biomass cookstoves and implications for metrics useful in setting international test standards, Environmental Science & Technology, 46(19):10827-10834. [ Links ]

Johnson, M., Edwards, R., Berrueta, V, and Masera, O. (2010). New approaches to performance testing of improved cookstoves, Environmental Science & Technology, 44:368-374. [ Links ]

Kimemia, D., and Annegarn H. J. (2011a). An urban biomass energy economy in Johannesburg, South Africa, Energy for Sustainable Development, 15(4):382-387. [ Links ]

Kimemia, D. K., Annegarn, H. J., Robinson, J., Pemberton-Pigott, C., and Molapo, V (2011b), Optimising the imbaula stove, Domestic Energy Use (DUE) Conference, 04 April 2011, Cape Peninsula University of Technology, Cape Town, South Africa. [ Links ]

Le Roux, L. J., Zunckel, M., and McCormick, S. (2009), Reduction in air pollution using the 'Basa njengo Magogo' method and the applicability to low-smoke fuels, Journal of Energy in Southern Africa, 20(3):3-10. [ Links ]

Lim, S. S., Vos, T., Flaxman, A. D. et al. (2012). A comparative risk assessment of burden of disease and injury attributable to 67 risk factor clusters in 21 regions, 1990-2010: a systematic analysis for the Global Burden of Disease Study 2010, Lancet, 380:2224-2260. [ Links ]

Lipsky, E. M. E., and Robinson, A. (2005). Design and evaluation of a portable dilution sampling system for measuring fine particle emissions from combustion systems, Aerosol Science & Technology, 39:542-553. [ Links ]

Makonese, T. (2011). Protocols for thermal and emissions performance testing of domestic fuels and stoves, MSc Thesis, University of Johannesburg, South Africa. [ Links ]

Makonese, T., Forbes, P., Mudau, L., and Annegarn, H. J. (2014). Aerosol particle morphology of residential coal combustion smoke, The Clean Air Journal, 24(2): 24-28. [ Links ]

Mdluli T. N. (2007). The societal dimensions of domestic coal combustion: People's perceptions and indoor aerosol monitoring, PhD Thesis, University of the Witwatersrand, Johannesburg. [ Links ]

Namork, E., Kururp, V. P., Aasvang, G. M., and Johansen, B. V. (2004). Detection of latex allergens by immuno-electron microscopy in ambient air (PM10) monitored in Oslo, Norway (1997-2003), Journal of Environmental Health, 67:20-26. [ Links ]

Nelson, P. F. (2007). Trace metal emissions in fine particles from coal combustion, Energy & Fuels, 21:477-484. [ Links ]

Roden, C. A., Bond, T. C., Conway, S., and Pinel, A. B. O. (2006). Emission factors and real-time optical properties of particles emitted from traditional wood burning cookstoves, Environmental Science & Technology, 40(21):6750-6757. [ Links ]

Roden, C. A., Bond, T. C., Conway, S., Pinel, A. B. O., MacCarty, N., and Still, D. (2008). Laboratory and field investigations of particulate and carbon monoxide emissions from traditional and improved cook-stoves, Atmospheric Environment, xxx:1-12. [ Links ]

Scorgie, Y., Annegarn, H., and Burger, L. (2004). Study to Examine the Potential Socio-Economic Impact of Measures to Reduce Air Pollution from Combustion. Report to Fund For Research into Industrial Development Growth and Equity (FRIDGE), Trade and Industry Chamber, Johannesburg. [ Links ]

Scorgie, Y, Burger, L. W., and Sowden, M. (2001). Analysis, synthesis and consolidation of the Qalabotjha and Embalenhle experiments, including other investigations. Report No. EMS/01/DME-01, Department of Minerals and Energy, Pretoria. [ Links ]

Shen, G., Xue, M., Wei, S., Chen, Y., Zhao, Q., Li, B., Wu, H., and Tao, S. (2013). Influence of fuel moisture, charge size, feeding rate and ventilation conditions on the emissions of PM, OC, EC, parent PAHs, and their derivatives from residential wood combustion, Journal of Environmental Sciences, 25(9):1808-1816. [ Links ]

Standish, B., Leiman, A., Boting, A., and van Zyl, H. (2007). Reducing the health care costs of urban air pollution: The South African experience, Journal of Environmental Management, 84:27-37. [ Links ]

se4all (2015). Sustainable Energy for All, a partnership programme between the United Nations and the World Bank. http://www.se4all.org (Accessed 27 May 2015). [ Links ]

Teramae, T., and Takarada, T. (2009). Fine Ash formation during Pulverized Coal Combustion, Energy & Fuels, 23:2018-2024. [ Links ]

Tissari, J. (2008). Fine particle emissions from residential wood combustion, PhD Thesis, University of Kuopio, Finland. [ Links ]

Uski, O. (2014). Toxicological effects of fine particles from small-scale biomass combustion, PhD Thesis, University of Eastern Finland, Finland. [ Links ]

Wang, X., Watson, J. G., Chow, J. C., Gronstal, S., and Kohl, S. D. (2012). An efficient multipollutant system for measuring real-world emissions from stationary and mobile sources, Aerosol & Air Quality Research, 12:145-160. [ Links ]

Ward, D. E., Hao,W. M., Susott, R. A., Babbitt, R. E., Shea, R. W., Kauffman, J. B., and Justice, C. O. (1996), Effect of fuel composition on combustion efficiency and emission factors for African savannah ecosystems, Journal of Geophysical Research-Atmospheres, 101:23569-23576. [ Links ]

Yi, H., Hao. J., Duan, L., Tang, X., Ning, P, and Li, X. (2008). Fine particle and trace element emissions from an anthracite coal-fired power plant equipped with a bag-house in China, Fuel, 87:2050-2057. [ Links ]

Zhang, J., Smith, K. R., Uma, R., Ma, Y., Kishore, V V. N., Lata, K., Khalil, M. A. K., Rasmussen, R. A., and Thorneloe, S. T. (1999). Carbon monoxide from cookstoves in developing countries: 1. emission factors, Chemosphere: Global Change Science, 1:353-366. [ Links ]

Received 1 June 2015

Revised 11 November 2015

* Corresponding author: taffywandi@gmail.com