Serviços Personalizados

Artigo

Indicadores

Links relacionados

-

Citado por Google

Citado por Google -

Similares em Google

Similares em Google

Compartilhar

Journal of Energy in Southern Africa

versão On-line ISSN 2413-3051

versão impressa ISSN 1021-447X

J. energy South. Afr. vol.25 no.2 Cape Town Mai. 2014

Challenges in household energisation and the poor

Philip Lloyd

Energy Institute, Cape Peninsula University of Technology, Cape Town, South Africa

ABSTRACT

While the electrification of households in South Africa since 1994 has been impressive, many of the major energy services in poor households are still met by traditional fuels such as, on the Highveld, coal; in coastal regions, paraffin; and in rural areas by wood. Their use is associated with a range of challenges, from chronic respiratory tract infections to asphyxiation by carbon monoxide to massive fires that destroy not only homes but also lives. State interventions such as the provision of Free Basic Electricity are costly and do not appear to be contributing towards any solutions. The challenges are assessed, and a range of mitigations proposed.

Keywords: electrification, poverty, coal, paraffin, fuelwood, Free Basic Electricity, indoor air pollution, fires, informal settlements

Introduction

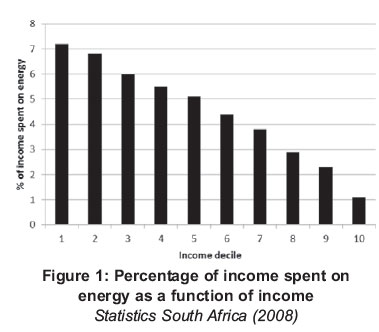

Every household needs energy services. The most basic services involve cooking, probably followed by lighting, water heating and space heating, although the need for space heating depends largely on the local climate. Every householder faces decisions as to how to obtain these services. For the wealthier, convenience is almost as important as cost; for the poor, cost dominates. This is not surprising, as it is clear that the proportion of household income expended on energy services is greater in poorer households than in wealthier. Many wealthy homes will not expend more than about 2% of their income on their energy services; in the poorest homes, as much as 7% of their income is devoted to cooking and staying warm. In disposable income terms, the proportion is much higher.

Studies of the very poorest homes have shown that, where climatic conditions are such that space heating is not vital, a minimum of about 1000MJ of energy per month suffices for basic needs. Where space heating is vital, then the home must find a minimum of about 4000MJ per month (Williams, 2004). The question facing the householder is how best to access this energy at the lowest possible cost. The decisions made have a major impact on life and health. Household energisation is therefore a very significant contributor to the ongoing trap of poverty. Accordingly, in this contribution we study the nature of the decisions facing the poorest householder, and the impacts on life and health.

Options for meeting the basic energy needs Rural

In rural areas, the poorest homes can still access biomass, which is generally a 'free' fuel, although, in places where population growth has increased the demand on this fuel, it can start to take on a cash value. But whilst it is generally free, collecting the fuel involves commitments in time and energy that are far larger than many realize. In studies in rural KwaZulu-Natal (Statistics South Africa, 2008) harvesting of fuel wood started as early as 02h00 and finished as late as 23h00. In winter, wood consumption averaged about 600kg/month although some households got by with about 300kg/month. In summer, the consumption was about half that of winter. The wood was rarely completely dry, so probably had a higher calorific value of the order of 12-13MJ/kg.

While this rural community relied largely on wood for its energisation, it made use of other fuels, particularly paraffin, primarily for cooking when it was raining. More than 10% of the homes had an LP gas cylinder, used for cooking on social occasions. This was remarkable, as the nearest source of gas was nearly 40 km away.

In the 2007 Household Survey (Williams, 1994), 13% of all households reported cooking on wood and nearly 20% relied on wood for space heating. Nearly 10% of all homes had no space heating at all. There was no direct disaggregation into rural and urban populations, but the provinces having the largest rural population made up the bulk of the wood users. For instance, in Limpopo, 52.5% of the population cook on wood, 24% in the Eastern Cape and 19% in each of Mpumalanga and KwaZulu-Natal. One reason why the wood use in Mpumalanga and KwaZulu-Natal is lower than in the other two rural provinces may be that over 10% of the homes in each province cook on coal.

Urban - coal

To turn now to the urban environment, there are marked geographic differences. On the Highveld (i.e. most of Mpumalanga, Limpopo, Gauteng, North West and Free State) and in parts of KwaZulu-Natal, coal is widely employed among the poor for cooking and space heating. The poorest employ an mbaula, a metal drum with a simple grid to support the coal, and holes in the side of the drum to admit air. Typically the mbaula is lit outdoors, and allowed to burn until it has almost finished smoking. It can then be used either outdoors or indoors for cooking, and finally is taken indoors for heating. As there are rarely chimneys in the homes, indoor air conditions with open braziers of coal burning for warmth are appalling. Some measurements revealed as much as 1600ppmv CO (2000mg/m3), well above levels at which fatalities are observed (WHO, 2010). Indeed, in winter in the Highveld, studies of death notices in the Soweto, Johannesburg, newspapers in the 1990's showed that, during the winter months, there were typically three families a week in which every member died 'accidentally' during the night.1

However, the problems caused by mbaulas are self-evident, and most families, as soon as they are able, invest in a cast-iron stove. These stoves were actually designed as wood burners - the hearth is long and narrow to accept pieces of wood - but they burn coal satisfactorily once it is lit and has been burning for a while. During the initial phase of combustion, however, the fire smokes badly, and it is only once flames are observed over the whole bed of coal that smoke emission dies down. Eventually the flames die down and there is more smoke, albeit at a far lower level than soon after ignition. The stoves have chimneys, so the smoke does not affect the indoor air quality severely - but on a cold Highveld day in the townships, it can be dark at noon from all the smoke.

The smoke not only presents a health hazard (it is rich in polyaromatic hydrocarbons), but it also represents an economic loss. Captured smoke amounted to about 15% by mass of the coal but carried over 20% of the heat content of the unheated coal.

The coal that is burned is of surprisingly high quality. The users will not accept less than a B grade, and prefer A grade.2 The size is also important. The mbaula requires a -75+25mm 'cobble';3 anything smaller creates too large a pressure drop and cuts the air flow, so preventing efficient burning. The stove needs a -25+12mm 'nut'; the addition of the chimney improves the draft and so allows a smaller coal to be used. Of course, this requires the chimney to be in reasonable condition. Unfortunately, most chimneys are made from galvanized steel <1mm thick, and are soon holed. Replacements are surprisingly costly, so users tend to adapt to poor burning until the chimney has almost collapsed.

The distribution of coal is an industry in itself (Qase et al., 2000). About five mines produce the coal, which is stockpiled during the summer months. The first cold day of winter sees queues of 30t coal trucks at the entrance to each mine. The trucks deliver primarily to individual merchants, but about 30% of the coal goes to wholesalers. The coal is primarily sold bagged in 50 kg sacks, and usually screened in some way before bagging, to remove most of the fine material generated during transport. In country towns, the fines are sometimes added to dung cakes to improve their combustibility. House-to-house deliveries are via a light truck or horse-drawn cart. Coal consumption is several bags a month in winter and usually less than a bag a month in summer, per household (Qase et al., 2000). Some break-bulk occurs, with a street market in 5 and 10 litre paint cans or hubcaps full of coal.

A really remarkable finding was that the cast-iron stove was one of the earliest purchases many recent migrants to the cities made. A second-hand stove sold for at least R2 000; an entry-level new one cost R4 000. Many coal merchants ran micro financing schemes to assist householders to purchase the appliances. Investigation gave some indication of why such expensive units were desired. They were multi-purpose, providing cooking, space and water heating, and even garbage disposal. Examination of the Soweto waste stream in winter showed that it contained essentially no combustibles (Personal communication, 1993). But above all the cast-iron stove provided a social centre, where people would meet.

In total, households consume about 1 million tons of coal annually (Qase et al., 2000). The inefficient combustion means that this tiny fraction of all coal burned in South Africa is responsible for 40% of the total particulate load in South African skies.

Urban - fuels other than coal

Outside the areas with ready access to coal, paraffin (kerosene) is the urban choice of fuel. It is burned primarily in wick stoves and heaters, although about 1 in 10 paraffin users have a pressurized appliance of the Primus type. About 400 000t of paraffin reaches this market annually, and the average user burns about 5 litres per month.

The problems paraffin use causes are manifold. Because much is sold in litre or smaller lots, not only is there risk of contamination, but ingestion is common. Children associate such bottles with cool drinks, and if they drink it, there is a risk of choking, when a few ml reaches the lungs. The paraffin attacks the lining of the lungs, and causes pneumonia that often leads to death.

The problems caused by the appliances are even more severe. The wick stoves in particular suffer from numerous design deficiencies. They can heat the fuel in the fuel tank to above the flash point, and if that occurs there is a risk of a very severe fire, in which the hot paraffin burns at a rate sufficient to give over 1MW. At that heat rate, the temperature inside a typical home will exceed 400oC within 40 seconds, and the home will be destroyed within 15 minutes. The radiant heat from such a fire will ignite nearby structures, so that it is not uncommon for 'shack fires' to involve several hundred dwellings at a time. There are no official statistics, but it is estimated that between 50 000 and 100 000 homes are destroyed annually in South Africa in this way. In one township, Duncan Village (a suburb of East London), some residents had seen their homes incinerated every year for four years.

The ferocity of these fires is such that people are regularly trapped inside their homes. In one study, it was found that it was rare to find more than one infant surviving such a fire - the parents did not have time to save more than one child. Several thousand die annually, and more suffer extensive burns. In Cape Town, the Red Cross Children's Hospital has developed a worldwide reputation for its skill in rehabilitating severely burned children. The Paraffin Safety Association has co-operated with several hospitals to establish a database of burn injuries - while there is a high degree of paraffin-related injuries, a surprising number come from other sources, including electricity, and burns from cooking utensils that are knocked or pulled over are common.

The safety of the appliances has been addressed by the SA Bureau of Standards. SANS 1908 and 1243 concern non-pressure and pressure-type appliances respectively. Both standards are now compulsory in terms of the regulations of the National Regulator of Compulsory Standards. Frustratingly, appliances meeting these standards have not been developed, and accordingly, there is a black market in illegal, unsafe appliances. Actions to seize and destroy imported cargoes have been widely publicized, but the trade continues. The only effect of the standards has been to push up the price of the illegal units. A stove used to cost about R25; it now costs over R100. The metal in these appliances is typically a 0.3mm sheet, and it corrodes rapidly in use. The life is further shortened by the owner using water to extinguish the flame that persists after the appliance is nominally switched off. Few appliances have a lifetime of more than 6 months if used daily. Towards the end of their life, the risk of fire increases substantially due to mechanical failure of the corroded parts.

In spite of these risks - which are widely recognized by the users, even in country districts (Williams, 1994) - the wick stoves meet the needs of the poor. One of their features is that, unlike the somewhat better designed pressure stoves, the heat can be reduced to permit simmering. As many staples require slow cooking, this feature means that the wick stoves are preferred and are actually more economical in use even though they are significantly less efficient thermally than the pressure stoves.

Another feature making paraffin the fuel of choice is the ability of users to trade in cupfuls of paraffin. Indeed, this is an often unrecognized need of the very poor - by the very nature of poverty, they may need to have energy supplies in very small quantities to cope with daily needs. Paraffin allows this readily, and we have already seen how coal can be sold in hubcaps full. It is one of the disadvantages of the next fuel we must consider, namely liquefied petroleum gas, known as LP gas or LPG.

Comparatively little LPG reaches the poor, which is surprising, as other societies at a stage of development similar to South Africa have found it the urban fuel of choice (Lloyd & Rukarto, 2001). The primary reason for this is the cost of LPG. The distribution chain from refinery to market place is multi-stage, with mark-ups at each stage. In one study, it was found that in China the street price was ~10% above the refinery gate price; in South Africa, it was ~250% of the refinery gate price. Part of the problem is the limited size of the market; part is monopolistic practices justified on grounds of safety (the safety record of LPG is exemplary, and highlights the hazards of paraffin); and in part it is the result of distribution having developed to service the LSM 5-7 group rather than the poor. The last could be considered a hangover from the days of apartheid. The Department of Energy is aware of the difficulty, but has failed to address the challenge since its first attempt in 1998. At present only about 100 000t/a finds its way into the whole of the domestic market.

The benefits of the use of LPG were apparent in 2007 when power from the nuclear reactor at Koeberg was lost. Eskom arranged to swop 100 000 cheap electric stoves for an LPG supply complete with cooker. The initiative saved 40MW of peak power, but stumbled when, in spite of demand, the petroleum industry could not supply.

Possibly because of the low national demand, the supply of LPG is limited. The only storage is an almost insignificant 5 000t at Richards Bay, a port on South Africa's east coast. Environmental approval has recently been granted for the construction of a 10 000t store at Saldanha on the west coast, and trial imports have already taken place. A company called Wild Orchard has set up a distribution network to supply gas in 5 kg cylinders to townships in the Cape at a price significantly below normal retail. This has not been without significant challenges. For instance, it was necessary to establish a store for a few hundred cylinders. The store required fire department permission, which could not be granted because the store was in an informal township, and not located on an identifiable stand. Work is in progress to allow the fire department to use GPS co-ordinates rather than stand numbers for location purposes.

There seems little doubt that if the logistics of getting LPG to low-income homes economically can be resolved, it will become the fuel of choice. It is significantly cleaner and much safer than paraffin. A range of affordable appliances can be fitted to a single cylinder. The appliances are generally more efficient than the alternatives. Control of the heat is simple and direct.

Wood finds some use in the urban environment. Some townships 'harvest' broken pallets from nearby industries. Removal of invasive acacia species under the "Working for Water" Programme has stimulated an industry in harvesting the cut timber for fuel, but this is probably only a short-term venture. There is concern about chemical preservatives in industrial timber collected as fuel, and its use in open fires for cooking is discouraged. However, because of limited availability, wood does not feature strongly in towns.

We must consider electricity. The electrification programme since 1992 has been an outstanding success. Nearly 80% of all households have access to grid electricity. However, the impact has been significantly less than was originally expected. A recent review (Lloyd, 2012) showed how uptake was slow for nearly a decade after first gaining access to electricity. The first use was for lighting and low power appliances such as entertainment and communications. Household demand was often less than the 50kWh/month of free basic electricity. After a year or so, small appliances such as kettles and irons came into use, and household use grew to the order of 150kWh/month. It took several more years before larger white goods such as refrigerators became common, and use grew to the order of 300kWh/month.

This slow uptake caused some grave problems. Both Eskom and municipalities invested quite heavily in the distribution infrastructure. Thereafter the revenue stream was far lower than had been anticipated, and there was considerable financial stress, particularly at the municipal level. The problem was exacerbated by the fact that many municipalities use electricity revenue to subsidize other municipal services. Lower-than-expected electricity revenues therefore had repercussions across the whole realm of service delivery. The fact that some households were being subsidized with free basic electricity aggravated the problem.

These problems are still being worked out. The Government has made several attempts to resolve the problems of the distribution industry. In 2008 the company EDI Holdings, which had been set up to oversee the restructuring of the industry, estimated there was a R25 billion shortfall in maintenance and refurbishment of the distribution system. SALGA estimates this has grown by at least R2.5 billion a year since then. The Department of Energy is reputed to be preparing a Cabinet minute to establish a fund - but it started the preparation in 2010.

Part of the problem is that Eskom distributes 55% of the nation's electricity to 45% of its customers; the municipalities buy electricity from Eskom and distribute the balance. Eskom by and large distributes satisfactorily; its distribution network is ageing but reasonably well maintained, and it is quite active in ensuring revenue collection -only payments from Soweto remain problematic. In contrast, the municipalities are struggling to maintain their distribution assets, and revenue shortfalls presently amount to billions. Even major metropoles such as Johannesburg are failing in what should be a reasonably straightforward business.

Ultimately it is the poor who suffer most from these problems. 50kWh/month of free basic electricity is wonderful - as long as there is electricity! When there is none, the free benefit is worthless. With hindsight, the provision of free electricity was probably a mistake. First, it gave people the impression that it could be free, which encouraged the culture of non-payment. Secondly, those who were not yet electrified were aggrieved at the double benefits enjoyed by those who were. Thirdly, the impression was gained that access to electricity was some form of right. It will take a generation to undo the damage that has been caused.

However, something unexpected emerged from the electrification programme - entrepreneurship ruled. As the programme electrified more and more homes, there were others just beyond the boundary who sought that barest minimum, to give them light and to recharge their cell phones. They could not wait. Illegal connections sprang from the electrified homes towards the nominally unelectrified. Leads of over 150 m were identified, with several homes along their route sharing the benefit (Lloyd et al., 2007). Of course, in some cases these leads are outright theft, which remains a problem throughout many townships, but the majority pays for the service they receive - even if they use funds collected from those to whom they have sold on.

Finally there are options that we have not explored in depth, but which deserve mention:

- Photovoltaics: These find some use in rural areas where there is no grid supply. To many, this is not real electricity - there is only sufficient power to charge a few small batteries and perhaps watch low-power television at night. Many systems have been 'acquired' from remote power systems installed by Telkom or Eskom -even self-powered emergency telephones on highways have lost their power this way. It says something about the ingenuity of the thieves that they can install and maintain their own mini-power-plant.

- Alcohol gel fuel: This enjoyed a brief period of excitement, if only because it promised a biofuels alternative. However, a clean burn requires mixing of the fuel with air, and it is impossible to mix a gel with air. Instead the gel fuel relies on the vapour pressure of alcohol and the convection caused by burning to mix the fuel with air. An extensive study identified only one appliance that gave a reasonably clean burn (Lloyd & Visagie, 2007). Also, the heating value of the alcohol is significantly less than that of paraffin, so cooking required a larger volume of fuel, and as it was priced at the same level as paraffin per unit volume, the users soon became disenchanted.

- Solar cooking: Numerous expensive pilot tests have succeeded in showing that this is no solution. At best, once the investigators depart, the users learn to cook when the conditions and their day's duties allow, otherwise the cooker merely takes up valuable space in an already crowded dwelling. An unpublished study suggested that there were two primary reasons for the failure of this 'solution'. Firstly, cooking is a social activity demanding personal involvement and personal attention. Mixing something up and leaving it out in the sun for a few hours gives no personal satisfaction, no opportunity for a quick taste to see how the flavour and texture are developing. Users reported distinct unease when using the solar cooker. Secondly, theft, though rare, occurred, and once the risk was recognised, solar cooking fell out of favour.4 A third and lesser reason was unexpected cloud, leaving an uncooked meal and an unhappy, hungry family.

Discussion

Many of the fuels employed in poverty pollute the environment, particularly the indoor air. This causes numerous respiratory problems, and the World Health Organisation estimates that it is the third most common cause of death in infants worldwide. Learning how to use them cleanly, if they are accessible and affordable, would obviously make a significant difference. However, it is not simple, as the example of coal illustrates. The users have made a considerable investment in the appliances employed to burn coal, and are obviously most reluctant to change, particularly when the stove provides so many services. The solution must be to remove the primary cause of the problem, which is the smoke. This is the solution that all developed societies which passed through this transition adopted. Britain, for instance, banned the use of raw coal domestically after the disastrous 'pea-soup' fogs of the 1960's. As a transition fuel, they developed smokeless fuel, which was coal from which the volatile component had been largely removed. It is the volatile components of coal which form the heavy smoke as the coal is heated towards the ignition temperature.

During the 1990's the Department of Minerals and Energy carried out extensive tests on low-smoke coal. If the volatile content was reduced to between 8 and 10% by mass, the fuel remained easy to ignite but the production of smoke was minimized. A large-scale demonstration was carried out in Qalabotjha near Villiers in the Free State, when for three weeks, the coal merchants distributed nothing but the experimental fuels (Lloyd, 1998). Unfortunately, the fuel had been ordered at too fine a size (-15+6mm). It had to be screened to produce a +10mm fraction which was found satisfactory. However, the quantity of fuel available was obviously reduced by screening, and towards the end of the experiment many homes reverted to conventional fuel. Nevertheless, the air quality was markedly improved during the course of the experiment, and the level of respiratory complaints reported at the clinic dropped markedly.

Attempts to proceed to the manufacture of low-smoke fuel failed, and the Department was then diverted by the rediscovery of the so-called Scotch method of lighting a coal fire, by igniting the coal from above and having the fire to burn downwards. In this way, the coal was not heated from below, and the volatiles driven off by heating were combusted rather than being emitted as particulate smoke. The Department promoted the method as Basa Mjengo Ngogo, the Old Womans Fire. While it demonstrably reduced the smoke from an mbaula, it was not effective in stoves (Leiman et al., 2007).

A business plan for low-smoke fuel was developed for the Department. It foresaw three factories producing low-smoke fuel by heating the coal to about 400oC, at which point the volatiles would be driven off and burned to provide the heat. Once the volatile content had dropped to below 10%, the fuel would be discharged, cooled away from contact with air, and stored until ready for sale. Coal would be delivered to the factories by rail, and distributed by road as at present. The factories were sited such that the haulage distance to the coal markets was much less than it is at present, with considerable savings on transport costs. The factories would operate year round, and the fuel stockpiles would therefore be created during the summer months at the factories, rather than at the mines. The whole process would be financed by a modest levy on coal sold into the domestic market, which would enable the low-smoke fuel to be sold at a price slightly below that of coal in the early years, when the volume of low-smoke fuel was small. As the volume built up, the revenue from the levy would reduce but the unit cost of production would also fall due to economies of scale. At some point, it would be possible to ban all further sales of unprocessed coal into the domestic market, while the total impact on the consumer would be modest.

Fixing the paraffin problem requires a new generation of appliances. Some lessons may be learned from the Japanese market. It may come as something of a surprise to learn that the Japanese market for safe paraffin appliances is large. Safety comes at a price, and the appliances may be too costly for the local market. However, the coal stove story carries the lesson learned with difficulty by every marketer - if you can satisfy people's needs, they will find a way to buy your product almost regardless of price. The poor are aware of the hazards that the existing paraffin appliances present. It is therefore a challenge to introduce them to more expensive appliances that meet their needs and also remove their fears.

To some extent this assumes that paraffin will remain the fuel of choice in the urban environment. It is entirely possible that the LPG market may change radically. In particular, there is at present a large commercial and industrial market for LPG. However, the natural gas industry is starting to show signs of life. If it should develop, then it will certainly displace much of the LPG from the industrial and commercial markets, which will therefore remove the present constraints on its supply into the domestic market.

And, of course, with the passage of time, more and more people should make the transition to the use of electricity for most of their household energy. Dealing with the traditional fuels makes one realize just how clean, how convenient and how economic electricity really is. Indeed, if one looks at electricity from the point of view of sustainable development, it ticks all the boxes - it is ecologically friendly, it is socially progressive, and it is economic. The three legs of sustainability are balanced. Of course, some will argue that, for instance, coal mining and combustion in a power plant carry environmental costs. While that is true, the costs are nowhere near those associated with the domestic use of fuels like wood, coal and paraffin.

Notes

1. The 'accidental' death is important; no statistics were kept on the cause of death other than that it was 'accidental'.

2. There have been repeated attempts to persuade users to accept waste coal of a D or sub-D grade, all of which have failed.

3. 'Cobble' and 'nut' are terms used in the coal trade to describe products of the given size.

4. In Botswana, wild animals rather than humans found partially cooked food perfectly palatable!

Acknowledgements

I was introduced to this fascinating subject by the late Prof David Horsfall, of the University of the Witwatersrand, some of whose work I was able to take up and complete after his untimely death. Much of the coal work had the support of the late Chris Grobelaar, of the Department of Minerals and Energy as it then was, and Noma Qase was invaluable in helping to unravel the coal markets. In Cape Town, Glenn Truran, Dehran Swart and Teri Kruger of the Paraffin Safety Association introduced me to the paraffin problem, and George Tatham educated me in the wonders of LP gas. At the Energy Research Centre (ERC) of the University of Cape Town, there were numerous colleagues, of whom Mark Howells, now at KTH in Stockholm, Alison Hughes and Bill Cowan were probably the greatest assistance. Of late, Prof Ernst Uken and Prof Nico Beute, associates at the Energy Institute, CPUT, have been most supportive.

References

Leiman, A., Standish, B., Boting, A. & van Zyl, H. (2007). Reducing the healthcare costs of urban air pollution: The South African experience, Journal of Environmental Management 84, pp 27-37. [ Links ]

Lloyd PJ. (1998). Developments in low-smoke fuel in South Africa, Proceedings of the 11th World Clean Air Congress, Durban, September 1998. [ Links ]

Lloyd, P Cowan, B., and Mohlakoana, N. (2005). Improving access to electricity - the lessons from Khayelitsha, Proceedings of the 13th International Conference on Domestic Use of Energy, Cape Peninsula University of Technology, 29-31 March 2005, pp 85-90. [ Links ]

Lloyd P.J., Dick A. and Howells M. (2004). The energy profile of a rural community, Journal of Energy in Southern Africa, 15 (3) pp 80-87. [ Links ]

Lloyd PJ.D. & Rukarto H. (2001). The potential of LP gas for household energy in South Africa, Journal of Energy in Southern Africa 12 (1) pp 329-35. [ Links ]

Lloyd PJ.D. & Visagie E.M. (2007). The testing of gel fuels, and their comparison to alternative cooking fuels, Paper No D5-1, 15th International Conference on Domestic Use of Energy, Cape Peninsula University of Technology, 10-13 April, 2007. [ Links ]

Lloyd, Philip (2012). Twenty years of knowledge about how the poor cook Proceedings of the Domestic Use of Energy, Cape Peninsula University of Technology, 3-4 April 2012, pp 21-30 ISBN 978-0-9814311-7-8. [ Links ]

Personal Communication, Blight, G.E., Department of Civil Engineering, University of the Witwatersrand, 1993. [ Links ]

Qase N., Lloyd PJ.D. & van Zyl H., (2000). Intervention potential for low-smoke fuels in the distribution chain, Energy Research Centre, University of Cape Town, Report to Department of Minerals & Energy, October 2000. [ Links ]

Statistics South Africa (2008). General household survey 2007. Statistical Release PO318, Statistics SA, Pretoria. [ Links ]

Statistics South Africa (2008). Income and expenditure of households 2005/2006. Statistical Release PO100, Statistics SA, Pretoria. [ Links ]

Williams, A. (1994). Energy supply options for low-income urban households. SA Energy Policy Research and Training Project, Paper No.11, Energy for Development Research Centre, University of Cape Town. [ Links ]

World Health Organisation (2010). WHO guidelines for indoor air quality: selected pollutants. Bonn, ISBN 978 92 890 0213 4. [ Links ]

Received 6 November 2012

Revised 26 March 2014