Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

Journal of Energy in Southern Africa

On-line version ISSN 2413-3051

Print version ISSN 1021-447X

J. energy South. Afr. vol.24 n.3 Cape Town Jan. 2013

RESEARCH ARTICLE

Operational evaluation of the performance of a solar powered absorption system in Pretoria

Tatenda J BvumbeI; Freddie L InambaoII

ISchool of Mechanical Engineering, University of KwaZulu-Natal

IISchool of Mechanical Engineerig, University of KwaZulu-Natal

ABSTRACT

A 35kW pilot solar powered absorption cooling system was designed and constructed at Moot Hospital in Pretoria to investigate the technical and economic performance of the technology. Technically, the system produced an estimated 43.938MWh of cooling energy per year and reached a maximum power of 31kW and operated with an average COP of 0.63, which compares favourably with the 0.7 given by the manufacturer. This system has since been decommissioned. Unfortunately, due to a lack of standard design and operation information, the system was overdesigned. As a result, the economic performance of this technology could not be accurately determined.

Keywords: solar powered absorption cooling; LiBr-water; system performance; economic performance

Nomenclature

Gt Solar irradiance over time, t

Qchiii Evaporator heat output

Qheat Generator heat input

Qsolar Collector solar energy output

Ta Ambient air temperature

Ti Collector inlet fluid temperature

η Collector thermal efficiency

Subscript

a air

I inlet

t time

1. Introduction

Air-conditioning is the dominant energy consuming service in buildings in many countries. The world demand for cooling and dehumidification of indoor air is growing due to increasing comfort expectations and increasing cooling loads, as well as building architectural characteristics and trends (Haw & Hughes, 2007). The main type of systems used for air-conditioning of buildings, are vapour compression systems. These systems have high energy consumption, cause high electricity peak loads and employ chlorine bearing refrigerants which have negative environmental impacts.

In the stratosphere the refrigerants break up due to UV-radiation and release their chlorine atoms and which then act as catalysts in the breakdown of the ozone layer. These refrigerants remain in the atmosphere for many years and trap heat more effectively than carbon dioxide resulting in an increase in global temperatures. The electricity consumption peaks occur only for a few weeks a year and cannot be covered at a reasonable cost, if one tries to apply a rational tariff system, as the investments needed in infrastructure are unjustified (Duffie & Beckman, 2006).

Bearing in mind that in South Africa there are prevailing electricity shortages and ever increasing energy prices, there is now a great need for cooling systems that use working cycles that are reasonably priced and can be driven by renewable energy sources such as solar, wind, geothermal and biogas, which have minimum impact on the environment. Solar energy, in particular, has the potential to supply a sizable percentage of the cooling energy demand because solar radiation levels in South Africa are among the highest in the world. The annual 24-hour solar radiation average for South Africa is 220W/m2. Most of the interior parts of the country receive average insolation in excess of 5kWH/m2 with some parts of the Northern Cape averaging 6kWh/m2/day (Mittal et al., 2005). In general, solar cooling is an attractive idea because the cooling loads and availability of solar energy are approximately in phase.

In the present study, the performance of a solar powered absorption cooling system that was designed, installed and commissioned at Netcare Moot Hospital (Pretoria) by Voltas Technologies in October 2009 is evaluated and analysed.

2. Overview of absorption cooling systems

The development of absorption refrigeration has been linked to periods of high energy prices (Florides et al., 2003). Due to an increase in knowledge regarding the amount of environmental degradation caused by vapour compression systems, a resurgence of interest in absorption cooling systems has been recorded.

The absorption cooling system is a genuine candidate for efficient and economic use of solar energy for cooling applications because of its simpler capacity control and mechanism, easier implementation, high reliability, silent operation, long service life and low maintenance costs. In comparison to vapour compression systems, absorption systems use low temperature thermal energy collected from the sun without the need to convert this energy into mechanical energy.

The basic physical process in an absorption system consists of at least two chemical components, one of them serving as the refrigerant and the other as the absorbent. For air-conditioning applications, absorption systems commonly use lithium bromidewater (LiBr-water) or ammonia-water (NH3-water) working pairs. The generator of the LiBr-water units can be powered by low cost solar thermal collectors thus making these units most suitable for solar applications. The NH3-water machine requires high generator temperatures in the range 125-170oC (Florides et al., 2003). This temperature requires the use of medium concentration ratio parabolic collectors, which have increased maintenance requirements, whereas the LiBr-water machines require a temperature in the range 75-120oC, which is easily, achieved using flat plate or evacuated tube collectors. The LiBr-water machine has a higher coefficient of performance (COP) and costs less than the NH3-water machine (Mittal et al., 2005). This is because the NH3-water machine requires a rectifier to prevent any water vapour entering the evaporator and also requires higher pressure hence higher pumping power. The LiBr-water machine has a limited range of operation due to onset of crystallization occurring at the point of the recuperator discharging into the absorber but has excellent performance at a low cost making it a favourable candidate for use in solar cooling systems.

Apart from the single-effect machines, double-effect machines are also available. These have a higher COP in the range 1.1-1.2, but require driving temperatures in the range of 140-160oC (Henning, 2007). As a result, these types of systems are only available in large capacities of 100kW and above. Single effect machines have a COP in the range of 0.5-0.8, while electrically driven compression chillers today work at COPs around 3 or higher. Therefore, solar fractions have to be higher than about 50% to start saving primary energy (Eicker & Pietruschka, 2009).

3. System description

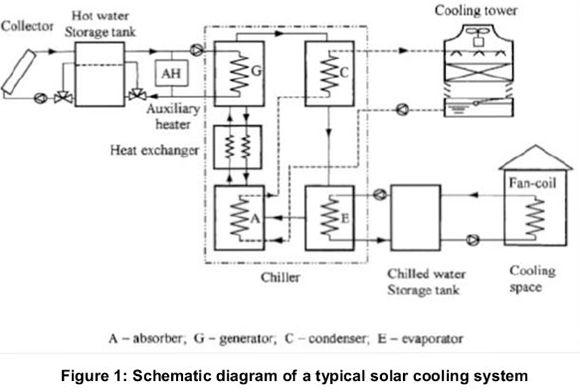

Solar cooling systems are generally composed of solar thermal collectors, a form of heat storage, a thermally driven cooling device, the distribution system, and a back-up system (Balaras et al., 2007).

The LiBr-water absorption cycle has the working pair fluid of LiBr (absorbent) and water (refrigerant). Heat is supplied to the generator to vaporize the water and separate the LiBr from the solution; the water vapour is cooled in the condenser and then passed to the evaporator whilst the LiBr is conveyed to the absorber as a solution with low refrigerant content.

The weak solution entering the generator is preheated by passing the strong solution through a heat exchanger. In the evaporator at low temperature and low pressure, the water evaporates and absorbs heat thereby providing cooling to the space to be cooled. In the absorber there is absorption of the evaporated refrigerant by the absorbent forming the refrigerant absorbent solution. The strong solution is then pumped to the generator to start the whole cycle again. The heat of absorption and condensation is removed by cooling water from a cooling tower. The cooling water flows through the absorber first because the absorber temperature affects the cycle efficiency more than the condensing temperature (Nurzia, 2008).

The system is made up of 52 evacuated tube collectors, two 6000 litre hot water storage tanks, a 35kW Yazaki single stage LiBr absorption chiller and an open wet cooling tower. The solar powered system is coupled to an existing electric vapour compression system so that cooling is achieved even when the solar energy is inadequate to cater for the building cooling load. Both chillers feed into a common chilled water storage tank. In the cooling absorption system under study, a Carel Building Management System was installed to measure and record the main operating parameters. The evacuated tube solar collectors making up the array have the following efficiency equation:

4. System control strategy

The control strategy of any solar powered absorption cooling system plays an important role in determining the amount of electricity that is saved and the amount of cooling energy that is made available. An adequate control scheme will maximize temperatures entering the hot water storage tank and the absorption chiller generator, leading to a better performance of the system (Solar Fred, 2010). The main components that are controlled are the solar valves and pumps, the hot water valves, the chillers (absorption and existing compression), cooling tower fan and cooling tower valve.

4.1 Solar valves and pump

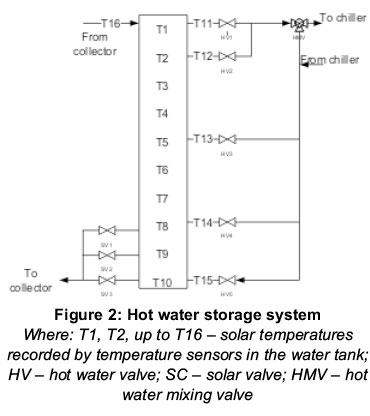

If the solar temperature (T) T16 is greater or equal to 85oC, the solar pump runs unless the average tank temperature is 93oC in which case the pump will stop. The pump will only start again if the average tank temperature exceeds 90oC. If the difference between the solar temperature and the temperature of the water coming out of the solar valve (SV) SV1 is greater than 3oC then SV1 opens. If the difference between the solar temperature and the temperature of the water coming out of SV2 is greater than 3oC and the difference of the temperature of the water coming out of SV1 and that coming out of SV2 is greater than 0oC, then SV2 opens. If the difference between the solar temperature and that of the water coming out of SV3 is greater than 3oC and the difference of the temperature of the water coming out of SV2 and that coming out of SV3 is greater than 0oC, then SV3 opens.

4.2 Water valves

If T1 or T2 are greater than 95oC, then a hot water mixing valve (HMV) closes to stop the high water temperature entering the chiller. If the temperature of the hot water returning from the chiller is greater or equal to T13, then the hot water valve (HV) HV3 opens. If the temperature of the hot water returning from the chiller is less than T13 and greater or equal to T14, then HV4 opens. If the temperature of the hot water returning from the chiller is less than T13 and if the hot water return from chiller < T14, then HV5 opens.

4.3 Chillers

The solar chiller has priority from 9:00-17:00. If the temperature at the top of the tank is greater or equal to 85oC:

0 = solar only.

1 = call I compressor, if chilled supply temperature is above 6.5oC.

2 = call 2 compressors, if chilled supply temperature is above 8oC.

The electric chiller has priority between 17:00-9:00; the solar chiller will only run if the temperature at the top of the tank is above 93oC.

4.4 Tower

A three way valve is used to bypass the cooling tower; if the cooling tower supply temperature is under 28oC, the valve is closed and the water coming out of the chiller goes back into it directly. At 28oC the valve starts to open and reaches 100% at 30oC. To improve the cooling of the water, an air fan starts when the cooling tower return temperature reaches 31oC. When the cooling tower return temperature reaches 33oC, the fan reaches its highest speed.

4.5 Pumps

There are three pumps namely: heat medium pump, chilled water pump and the cooling tower pump. All these pumps are started when the chillers require them to and they all run at 100%.

5. Results and discussion

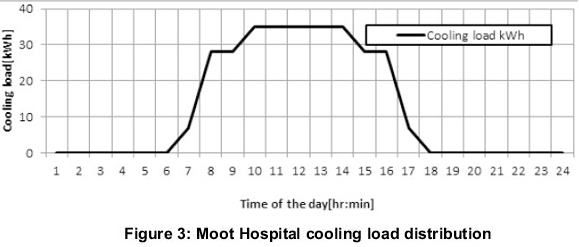

According to the design information provided by Voltas Technologies, this system was designed to provide the amount of cooling energy provided in Figure 3. The chiller was supposed to be switched on at 9:00 and provide an hourly average of 20% or 7kW of its nominal capacity, increasing to 80% or 28kW at 10:00 and 100% or 35kW at 12:00. It would continue providing 35kW of energy for five hours until 17:00, then 28kW for two hours until 19:00 when it would provide 7kW for an hour before being switched off. The absorption chiller is considered as a black box, a component that simply outputs chilled water when supplied with hot water. These design values were arbitrarily chosen as the amount of the building cooling load that the absorption cooling system was supposed to cover.

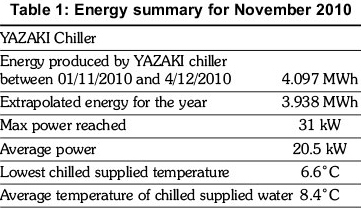

The chiller is energized by water temperature between 70oC and 95oC, but the system control strategy states that the chiller will only start producing cooling energy if the hot water temperature being fed into the generator exceeds 81oC. In this study, the system performance values at Moot Hospital were recorded at 15 minute intervals and there are 3307 data points from 13:00 on November 1st to 18:00 on December 4th. Of these recorded values, 846 of them, representing 25.5% of the time, were above 70oC, suggesting that the chiller could have run for 25.5% of the time if required. The generator inlet temperature exceeds the threshold value of 81oC 494times, which represents 14.9% of the time. This results in part load behaviour for the chiller and the amount of cooling energy produced is presented in Table 1.

Pretoria experiences its greatest need for airconditioning in the period from November to the end of February. The average insolation in this period is 6.43kWk/m2/day, the average highest temperature experienced is 28oC, the average daily mean temperature is 21.64oC and the average of the mean monthly sun hours is 255.5hrs.

In this high air-conditioning energy demand period, from 9:00-17:00, the solar powered chiller is in priority mode. If the temperature at the top of the tank is higher than 81oC, the solar absorption chiller can operate in either of two modes. It either operates alone or in combination with one stage of the electric chiller if the chilled water temperature is above 6.5oC. If the chilled water temperature is above 8oC, then it operates with two stages of the electric chiller. From 17:00-9:00, the electric chiller has priority, but if the temperature at the top of the hot water storage tank is above 93oC then the solar absorption chiller will operate. A three way valve is used to bypass the cooling tower; if the cooling tower supply temperature is under 28oC, the valve is closed and the water coming out of the chiller goes back into it directly. When the temperature reaches 28oC, the valve starts to open and reaches 100% when the temperature reaches 30oC.

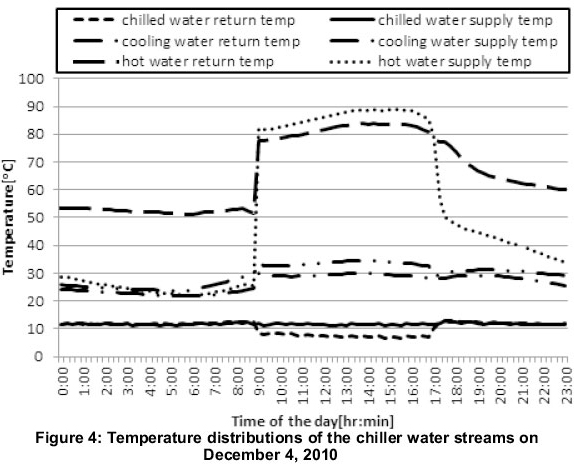

The temperature distributions for the input and output streams into the absorption chiller on December 4 2010 are shown in Figure 4. The chiller is on a time schedule and switches on at 9:00. Before 9:00 the recorded chiller hot water inlet temperature is about 25oC since the chiller will not be drawing any water from the hot storage tank. At 9:00, the chiller starts getting water from the tank, so the inlet water temperature rises from 25.1oC to 82oC. This rapid rise at the chiller inlet and outlet is as a result of the three way valve opening to allow water into the chiller when the chiller is switched on. This temperature gradually increases to a maximum of 88.8oC at 15:00 as incident solar energy increases. The cooling effect starts to be produced at 9:00 when the chiller is switched on, hence the marked decrease in the chilled water temperature from 12.5oC to 8.4oC. This temperature eventually stabilizes and reaches a lowest temperature of 6.8oC at 13:45 as seen by the almost flat line on the graph between 9:00 and 17:00.

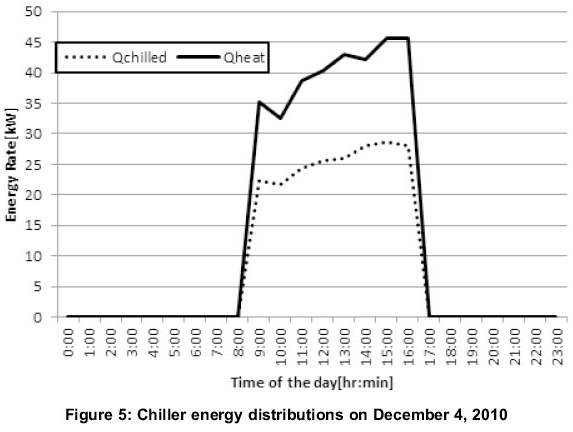

The distribution for energy produced is shown in Figure 5. The system starts producing cooling ener- gy at 9:00 when it is switched on since the hot water supply temperature is 82oC at that time. It produces 22.2kW from 35.2kW of heat supplied by the hot water, giving a COP of 0.63. This COP value remains almost constant throughout the day, indicating a steady supply of hot water from the storage tank. The maximum values of cooling energy produced and heat energy supplied are 28.6 and 45.7 respectively.

The distribution of the COP of the chiller is shown in Figure 6. The coefficient of performance (COP) for the chiller is given as:

The solar coefficient of performance (SCOP) is given as:

Using equations (2) and (3) and the energy distributions shown in Figure 5, we get the distribution shown in Figure 6. The COP of the chiller has an average value of 0.63, which is comparable to the manufacturer's value of 0.7. The solar coefficient of performance has an average of 0.11.

5.1 Economic analysis

The system at Moot Hospital was over designed and unfortunately is not helpful in determining the economic performance of solar powered absorption system. This over design resulted in the system being decommissioned in November, 2011. It is generally observed that the economic performance of an absorption cooling system increases with the chiller cooling capacity.

Table 2 courtesy of Voltas Technologies shows chiller capacities and the respective electric consumptions and prices. It can be observed that a 17.5kW chiller costs about R200 000 which is slightly under a third of the price of a 175kW chiller, whose capacity is ten times larger. The power demand for both machines is approximately the same.

6. Conclusions

With proper design, solar powered absorption cooling has the potential to replace a sizeable amount of cooling energy demands - in the system under study; use of the electric chiller was reduced by more than 50%. The cooling effect achieved is directly proportional to the amount of sunshine available. To ensure continuous operation and reliability of the system, use is made of a hot water storage tank.

Acknowledgements

The authors would like to acknowledge the assistance given by Voltas Technologies particularly Messrs Frank Major and Hartmut Martin and the financial support from the Centre for Engineering Postgraduate Studies (CEPS) and the DVC-Research, Prof Nelson M. Ijumba.

References

Balaras, C.A., Grossman, G., Henning, H-M., Infante-Ferreira, C.A., Podesser, E., Wang, L. and Wiemken, E. (2007). Solar air conditioning in Europe - an overview, Renewable and Sustainable Energy Reviews, 11(2): 299-314. [ Links ]

Duffie J.A. and Beckman W.A. (2006). Solar Engineering of Thermal Processes. 3rd ed. New York: Wiley. [ Links ]

Eicker, U. and Pietruschka, D. (2009). Design and performance of solar powered absorption cooling systems in office buildings. Energy and Buildings, 41: 81-91. [ Links ]

Florides G.A., Kalogirou, S.A., Tassou, S.A., Wrobel, L.C. (2003). Design and construction of a LiBr-water absorption machine. Energy Conversion and Management 44(15): 2483-2508. [ Links ]

Haw, M. and Hughes, A. (2007). Clean energy and development for South Africa: Background data. Report 1 of 3. Energy Research Centre, University of Cape Town. [ Links ]

Henning, M. (2007). Solar assisted air conditioning of buildings - an overview Applied Thermal Engineering, 27(10): 1734-1749. [ Links ]

Mittal, V., Kasana K.S. and Thakur N.S. (2005). The study of solar absorption air-conditioning systems. Journal of Energy in Southern Africa, 16(4): 59-66. [ Links ]

Nurzia, G. (2008). Design and simulation of solar absorption cooling systems. PhD Thesis: University of Bergamo. [ Links ]

Solar Fred. (2010). Solar Thermal 101: Evacuated tube collectors. Available at: http://www.freehotwater.com/solar-thermal-101-evac-uated-tube-solar-collectors/ (Accessed 31 November 2011) [ Links ]

Received 10 January 2012

Revised 20 June 2013