Serviços Personalizados

Artigo

Indicadores

Links relacionados

-

Citado por Google

Citado por Google -

Similares em Google

Similares em Google

Compartilhar

Journal of Energy in Southern Africa

versão On-line ISSN 2413-3051

versão impressa ISSN 1021-447X

J. energy South. Afr. vol.24 no.2 Cape Town Mai. 2013

RESEARCH ARTICLE

The Manica Charcoal Stove Project

Chris Bradnum

Department of Industrial Design, University of Johannesburg, South Africa

ABSTRACT

A study was conducted by staff and students from the Department of Industrial Design in the Faculty of Art, Design and Architecture (FADA) at the University of Johannesburg on alternative charcoal stove design under the title Manica Charcoal Stove Project for developing communities. The project was started in support of the principle designs developed for the Maputo Ceramic Charcoal Stove, now known as the Poupa Carvão (POCA) charcoal stove, developed by Crispin Pemberton-Piggott of the Program for Biomass Energy Conservation (ProBEC) which is supported by GIZ. A research group consisting of two academic staff members and four 3rd year Industrial Design students visited the town of Manica in Mozambique in 2008 to complete user field testing and use these results to inform alternative charcoal stove designs. The project falls under the broad area of design for social development and expands on aspects of community centred design developed within the Department of Industrial Design at the University of Johannesburg. This paper briefly describes the research method and the design process used to develop the stove concepts. It discusses aspects related to the design of new charcoal burning stoves and touches on the manufacturing systems available for stove production in the region. It evaluates the principles of user centred design in developing community projects and gives direction to further studies of this kind.

Keywords: community centred design, user centred design, design for development, charcoal stove design

1. Introduction

In August 2008, a field study was completed in Manica, Mozambique, on alternative charcoal stove design under the title: Manica Charcoal Stove Project. A group consisting of two academic staff members and four 3rd Year students from the Department of Industrial Design at the University of Johannesburg visited the town of Manica in Mozambique to complete user acceptance testing in the field and use these results to inform alternative charcoal stove designs. The field trip was the culmination of several months of research, design and development work that had started in the department in May 2008.

The project was initiated in support of the design principles of an improved clay charcoal stove developed by Crispin Pemberton-Piggott for the Programme for Biomass Energy Conservation (ProBEC).1 The first version of the improved clay charcoal stove was called the Maputo Ceramic Charcoal Stove2 (see Figures 1 and 2) and later became known as the Poupa Carvão (POCA) charcoal stove.

In May 2008, the Department of Industrial Design was approached by ProBEC to re-engineer the Maputo Ceramic Charcoal Stove in metal. At that stage, the ceramic materials used in the Maputo Ceramic Charcoal Stove proved to be problematic in that the stoves would crack after little use and the stoves were brittle and could break if accidentally knocked over. The entire 3rd Year group of industrial design students were involved in the initial stages of research, design and development of a metal translation of the original stove based on the working principles developed by ProBEC for the Maputo Ceramic Charcoal Stove.

The working principles given to the students based on the Maputo Ceramic Stove were:

- The stove requires a specific ratio of air coming in through the base.

- The air entering into the burn area should be preheated.

- The fire grate should have the optimum amount of air coming in below the coals as too little air will choke the combustion, while too much air will cool the flue gases.

- There needs to be a gap around the edges of the burn area to allow a specified amount of air to flow over the top of the coals.

- The stove should be insulated to improve the preheating of air to the burn areas and to ensure that the stove limits the loss of radiating and conducting heat from the burning charcoal that is not directed towards the pot.

- The ratio of air released between the pot and the stove top (pot holder area) should also be controlled and allow for a specific amount of air to flow out.

- The shape of the stove body should encourage an acceleration of hot gases as they are pushed towards the pot base.

- The configuration and layout of the Maputo Ceramic Charcoal Stove should be maintained as far as possible.

The primary objectives for adapting the working principles must result in:

- A reduced amount of charcoal used to effectively cook meals.

- The complete combustion of the charcoal and gasses to increase the energy output and reduce toxic emissions.

- The maximum use of energy potential from the amount of charcoal used.

- The reduction of the amount of charcoal used to assist in slowing the rate of deforestation in SADC regions.

- The stove should be able to burn lower grade charcoal (from fast growing trees) to reduce the loss of rare indigenous hardwood trees.

The project set up at the university required that the entire group of 3rd year students develop two distinct solutions for their stove designs: a version suitable for mass manufacture and a craft manufacture version. The mass manufacture version was intended for manufacture at production facilities in industrialised centres such as Johannesburg or Maputo and the craft version was intended for manufacture at village level from a set of instruction manuals and templates developed for this purpose and using materials and manufacturing processes on hand.

At the end of the concept phase, students manufactured prototypes of their solutions, which were then tested by ProBEC using a standard efficiency test. ProBEC found that many of the stoves showed significant efficiency improvements from traditional metal charcoal stoves found in Mozambique and compared well with the results they were getting from the Maputo Ceramic Charcoal Stove. A component missing from this design project however, was the actual stove user. This is a regular failing of projects intended for developing communities: the designers working in isolation from the people who will eventually use the product.

Participatory design integrates two radical propositions about design. The first is the moral proposition that the people whose activity and experience will ultimately be affected most by a design outcome ought to have as substantial say in what that outcome is ... the second is the pragmatic proposition that the people who will need to adopt, and perhaps to adapt to an artefact or other outcome of design, should be included in the design process, so that they can more offer expert perspectives and preferences regarding the activity that the design will support, and most likely transform. The pragmatic proposition is that directly including the users' input will increase the chances of a successful design outcome. (Carroll & Rosson, 2007: 243)

In preparation for the launch of the Maputo Charcoal Stove, ProBEC asked Dr Peter Coughlin to conduct a baseline study on charcoal stove use in Maputo in 2007. According to Coughlin, the aim for ProbBEC to introduce the ceramic stove programme was '...not only to introduce a much more efficient charcoal stove but also to promote more energy efficient cooking techniques to save charcoal and, hence, trees and reduce people's exposure to smoke, a major cause of respiratory illnesses' (Coughlin, 2007:1). Coughlin's baseline study was used to determine amongst other considerations the 'practices used by people when cooking on traditional [metal] stoves'. Furthermore, the study would ascertain the environment in which stoves were used, and the frequency and duration of use. Although these components are crucial to the general understanding of users engagement with their cooking technology, this study does not include users as a component of the decision making process in the development of an improved stove. In this author's opinion, the Maputo Charcoal Stove can therefore be understood as the introduction of appropriate technology from an outside source rather than an inclusive co-creation or user centred design process. The Department of Industrial Design has been involved in many community design projects in which the community inform the principles of the design. From experience, this approach leads to a greater acceptance of the product and a solution that is sensitive to the actual needs not simply the technology being produced.

Fortuitously the class work phase of the project ended at the same time as calls for entries to the Sanlam Creativity for Progress Competition were launched.3 The university's Corporate Social Investment division sent Schalk van Heerden4 to the Department of Industrial Design to evaluate the potential of the stove project as an entry for the competition. Van Heerden believed that the project had merit and in discussions he provided details of the research he had been involved in within the town of Manica in Mozambique. From his experience in this town he indicated that residents use charcoal as the main source of energy for household cooking. They also use a stove which is manufactured by metalworkers in Manica and that there is a growing problem of deforestation from charcoal production and usage. He suggested that the department continue the research in Manica towards the development of an improved charcoal stove.

The opportunity to interact with stove users, stove manufacturers and even charcoal manufacturers was an excellent prospect to further develop the product and also provide the students and academic staff with a real life project in which they could further develop their expertise of product user interaction and community centred design projects.

A group of four of the industrial design third-year students volunteered for the further research and development of the charcoal stove, now the newly named Manica Charcoal Stove Project. The research group that went to Manica in August 2008 comprised students: Victor Bezuidenhout, Theo Olivier, John Harverson and Ross Nelson; two academic staff members: Chris Bradnum and Angus Campbell; as well as Schalk van Heerden as the expert on the region and member of the administration of the soccer club: Groupo Desportivo de Manica from where the project was run. At the end of the project, the students and academic staff were required to complete reports on the project for the department and for the Faculty of Art, Design and Architecture's Research Newsletter. Much of this paper draws on these reports.

2. User-centred design process

The concept of user-centred design has arguably given rise to one of the most fundamental changes in the field of design over the past few decades. Design has since shifted focus from giving form to objects and information to enabling user experiences, and from physical and cognitive human factors to the emotional, social, and cultural contexts in which products and communications take place. (Boztepe, 2007: 57)

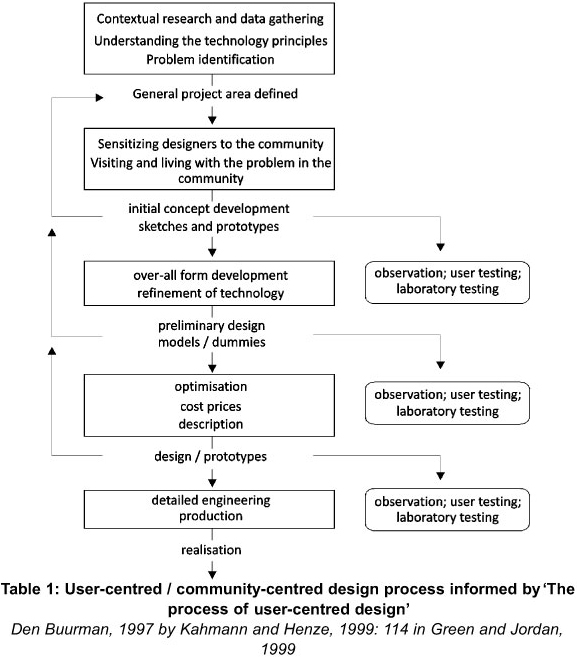

The design process used for this project was loosely based on the process of user-centred design by van Buurman (1997) as discussed in Kahmann and Henze (1999: 114 in Green and Jordan, 1999) (see Table 1) but adapted by the research group for the specific needs of the project. The research group investigated the town of Manica to contextualise the environment, cooking processes, stove technology in use and manufacturing processes available. Stove users were asked to demonstrate typical meals being cooked by using the locally manufactured Fugão, observations and interviews of these processes were recorded. The research group conducted interviews with local craftsmen, shop owners and stove users to understand technical factors influencing the manufacture and sales of stoves. Through the combined set of interviews and direct demonstration the research group were able to understand the principles of stove use and formulate a stove use profile.

Design research is not only concerned with the techniques for planning and giving form to a product but also with use. Since products are made for people, the user response to a product is an essential part of the research field. Because the subject of design research, then, is not only of products but also the human response to them. (Margolin, 2000)

Once the contextual research and data gathering phase of the design process was completed the research group had developed a comprehensive understanding of many of the factors that influence stove users, stove use, stove manufacturers and the issues of charcoal production. Through this process the research group became sensitised to some of the complex issues of the region and the community. These factors were then applied to the development of a number of design solutions which were discussed with local users and stove manufacturers. User testing on the stoves and basic efficiency tests were conducted. Some of the stoves went through a phase of further refinement before the field trip was completed.

3. Contextualising the field research and data gathering

The first phase of community design projects is to contextualise the people and place. In this research and development project, the research group were fortunate enough to have members of the soccer club, Groupo Desportivo de Manica, where the research group based its research, to assist with and refine the information gathered. To this end, the research group relied on Schalk van Heerden for his insight gained from living in the region and the research completed for his mini thesis; interviews, conversations and confirmation of these with Nelson Veremo, an English teacher and administrator at the soccer club who has lived and worked in Manica his whole life; and Shortcover Chikwandingwa, the General Manager at the Grupo Desportivo de Manica, who also happens to be highly regarded musician in Southern Africa.

3.1 Manica, Mozambique

Manica town is situated in the province of Manica in Mozambique around 20 km from the border with Zimbabwe on the Mutare - Beira highway. This link is also known as the Beira Corridor which connects Malawi, Zimbabwe and Zambia to the port of Beira. Before the Portuguese were expelled from Mozambique in 1974, Manica was known as Macekece. 'On 6 September 1974, more than 400 years of Portuguese rule in Mozambique came to an end 'officially' (Swift 1974:184)5 (van Heerden, 2005: 20). The remnants of the Portuguese era can be seen in the ill maintained, but still structurally sound buildings in the town. This gives the town a Luso-African6 appearance in this African landscape. Manica has a population of around 40 000, with Shona and Portuguese being the main spoken languages. Portuguese is the language of all education in schools and is used for all the signage in the town. Manica is surrounded by hills and mountains and is itself reasonably hilly, but flattens out as you move eastwards towards the town of Chimoio.

3.2 Cooking economy

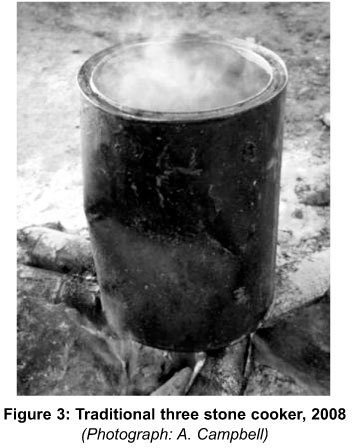

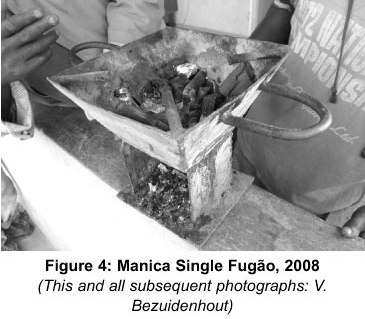

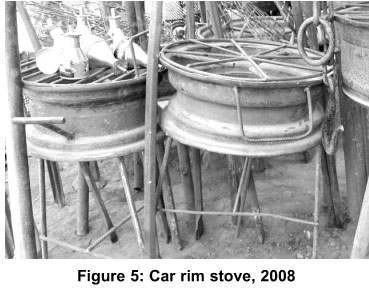

Within Manica town and the surrounding area, the majority of the population use fire as the main source of energy to cook food. The systems range from the traditional three stone cooker which uses wood (see Figure 3) through to the metal Fugão ('stove' in Portuguese) which uses charcoal (see Figure 4). The Fugão itself appears to be a product of earlier UN intervention as a similar stove can be found in many areas of development within Southern Africa including Kenya, Madagascar and Tanzania. The Fugão is manufactured in Manica from +/-4mm thick mild steel sheet metal, which is obtained from recycling and flattening sheet metal railway sleepers. These metal sleepers are being replaced with concrete sleepers along the railway around Manica and have become a useful resource for the manufacture of many products including the Manica Fugão. There are other ingenious charcoal stoves used in the area such as the stoves manufactured from old car rims (see Figure 5), but the stove made from railway sleepers is the most popular.

The standard Manica Fugão can be purchased for 100Mtn (2.83US$)7 for the single stove and 200Mtn (5.67US$) for the double stove version. A second-hand railway sleeper from which these stoves are manufactured can be purchased for 100Mtn (2.83US$) and from this a craftsman can manufacture 4 double stoves or 7 single stoves. The manufacturing tools and processes available to crafters making these Fugão includes: electric grinders, hacksaws, arc welding and chisel and hammer beating to complete the work. A single Fugão takes a skilled craftsman about 2 hours to complete.

In Manica, a school teacher earns 3500Mtn (99.15US$) per month and the minimum wage in Mozambique is 1800Mtn (50.99US$) per month, making the purchase of a charcoal stove a big decision in the average household. Charcoal bags are rated by bag size and bucket quantities. A stove user can purchase a single bucket of charcoal for 30Mtn (0.85US$) or a small bag (around 3 X 20 litre buckets of charcoal) for 70Mtn (1.98US$) or the large bag (around 5 X 20 litre buckets of charcoal), which sells for 100Mtn (2.83US$) depending on the time of the year (prices given are winter prices). Winter prices are higher than in summer because the rain in summer makes the charcoal making process easier and therefore most cost effective. The average household, based on two adults and two children, uses up to one large bag of charcoal per month for their cooking needs. According to van Heerden, (2005: 23):

The main diet of people in Manica consists of sadza (porridge made from grounded maize) and cove (relish), with bacajão (dried fish) added when sufficient funds are available. This is complemented by the eating of pão (bread) and on rare occasions chicken, beef or goat's meat. Energy needs are therefore satisfied by mainly either firewood or carvão (charcoal) to cook the sadza and relish (cove or bacajão).

3.3 Deforestation

The prime area for charcoal manufacture is between 15 km and 20 km west of Manica and can be accessed along rutted dirt roads. This was the area in which the Zimbabwe Liberation Army kept camp during the Rhodesian war. After Zimbabwe's independence in 1980, the area became the base intermittently for Renamo and Frelimo during the Mozambique civil war, which lasted from 1976 to 1992. After the civil war, farming activity started returning to the area and the woodlands began to be utilised for charcoal manufacture to clear the way for the farming (Chikwandingwa, 2008; Veremo, 2008, van Heerden, 2005). 'Fuel to cook is obtained predominantly by one of two ways and sometimes by both. These consists of either going directly into the forested areas surrounding the town to cut wood (lenha) or to buy either wood or charcoal in the market (Mercado)' (van Heerden, 2005: 23). However, according to van Heerden, charcoal has become the predominant source of fuel for cooking in Manica as the trees closest to town have all but disappeared or are located on farm lands.

In Manica, a tree cutting license is required for all individuals involved in tree felling activities, other than tree cutting on their own land. This license can be purchased from the local municipality (Conselho Municipal da Cidade de Manica) for 570Mtn (16.15US$). The license is valid for a year and allows cutting only in an allocated area. According to van Heerden: 'Penalties for illegal tree utilisation are also given by the Agriculture Department and include financial fines or physical labour like digging or weeding. In extreme cases, people are jailed and in Manica, prisoners are rented out for physical labour and the income from their work goes into the state purse.' (van Heerden, 2005: 29).

There is strong evidence that the tree resources surrounding Manica are not being managed well. Through discussions with stove users, community members and soccer club staff, the indications are that uncontrolled tree felling has changed the landscape around Manica. The mountains to the North of Manica are almost barren, where they used to be densely populated by hardwood trees. There are signs that trees from the Vumba Mountains to the South of Manica are also being used for charcoal production. The trees on the Vumba Mountains are protected by law, but illegal cutting is still taking place.

From van Heerden's research he determines that Manica has a good supply of electricity but because of the high costs to connect households to the grid and the relative scarcity of electric stoves, utilization of this resource is well below capacity. 'As the town of Manica grows and as wealth increases, so would the use of electricity which is viewed as the preferred source of energy for cooking and lighting' (van Heerden, 2005: 34).

4. Product development

The product development phase within the Manica community included several research components: observational studies, informal interviews, design through experimentation and user feedback and involvement as a key component of the decision making processes and further development. Each of the designs was also tested using a basic water boil test to determine a simple efficiency calculation. The product development also carefully considered the capabilities of local manufacturers and many of the prototypes were outsourced to these manufacturers. The inclusion of local manufacturers during this stage allowed the design team to better understand the level of skill, capabilities and limitations of these manufacturers.

4.1 Stove use profile

The research group observed users cooking meals on the Manica Fugão and conducted a series of interviews to ascertain the process of using the stove. What follows is a collection of observations and interpretations on Fugão use.

The Fugão are used not only for cooking but also for heating water for tea and coffee and for space heating during winter months. The Fugão are often used more than three times a day for cooking and heating needs. The Fugão is lit in one of two ways: under-lighting using a combination of leaves, paper or tinder; or top-lighting by melting a plastic bag under a match flame and dribbling the burning plastic onto the charcoal. The Fugão are lit outdoors and once the charcoal is fully alight and the smoke dissipates, they are then often carried indoors for use. The burn temperature of the coals is controlled by facing the opening below the coals into or out of a draft. This control mechanism functions well even indoors as windows and doors are generally left open during the cooking process to reduce the indoor smoke. Some stove users also cook outdoors in areas surrounding the house which improves this control function further.

More charcoal is added to the burning embers to increase the heat of the fire during the cooking process. The food that takes the longest to cook and retains its heat well, such as beans, is cooked first and left to stand whilst the other food is cooking. During cooking, the radiating heat from the Fugão is used to keep already cooked food warm, by placing the pots around the base of the stove. When the fire is no longer needed for cooking, the charcoals are placed into a metal dish using wire tongs, and taken outside and quenched with water or the Fugão itself is moved outdoors and the coals are quenched in the stove. By quenching the coals in the Fugão, the lifespan of the product can be drastically reduced as the metal will start to rust and the body could split apart around the welded joints. The charcoals that are quenched can be re-used, in conjunction with new charcoal, for future cooking. New charcoal is used for the lighting of the fire, and the used charcoal can be added to the hot fire even when it is still wet. On average, 800 grams of charcoal is used for 1½ hours of cooking. This mass includes the charcoal added during the cooking process.

Ash from the fire is valuable to stove users, as it has many uses. The users believe ash has medicinal properties: ash is either ingested dry or mixed with water and then drunk to treat constipation, or used as a cough remedy. Ash is used as an abrasive medium to clean pots. The charcoal ash is also scattered in and around toilets to deter flies.

The handles of the Fugão are made from a mild steel rod which is welded to the stove body. During the cooking process these handles become very hot. Temperature measurements show that the handles often exceed 50°C, which makes them dangerous to touch and can burn the users if they do not use protective materials to cover the handle during use. Fugão users move the stove several times during cooking and the handles are a key interface point.

4.2 Manufacturing considerations

The approach followed by the research group for this project, as in many of the community centred projects the Department of Industrial Design has been involved in, is to source and include local manufacturers for the implementation of design solutions. To this end, the research group needed to understand the capabilities of local manufacturers as well as materials and processes used. What follows is a collation of data on the current Fugão manufacturing process as well as additional factors that could influence future stove design for manufacture.

Although the local manufacturers are skilled, the designed product should allow for some flexibility on tolerances as these will not be consistent for all stoves. Manufacturers are intimidated by engineering drawings and alternate instruction mechanisms, such as sample templates, should be found to assist them in the stove manufacture. The materials available for the current Fugão are the railway sleeper, but this is not an infinite resource. Material substitutes should be found to replace this resource in time. The product needs to be manufactured in such a way that on-going repairs can be executed easily. Components or entire sections should be easy to replace when they break or wear out.

The new stove needs to last between 3 to 5 years in order to be competitive, as this is the current lifespan of the Manica Fugão. When deciding on dimensions, two factors need to be taken into consideration; the size and dimensions of the existing stove as well as average pot sizes used for cooking. The most commonly used pot in Manica has a base diameter of 230 mm with a depth of 115 mm. These pots are manufactured by skilled local crafters out of sheet aluminium imported from Zimbabwe.

4.3 Design solutions

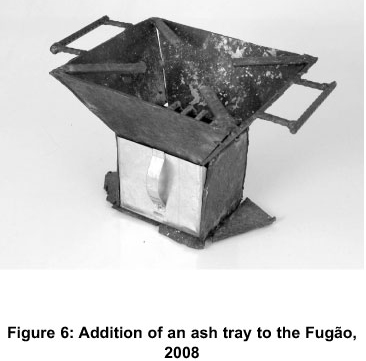

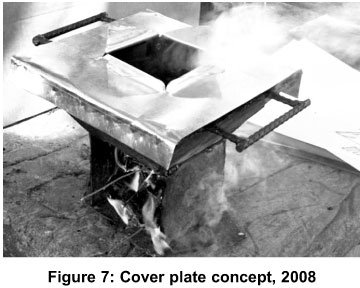

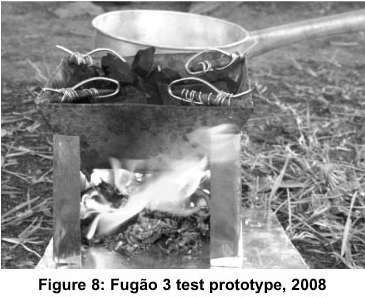

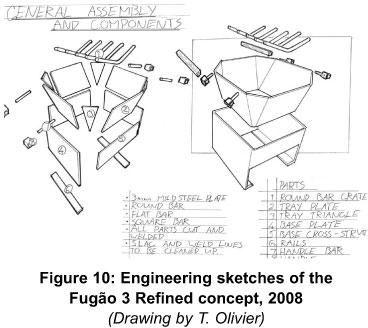

The research group began design and development work on the stoves based on the scientific principles of the Maputo Ceramic Charcoal Stove and informed by the experience of the stove users in Manica. The intention of this phase of the project was to develop solutions from concept sketches into physical test models, test the scientific validity of the new design through basic efficiency tests and also test the user reaction to the designs proposed. This phase resulted in several minor improvements to the current Fugão including: the addition of a removable ash tray and the addition of a cover plate. In addition to this, several new stoves were developed: the Prism Design, Double Walled Fugão, Fugão Based on Scientific Principle, Fugão 3 and Fugão 3 Refined, the Pot Skirt, Broken Fugão Concept 1 and Broken Fugão Concept 2. What follows is a brief collection of the more interesting designs and some of the results obtained.

4.3.1 Removable ash tray concept

The intention of this concept was to control and limit the airflow below the burning charcoal as well as to include a built in ashtray to clean out and transport the ash. This concept was not received well by the stove users as the perception exists that the large opening improves the function of the stove.

4.3.2 Cover plate concept

A problem identified with the Manica Fugão is the loss of energy through the large gap between the pot and the stove top. The cover plate concept was developed to harness and direct all the heat to the pot base. The test results were however disappointing as the cover plate did not perform as anticipated. Not only did the cover plate not improve the performance of the Fugão, but it created a set of new issues. The addition of charcoal during cooking is difficult because the cover plate becomes too hot to remove, the stove generated a lot more smoke than the standard Fugão during operation and the stability of the cover plate was also questionable. The research group decided not to pursue the cover plate concept any further.

4.3.3 Fugão 3

The aim of the Fugão 3 concept was to reduce the heat loss through the top opening of the stove, by cutting off the corners and changing them into faceted faces. This would allow the pot itself to act as an effective seal against heat loss between the stove top and the pot base. This shape also reduced the amount of charcoal that can fit into the stove. The walls of the base were raised to help insulate the stove burn area against heat loss and to preheat the air coming in below the charcoal grate. The prototype was manufactured by the students in galvanised iron rather than in the sleeper material. The users were concerned about the products longevity because of the use of the galvanised iron. However, the users did respond positively to the larger footprint and the additional stability this might provide during cooking.

4.3.4 Fugão 3 refined

This stove design was a development on the Fugão 3 concept. Key developments included wooden handles to improve safe handling of the stove, a reduction in the amount of material used for manufacture from the Fugão 3 concept, a removable ash tray, a larger footprint to improve the stoves stability, and the double wall base and the faceted corners to improve the efficiency. The manufacturers were concerned that this stove would add complexity to the manufacturing process and raise the overall cost of the product. Users indicated their appreciation for the removable ash tray and the inclusion of a larger base and the stability this may offer in use.

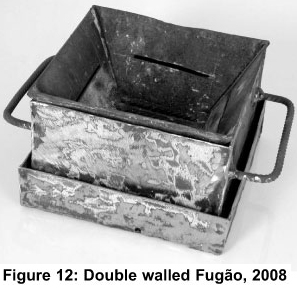

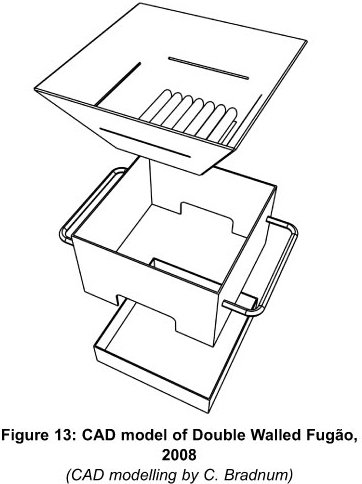

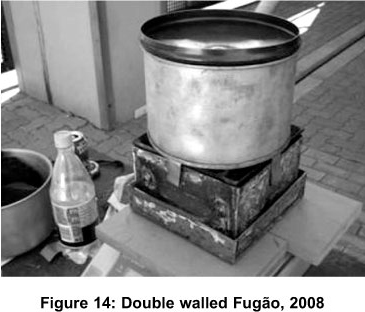

4.3.5 Double walled Fugão

This stove was developed as a close approximation of the principles of the Maputo Ceramic Charcoal Stove. Included in this design was a system to preheat the air entering under the coal grate and flowing over the top of the fire; an ash tray below the stove; a limited amount of air coming from outside the stove; and a limited amount of air entering below the charcoal. The design was manufactured in Manica by Fugão makers according to engineering sketches and dimensioned 2D drawings supplied. However, these drawings appeared to intimidate the manufacturers and they indicated that they would prefer templates and step by step photographs to explain the manufacture process required. Although this stove did achieve better results that the Manica Fugão, it did not show substantial improvement and would cost a lot more than the current Fugão because of the additional materials required in its manufacture.

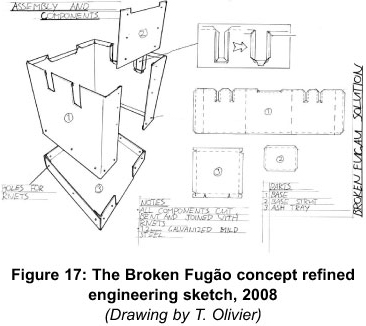

4.3.6.Broken Fugão concept 1

The Broken Fugão Concept offered a replacement base for broken stoves, of which there were many found in Manica, and improved the efficiency of those stoves. The replacement base creates a double wall, which insulates the fire grate and heats up the air coming into through the gate below the charcoal. Through this double walled insulation, there is less heat loss from around the fire grate. The replacement base also creates an insulating effect around the pot and directs additional escaping heat up the sides of the pot. However, users were concerned that the concept did not include handles to move the stove in use and this would make it impossible to control the temperature of the stove by directing the stove into or out of the wind.

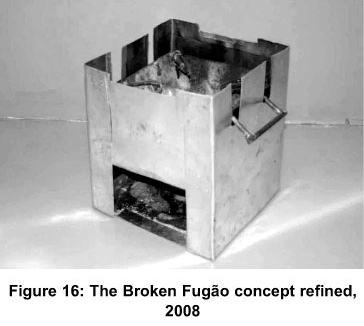

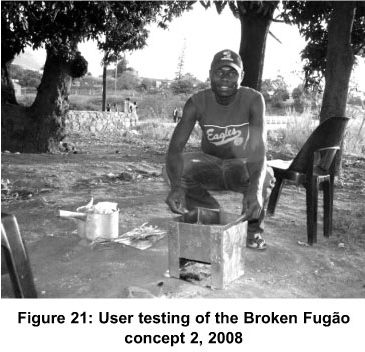

4.3.7. Broken Fugão concept 2

This concept develops a replacement base made from galvanised steel. It can house any broken Manica Fugão grate top area and handles, where the handles of that Fugão act as the supports to hold the stove in place in the new base. The new base also serves as a pot skirt, and provides the double wall to assist in the preheating of air coming in below the charcoal grate. The handles were not permanently attached to the outer shell making moving the stove difficult and a little dangerous. Improvement made to the fundamental principle of assembly could make this a viable option as this stove displayed good efficiency results.

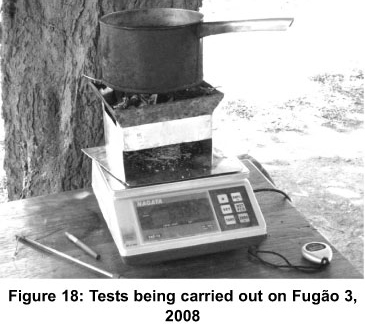

4.4 Efficiency test process and results

The Partnership for Clean Indoor Air (PCIA) website gives details on the three test procedures for evaluating stoves: the Water Boiling Test (WBT), the Controlled Cooking Test (CCT) and the Kitchen Performance Test (KPT) (PCIA, 2009). PCIA summarise the CCT as a test of stove performance using a simulation of local cooking methods, food types, fuels and cooking pots in a laboratory environment. The KPT is a field test assessing household fuel usage when using the stove to complete daily cooking tasks. The testing completed in Manica did not include formal CCT or KPT tests because of the time constraints of the field test period, rather testing focussed on a version of the Water Boiling Test to test efficiency and some informal cooking tests with stove users making meals on some of the stoves. 'The Water Boiling Test (WBT) is a simplified simulation of the cooking process. It is intended to help stove designers measure how efficiently a stove uses fuel to heat water in a cooking pot and the quantity of harmful emissions produced while cooking.' (WBT 2009:1).

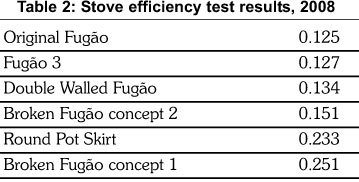

The research team conducted a version of the water boiling test on each of the stove designs, as well as on the original Fugão, centred on Prof Phillip Lloyd's test procedure for paraffin stoves. The selection of this test method was based on the author's previous experience on paraffin stove testing and this was deemed to be a viable basic test method for the limited time available in Manica (Efficiency Testing, 2004). This simple process includes weighing the stove, the charcoal, the pot and the water at the beginning of the test. Additional charcoal was also set aside and weighed to allow the testers to add charcoal during the test process, if and when necessary. The stove was then lit. Once the water reached boiling point, measured by temperature and rapid bubbles in the pot, incremental measurements were taken at intervals of 5 minutes over a 30 minute period. At the end of the test, the weight of the used charcoal loss was calculated as well as the amount of water that was lost due to evaporation. By using Lloyd's efficiency calculation, an efficiency percentage was calculated for each stove. Figure 18 indicates the various stoves' levels of efficiency, relative to one another (see Table 2).

An efficiency field test kit was transported from the university to test the stoves on site. This kit comprises a 30 kg electronic scale, an electronic thermometer, a cylindrical measure, stop watches, verniers and calculators. For the efficiency test procedure, the following calculation was used:

Efficiency = (MW*HW)/(Mf*Hf) In this calculation:

MW = weight loss of water over time

HW = latent heat of water 2 260.74 KJ/kg

Mf = weight loss of fuel over time

Hf = calorific value of charcoal 31 448.9 KJ/kg (Efficiency Testing, 2004).

The initial testing on the field trip did not yield any results as the stoves were unable to arrive at a boiling temperature for the water. A revised version of tests reduced the amount of water to 1 litre and used a LPG gas stove to bring the water to boil to allow for the testing to be conducted, the tests were then run for 30 minute sessions.

The results of the testing showed the most positive efficiency for the stoves which included pot skirts. Including a pot skirt or at least directing the heat around the sides of the pot improves efficiency and thereby reduces the amount of charcoal required.

4.5 User feedback on stove designs

'Social entrepreneurs', says Dees, 'make sure they have correctly assessed the needs and values of the people they intend to serve and the communities in which they operate. In some cases, this requires close connections with those communities.' Similarly, it is vital that social-impact designers put the needs of the community they are serving above all else. This may seem obvious - designers generally work with the user in mind and push their designs to fulfil the user's desires. But in traditional design, such interests are matched with the needs of the business, producers, and even designers themselves. Social design must step back from that balanced approach and put users at the fore of all design activities. Only then is it possible to honestly make an impact, not merely create a well-designed object. (Ford, 2010)

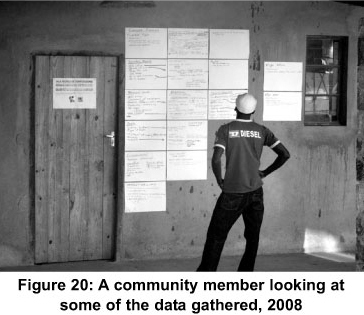

The research was conducted from the Desportivo Sports Centre, in the heart of Manica town. From this location the research group were able to constantly involve the community throughout the design process. Drawings were put up on the walls outside the club, research findings were posted and assumptions were dispelled through inviting the public off the street to discuss all aspects of the project. Stove testing was conducted at the entrance to the club, virtually on the street, and this drew crowds of interested onlookers who also offered their opinion on the design progress. The initial thoughts and gathered data were posted on the wall of the Desportivo main building, so that anybody who was interested could look through the work and offer comment. In this way, the research group received constant feedback from community members.

The research group completed user testing on all the stoves designed. User groups were set up to investigate the potential for the new stoves. A few unstructured cooking exercises with participants cooking a local meal on each of the stoves were conducted. The results of these tests allowed for further development and refinement of the stoves designed. Although the best performing stoves, which included the pot skirt type concept, would show a decrease in the use of fuel over an extended period of time, users were concerned about the cost implications when purchasing the stove, the issues of the varying pot sizes and pot skirt fit, and the possibility of burning their hands on the pot handle in use. Given more time, the research team would have liked to have commissioned the manufacture of a series of these stoves in the area and run extended home use tests. However, this was not done and can be seen as a limitation of the project.

5. Conclusion and recommendations

The field study component of the Manica Charcoal Stove Project took place over 14 days, a very short period of time. Within that time, an enormous amount of data was collected and should be useful for future projects in the area. However, a longer period of investigation will uncover more of the subtleties of cooking, lifestyle and needs of the community. Additionally, as the researchers gain the trust of the user group, the feedback and interaction on design solutions will become more direct and honest.

This project needs more work. With more funding and more user testing, the ambition is to develop a reasonably efficient stove for the short term with improvements and developments in efficiency happening over time. This could then be translated to areas outside of Manica and possibly to other SADC countries. However, in the same way that the users of Manica needed to be consulted throughout the design process, other users in other countries will require similar opportunities to be involved in the development of a product that will impact on their lives.

The principle design technology developed for the ProBEC Maputo Ceramic Charcoal Stove, although good, has not considered the users well enough and would certainly be difficult to introduce to a town like Manica. Designers need to interact with users of their products in order to grasp both the complexities and subtleties of use. The trip to Manica resulted in many design solutions, with the pot skirt type designs showing the best potential for further development for manufacture and implementation. All of the stoves designed included users in the process of development and also included local manufacturers. With further development, it is possible that a good design solution could be tested in a final phase of user interaction and that the resulting product could be made into templates for local manufacturers to produce.

As the department becomes more experienced at community and design for development projects, a few reoccurring guiding principles start to emerge. Each community centred project has its own challenges and it is difficult to formulate a single set of rules before starting these types of projects. A key component to the success of such products is to have good contextual research, excellent and reliable advisors who have sensitivity for the people and the region, and a research and design group who are willing to listen to the users and experiment with solutions around the issues identified.

Beyond this, the following recommendations may be applicable for future projects of this nature:

- Gather extensive research data on the area to develop a good contextual understanding of the people and the places.

- Place the user and community at the centre of the project and through an inclusive process develop the solution with them. Listen to the users, understand their needs.

- If appropriate use / adopt / adapt / apply the technology / principles that best fit the need. In other words: adapt the scientific / tested best practice principle to fit the project at hand.

- Observe the users in action, see what subtle principles they have invented to make their lives easier or the way in which they prefer to use the product. Gain a good understanding of the systems they have put in place to optimize the product.

- Design an appropriate solution that is sensitive to the acceptance by the user. If necessary retain some of the original aesthetics of the product that your solution will be replacing. This is to allow the users to continue to respond / engage / wish to use the product you propose.

- Resolve ergonomic and safety issues, designers have a responsibility to make sure the users are safe at all times when interacting with their products. Make sure the users will not harm themselves through using the product.

- Capacity building and sustainable practice: design the product to be manufactured at source. Empower communities rather than mass produce remote from users.

- Empower the manufacturer to continue to design and develop the project even after the intervention has taken place. The manufacturers are in touch with the users and should therefore be able to make the adjustments as required from interacting with their product users.

- Use locally available and recycled materials as far as possible.

- Hand over the plans for the design solution to a cross section of local manufacturers to allow them to manufacture the stove without needing to pay for the intellectual property.

Notes

1. The Programme for Biomass Energy Conservation (ProBEC), implemented by the German Organisation for Technical Cooperation (GIZ), formerly known as GTZ, was an official SADC programme and the only one focused on basic energy. ProBEC ), and the University of Johannesburg collaborated to establish a Stove Testing and Research Centre (SeTaR Centre), which is partially housed in the Department of Industrial Design. This research centre forms part of the support infrastructure for aspects of projects within the broader theme 'Energy Research' within the University of Johannesburg and will add value to the university's mission to conduct relevant and useful research for developing communities in the Southern African Development Community (SADC) region by testing stoves intended for developing communities and offering design improvements for these stoves.

2. The Maputo Ceramic Charcoal Stove was an early model of what is now called the Poupa Carvão (POCA) charcoal stove in which ProBEC and the GTZ have since invested a lot more research and development effort and money (Ceramic mix, tolerances etc).

3. 'Sanlam is the sponsor of the Creativity for Progress Competition, which is run among South African academic institutions. The theme for the competition is a better life for people in informal settlements. It provides an excellent opportunity for student groups and faculties to come up with innovative concepts on how to improve their life in informal settlements.' (Sanlam, 2008)

4. The Manica Charcoal Stove Project was given great insight into the town of Manica and the issues of deforestation, the use of charcoal stoves in the town and details of the town and surrounding areas from the BA (Honours) mini thesis completed by Schalk van Heerden in 2005. van Heerden lived in the town for five years from 2002 to 2007 and continues to maintain his link to the town through his involvement with the local soccer club: Groupo Desportivo de Manica. His research provides the background and grounding required to give the designers the understanding they required for this study. His connections within the town and its people were also leveraged to assist with the research process and gain access to the local community.

5. From van Heerden, 2005: SWIFT, K. 1974. Mozambique and the Future. Cape Town: Don Nelson.

6. Refers to in this context as the amalgamation of various architectural styles in the region and how these influenced each other. Luso - standing for Lusitania and the African mixed style.

7. United States Dollar (US$) / Meticais (Mtn) rate of exchange calculated on 1 US Dollar = 35.30 Mozambique Meticais (September, 2010: www.oanda.com/convert/classic)

Acknowledgement

The author would like to thank Schalk van Heerden for his invaluable contribution to the success of the Manica Charcoal Stove Project. Further thanks are extended to Victor Bezuidenhoudt, John Harverson, Ross Nelson and Theo Olivier for completing the field research and testing for the project. He would also like to thank Nelson Veremo, Shortstop Chikwandingwa and the members and management of the Grupo Desportivo de Manica for their hospitality and assistance throughout the project. This project would not have been possible without the active participation of the people of Manica Town.

References

Bezuidenhout, V., Harverson, J., Nelson, R. & Olivier, T. (2008). The Manica Charcoal Stove Project -Research report for the design and development of a more efficient charcoal stove. Research report for the Department of Industrial Design. Johannesburg: University of Johannesburg. Unpublished manuscript. [ Links ]

Boztepe, S. (2007). User value: competing theories and models. [O] International Journal of Design, August 2007 Volume 1 (2). Available at: www.ijdesign.org. [ Links ]

Bradnum, C. (2008). Manica charcoal stove project. FADA Research Newsletter, December 2008, Issue 11. [ Links ]

Blunck, M. (2010). Comments on the CDM programme of activities 'improved cook stoves for East Africa (ICSEA)' Eschborn, Germany: Poverty-oriented Basic Energy Services (HERA) / Deutsche Gesellschaft für Technische Zusammenarbeit (GTZ) GmbH. Available at: cdm.unfccc.in1/filestorage/Q/U/M/QUMUW3OVANGJT9SPQ5IXQZ2F6EHTOP/ Comments.pdf?t=Vkx8bWlzNGhwfDB4FhfeyyNxOIUj_P0wOD1c. [ Links ]

Carroll, J. & Rosson M, B. (2007). Participatory design in community informatics. Design Studies 28, Great Britain: Elsevier Science Ltd. [ Links ]

Chidamba, C.T. (2010). Report on the impact assessment of the POCA (POupa CArvão) charcoal stove. Maputo: ProBEC. [ Links ]

Coughlin, PE. (2007). Baseline survey of market and household cooks. Maputo: EconPolicy Research Group, Lda. And Program for Biomass Energy Conservation (ProBEC). [ Links ]

Coughlin, PE. (2008). Field testing for ceramic stoves: survey results from three boroughs in Maputo and Matola. Maputo: ProBEC. [ Links ]

Ford, R. (2010). What Social Entrepreneurship Can Teach Social Design. [O] Available at: changeobserver.designobserver.com/entry.html?entry=15148. [ Links ]

Feldmann, L. & Brinkmann, V. (2007). Marketing in household energy interventions - GTZ experiences from different African countries. GTZ / HERA -Household Energy Programme. Johannesburg: Boiling Point, No 54, Pages 20-22. Available at: www.hedon.info/tiki-download_item_attachment.php?attId=73. [ Links ]

Kahmann, R. & Henze, L. (1999). 'Usability Testing under Time-Pressure in Design Practice' in Green, W. S. & Jordan, PW. (Eds.) Human factors in product design. London: Taylor and Francis. [ Links ]

Margolin, V. (2000). Building a Design Research Community. Proceedings of the Politecnico di Milano Conference, May 18-20, Milan: Politecnico di Milano. [ Links ]

PCIA (The Partnership for Clean Indoor Air) 2013. Accessed at: www.pciaonline.org. [ Links ]

Sanlam, (2008). Sanlam inter-university creativity for progress challenge [O] Available at: web.up.ac.za/UserFiles/SANLAMINTER%20UNIVERSITY%20CREATIVITY%20CHALLENGE.doc Sanlam Creativity for Progress Competition. [ Links ]

Van Heerden, S. (2005). Relative sustainability: The 'tragedy of the commons', trees, institutions and environment in Manica, Mozambique. Mini dissertation submitted in partial fulfilment of the requirements for the degree of BA (Hons) in the Department of Anthropology & Development Studies. Johannesburg: University of Johannesburg. [ Links ]

WBT (Water Boiling Test) (2009). The Water Boiling Test Version 4.1.2: Cookstove Emissions and Efficiency in a Controlled Laboratory Setting. Available at: www.pciaonline.org/files/wbt4.1.2_0_0.pdf. [ Links ]

Winiarski, L. & Still, D. (2001). Increasing fuel efficiency and reducing harmful emissions in traditional cooking stoves [O] Available at: www.hedon.info/docs/BP47-14-StillWiniarski.pdf

Interviews and e-mails

Chikwandingwa, S. (2008). General discussion with Shortcover Chikwandingwa, General Manager at the Grupo Desportivo de Manica and highly regarded musician in Southern Africa throughout the field trip (all notes confirmed by Chikwandingwa). [ Links ]

Efficiency Testing, (2004). Email from Dr Phillip Lloyd. ERC, UCT; 25-10-2004. [ Links ]

Van Heerden, S. (2008). General discussion with the University of Johannesburg, Corporate Social Investment Administration Assistant and Grupo Desportivo de Manica Project Manager throughout the field trip (all notes confirmed by van Heerden). [ Links ]

Veremo, N. (2008). General discussion with Nelson Veremo, English teacher at the Grupo Desportivo de Manica throughout the field trip (all notes confirmed by Veremo). [ Links ]

Received 18 July 2011

revised 18 March 2013