Serviços Personalizados

Artigo

Indicadores

Links relacionados

-

Citado por Google

Citado por Google -

Similares em Google

Similares em Google

Compartilhar

Journal of the South African Institution of Civil Engineering

versão On-line ISSN 2309-8775

versão impressa ISSN 1021-2019

J. S. Afr. Inst. Civ. Eng. vol.65 no.2 Midrand Jun. 2023

http://dx.doi.org/10.17159/2309-8775/2023/v65n2a1

TECHNICAL PAPER

Spalling of concrete in fire - an overview and local relevance

J E van der Merwe

ABSTRACT

Concrete has traditionally been considered as a material with favourable fire resistance. The development of modern concretes with low permeability has, however, resulted in the increased occurrence of spalling when exposed to fire. Recent fire damage in South Africa during the riots in July 2021 resulted in such damage.

This paper presents an overview of explosive spalling of concrete in fire, recent local observations, and developments in the field. It is shown that various (often interrelated) factors influence the susceptibility of concrete to spall in fire, and that much research is still needed to fully understand the phenomenon and, specifically, how to accurately predict its occurrence. Recent observations in South Africa support conclusions in the literature that, as an accidental loading case or as life-safety performance criteria, overall structural integrity is rarely compromised. However, as the use of higher concrete grades increases, the relevance of this risk should be considered by practising engineers.

Keywords: fire exposure, pore pressure, explosive spalling, reinforced concrete

INTRODUCTION

Fires in structures pose a significant threat to occupants and property owners. Structural engineers are responsible for limiting the probability of injury, loss of life and damage to property to acceptable levels. Traditionally, concrete has been considered as incombustible, chemically stable, and as a material with favourable insulating properties, performing well during a fire (Buchanan & Abu 2017). A gradual decrease in compressive strength does, however, occur with increased concrete material temperature. A marked reduction in strength is associated with the 300°C isotherm, which is often accompanied by a discolouration of the cement matrix (Albrektsson et al 2011). Such thermal degradation can impair the continued service of reinforced concrete elements after a fire, but will seldom prevent safe evacuation during a fire for normal concrete grades. As an accidental load case then, such damage might be considered as detrimental to structural integrity, but low hazard.

Spalling of concrete is known to occur in some cases of fire exposure. This typically leads to a loss of concrete cover, resulting in a loss of thermal insulation to reinforcement and increased thermal degradation of the confined concrete core and high temperature exposure of reinforcement steel. In severe cases, spalling depth can extend into the confined core of reinforced concrete elements which, together with high-temperature exposure of reinforcement, can lead to collapse.

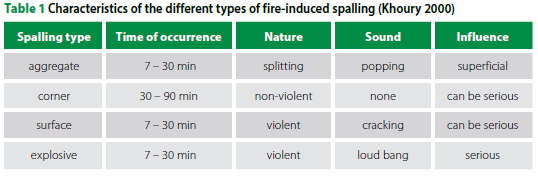

Various types of fire-induced spalling have been defined to date, as summarised in Table 1. The earliest forms of spalling are surface spalling, aggregate spalling, and explosive spalling, of which explosive spalling is considered the most violent. Due to the early, violent and often extensive nature of explosive spalling, it is considered as the greatest hazard to reinforced concrete structures if the extent is substantial.

Partial collapse of reinforced concrete building structures as a result of fire has been observed in the past. In many cases, however, reinforced concrete slabs are able to maintain structural integrity after spalling has occurred. Bailey (2002) concluded that this is most likely due to slabs acting in compressive membrane action following thermal expansion, although reduced loading benefits response as well.

The development of concrete with increased strength and reduced permeability, such as high-strength concrete (HSC) and self-compacting concrete (SCC), holds many advantages, such as increased durability and reduced element sizes. These advantages lead to its increased use in high-rise buildings, tunnel linings and warehouse floors. However, the low permeability of such compact modern concrete types leads to an increased risk of explosive spalling during fire exposure (Mindeguia et al 2013). This makes the assessment of spalling susceptibility of concrete, the possible extent of damage that might prevent safe evacuation during a fire, ways of preventing its occurrence, and the repair of such damage, increasingly relevant to structural engineers. Recent local observations illustrate this point.

Recent observations of fire-induced spalling of concrete in South Africa

The July 2021 riots in South Africa resulted in extensive fire damage to a warehouse structure in Durban. In addition to partial collapse of the steel superstructure, extensive fire-induced spalling of concrete elements resulted, as shown in Figure 1.

Severe explosive spalling of the steel-fibre-reinforced concrete floor occurred in isolated locations (Figure 1(a)) to depths of up to half of the floor thickness. Similarly, extensive spalling resulted to slab soffits of the adjacent office building, exposing bottom reinforcement (Figure 1(b)). Such spalling around columns has been shown to drastically reduce punching shear resistance (Lu et al 2018). Localised fires in reinforced concrete structures inside the warehouse space showed substantial spalling of the top of slabs, as well as cases of corner spalling of columns, exposing reinforcement to fire (Figures 1(c) and 1(d)).

PROPERTIES INFLUENCING SPALLING

Numerous parameters influence the susceptibility of concrete to spall in fire, ranging from material production to construction and operational conditions. Properties can be grouped into the following four categories (Van der Merwe 2019):

Concrete mixture composition

The aggregate type is said to influence spall-ing susceptibility, with siliceous aggregate concretes often reported as being more susceptible to spalling (Fib Bulletin 38: 2007). Substantial thermal damage can result due to the difference in the thermal expansion coefficient of aggregate and the surrounding cement paste. Quartz in siliceous aggregates is generally associated with a phase change at high temperatures that results in a rapid increase in volume and subsequent thermal damage to concrete (Bazant & Kaplan 1996).

Although some contradictory results have been reported in the literature, there appears to be general agreement that a larger coarse aggregate size reduces spalling susceptibility. Experimental results by Pan et al (2012) support this, suggesting the cause to be related to an increased characteristic length of the fracture process zone that is associated with larger aggregates, although increased permeability is likely an additional contributing factor (Van der Merwe 2019).

High cement and silica fume content is also said to increase spalling susceptibility, correlating with lower permeability and a subsequent higher internal pressure buildup potential (e.g. Klingsch 2014; Kodur & McGrath 2006).

Material properties of hardened concrete

It has often been stated in the literature that greater compressive strength is often associated with increased spalling susceptibility (e.g. Majorana et al 2010). General consensus is that this is due to the compact microstructure that is associated with greater compressive strength. A strong correlation has been shown to exist between the compressive strength of concrete and its intrinsic permeability (Van der Merwe 2022c), suggesting that higher concrete grades can be expected to be associated with higher pore pressure build-up during fire exposure. Related to such a compact microstructure is the permeability of concrete, which governs pore pressure build-up potential (Bazant & Kaplan 1996). Since the permeability of concrete can be reduced without increasing compressive strength, Hertz (2003) concluded that permeability is a more relevant indication of spalling risk than compressive strength.

In addition to permeability, the moisture content determines pore pressure build-up during fire exposure, and is therefore considered by many as a crucial parameter related to spalling susceptibility (e.g. Hertz 2003). In addition to its influence in pore pressure build-up, increased moisture content can be expected to increase the thermal stress gradient (Fib Bulletin 38: 2007). Latent heat during the phase change from liquid water to vapour is associated with an increased specific heat of concrete, with a subsequent slower increase in temperature away from the heated surface and a resulting increase in thermal stress. Similarly, thermal properties that affect thermal stress development are also associated with spalling risk, including the specific heat and thermal conductivity of concrete.

Since fracture energy determines the specific energy required for crack propagation, lower fracture energy is associated with increased spalling risk. Bazant and Prat (1988) concluded from experimental results that the fracture energy of concrete gradually decreases with increased temperature, thereby making concrete gradually more susceptible to spalling with increased temperature.

Structural properties

Previous investigations have shown that the spalling susceptibility of concrete generally increases (i) with increased element size (Boström et al 2007), (ii) where structural geometry results in stress concentration at sharp corners (Khoury & Anderberg 2000), and (iii) where thermal restraint prevents expansion of concrete during heating (Majorana et al 2010).

Loading

It is generally accepted that an increased heating rate increases spalling susceptibility due to increased thermal stress development (Kodur & Phan 2007). Experimental observations have also shown that moderate compressive stress increases spalling susceptibility (Carré et al 2013). Moderate compressive stress adds to the overall internal stress state, but has also been shown to reduce the intrinsic permeability of concrete (Van der Merwe 2022b), which in turn can result in increased pore pressure development.

PLAUSIBLE MECHANISMS OF SPALLING

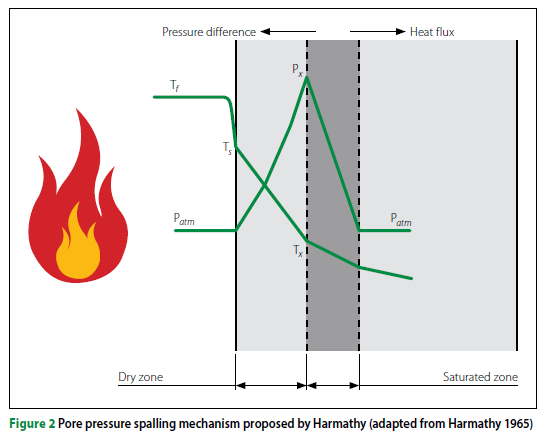

Various mechanisms for explosive spalling have been proposed, and some academic debate in this regard continues to date. Shorter and Harmathy (1961) and Harmathy (1965) proposed that pore pressure build-up in the concrete matrix at elevated temperatures is the main mechanism responsible for spalling. Once moisture evaporation starts, the resulting pressure gradient forces part of the moisture to the heated surface, whilst the direction of heat flux forces the remainder to the cooler inner region. Here condensation is said to result in a region of increased moisture content. As heating continues, two distinct zones result - a dry region near the heated surface, and a saturated zone (moisture clog) deeper in the concrete section (Figure 2). The low permeability in this moisture clog results in gradually increasing pore pressure and finally in spalling when the high-temperature tensile strength of concrete is exceeded.

Despite such a moisture clog having been experimentally shown to develop, it is widely accepted that pore pressure alone cannot be responsible for spalling since the mechanism does not account for increased spalling risk due to confinement (Jansson & Boström 2012) and since resulting pore pressure is usually well below typical ranges of concrete tensile strength (Bazant & Thonguthai 1979).

The high heating rate imposed during fire exposure results in a high temperature gradient over the depth of a concrete section which, in turn, leads to the development of thermal stress. The compressive stress state that results near the heated surface was proposed by Saito (1966) as a mechanism of explosive spalling. It was suggested that such compressive stress induces cracks that separate a surface layer. Thermal buckling of this weakened delaminated layer is the proposed cause of spalling. Experimental observations have shown, however, that spalling can occur in some concretes at heating rates much lower that those that would impose meaningful thermal stress, suggesting that thermal stress alone cannot be a mechanism of spalling (Klingsch 2014).

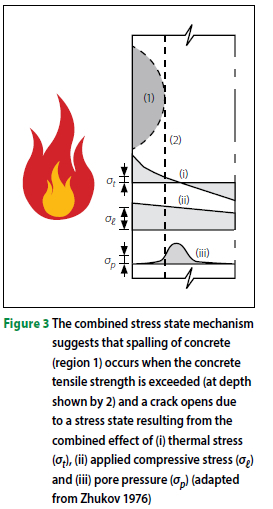

The most widely accepted mechanism is the combined stress state mechanism proposed by Zhukov (1976). With reference to Figure 3, this mechanism suggests that explosive spalling occurs when the combined effect of thermal stress, pore pressure development and level of applied compressive stress exceeds the temperature-dependent tensile strength of concrete.

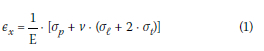

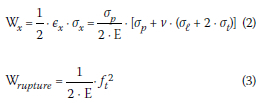

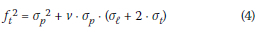

Considering the total strain in the direction of spalling (Equation 1), pore pressure (σp) acts directly in this direction, whilst Poisson effects from thermal stress (σt) and applied compressive stress (σ£) add to this effect.

Explosive spalling is said to occur when the strain energy (Wx, Equation 2) exceeds the rupture strain energy (Wrupture, Equation 3).

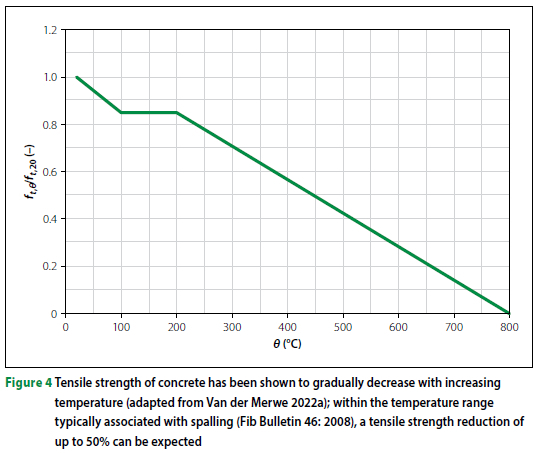

Combining Equations 2 and 3, it follows that explosive spalling is initiated when the combined internal stress state exceeds the tensile strength of concrete, as shown in Equation 4. With increased material temperature, the tensile strength of concrete can be expected to gradually decrease as shown in Figure 4.

PREDICTIVE MODELS

Numerous attempts have been made to develop a means of predicting the occurrence of explosive spalling of concrete in fire, ranging from nomograms, analytical models and numerical models. To date, however, none of these have been validated as a reliable means of predicting this phenomenon.

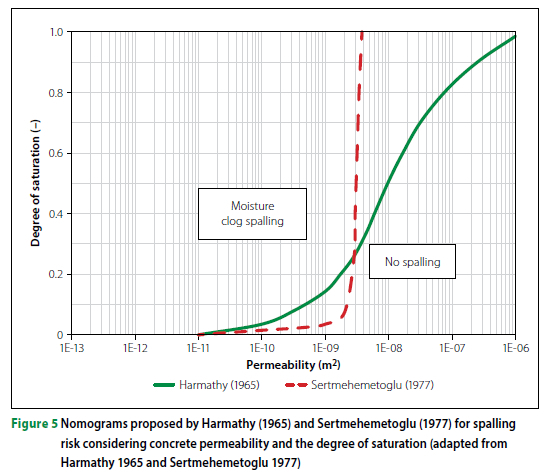

Moisture clog theory

Harmathy (1965) proposed analytical expressions for the movement of a moisture clog in concrete. Based on these expressions, he proposed a limit criterion for the pore saturation associated with fire-induced spalling. His proposed nomo-gram (Figure 5) provides a graphical means of evaluating the risk of explosive spalling based on a limit value for pore saturation with permeability. This model was modified by Sertmehemetoglu (1977) to account for the difference in permeability, viscosity, and pressure between the moisture clog and the heated surface. Comparing these two models in Figure 5, shows that the modified model suggests a narrower range of permeability associated with spalling susceptibility, which can be expected to shift to higher or lower permeability values depending on the concrete tensile strength.

Level of compressive stress and element thickness

Based on experimental results by Meyer-Ottens (1972), Sertmehemetoglu (1977) proposed a nomogram for spalling susceptibility based on the level of applied stress and the thickness of a concrete element heated from two sides (Figure 6). An adapted version of this nomogram was later incorporated in Eurocode (EN 1995).

Numerical models

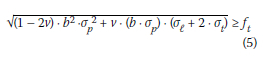

Each of the two nomograms described above clearly accounts for parameters known to be associated with explosive spalling, but neglects other known contributing parameters. Numerical models have been proposed to account for all known effects that contribute to explosive spalling. Gawin et al (1999) proposed a hygro-thermal model which, amongst others, accounts for the effect of moisture movement and heat flux. Their model for the high-temperature development of intrinsic permeability was subsequently considered by Dwaikat and Kodur (2009) to propose a hydrothermal model for the assessment of spalling risk. The model accounts for temperature variation, pore pressure and moisture movement that are considered as coupled equations to be solved numerically. Spalling is then identified when the pore pressure exceeds the high-temperature tensile strength of concrete. Elaborating on this model to account for pore pressure in all directions, and for Biot's coefficient, which determines the extent to which pore pressure affects the internal stress state of the concrete matrix, Lu (2015) proposed the numerical model shown in Equation 5.

Considering a 150 mm thick concrete slab exposed to fire on one side, and with a reference concrete tensile strength of 2.5 MPa, Lu (2015) proposed a boundary intrinsic permeability value of 2 χ 10-17 m2. The correlation between concrete tensile strength and intrinsic permeability investigated by Van der Merwe (2019) suggests that such intrinsic permeability values are, however, unlikely for the concrete tensile strength assumption.

GENERAL METHODS OF PREVENTION

Experimental observations of explosive spalling have shown the occurrence of this phenomenon to be complex and often erratic. Fib Bulletin 38 (2007) reports a test series of ten similar specimens where five samples spalled, whilst five did not. Elsewhere this observation is supported, mentioning that, for concrete samples from the same batch and under identical curing and testing conditions, some samples would spall whilst others would not (Connolly 1995; Majorana et al 2010). To this extent, Bisby et al (2014) recommend that "... attempts should be made to avoid spalling... in practice, since spalling introduces uncertainties that are very difficult to rationally account for in design" Where a risk of spalling is therefore suspected, or where the consequence of explosive spalling is expected to have a substantial effect on structural integrity or the safe evacuation of occupants, preventative methods should be considered.

Addition of fibres

In addition to improving ductility, the addition of steel fibres to concrete increases its tensile strength. Since it is generally believed that spalling occurs when the high-temperature stress state in concrete exceeds its tensile strength, steel fibres can be expected to increase the resistance to explosive spalling. Nevertheless, contradicting experimental observations of its beneficial effect have been reported, with some tests showing improved spalling resistance (Kodur et al 2003), whilst others notice no substantial improvement (Klingsch et al 2013). Moreover, the addition of steel fibres has been noted to increase the violent nature of explosive spalling in some cases due to the release of a greater build-up of energy accommodated by the increased tensile strength (Fib Bulletin 38: 2007). This supports recent observations of a steel-fibre-reinforced concrete warehouse floor (Figure 1a).

It is widely agreed that the addition of polypropylene fibres (PP-fibres) reduces the risk of spalling. Explosive spalling of concrete with compressive strength of up to 150 MPa has been found to be avoided when adding 0.05 - 0.10% PP-fibres (Fib Bulletin 38: 2007). Most conclusions in literature seem to agree that the observed benefit of adding PP-fibres is related to increased permeability and improved moisture transport, thereby reducing pore pressure build-up (e.g. Heo et al 2012; Klingsch et al 2013; Maluk et al 2017). Increased entrained air during the concrete mixing process, and poor adhesion between fibres and the surrounding concrete matrix have been proposed as potential mechanisms for the beneficial effect of adding PP-fibres, but the formation of continuous channels after fibres melt, and differential thermal expansion are the two most widely argued mechanisms. Following experimental tests of HSC with PP-fibres, Kalifa et al (2001) studied test samples with a scanning electron microscope. They concluded that molten PP-fibres are absorbed into the surrounding porous cement matrix. The interconnected channels created in this manner are said to increase permeability and, subsequently, reduce pore pressure. Another proposed mechanism suggests that there exists a difference in thermal expansion between PP-fibres and the surrounding concrete matrix, resulting in micro cracks that increase overall permeability and, subsequently, reduce pore pressure. Zhang et al (2018) investigated ultra-high performance concrete with PP-fibres after heating to elevated temperatures at 5°C/min. A subsequent review of samples with a scanning electron microscope revealed micro cracks in the concrete matrix between fibres prior to melting, suggesting that the thermal expansion mismatch between fibres and the cement matrix is responsible for the reduced spalling risk. Despite the variation in conclusions, it is clear that PP-fibres reduce the risk of explosive spalling by increasing permeability. It is argued here that the interconnectedness of increased porosity that is required to increase permeability, is more likely to result from the formation of microcracks than absorbed molten fibres.

Protective barriers

The aim of protective barriers, be they panels, mortar or intumescent paint, is to minimise heat transfer to concrete in the event of a fire. No design criteria are currently available for the use of these measures to avoid explosive spalling. As such, careful experimental validation of protective barriers is typically required. Reviewing a series of fire tests by Klingsch et al (2013), Lu (2015) concluded that the provision of an insufficient protection layer can, in some cases, increase the violent nature of explosive spalling. Figure 7 compares explosive spalling of a slab with and without a protective lining (Klingsch et al 2013). Although the protective lining delayed the occurrence of spalling, damage occurred to the same depth. Moreover, compared to the gradual, layer-by-layer spalling observed for the slab without a protective layer, spalling occurred with a single loud explosion where the protective layer had been applied.

Reinforcement details

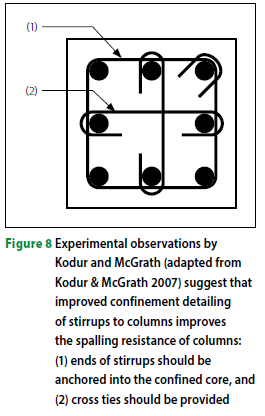

A series of experimental and numerical investigations of the behaviour of reinforced concrete columns in fire were conducted by Kodur and McGrath (2006), and Kodur and Phan (2007). They concluded that transverse confinement reinforcement details that are typically recommended in regions of seismic hazard are well suited to improve the explosive spalling resistance of columns. The detail calls for (i) a reduced transverse reinforcement diameter with decreased vertical spacing instead of larger diameters at greater spacing, (ii) the provision of cross ties, and (iii) anchorage of tie ends into confined concrete, i.e. a 135° hook instead of the more common 90° hook (Figure 8).

CURRENT REGULATIONS AND GUIDELINES

Eurocode 2 (EN 2004) addresses the fire design of concrete structures and is perhaps the most suitable current reference, since the suite of SANS standards does not include similar clauses. This standard recommends that the occurrence of spalling should either be prevented, or that the engineer should consider the consequences of spalling on the structural capacity of elements. Spalling is addressed separately for normal strength concrete (NSC) and high strength concrete (HSC). It is suggested that spalling of NSC is unlikely to occur if the initial free moisture content is less than 3%. An earlier version of this standard (EN 1995) mentioned that this moisture content would most likely not be exceeded if a concrete element is subjected to internal exposure. Where this limit is exceeded, the risk of spalling should be more carefully investigated, considering (i) the moisture content, (ii) aggregate type, (iii) concrete permeability, and (iv) the expected (or design) heating rate. It does, however, give no guidance as to how these factors should be reviewed to assess spalling susceptibility. Nevertheless, the standard recommends that no further in-depth spalling assessment is necessary if the tabulated concrete material property data and the recommended reinforcement details are considered by the engineer.

HSC up to class C80/95 with a silica fume content of less than 6% of the cement mass, is treated as NSC. For higher concrete classes, or where the silica fume content exceeds 6%, four possible methods are recommended to prevent the occurrence of spalling:

(A) providing mesh reinforcement near the exposed concrete surface

(B) prescribing concrete that has been proven (experimentally or by experience) not to be susceptible to spalling

(C) providing a protective layer that has been shown to prevent spalling

(D) including a minimum of 2 kg/m3 monofilament polypropylene fibres.

However, even when adhering to regulations, spalling can still occur. A full-scale fire test was performed on a seven-storey reinforced concrete building in Cardington in 2001 (Bailey 2002). Adhering to prescriptive rules, Eurocode recommendations suggest that spalling should not occur and that its occurrence can be ignored. Nevertheless, severe spalling did occur. The outcome highlights our poor understanding of the phenomenon of explosive spalling, and the limited means available to practising engineers to assess the spalling susceptibility of concrete.

DEVELOPMENTS

Recent findings are set to influence the evolution of Eurocode provisions pertaining to the susceptibility of concrete to spall explosively in fire. Eurocode (EN 2004) mentions that spalling should not occur if the moisture content is below k% by weight, with 2.5 < k < 3.0% and a recommended value of 3%. Although the moisture content of concrete is undoubtedly an important parameter affecting the propensity of concrete to spall during fire exposure, it is difficult to predict what the moisture content of a concrete element will be, and equally hard to influence its value.

Moreover, spalling has been observed at lower moisture content levels (e.g. Zheng et al 2010). Results from various studies suggest that the relevance of moisture content as a parameter affecting spalling susceptibility depends on the type of aggregate, cross-sectional shape of the element, level of com-pressive stress, concrete mixture and heating rate (Jansson 2013). It has been suggested that such a moisture content limit be replaced by a list of concrete conditions known to result in a high moisture content and limited drying (Jansson 2013). These can include concrete exposed to saturated conditions or with permanent formwork that prevents drying.

CONCLUDING REMARKS

Although less severe types of fire-induced spalling might affect normal concrete strength grades to a limited extent, the susceptibility of concrete to spall explosively in fire is likely to become an increasingly relevant risk to be considered by structural engineers as the use of denser concretes and higher concrete grades increase in South Africa. This paper highlighted some key considerations, but also showed that, to a large extent, this phenomenon remains poorly understood. Much research is still needed in order to more accurately assess this risk. To date, the only accurate method of assessing the susceptibility of concrete to spall explosively in fire, is to perform fire tests of representative concrete elements. Since both the size and geometry of a concrete element influence the risk of spalling, small-scale samples, such as standard concrete cubes or cylinders, should not be considered as representative (e.g. Boström et al 2007). Due to the great cost of such fire tests, various studies attempted to develop a numerical means of assessing spalling susceptibility. Significant progress has been made towards such a numerical means of assessment (Lu 2015; Lottman 2017), but fundamental input parameters for such models have not been the focus of many studies (Van der Merwe 2019). Considering results reported to date, the most effective method of prevention is to include polypropylene fibres to a concrete mixture.

ACKNOWLEDGEMENTS

The author wishes to thank Prof Dr Mario Fontana, retired professor at ETH Zurich, for his guidance during the author's doctoral study focusing on material properties related to explosive spalling of concrete in fire.

List of symbols

b Biot's coefficient (-)

E Young's modulus of concrete (Pa)

ft tensile strength of concrete (Pa)

ft20 tensile strength of concrete at ambient temperature (Pa)

ftθ tensile strength of concrete at temperature θ (Pa)

k moisture content (%)

patm atmospheric pressure (Pa)

px pore pressure at depth x (Pa)

Tf or θ fire (gas) temperature (°C)

Ts concrete surface temperature (°C)

Tx concrete temperature at depth x (°C)

Wrupture rupture strain energy (J)

Wx strain energy in direction x (J)

εx strain in direction x (-)

ν Poisson's ratio (-)

σt applied compressive stress (Pa)

σp pore pressure (Pa)

σt thermal stress (Pa)

REFERENCES

Albrektsson, J, Flansbjer, M, Lindqvist, J E & Jansson, R 2011. Assessment of concrete structures after fire. SP Report 2011:19. SP Technical Research Institute of Sweden. [ Links ]

Bailey, C 2002. Holistic behaviour of concrete buildings in fire. Proceedings of the Institution of Civil Engineers, Structures and Buildings, 3: 199-212. [ Links ]

Bazant, Z P & Thonguthai, W 1979. Pore pressure in heated concrete walls: Theoretical prediction. Magazine of Concrete Research, 31(107): 67-76. [ Links ]

Bazant, Z P & Prat, P C 1988. Effect of temperature and humidity on fracture energy of concrete. ACI Materials Journal, 85(4): 262-271. [ Links ]

Bazant, Z P & Kaplan, M F 1996. Concrete at High Temperatures: Material Properties and Mathematical Models. New York: Longman. [ Links ]

Bisby, L, Mostafaei, H & Pimienta, P 2014. State-of-the-art on fire resistance of concrete structures: structure-fire model validation. Draft report submitted to Applied Research Associates, Albuquerque, NM. [ Links ]

Boström, L, Wickström, U & Adl-Zarrabi, B 2007. Effect of specimen size and loading conditions on spalling of concrete. Fire and Materials, 31: 173-186. [ Links ]

Buchanan, A H & Abu, A K 2017. Structural design for fire safety. Hoboken, NJ: Wiley. [ Links ]

Carré, H, Pimienta, P, La Borderie, C, Pereira, F & Mindeguia, J-C 2013. Effect of compressive loading on the risk of spalling. MATEC Web of Conferences, 6: 01007. [ Links ]

Connolly, R J 1995. The spalling of concrete in fires. PhD Thesis. Birmingham, UK: Aston University. [ Links ]

Dwaikat, M B & Kodur, V 2009. Hydrothermal model for predicting fire-induced spalling in concrete structure systems. Fire Safety Journal, 44: 425-434. [ Links ]

EN (European Standard) 1995. ENV1992-1-2 (1995). Eurocode 2: Design of concrete structures. Part 1-2: General rules - Structural fire design. Brussels: European Committee for Standardization. [ Links ]

EN 2004. EN 1992-1-2 (2004). Eurocode 2: Design of concrete structures. Part 1-2: General rules -Structural fire design. Brussels: European Committee for Standardization. [ Links ]

Fib Bulletin 38: 2007. State-of-the-art report. Fire design of concrete structures. Materials, structures and modelling. Task Group 4.3-1. Lausanne, Switzerland: International Federation for Structural Concrete. [ Links ]

Fib Bulletin 46: 2008. State-of-the-art report. Fire design of concrete structures. Structural behaviour and assessment. Task Group 4.3. Lausanne, Switzerland: International Federation for Structural Concrete. [ Links ]

Gawin D, Majorana, C E & Schrefler, B A 1999. Numerical analysis of hygrothermal behaviour and damage of concrete at high temperature. Mechanics of Cohesive-Frictional Materials, 4: 37-74. [ Links ]

Harmathy, T Z 1965. Effect of moisture on the fire endurance of building elements. In: Moisture in Materials in Relation to Fire Tests. West Conshohocken, PA: ASTM International, 74-95. [ Links ]

Heo, Y-S, Sanjayan, J G, Han, C-G & Han, M-C 2012. Limited effect of diameter of fibres on spalling protection of concrete in fire. Materials and Structures, 45: 325-335. [ Links ]

Hertz, K D 2003. Limits of spalling of fire-exposed concrete. Fire Safety Journal, 38: 103-116. [ Links ]

Jansson, R & Boström, L 2012. Determination of fire spalling of concrete: Relevance of different test methods. Proceedings, 7th International Conference on Structures in Fire, Zurich, Switzerland, 6-8 June 2012, pp 581-587. [ Links ]

Jansson, R 2013. Fire spalling of concrete: Theoretical and experimental studies. PhD Thesis Stockholm, Sweden: KTH Royal Institute of Technology. [ Links ]

Kalifa, P, Chéné, G & Gallé, C 2001. High-temperature behaviour of HPC with polypropylene fibres: From spalling to microstructure. Cement and Concrete Research, 31: 1487-1499. [ Links ]

Khoury, G A 2000. Effect of fire on concrete and concrete structures. Proceedings of Structural Engineering Materials, 2: 429-447. [ Links ]

Khoury, G A & Anderberg, Y 2000. Concrete spalling review. Fire Safety Design, 60: 5-12. [ Links ]

Klingsch, E, Frangi, A & Fontana, M 2013. Explosive spalling of concrete in fire. IBK Test Report 352. Zurich, Switzerland: ETH Institute of Structural Engineering (IBK) [ Links ]

Klingsch, E W H 2014. Explosive spalling of concrete in fire. PhD Thesis. ETH Zurich, Switzerland. [ Links ]

Kodur, V K R, Cheng, F-P, Wang, T-C & Sultan, M-A 2003. Effect of strength and fiber reinforcement on fire resistance of high-strength concrete columns. Journal of Structural Engineering, 129(2): 253-259. [ Links ]

Kodur, V K R & McGrath, R 2006. Effect of silica fume and lateral confinement on fire endurance of high strength concrete columns. Canadian Journal of Civil Engineering, 33: 93-102. [ Links ]

Kodur, V K R & Phan, L 2007. Critical factors governing the fire performance of high-strength concrete systems. Fire Safety Journal, 42: 482-488. [ Links ]

Lottman, B B G 2017. The spalling mechanism of fire exposed concrete. PhD Thesis. Technical University of Delft, Netherlands. [ Links ]

Lu, F2015. On the prediction of concrete spalling under fire. PhD Thesis. ETH Zurich, Switzerland. [ Links ]

Lu, F, Beartschi, R, Van der Merwe, J & Fontana, M 2018. The effect of explosive spalling on punching shear strength of concrete slabs exposed to fire. Proceedings, 10th International Conference on Structures in Fire. Ulster University, Belfast, Ireland, pp 77-84. [ Links ]

Majorana, C E, Salomoni, V A, Mazzucco, G & Khoury, G A 2010. An approach for modelling concrete spalling in finite strains. Mathematics and Computers in Simulation, 80: 1694-1712. [ Links ]

Maluk, C, Bisby, L & Terrasi, G P 2017. Effects of polypropylene fibre type and dose on the propensity for heat-induced concrete spalling. Engineering Structures, 141: 584-595. [ Links ]

Meyer-Ottens, C 1972. Zur Frage der Abplatzungen an Betonbauteilen aus Normalbeton bei Brandbeanspruchung. PhD Thesis. Braunschweig University of Technology, Germany. [ Links ]

Mindequia, J-C, Pimienta, P, Carré, H & La Borderie, C 2013. Experimental analysis of concrete spalling due to fire exposure. European Journal of Environmental and Civil Engineering, 17(6): 453-466. [ Links ]

Pan, Z, Sanjayan, J & Kong, D 2012. Effect of aggregate size on spalling of geopolymer and Portland cement concretes subjected to elevated temperatures. Construction and Building Materials, 36: 365-372. [ Links ]

Saito, H 1966. Explosive spalling of prestressed concrete in fire. Bulletin of the Fire Prevention Society of Japan, 15(2): 23-30. [ Links ]

Sertmehemetoglu, Y 1977. On a mechanism of spalling of concrete under fire conditions. PhD Thesis. University of London, UK. [ Links ]

Shorter, G W & Harmathy, T Z 1961. Discussion: "The fire-resistance of prestressed concrete beams" by L A Ashton & S C C Bate. Proceedings of the Institute of Civil Engineers, 21(2): 313-315. [ Links ]

Van der Merwe, J E 2019. Constitutive models towards the assessment of concrete spalling in fire. PhD Thesis. ETH Zurich, Switzerland. [ Links ]

Van der Merwe, J E 2022a. Evaluation of concrete tensile strength as a function of temperature. Construction and Building Materials, 329: 127179. [ Links ]

Van der Merwe, J E 2022b. Effect of compressive stress on the intrinsic permeability of concrete. Results in Materials, 14: 100280. [ Links ]

Van der Merwe, J E 2022c. Towards the estimation of concrete intrinsic permeability. Cement and Concrete Research, 159: 106885. [ Links ]

Zhang, D, Dasari, A & Tan, K H 2018. On the mechanism of prevention of explosive spalling in ultra-high performance concrete with polypropylene fibers. Cement and Concrete Research, 113: 169-177. [ Links ]

Zheng, W Z, Hou, X M, Shi, D S & Xu, M X 2010. Experimental study on concrete spalling in prestressed slabs subjected to fire. Fire Safety Journal, 45: 283-297. [ Links ]

Zhukov, V 1976. Reasons of explosive spalling of concrete by fire. Beton I zhelezobeton (Concrete and Reinforced Concrete), Vol 3. [ Links ]

Correspondence:

Correspondence:

J E van der Merwe

Department of Civil Engineering, University of Pretoria

Private Bag X20, Hatfield, Pretoria 0028, South Africa

E: vandermerwe.johann@up.ac.za

DR JOHANN VAN DER MERWE (Pr Eng, MSAICE) is a senior lecturer in the Department of Civil Engineering at the University of Pretoria. He completed his BEng and MSc(Eng) degrees at Stellenbosch University, and his doctorate at the Swiss Federal Institute of Technology in Zurich (ΕΤΗ Zurich). He worked as a consulting design engineer for a number of years before joining the University of Pretoria in 2023. After first researching the material properties governing the behaviour of concrete in fire and the seismic analysis of structures, he is now concentrating his research efforts on topics related to improved sustainability of building structures.