Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

Journal of the South African Institution of Civil Engineering

On-line version ISSN 2309-8775

Print version ISSN 1021-2019

J. S. Afr. Inst. Civ. Eng. vol.65 n.1 Midrand Mar. 2023

http://dx.doi.org/10.17159/2309-8775/2023/v65n1a1

TECHNICAL NOTE

Establishing competent ground conditions with the DPSH

C J MacRobert; T J Stergianos

ABSTRACT

Insufficient information is currently available to fully understand the mechanism of rod friction in DPSH (Dynamic Probe Super Heavy) probing. Consequently, a method is proposed to distinguish profiles in which friction results in excessive blow counts based on normalised profiles. While friction-impacted DPSH profiles are difficult to interpret, those unaffected by friction show better equivalence to SPT (Standard Penetration Test) profiles, especially if used to screen for competent (SPT blow counts > 30) ground conditions.

Keywords: site investigations, in-situ testing, dynamic penetration testing, soil classification, statistical analysis

INTRODUCTION

MacRobert (2017) showed that a narrow range of Dynamic Probe Super Heavy (DPSH) blow counts (N30SB) could be associated with very loose and loose consistencies. However, the range of N30SB values associated with medium-dense and dense horizons was very large. This brings into question the usefulness of the DPSH to establish the presence of competent horizons in the ground. Standard Penetration Test (SPT) blow counts (N) above 50 are commonly taken to indicate the presence of a very dense and competent layer within the ground (Decourt et al 1988). For foundation design, screening foundations subject to small settlements are often based on finding the depth below which N > 30 (Lommler 2012). This research sought to re-examine the existing MacRobert (2017) data set and recently collected data to establish whether the DPSH can be used to establish the presence of a competent layer.

METHODOLOGY

Test sites

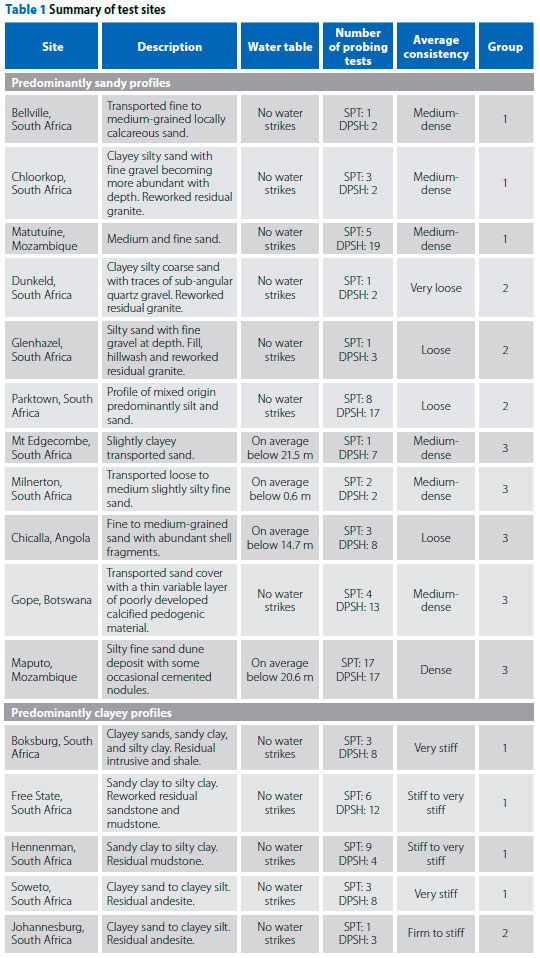

Table 1 summarises the various sites considered in this study. The location, soil profile, water table depth, number of respective probing tests performed, average consistency and site grouping are provided. Only DPSH and SPT testing conducted adjacent to each other, for comparative purposes in the original site investigation scope, were compared. Note that some sites and probes analysed in MacRobert (2017) have been excluded as there was insufficient information from borehole logs to interpret and predict conditions at the final DPSH depth.

Statistical approach

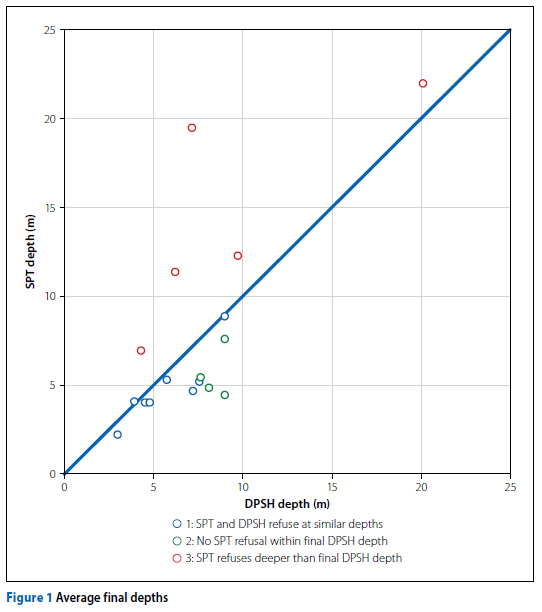

Table 1 shows sites divided into three groups. The sites in Group 1 were those where the average final DPSH depth coincided within a single standard deviation of the average depth at which SPT N exceeded 50. Group 2 profiles were those where no SPT exceeded 50 within the average final DPSH depth. Group 3 sites were those where the average depth at which SPT N exceeded 50 was greater than the final DPSH depth. Group 3 DPSH probings encountered significant rod friction leading to large blow counts at shallow depths. Average final depths for the three groups are shown in Figure 1. Each N30sB profile was normalised by depth (i.e. depth at a given N30SB divided by respective final probe depths) and a third-degree polynomial plotted through. These regression curves were used to establish bounds for the three groups. Analysis was carried out on raw blow counts, as the analysis suggested the range of blow counts was more important than a blow count for which a correction (i.e. overburden, rod length, borehole diameter, energy corrections) may be relevant.

RESULTS

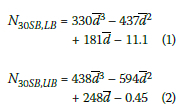

While it was not possible to differentiate the three groups based on known properties of the profile (e.g. clayey vs sandy profiles, dense vs loose or water table), the shape of resulting N30SB profiles could be differentiated (Figure 2). In this figure N30SB values for each probing in the dataset are plotted against normalised depth (i.e. depth at which the N30SB value was recorded divided by the final probed depth). Figure 2(b) shows Group 2 profiles along with a proposed lower bound (Equation 1). This lower bound was obtained by ensuring that less than 10% of Group 2 profiles had more than 50% of N30SB values above the bound. Figure 2(c) shows Group 3 profiles and the corresponding upper bound (Equation 2). This upper bound was obtained by ensuring that less than 10% of Group 3 profiles had more than 50% of N30SB values below the bound. Figure 2(a) shows Group 1 profiles along with the two proposed bounds. Seventy percent (70%) of Group 1 profiles had fewer than 50% of N305B values above or below the bounds. These bounds are defined by:

Where:

N30SB LB is the lower bound N30SB UB is the upper bound d is depth normalised by the final DPSH depth.

Figure 2(d) shows the proposed use of the bounds. Due to considerable overlap in N30SB for d < 0.2, any blow counts above this should be ignored. If more than 50% of N30SB values for d > 0.2 lie above the upper bound, then probing is considered to fall into Group 3. If more than 50% of N30SB values after d > 0.2 lie below the lower bound, that profile is considered to fall into Group 2. However, if neither of these conditions are met, probing is considered to fall into Group 1 and corresponds to reaching a competent horizon (i.e. N > 50). Classifying a profile as Group 1 does not necessarily mean that 50% of N30SB fall between the bounds.

It should be noted that setting these bounds so that no probings would be misassigned resulted in their overlap. Consequently, engineering judgement is required to interpret N30SB profiles that plot within ± 5 N305B of the bounds. It is recommended in such situations to consider the average normalised profile for a site (based on a minimum of 5 DPSH probings on a site). Due to greater risk in failing to identify probings falling into Group 2, DPSH probing where the majority of N30SB for d > 0.75 fall below the lower bound should be classified into Group 2 regardless of whether most other points plot within the bounds.

Figure 3 illustrates correlation between N30SB and N for the three groups. While Group 1 data generally trends along the line of unity (Figure 3(a)), scatter suggests superficial equivalence. On the other hand, the MacRobert et al (2011) correlation unnecessarily underestimates high blow counts for Group 1. A blow count of 30 is often used as a screening threshold in foundation decisions (Lommler 2012); consequently, N values for N30SB above and below 30 are highlighted by box plots to the right of Figure 3. For Group 1 profiles, using this threshold will lead to similar consistency delineations. That is, for N30SB < 30, 50% of N were below 30, and for N30SB > 30, 92% of N were above 30.

Assuming equivalence or using the MacRobert et al (2011) correlation between N and N30SB for Group 2 data (Figure 3(b)) does not result in significantly different values, although subject to scatter. For Group 2, neither N30SB nor N exceeded 30; consequently delineating a profile based on a blow count of 30 would be acceptable for Group 2 profiles. Figure 3(c) shows the great difficulty in interpreting Group 3 profiles. The MacRobert et al (2011) correlation unfortunately overestimates many N values, and using N30SB > 30 as a consistency delineation is unsafe, as 72% of equivalent N are less than 30. The only basis for rational design for Group 3 profiles is to resort to other investigation procedures (e.g. a borehole with SPT N at regular intervals).

Final N30SB varied considerably within the data, reflecting little guidance on DPSH refusal criteria. The data suggests that N30SB > 75 is an appropriate refusal criterion; however, specifying a single N30SB as a refusal criterion is problematic. For instance, if N30SB > 75 is specified as refusal, an intolerable number of Group 3 probings would terminate at a shallow depth and be classified as Group 1 when normalised. Consequently, it is suggested that if N30SB exceeds 50 in the first 3 m, probing should be continued until N30SB exceeds 100. Should N30SB not exceed 50 in the first 3 m, probing should be continued until N30SB exceeds 75. In both cases it remains to be ascertained whether the profile falls into Group 1 or Group 2, thereby providing useable information.

As mentioned earlier, there was no clear distinction in the shape of N30SB profiles based on soil type (i.e. clayey vs sandy). While clayey profiles fell into either Group 1 or Group 2 (i.e. less influenced by rod friction), this is difficult to generalise, as sandy profiles fell into all three groups. This lack of a clear soil type link to rod friction is reflected in work by others (Stefanoff et al 1988). The approach presented here, to establish whether rod friction is present, is independent of soil type.

CONCLUSIONS

While it was not possible to link DPSH rod friction to characteristics of a profile, a method to identify profiles influenced by rod friction is presented. Large N30SB values (above 50), obtained when DPSH probing in rod friction impacted profiles, are largely meaningless unless a site correlation with a more robust test is developed. For profiles unaffected by rod friction, N30SB and N are roughly equivalent but subject to considerable scatter. It is recommended that even when DPSH probings are unaffected by rod friction, N30SB values are best used for screening equivalent N above and below 30, to establish competent founding horizons.

ACKNOWLEDGEMENTS

The authors wish to thank the various geotechnical consultants and contractors for kindly providing the analysed data. Comments from Dr Nanine Fouché improved the manuscript.

List of notations

d Normalised depth

N Standard Penetration Test blow count

N30SB Dynamic Probe Super Heavy blow count (over 300 mm)

REFERENCES

Decourt, L, Muromachi, T, Nixon, I, Schmertmann, J, Thorburn, S & Zolkov, E 1988. Standard Penetration Test (SPT): International Reference Test Procedure. Proceedings, 1st International Symposium on Penetration Testing, 20-24 March 1988, Orlando, FL. AA Balkema, 3-26. [ Links ]

Lommler, J C 2012. Geotechnical Problem Solving. New York: Wiley. [ Links ]

MacRobert, C J 2017. Interpreting DPSH penetration values in sand soils. Journal of the South African Institution of Civil Engineering, 59(3): 11-15. doi: 10.17159/2309-8775/2017/v59n3a2. [ Links ]

MacRobert, C, Kalumba, D & Beales, P 2011. Correlating standard penetration test and dynamic probe super heavy penetration resistance values in sandy soils. Journal of the South African Institution of Civil Engineering, 53(1): 46-54. [ Links ]

Stefanoff, G, Sanglerat, G, Bergdahl, U & Melzer, K-J 1988. Dynamic Probing (DP): International reference test procedure. Proceedings, 1st International Symposium on Penetration Testing, 20-24 March 1988, Orlando, FL. AA Balkema, 53-70. [ Links ]

Correspondence:

Correspondence:

Charles John Macrobert

Department of Civil Engineering, Stellenbosch University

Private Bag X1, Matieland 7602, South Africa

ORCID Number: 0000-0002-7141-1339

T: +27 21 808 4079; E: macrobert@sun.ac.za

Theo John Stergianos

Department of Civil Engineering Stellenbosch University Private Bag X1

Matieland 7602, South Africa

ORCID Number: 0000-0003-3193-0801

T: +27 10 823 1621; E: theo@PeraGage.com; E: tjstergianos@gmail.com

DR CHARLES JOHN MACROBERT (Pr Eng, MSAICE) is a Senior Lecturer of Geotechnical Engineering in the Department of Civil Engineering at Stellenbosch University. His research focuses include improving geotechnical design thinking by considering case studies, analysis of failures, and participant observation. He also provides specialised consulting for characterisation and modelling of geomaterials for global stability and seepage assessments. His emphasis on practice enables him to confidently teach the professional art of engineering.

THEO JOHN STERGIANOS received his BEng (Civil) and MEng (Civil) degrees from Stellenbosch University, majoring in Geotechnical Engineering. He works for PeraGage (a specialist geotechnical engineering consultancy) as a geotechnical engineer. His interests lie in foundation design, geomechanics and geotechnical investigations. Currently, he is involved with large-scale field tests for future wind farms and other smaller projects in the Cape region. His research interests lie in dynamic penetration testing methods.