Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

Journal of the South African Institution of Civil Engineering

On-line version ISSN 2309-8775

Print version ISSN 1021-2019

J. S. Afr. Inst. Civ. Eng. vol.64 n.3 Midrand Sep. 2022

http://dx.doi.org/10.17159/2309-8775/2022/v64n3a1

TECHNICAL PAPER

Variability of oxygen permeability index values in concrete construction: A proposed approach for parameter margins to guide concrete mixture design

G W Nganga; M G Alexander; Y Ballim

ABSTRACT

Specifications for durability that are based on performance tests on concrete during the early stages of construction are finding acceptance throughout the world. In South Africa the durability index (DI) approach has been accepted into local specifications. This raises a challenge in the design of a concrete mixture for a construction project that takes account of the variability in materials and test conditions to ensure that the concrete will achieve the specification requirements when subjected to DI testing on in-situ samples. This paper proposes a statistical approach to accounting for this variability in concrete mixture design with oxygen permeability index (OPI) testing, in a manner that acknowledges the variability of both laboratory-based and in-situ sample testing for compliance. The OPI test results obtained on nominally similar concretes on actual construction projects undertaken by the South African National Roads Agency Limited (SANRAL), which included the DI-based specifications, were used to illustrate the operation of the proposed approach. The results show that the target value of OPI to be achieved in the design of concrete mixtures is influenced by the level of quality control on construction sites but that this can be managed through an appropriate statistical approach.

Keywords: durability, durability index tests, variability, quality control, margins

INTRODUCTION

Most concrete deterioration mechanisms involve the transport or movement of fluids through the pore structure of concrete. Durability index (DI) testing is aimed at measuring one or more of the fluid-transport properties of the near-surface or cover zone of a reinforced concrete (RC) member or structure as a measure of the fluid transport properties, and so indexing the quality of this zone. A number of test methods have been developed globally, such as the Cembureau test (Kollek 1989), the Torrent test (Torrent 1992), the Autoclam test (Basheer et al 1994), and other tests reported in RILEM TC 116-PCD (1999), RILEM TC 189-NEC (2007) and RILEM TC 230-PSC (2016). In South Africa the principle of the DI approach to assuring long-term durability of RC structures is finding increasing acceptance by concrete engineers and technologists (Alexander & Mackechnie 2003; Alexander et al 2008).

Much like the compressive strength test, DI testing is intended to provide an early-age measure of the likely durability performance of concrete used in the construction of RC structures. Such testing gives the owner, the designer and the constructor of the structure the assurance that the structure is likely to perform satisfactorily over its intended service life, and that, should the test results indicate a reason for concern, remedial action can be taken before the structure is brought into service. This approach is also an acknowledgement of the fact that long-term durability of concrete is most effectively achieved through proper attention to quality management of the materials and methodologies used in the construction of an RC structure.

However, unlike the compressive strength test, construction practice variables, such as the type of formwork, compaction, mix segregation and type of curing, have a large effect on the fluid-transport properties of the surface zone of the concrete. This, in turn, influences the DI measure obtained when the test is conducted on the in-situ concrete, which can be very different from the measure obtained on samples prepared using similar concrete under standardised laboratory conditions. During the early stages of the development of the DI approach to long-term assurance of concrete durability, there was debate about the relative merits of conducting the DI test using different approaches (Gouws et al 2001):

1. Tests conducted under laboratory conditions on samples extracted from cubes made with the concrete used in the structure: This assesses the quality of the concrete used in the construction but does not account for construction process variables.

2. In-situ, non-destructive testing of the actual structure after construction: This allows a higher test sampling frequency, but the results may be influenced by environmental conditions, particularly the moisture content of the concrete at the time of testing.

3. Extracting small samples from the actual structure for pre-conditioning and testing under standard laboratory conditions and procedures: This eliminates the influence of sample moisture content at the time of testing, but does cause disturbance to the concrete surface, limiting the frequency of testing.

4. The use of test panels on site that are cast, compacted, and cured identically to the main structure (Ronny 2011).

There is general agreement that DI results are only meaningful as indicators of the potential durability of RC structures if the tests are conducted on concrete in the actual structure. Tests have been developed using approach (2) above, e.g. the Torrent test (Torrent 1992), with the test conducted in situ on the actual structure.

Approaches (3) and (4) have been adopted in South Africa (Alexander et al 2008), with the test procedures using core samples extracted from the near-surface zone of the concrete structure or test panels and brought into the laboratory for moisture preconditioning and testing. This approach has found expression in national specifications where, based on repeatability and reproducibility considerations, the chloride conductivity index (CCI) and the oxygen permeability index (OPI) tests have been adopted as DI tests for regulatory control of the quality of RC construction.

This approach to DI testing raises questions about the way in which concrete mixtures are to be designed to ensure that the specified requirements, which relate to the as-built structure, can be satisfied. Unlike the case of compressive strength specification, designing concrete mixtures to satisfy DI specifications requires accounting for variability in materials and testing, as well as in construction methodology. It is therefore necessary to determine the target level of DI performance that should be used in the design of a concrete mixture, in order to provide the necessary confidence that a minimum DI performance will be achieved in the structure, within acceptable statistical limits of 'failure'. This means that the difference between the target and such a minimum or 'characteristic' DI value must necessarily be based on a statistical evaluation of the variability in the production of the concrete itself, as well as the variability of the methods used in the construction process.

The primary objective of this paper is to propose an approach to understanding and developing the statistical margins that may be used in the design of concrete mixtures in cases where DI testing is a part of the performance specifications for concrete. The approach adopted is based on the argument that the potential DI performance of the concrete as a material should be determined using approach (1) above. This should then be the basis for determining the margins for a target DI performance to be achieved in assessing the quality of the surface concrete in the actual structure, when testing samples extracted from the structure under laboratory conditions (approach (3) above). The ability to determine suitable margins between the potential DI values for the concrete and the likely in-situ values, is essential to bring greater confidence to the process of concrete mixture design at the preconstruction stage.

The approach proposed in this paper is illustrated using a database of OPI test results that were obtained on concrete construction projects commissioned and monitored by SANRAL (South African National Roads Agency Limited). The suite of projects was coherent in the sense of geographical location, concrete characteristics, concrete supplier, and diligence in oversight and quality control. The data therefore presented a unique opportunity for considering an approach to accounting for variability in DI testing in concrete mixture design.

THE DURABILITY INDEX APPROACH TO CONCRETE QUALITY CONTROL

Fluid-transport properties of cover concrete as durability indicators

Durability is not an inherent material property of concrete, because the concept captures both the concrete 'system' (component materials and the processing during construction) and the aggressiveness of the environment to which the structure is exposed. In this sense, durability cannot be directly measured from a sample of the concrete in the way that, say, compressive strength is measured. However, the recognised need to influence, measure and control the quality of concrete during the construction stage, as it relates to long-term durability, has led to an approach referred to as the DI approach, including testing (Alexander & Mackechnie 2001; Alexander et al 2008).

As mentioned, the DI approach to quality assessment draws from the idea that most of the processes of concrete deterioration involve the transport of fluids through the pore structure of the concrete. Also, in the particular context of reinforced concrete, the quality of the cover concrete is a primary determinant of the rate and extent of reinforcement corrosion that is likely to occur in the life of the structure. DI testing therefore involves measurement of one or more fluid-transport properties of the near-surface or cover zone of the concrete.

It is useful to draw parallels between DI and compressive strength testing. The compressive strength of a concrete sample prepared, cured and tested under standard conditions is, at best, an indicator (or index) of the likely strength in the actual concrete structure. While the constituents of the concretes are similar, the concrete in the structure is subjected to very different compaction, curing and stress conditions from that of the small laboratory sample tested. Nevertheless, the test result is valuable as an indicator of the potential strength of the in-situ concrete, and its interpretation is based on the collective and agreed experience of the structural engineering community - such agreement being expressed in design codes and specifications.

The parallel, however, ends here. In the case of DI testing, the concern is with the fairly small cover zone of the concrete element, where the properties are more strongly affected by construction processes such as curing, formwork type, ambient temperature and humidity conditions, in ways that do not influence the bulk internal concrete responsible for strength and other engineering properties. For this reason, DI testing has to be focused on testing concrete samples from the actual structure.

This raises a question about how concrete mixtures are to be designed, before construction, if DI testing is part of the performance specification of the project. Responding to this important question demands an understanding of the relationship between DI test results obtained from laboratory samples and those obtained from samples extracted from the structure. This necessarily requires a probabilistic approach to developing the acceptable margins of DI values obtained from tests on laboratory samples that will assure achievement of the DI specification requirements in the actual concrete structure, with acceptable levels of probability of failure.

Development of the South African durability index approach

The three DI tests that have been developed in South Africa are the following:

1. oxygen permeability index (OPI), which tests the gas permeability of a concrete sample when subjected to a falling head of pressure (Ballim 1991; Ballim 1993; Alexander et al 1999)

2. water sorptivity index (WSI), which measures sorptivity and water-penetrable porosity of the concrete (Ballim 1993)

3. chloride conductivity index (CCI), which provides a rapid indication of chloride conductivity in a sample (Streicher & Alexander 1995).

The early development of these tests emerged from laboratory-based research that established the theoretical foundations for the test approaches and demonstrated their sensitivity to the chemical and micro-structural properties of concrete related to deterioration and durability.

These DI tests are carried out using circular specimens with a diameter of 70 mm and a thickness of 30 mm, obtained from the cover zone of the concrete. As mentioned earlier, an important departure of the South African approach from other DI test methods, is the fact that the test samples are extracted from the concrete element and preconditioned in a drying oven in the laboratory. The primary motivation for this approach has been the need to ensure similar moisture conditioning of the pore structure of the concrete sample, given the strong influence of pore moisture content on the measured fluid-transport properties of the concrete being tested. Oven-drying of the sample before testing allows measured fluid-transport of different concretes to be compared on the basis of an 'equivalent' state of dryness.

The primary criteria that guided the development of these tests were that they should (Ballim 1994; Alexander 2004):

■ require equipment that is relatively easy to manufacture and at low cost

■ be simple, quick and easy to undertake

■ be applicable both for on-site elements and in laboratories

■ require minimal sample preparation

■ be conducted at an early age - typically 28 days.

These criteria made the tests suitable for use as measures for site quality control of concrete cover properties and assessing the quality of construction as, in addition to material constituents and properties, the tests are also sensitive to construction processes such as curing and compaction. Furthermore, the tests are useful in optimisation of materials in a concrete mixture (Alexander & Mackechnie 2003) and in service life design where correlations have been established between index values (OPI and CCI) which are then used as input parameters in prediction models (Mackechnie 1999; Mackechnie & Alexander 2002).

Adopting DI test methods as specifications

Following the early laboratory-based development of the test methods, a series of studies was undertaken to assess the usefulness of the test methods as indicators of concrete quality on actual structural concrete construction projects (Alexander et al 1997; Alexander & Mackechnie 2003).

Three studies were undertaken, particularly to consider the OPI as a control test for assessing the effectiveness of curing on construction projects:

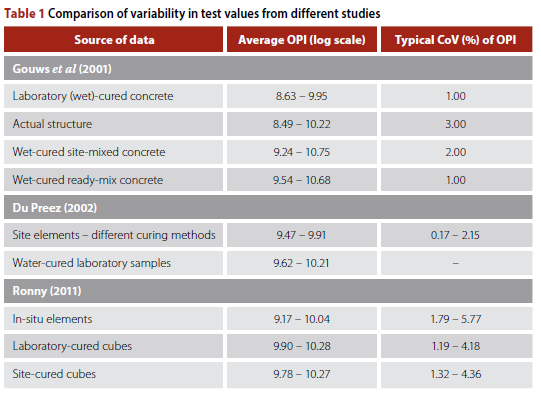

■ Gouws et al (2001) considered the variability of test results for samples obtained from concrete elements made and cured in the laboratory, actual structures, elements prepared using site-mixed concrete, and elements prepared using ready-mix concrete.

■ Du Preez (2002) assessed the variability in OPI test results for concrete elements prepared using different curing methods and different supplementary cementitious materials, for samples obtained from structures (slabs and walls), and from smaller companion water-cured laboratory cubes.

■ Ronny (2011) considered the variability in OPI results for samples obtained from the in-situ structures, laboratory-cured cubes, site-cured cubes and larger trial panels.

The range of variability in OPI test results obtained from these studies, expressed as average values and coefficient of variation (CoV (%)), is summarised in Table 1. These results and those from similar studies indicated that, as expected, the test results from laboratory-prepared and cured samples have a lower variability in comparison to site elements. Also, the high variability of results reported by Ronny (2011) for the in-situ elements pointed to the likelihood of the sensitivity of the OPI test to the variable construction practices on a particular project.

The generally positive experience of the utility value of DI testing on actual construction projects led to owners of large concrete infrastructure, most notably SANRAL, to consider using these tests in their internal project specifications for control of the quality of concrete construction. This initial 'informal' adoption of the DI approach was valuable in providing a more substantial data set and a base of experience, which led in turn to the idea of DI testing as an approach to construction quality assurance through national specifications.

The informal adoption of a test approach by a small number of agencies responsible for infrastructure provision to more formalised inclusion in national specifications demanded a rigorous assessment of the repeatability and reproducibility of the proposed DI tests. This was necessary to provide confidence that the test results are suitably repeatable within a particular laboratory, as well as reproducible across different laboratories using the same test methods. It was also accepted that the primary value of the chloride conductivity test was to assess the acceptability of a concrete mixture design for use in a chloride environment before the actual construction project begins. However, the OPI and water sorptivity tests were considered for possible use as routine quality control tests during actual construction - again in a manner similar to the use of the compressive strength test.

Two series of round-robin tests were undertaken in South Africa to assess the precision of the DI tests (Grieve et al 2003; Stanish et al 2004; Stanish et al 2006). This initiative was led by the cement industry, supported by university-based researchers, and included a range of university and commercial laboratories that were capable of undertaking the tests. The results of these round-robin tests confirmed the use of the CCI as a suitable acceptance criterion for concrete mixture approval at the commencement of a construction project. In the case of the routine quality assurance tests, it was found that the water sorptivity test did not at that time provide suitable confidence in its repeatability and reproducibility to be adopted as a national specification, and that this test method may require further development. However, the OPI test was found to be suitable for this purpose, with the repeatability determined as 1.4% and its reproducibility as 1.8%. An important observation that was made in this exercise was that, for the OPI test, the CoV was very similar within and between laboratories (Stanish et al 2004). These conclusions allowed the CCI and the OPI tests to be adopted into the national test standards in South Africa (SANS 3001-CO3 parts 1, 2 and 3 (SANS 2017a; 2017b; 2017c)).

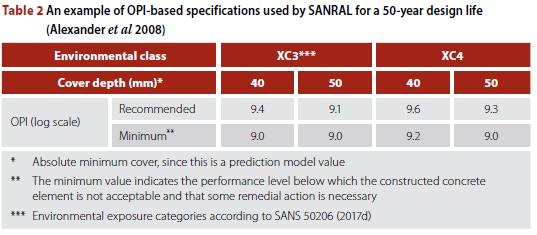

SANRAL has persisted in their use of the DI performance-based approach in their road infrastructure development projects. Table 2 is an extract from a SANRAL specification which shows the approach adopted to account for the intersections of environmental aggressiveness, design decisions and required durability index performance (in this case, OPI).

In their project specifications, SANRAL (2010) include a provision for RC structural elements which are to be designated for both strength and durability performance testing requirements. Such structures include bridge piers, abutments, concrete median barriers, retaining walls, culverts, parapets and bridge decks. However, while there is good guidance on the statistical approaches necessary to design concrete mixtures to satisfy the requirements for strength testing, such guidance for DI test requirements have yet to be developed.

The data on OPI test results that have been gathered from extensive SANRAL projects over the past years provide a useful basis for developing the necessary conceptual and statistical approaches to the design of concrete mixtures for DI performance testing. Nganga (2012) undertook an analysis of the mean values and variability of a portion of the SANRAL data obtained during the Gauteng Freeway Improvement Project (GFIP) in Gauteng. Moyana (2015) undertook a similar analysis of the SANRAL data of OPI testing on construction projects that were mixture design margins for DI performance that are presented in this paper.

DESIGNING CONCRETE MIXTURES IN RESPONSE TO DI SPECIFICATIONS

A durability specification that is based on a quantifiable performance test, such as shown in Table 2, demands an approach to concrete mixture design that provides reasonable assurance that the required performance can be met. As with mixture design for compressive strength, this requires an understanding of the statistical variation in results in order to determine the allowable margins of design. There are therefore two levels of variability to be acknowledged in determining the margins in concrete mixture design for durability:

1. The difference between the specified performance value and the mean of test results determined from laboratory prepared samples: This difference accounts for the variability in the materials and laboratory process used to manufacture the concrete.

2. The difference between the specified performance value and the mean of test results determined from tests conducted on the as-built structure: This difference accounts for the materials and mixing variables together with the construction variables that influence the surface quality of the as-built structure.

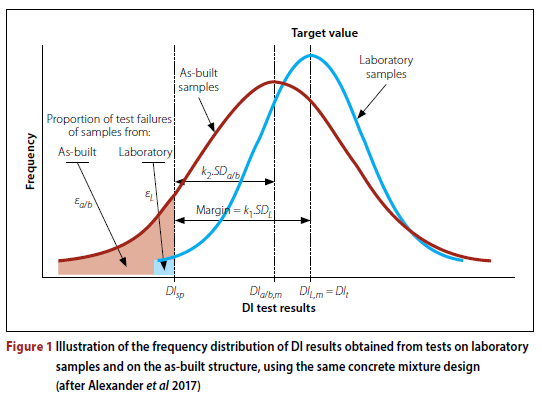

Of course, at the time of concrete mixture design before construction commences, the margin of durability performance used in assessing the suitability of the proposed concrete must also account for the difference in the mean values of the two test conditions described above (Alexander et al 2017). This situation is illustrated in Figure 1, which also indicates the parameters used in the later analyses of the OPI results obtained from actual construction projects.

The following variables and parameters are indicated in Figure 1:

DISp = performance value of DI as specified

DIa/b m = mean of the DI results obtained for test on the as-built structure

DIL,m = mean of the DI results obtained for tests on laboratory samples

DIt = target DI value for concrete mixture design = DILm

SDa/b = standard deviation of the DI results obtained for tests on the as-built structure

SDL = standard deviation of the DI results obtained for tests on laboratory samples

εa/b = acceptable proportion of failure in DI tests conducted on the as-built structure

εL = acceptable proportion of failure in DI tests conducted on laboratory samples

k1,k2 = constants determined from εa/b and εl in relation to the statistical distribution of results In Figure 1, the laboratory samples represent the 'material potential' of the concrete, in the sense that these samples derive from a mix produced under controlled conditions and without any of the vagaries of the site application included. Of course, the same concept can be applied to samples produced in well-controlled ready-mix or site-mixing operations, prior to the concreting being executed on site. Under such conditions, it should be expected that the 'laboratory samples' should have a significantly lower proportion of test failures in relation to the specified DI value.

ASSESSMENT OF OPI TEST RESULTS FROM SANRAL PROJECTS

The first significant use of the OPI tests in performance-based specifications by SANRAL was in the GFIP (Nganga 2012). The section below summarises the results from various work packages, which were studied by Nganga (2012), with a view to quantifying DI test variability on the projects. In addition, test results from SANRAL projects undertaken over the period 2011 to 2015 were studied by Moyana (2015) and are included here for an analysis of variation and development of an approach to determining the mix design target value (DIt).

Laboratory test data for ready-mix concrete (RMC) used in GFIP projects and in-situ data from a GFIP bridge (Nganga 2012)

The concrete supplied to some of the projects in the GFIP was obtained from a reputable RMC supplier in Gauteng. Concrete samples were subjected to OPI testing (as the DI test) under laboratory conditions by the supplier and these results were considered as representative of the material potential of the concrete supplied to the projects, in the sense that these results exclude the variables associated with construction methodology.

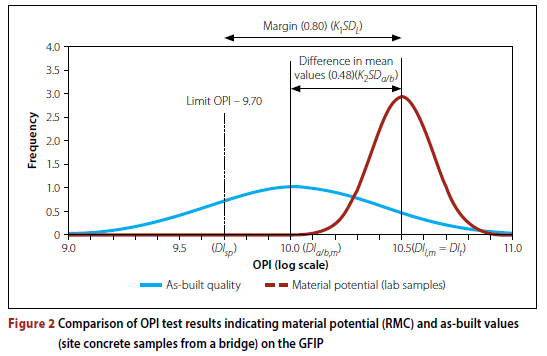

Samples for these OPI tests were obtained from 100 mm cubes made at the point of discharge of the concrete, and moist-cured for 28 days prior to preparation for testing. The results from nine OPI tests were provided by the RMC supplier at the time of the study. Further, as a basis for initial comparison, in-situ (or site-based) OPI test results from a reinforced concrete bridge on Sub-Project 4 of the GFIP were obtained. These sets of results were fitted to normal distribution curves and the profiles are shown in Figure 2.

Not only is the mean value for the as-built structure lower (more permeable concrete) than the RMC results (mean OPI of 10.02 compared with 10.50), but the variability is considerably higher (CoV of 3.91% compared with 0.66%). While the bridge project achieved a mean OPI value higher than the specified minimum value (DISp) of 9.70, 22% of results were below the specified value (= εa/b). A further point of interest from Figure 2 is that the ready-mix supplier had obtained a 'material potential' mean OPI value of 10.50, and the difference between the two mean values (0.48) is an indication of the level of quality control and variability in concrete construction at the site.

SANRAL GFIP data for the period 2008 - 2010

Nganga (2012) also analysed a more substantial amount of data on OPI values from five Sub-Projects of the GFIP. Projects were selected when the available sample size (n) of test results for each project was suitably large (generally n > 30). For all the projects assessed, a minimum acceptable OPI limit of 9.70 (DIsp) was specified. Also, the as-built test samples were generally obtained from the in-situ structures - test panels in some cases. These panels were cast from identical concrete under the same conditions and in the same localities as the actual structures, and treated and cured in the same manner (Ronny 2011).

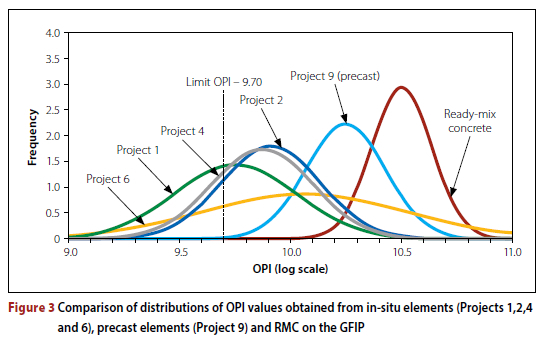

Figure 3 shows the results of the analysed data of OPI results from five Sub-Projects of the GFIP, fitted to normal distribution curves, together with the profile of the OPI results from the RMC supplier. It should also be noted that the data from Sub-Project 9 was obtained from precast concrete elements (freeway barrier walls) that were prepared under well-controlled production conditions. From the comparisons in Figure 3 it is clear that:

■ As expected, the mean values in all the as-built results are lower than that of the OPI potential for the concrete achieved with the RMC samples.

■ The better-quality control conditions of the precast elements in Sub-Project 9 are evident from the better performance of this concrete when compared with that of the conventionally constructed elements.

■ With the exception of Sub-Project 6, there is a general trend of increasing variability with decreasing mean values. Sub-Project 6 shows the highest variability (spread or range) which is typical of poorer quality control during construction but with a comparatively high mean OPI value.

■ All the projects attained the recommended minimum mean value of 9.70, with mean values ranging from 9.75 for Project 1 to as high as 10.25 for Project 9. However, the mean value of test results was used as the acceptance criterion and there was no requirement for a maximum proportion of failed test results that had to be achieved with in-situ tests. Given such a specification approach, the GFIP would have accepted up to 50% failures in the test results, if it is assumed that test results were normally distributed.

■ Sub-Project 1 suffered from the combined problems of a mean OPI very close to the target value of 9.70, and a high variability, while Sub-Project 6, despite showing a higher variability of test results, also had a higher mean OPI value, thus reducing the proportion of failed tests.

■ Fitting OPI test data to normal distribution curves allows distinctions to be drawn between the levels of control of construction site practice when nominally similar concrete is used by different constructors on different sites.

SANRAL project data for the period 2011 - 2015 (Moyana 2015)

Moyana (2015) carried out a further assessment of test results from a range of SANRAL projects across South Africa. In this study, the main objective was to collect and organise the DI test results to form a database of experience with DI testing. Five data sets were obtained and these were analysed to assess the mean values and variability in test results. This data was also obtained from projects with a test sample size of more than 30. For the purpose of comparison of this data with that from the GFIP, an OPI acceptance limit value of 9.70 was used rather than the adjusted value of 9.40 found in Table 6000 of the SANRAL specifications (SANRAL 2009).

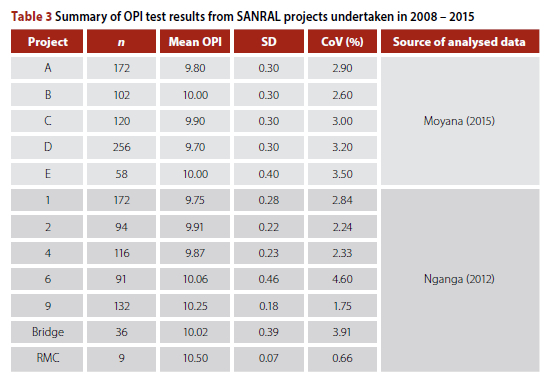

The important statistical parameters of both the Nganga and the Moyana data sets are shown in Table 3. The table shows the number of test results in each data set (n), the mean OPI value, the standard deviation (SD) and the coefficient of variation (CoV) for all tests in the group.

Table 3 shows that all the projects assessed by Moyana achieved a mean OPI value equal to or greater than the specified value of 9.70. Also, the patterns of variability, as indicated by the SD and CoV values, are similar across the two analysed data sets.

TOWARDS AN APPROACH TO DETERMINE THE TARGET OPI FOR CONCRETE MIXTURE DESIGN FROM THE SPECIFIED OR CHARACTERISTIC OPI VALUE

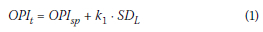

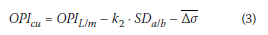

Referring to Figure 1 and for the present discussion taking the durability index (DI) as OPI, the target OPI value to be used in concrete mixture design (OPIt) as the mean of laboratory test results is related to the specified value (OPIsp) by:

Where: SDL is the standard deviation of laboratory tests and k1 is a constant that is determined from the acceptable proportion of failures in a series of tests on samples of the same concrete.

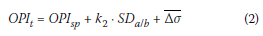

However, as can be seen from Figures 2 and 3, it is difficult to identify a possible relationship between the acceptable level of failed tests with laboratory samples to that of the as-built samples, mainly because of the high variability of concrete site practice and quality control. It may therefore be better to rely on an average difference between the mean OPI values of laboratory tests and as-built tests to incorporate the idea of an 'average' quality control practice on site. The target OPI for mixture design can then be determined from:

Where: SDa/b is the standard deviation of tests from the as-built element, k2 is a constant that is determined by the acceptable proportion of failures in a series of tests on samples of the as-built element, and ∆σ is the average difference between the mean OPI determined in the laboratory tests and that of the mean OPI values from tests on the as-built elements.

For the data sets shown in Table 3, ∆σ = 0.57 in the range of 0.25 to 0.8, and the average standard deviation is 0.3 in the range 0.18 to 0.39.

Equation 2 also allows development of the concept of a 'characteristic OPI' value for a particular concrete. The characteristic OPI (OPIcu) is the value below which a prescribed proportion of test results will occur. For the sake of illustration, and given the relatively high variability of OPI tests and the fact that greater deviations from an accepted value are usually taken for serviceability conditions, we may take the prescribed proportions of failures as 20%. For a normal distribution of test results, k2 = 0.84 in Equation 2. This means that OPIcu will lie 0.84 standard deviations to the left of the mean and the area under the normal distribution curve to the left of OPIcu is approximately 20%.

Taking this approach and re-writing Equation 2, the characteristic OPI value for a set of in-situ tests is given by:

Where: OPIL/m is the mean value of OPI tests conducted on laboratory samples.

Table 4 shows the characteristic OPI values for the results analysed from the different SANRAL projects presented in Table 3, according to Equation 3.

Table 4 shows that, had the SANRAL projects analysed in this paper been subjected to an additional requirement of a maximum of 20% failures in testing for OPI, the required OPI level of 9.70 would have been satisfied in five of the projects while the other six would have required additional testing or some form of remedial action during the construction stage. Of course, the results in Table 4 are based on an average difference of means (∆σ) that was determined from the data presented in this paper. It will be necessary to significantly expand the base of data from actual construction projects to give more confidence in the Aa value used in Equations 2 and 3 to account for the likely variation in quality control and assurance on reinforced concrete construction projects.

Nevertheless, Equation 2 provides the concrete mixture designer with a useful first estimate to the likely target OPI value to be achieved in laboratory tests in order to satisfy a specified OPI value from tests on the as-built structural elements. The averages of standard deviation and difference between means, drawn from data such as that presented here, obtained from selected SANRAL projects, can be used together with a value for k2 that provides the necessary assurance of an acceptable level of failed test results, to give a target mean OPI value from laboratory-based tests.

CONCLUSIONS

1. The use of the OPI test on RC construction projects provides a useful basis for developing a rational approach to specifying durability index tests to better assure the long-term durability of such structures.

2. A statistical analysis of variability of in-situ OPI test results, assuming a normally distributed profile of the results, provides a suitable measure of the degree of quality control over the construction methodology on particular construction sites. Such a measure can be quantified through parameters such as the mean, standard deviation and coefficient of variation of the test results.

3. The mean values of in-situ OPI tests on the SANRAL projects assessed showed that the separate projects generally satisfied the specification requirements for the minimum OPI value.

4. Given the higher levels of quality control, tests on the precast concrete elements showed lower variability and a higher mean OPI result than the tests conducted on conventionally constructed structures.

5. Equation 3 provides a useful initial estimate of the target OPI value to be achieved in laboratory testing of samples at the concrete mixture design stage to provide assurance that the specified minimum OPI value will be achieved with in-situ testing during construction.

6. It is necessary to expand the amount and range of data on durability index testing to develop increasing confidence in the average difference between the means of test results from laboratory and in-situ testing, and to better quantify the effects of the range of variability in site practices for RC construction. Furthermore, the RC design and construction community should find agreement on the acceptable level of DI test failures on a project to better define the concept of a 'characteristic' DI value.

ACKNOWLEDGEMENTS

The authors would like to acknowledge Ms Alice Titus Bakera, a PhD student at the University of Cape Town, for her assistance in the preparation of the paper. We also acknowledge SANRAL for their provision of DI tests results from various infrastructure projects being undertaken in the country.

REFERENCES

Alexander, M G, Mackechnie, J R & Hoppe, G E 1997. Measures to ensure effective curing and concrete durability during construction. Proceedings, 15th Annual Transportation Conference, July 1997, Pretoria. [ Links ]

Alexander, M G, Ballim, Y & Mackechnie, J R 1999. Guide to the use of durability indexes for achieving durability in concrete structures. Monograph No 2. Department of Civil Engineering, University of Cape Town and University of the Witwatersrand. [ Links ]

Alexander, M G & Mackechnie, J R 2001. Use of durability indexes to achieve durable cover concrete in reinforced concrete structures. In Skalny, J P & Mindess, S (Eds). Materials Science of Concrete. Westerville: American Ceramic Society, 483-511. [ Links ]

Alexander, M G & Mackechnie, J R 2003.Concrete mixes for durable marine structures. Journal of the South African Institution of Civil Engineering, 45(2): 20-25. [ Links ]

Alexander, M G 2004. Durability indexes and their use in concrete engineering. Proceedings, Kovler, K, Marchand, J, Mindess, S &Weiss, J (Eds), International RILEM Symposium: Concrete Science and Engineering, A Tribute to Arnon Bentur, 24 March 2004, Evanston, IL. RILEM, PRO36.9-22. [ Links ]

Alexander, M G, Ballim, Y & Stanish, K 2008. A framework for use of durability indexes in performance-based design and specifications for reinforced concrete structures. Materials and Structures, 41(5): 921-936. [ Links ]

Alexander, M, Bentur, A & Mindess, S 2017. Durability of concrete: Design and construction, 1st ed, Boca Raton, FL, CRC Press. [ Links ]

Ballim, Y 1991. A low cost, falling head permeameter for measuring concrete gas permeability. Concrete Beton, 61: 13-18. [ Links ]

Ballim, Y 1993. Towards an early age index for the durability of concrete. Proceedings, Dhir, R K & Jones, M R (Eds), International Conference, Concrete 2000 - Economic and Durable Construction through Excellence, London. London: E & FN Spon, 1003-1012. [ Links ]

Ballim, Y 1994. Curing and durability of concrete. PhD Thesis. Johannesburg: Faculty of Engineering, University of the Witwatersrand. [ Links ]

Basheer, P A M, Long, A E & Montgomery, F R 1994. The Autoclam - a new test for permeability. Concrete, 28(4): 27-29. [ Links ]

Du Preez, A A 2002. A site study of durability indexes for concrete in marine conditions. MSc Dissertation. Cape Town: Department of Civil Engineering, University of Cape Town. [ Links ]

Gouws, S M, Alexander, M G & Maritz, G 2001. Use of durability index tests for the assessment and control of concrete quality on site. Concrete Beton, 98(4): 5-16. [ Links ]

Grieve, G R H, Alexander, M G, Ballim, Y & Amtsbuchler, R 2003. Evaluation of the inter-laboratory precision for three South African-developed durability index test methods. Proceedings, 11th International Congress on the Chemistry of Cement 11-16 May 2003, Durban. [ Links ]

Kollek, J J 1989. The determination of the permeability of concrete to oxygen by the Cembureau method -a recommendation. Materials and Structures, 22(3): 225-230. [ Links ]

Mackechnie, J R 1999. Prediction of carbonation in concrete. Cape Town: Department of Civil Engineering, University of Cape Town. [ Links ]

Mackechnie, J R & Alexander, M G 2002. A pragmatic prediction model for chloride ingress into concrete. Proceedings, Andrade, C & Kropp, J (Eds), 3rd RILEM Workshop on Testing and modelling the chloride ingress into concrete, 9-10 September, 2002, Bagneux, France. pp 65-76. [ Links ]

Moyana, P 2015. A database of durability index test results. BSc Dissertation. Cape Town: Department of Civil Engineering, University of Cape Town. [ Links ]

Nganga, G W 2012. Practical implementation of the durability index performance-based approach. MSc Dissertation. Cape Town: Department of Civil Engineering, University of Cape Town. [ Links ]

RILEM (International Union of Laboratories and Experts in Construction Materials, Systems and Structures). TC 116-PCD 1999. Permeability of concrete as a criterion of its durability final report: Concrete durability: An approach towards performance testing. Materials and Structures, 32(4): 163-173. [ Links ]

RILEM TC189-NEC. 2007. Torrent, R & Fernandez Luco, L (Eds). Non-destructive evaluation of the penetrability and thickness of the concrete cover: State-of-the-art report. Amsterdam: Springer. [ Links ]

RILEM TC230-PSC. 2016. Beushausen, H & Fernandez Luco, L (Eds). Performance-based specifications and control of concrete durability. Amsterdam, Netherlands: Springer. [ Links ]

Ronny, R 2011. Adequacy of durability specifications for concrete bridges on national roads in South Africa. MSc Dissertation. Durban: Department of Civil Engineering, University of KwaZulu-Natal. [ Links ]

SANRAL (South African National Roads Agency Limited) 2009. Table6000/1: Concrete Durability Specification Targets (Civil Engineering Structures only) for Carbonation-Induced Corrosion (from Atmospheric & Industrial) and Chloride-Induced Corrosion (from Groundwater, Seawater & Sea spray). Pretoria: SANRAL. [ Links ]

SANRAL 2010. Review of Project Specifications. Internal project document: SANRAL. [ Links ]

SANS (South African National Standard) 2017a. SANS 3001-CO3-1 2015. Civil Engineering Test Methods Part CO3-1: Concrete Durability Index Testing. Preparation of Test Specimens. Pretoria: SABS Standards Division. [ Links ]

SANS 2017b. SANS 3001-CO3-2 2015. Civil Engineering Test Methods Part CO3-2: Concrete Durability Index Testing: Oxygen Permeability Test. Pretoria: SABS Standards Division. [ Links ]

SANS 2017c. SANS 3001-CO3-3 2015. Civil Engineering Test Methods Part CO3-3: Concrete Durability Index Testing: Chloride Conductivity Test. Pretoria: SABS Standards Division. [ Links ]

SANS 2017d. SANS 50206 2015. Concrete: Specification, performance, production and conformity. Pretoria: SABS Standards Division. [ Links ]

Stanish, K, Alexander, M G & Ballim, Y 2004. Durability Index inter-laboratory test results: Analysis of Variance. Research Report. Department of Civil Engineering, University of Cape Town and University of the Witwatersrand. [ Links ]

Stanish, K, Alexander, M G & Ballim, Y 2006. Assessing the repeatability and reproducibility values of South African durability index tests. Journal of the South African Institution of Civil Engineering, 48(2): 10-17. [ Links ]

Streicher, P E & Alexander, M G 1995. A chloride conduction test for concrete. Cement and Concrete Research, 25(6): 1284-1294. [ Links ]

Torrent, R J 1992. A two-chamber vacuum cell for measuring the coefficient of permeability to air of the concrete cover on site. Materials and Structures, 25(6): 358-365. [ Links ]

Correspondence:

Correspondence:

Gladwell Wanjiku Nganga

Department of Civil Engineering, University of Nairobi

PO Box 22753 -00400, Nairobi, Kenya

T: +254 713 575 266, E: g7shiku@gmail.com

Mark Alexander

Department of Civil Engineering, University of Cape Town

Private Bag, Rondebosch 7701, South Africa

T: +27 21 650 4012, E: mark.alexander@uct.ac.za

Yunus Ballim

School of Civil and Environmental Engineering, University of the Witwatersrand

Private Bag 3, Wits 2050, South Africa

T: +27 11 717 7103, E: yunus.ballim@wits.ac.za

GLADWELL WANJIKU NGANGA is a civil engineer currently working at the Materials Testing and Research Division (MTRD) in the State Department of Infrastructure, Ministry of Transport, Kenya. She holds a BSc in Civil and Construction Engineering from the University of Nairobi, an MSc in Civil Engineering from the University of Cape Town, and she is currently pursuing a PhD on a part-time basis at the University of Nairobi. She has a keen interest in concrete materials, durability of concrete structures, sustainability, materials testing and quality control.

EMERITUS PROFESSOR MARK ALEXANDER (Pr Eng) is a Senior Research Scholar in Civil Engineering at the University of Cape Town. He holds a PhD from the University of the Witwatersrand, Johannesburg, and is a Fellow of the University of Cape Town, of RILEM, ofthe South African Institution of Civil Engineering, and ofthe South African Academy of Engineering. He teaches and researches in cement and concrete materials engineering relating to design and construction, with interests in concrete durability, service life prediction, concrete sustainability, and repair and rehabilitation of deteriorated concrete structures.

EMERITUS PROFESSOR YUNUS BALLIM of the School of Civil and Environmental Engineering at the University of the Witwatersrand does research mainly in cement and concrete materials science and engineering. He has held a National Research Foundation rating since 1994, and has served on a number of international Technical Committees related to cement and concrete materials research. He is also an Honorary Fellow of SAICE (South African Institution of Civil Engineering) and a Senior Member of RILEM (International Union of Laboratories and Experts in Construction Materials, Systems and Structures).