Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

Journal of the South African Institution of Civil Engineering

On-line version ISSN 2309-8775

Print version ISSN 1021-2019

J. S. Afr. Inst. Civ. Eng. vol.64 n.2 Midrand Jun. 2022

http://dx.doi.org/10.17159/2309-8775/2022/v64no2a3

TECHNICAL PAPER

An assessment of a practical implementation of the deemed-to-satisfy durability design and specification approach in the Swakopmund-Walvis Bay Freeway upgrade project in Namibia

M Otieno; K Walter

ABSTRACT

Steel corrosion in reinforced concrete (RC) structures in the marine environment is a major concern for engineers and asset managers. This paper presents an assessment of the application of a deemed-to-satisfy durability design and specification approach on the newly constructed RC bridges on the Swakopmund-Walvis Bay Freeway upgrade in Namibia, with a desired service life of at least 100 years. The deemed-to-satisfy design and specification approach comprised a combination of South African recommendations for binder type, minimum binder content and w/b ratio, EN 206-1 recommendations for cover depth, and South African National Roads Agency Limited (SANRAL) durability index targets along with on-site concrete quality control guidelines on placement, compaction and curing. As-built concrete durability properties (i.e. water sorptivity, oxygen permeability and chloride conductivity) and cover depth were measured and used to check (using a Fickian-based service life model) if the deemed-to-satisfy specifications were adequate. The results showed that the as-built concrete durability properties surpassed the deemed-to-satisfy durability performance targets, while the on-site cover depth values showed significant inadequacies in some bridge elements. The service life estimations showed that the deemed-to-satisfy durability performance specifications were adequate. Considering the relatively high concrete quality achieved on site, it is clear that the 100-year service life could have been achieved more sustainably using a good balance of concrete quality and cover depth [e.g. a lower concrete quality (using less cement) or lesser coved depth] if a more rigorous performance-based durability design and specification approach had been used. Ultimately, the service life analyses using the as-built concrete model input parameters highlight not only the critical importance of both concrete quality and cover depth in achieving durable RC structures prone to steel corrosion, but also the inherent limitations of the deemed-to-satisfy durability design and specification approach.

Keywords: corrosion, marine exposure, durability index, service life, chloride ingress

INTRODUCTION

Infrastructure development projects in Southern Africa - and in Africa at large -have increased substantially in the last few decades. In the majority of these projects, steel reinforced concrete (RC) is usually the preferred construction material owing to its well-known advantages over other materials (Neville 2011). These infrastructure developments are costly capital investments by local and national governments that nowadays demand an almost maintenance-free service life in order to optimise the longterm return on investment. As a result, it is now acutely incumbent upon engineers, contractors and other stakeholders to work together to ensure that the risk of durability failure is minimised by implementing appropriate design, specification and construction approaches and procedures so that new RC structures meet the desired minimum design life. Specifically, RC structures in marine environments have an inherent high risk of chloride-induced corrosion of the steel reinforcement (Mackechnie 2001), and a number of studies (Tuutti 1982; Nilsson et al 1996; Bentur et al 1997) have been dedicated to understanding both the mechanisms of deterioration and the development of design approaches (Tang 1996; DuraCrete 1998; LIFE-365 2005) in order to meet and/or extend the desired design life.

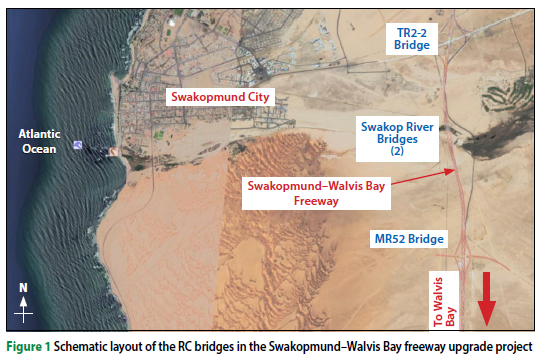

Durability design and specification of RC structures can be implemented using either a prescriptive approach or a performance-based approach, or a combination of both (Beushausen et al 2016). The case study presented in this paper assessed the durability potential of four newly constructed post-tensioned RC bridge structures on the Swakopmund-Walvis Bay Freeway upgrade project in Namibia (Figure 1). In the project, concrete durability design and specifications were made using a deemed-to-satisfy approach comprising South African recommendations for binder type, minimum binder content and w/b ratio (Mackechnie 2001), EN 206-1 (EN 2013) recommendations for cover depth, and South African National Roads Agency Limited (SANRAL) durability index target recommendations (Nganga et al 2017). The following section presents a brief overview of the durability index approach that was critical in checking if (i) the SANRAL-adopted specifications were achieved on site, and (ii) the desired service life was achieved.

Durability index approach

South African durability indexes (DIs) comprise a suite of three tests, namely oxygen permeability, water sorptivity and chloride conductivity, typically referred to as the durability index tests (Alexander 2018) - SANS 3001:CO3-1 (SANS 2015a), SANS 3001:CO3-2 (SANS 2015b) and SANS 3001:CO3-3 (SANS 2015c). The tests are performed on concrete disc specimens (70 ± 2 mm diameter, 30 ± 2 mm thickness) and are used to quantitatively assess the penetrability of concrete with respect to gas permeability, absorption (or capillary suction) and diffusion, respectively. The penetrability of concrete with respect to these transport parameters is characterised using durability indexes, namely the oxygen permeability index (OPI), the water sorptivity index (WSI) and the chloride conductivity index (CCI). The latter was of specific interest considering the marine exposure environment of the RC bridge structures assessed in this study, but the other two indexes were also determined, as will be seen later in the paper.

This approach links the DI parameters, service life models and performance specifications, and can therefore be used for pre-qualification and specification of concrete mixes, and/or in service life design in a performance-based durability design and specification framework (Alexander et al 2008; Beushausen et al 2021). It has been successfully implemented in a number of construction projects including major freeway projects by the South African National Roads Agency Limited (SANRAL) (Nganga et al 2017). In the Swakopmund-Walvis Bay Freeway upgrade, the tests were crucial in checking if the SANRAL-adopted DI specifications were achieved on site.

In the project presented in this paper, the South African chloride ingress model (Mackechnie 2001) was used after construction to assess the potential durability performance of the post-tensioned RC bridges. The model uses the 28-day CCI of a given concrete to predict the time-integrated (i.e. long-term) diffusion coefficient which is used in a Fickian model together with other input parameters (e.g. cover depth, chloride threshold, etc) to predict the expected design life. In this study, Crank's solution to Fick's second law of diffusion (Poulsen & Mejlbro 2006) (Equation 1) was used:

where Cx t is the chloride concentration at a depth x from the concrete surface at a given time t, Cs is the surface chloride concentration, Da is the apparent chloride diffusion coefficient, and erf is the mathematical error function.

According to this model, the design life is defined as the time taken for chlorides to penetrate through the concrete cover and reach a critical concentration at the steel level necessary to induce steel corrosion. Equation 1 was used to determine the potential design life using input parameters (cover depth and diffusion coefficient) obtained from the as-built concrete and compared with the design life that had been assumed based on the deemed-to-satisfy design approach that was used.

Deemed-to-satisfy durability design and specification approach

In this approach, specifications are based on a selection of a set of durability parameters (e.g. cover depth, binder type, etc) depending on the type of structure and aggressivity of the exposure environment. From a design and specification point of view, it is assumed that if the aggressivity of an exposure environment is similar to that used to recommend the adopted durability parameters and/or targets, and the as-built concrete meets the durability targets, then the concrete is deemed to meet the corresponding durability potential, usually in terms of design life (Alexander et al 2008; Beushausen et al 2021).

THE SWAKOPMUND-WALVIS BAY FREEWAY UPGRADE PROJECT

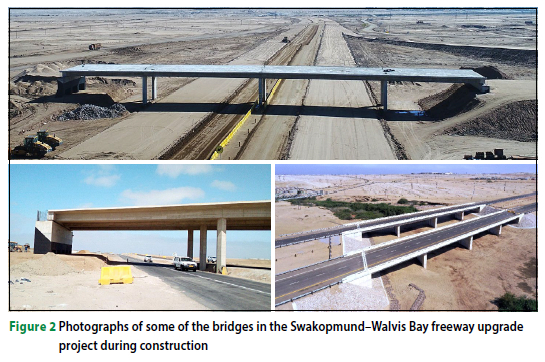

The focus project in this study was the Swakopmund-Walvis Bay 30-km freeway upgrade in the Erongo region on Namibia's Atlantic west coast. It forms part of the inland route between the cities of Walvis Bay and Swakopmund, as well as the Trans-Kalahari, Trans-Kunene and Trans-Zambezi highways. The project is expected to increase the movement (including import and export) of goods considerably along these corridors. The project was funded by the Namibian government (the client) under the Roads Authority of Namibia, to a total estimated cost of circa 950 million Namibian dollars (1 ZAR = 1 Namibian dollar). The project consisted of constructing four post-tensioned RC bridges with overall deck lengths ranging between 56 m and 109 m. Two of the bridges spanning the Swakop River were each constructed using more than 2 500 m3 of concrete, while an excess of 1 700 m3 of concrete was used in the remaining two bridges (see Figure 2).

The harsh marine exposure conditions posed a high risk of steel corrosion in the RC bridges, and therefore demanded that careful durability design, specification and construction considerations be intentionally made. The client's brief to the consultant included a requirement for durable RC bridges with a functional life of at least 100 years, with the client willing to accommodate the associated cost implications.

Exposure environment of the bridges and their characterisation

Coastal environments are known to be aggressive to steel RC structures; structures in these environments experience severe chloride-induced steel corrosion and subsequently premature durability failure (Richardson 2002; Elsener 2005; Otieno et al 2016; Beushausen et al 2021). Past studies have shown that the Namibian coast is one of the most aggressive environments in Southern Africa with respect to steel corrosion in RC structures (Bulley 1986). Typical examples depicting the aggressiveness of the Namibian coast include:

i. A case study on the corrosiveness of the Namibian coast is the Omaruru River RC Bridge in Henties Bay which showed that the bridge, constructed in 1982 using a 45 MPa concrete (presumably made with plain Portland cement) and 50 mm cover depth, suffered severe chloride-induced corrosion of main reinforcing steel in both the bridge deck and piers only 11 years after its construction, necessitating major repair works in a bid to ensure it meets its desired design life (Hess 1996).

ii. A 20-year study on corrosion along the Southern African coastline which showed that the Namibian coastline exhibited higher corrosion rates for mild steel (up to 0.85 mm/yr at the Walvis Bay military base located about 20 km from the coast) than those recorded in Cape Town and Durban (Callaghan 1991).

The aggressiveness of the Namibian coast can be attributed to its climatic conditions. The Namibian coastal towns experience a high relative humidity ranging between 69% and 96% in Swakopmund and between 73% and 95% in Walvis Bay while the average rainfall between Swakopmund and Walvis Bay is only 10 mm per annum (Robertson et al 2012). This is significantly higher than that in the dry inland environment such as Windhoek which has a relative humidity between 18% and 51%, and is comparable to other aggressive coastal environments in Southern Africa such as Durban (73-83°%) and Cape Town (71-83°%) (SA Weather). Strong south-westerly winds are carried over the Namibian coastline due to the South Atlantic anticyclone over the ocean to the southwest of Namibia. The winds undoubtedly transport airborne chlorides to the inland environments and cause foggy conditions; between 113 and 140 fog days per annum have been recorded on the stretch of coastline between Swakopmund and Walvis Bay (Bulley 1986; Olivier 1995).

Based on the characterisation of the exposure environment, it was clear that chloride-induced steel corrosion would be the dominant mode of deterioration in the post-tensioned RC bridges. Durability service life design considerations for the bridges were therefore based on this mode of deterioration. Using the EN206-1 (EN 2013) exposure environment classifications, the bridge exposure environments were categorised as 'XS1' which denotes 'structures exposed to airborne salt but not in direct contact with seawater or inland saline waters'. For this project, the two critical sources of chlorides in this environment were identified as both (i) air-borne chlorides, and (ii) from trucks transporting salt along the road and from the tyre tracks of vehicles approaching from the adjacent salt-gravel roads.

Deemed-to-satisfy durability specifications for the project

The desired design service life of the RC bridges was 100 years (DoT 1981: TMH7).

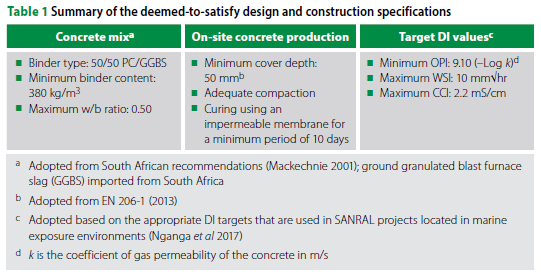

In the application of the deemed-to-satisfy durability design and specification approach, past experiences and studies were relied on to specify salient concrete mix parameters such as binder type and content, maximum water-to-binder (w/b) ratio, and site quality control aspects including adequate compaction and proper curing (DoT 1981: TMH7; COLTO 1998). A minimum cover depth of 50 mm was specified for all RC bridge elements following the recommendations of EN206-1 for structures classified as XS1 (EN 2013). Table 1 presents a summary of the deemed-to-satisfy design and construction specifications that were adopted for the project.

In addition to these specifications, it is worth mentioning that the structural design serviceability limit state crack widths were limited to less than 0.20 mm by varying both the maximum tensile stresses in the concrete and bar-to-bar spacing to within acceptable limits (DoT 1981: TMH7). Cracking is directly related to durability of the bridge structures, as studies have shown that the presence of cracks (even incipient cracks) in concrete significantly increases the risk of steel corrosion in cracked RC structures (Otieno et al 2010; Otieno et al 2016; Otieno 2017). The limitation of crack width to 0.20 mm is much higher than crack widths as low as 30 μm which permit chloride ingress (Djerbi et al 2008), but lower than the commonly referred to threshold of 0.40 mm below which long-term steel corrosion propagation is similar to that in uncracked concrete depending on the combination of parameters such as concrete quality and cover depth (Pettersson & Jorgensen 1996; fib-Model-Code 2010). Furthermore, a 0.20 mm crack width is also susceptible to physical and/or chemical crack sealing, which ultimately reduces the risk of steel corrosion in RC structures (Schießl & Edvardsen 1993; Edvardsen 1999; Gagné et al 2001; Neville 2002).

Other durability-related project specifications

In addition to the deemed-to-satisfy durability specifications, the following were also specified and implemented:

i. All above-ground concrete elements were coated with a silane-based water-repellent impregnation cream.

ii. All concrete faces in contact with soil were coated with a bitumen-based protective coating.

iii. The top surfaces of the bridge decks were coated with a waterproof spray-on polyurea.

iv. In areas where inadequate cover depth to steel reinforcement was measured, an additional overcoat of a cementitious waterproofing and protective slurry mortar was applied.

The above preventive measures were taken by the engineer in order to reduce the inherent risk of steel corrosion in the bridges considering the harsh marine exposure environment. However, it will be important to assess whether these measures were necessary to ensure that the bridges meet their desired 100-years design life. This will be re-visited later in the paper.

VERIFICATION OF THE DEEMED-TO-SATISFY DURABILITY PROJECT SPECIFICATIONS

The underlying assumption in a deemed-to-satisfy approach is that, within reasonable limits, an RC structure constructed using the adopted design and specification parameters (e.g. w/b ratio, binder type, cover depth, curing, etc) will meet the desired durability performance, i.e. design life. Verification of the as-built durability performance of the RC structure is therefore an important and useful process to ascertain its assumed durability performance - more than it is in a rigorous performance-based design and specification approach (Beushausen et al 2021). This is important, because in cases where the RC structure is found to be deficient in meeting the desired durability performance, appropriate remedial action can be taken promptly. In the verification process, the steps outlined below, which are covered in the following sections, were followed:

i. Durability index testing of the as-built concrete

ii. In-situ cover depth measurements

iii. Service life estimation using the South African chloride ingress model.

Durability index testing

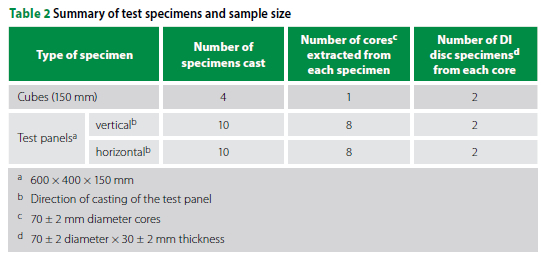

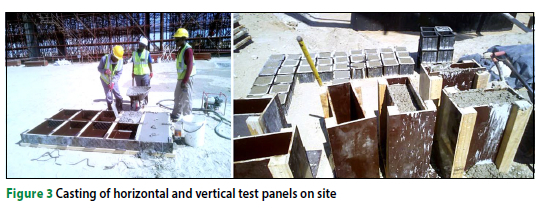

Companion disc specimens for DI testing were obtained from either 150 mm cubes or 600 χ 400 χ 150 mm test panels - see Table 2 for a summary of the sample size, and Figure 3 for photographs of the test panels from which DI test scores were taken. The test panels were cast to match the direction of casting of the bridge element of interest. All the specimens for durability testing were made using the concrete used to cast selected bridge elements (piers, abutments and decks). More test panels were cast compared to the cube specimens to cater for the expected inherent variability in the as-built concretes in the various bridge elements. The cube specimens were cured in a water bath for 28 days in the laboratory, while the test panels were cured on site following the same curing regime as the in-situ bridge elements. The cube specimens were used to determine the potential durability properties (OPI, WSI and CCI) of the concrete used in the project while the test panels were used to determine the actual (in-situ) durability properties of the as-built concrete.

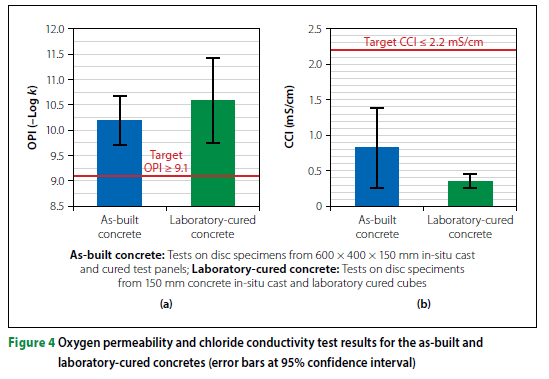

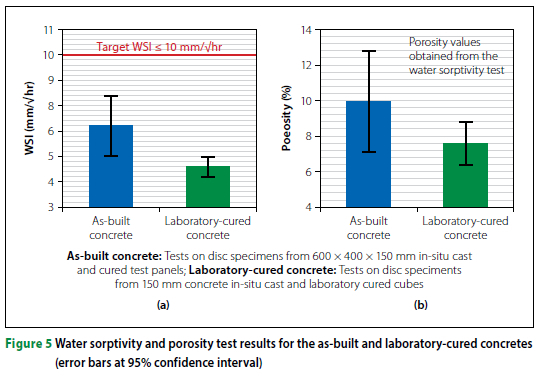

Due to logistical on-site challenges experienced in the course of the project, the DI test specimens were cored from the cube specimens and test panels at the end of the respective curing durations and then stored in the site laboratory and later transported to a laboratory in Windhoek for cutting to the required disc specimen thickness of 30 ± 2 mm. The disc specimens were then transported to the University of the Witwatersrand (Wits) in Johannesburg for DI testing in the concrete laboratory of the School of Civil and Environmental Engineering. The whole process resulted in the specimens being tested at different ages ranging from 50 to 132 days after casting (even though the curing durations were not altered), and one would expect that this could have resulted in a large variability in the DI test results. To test this hypothesis, statistical analyses were carried out to assess the variabilities in the DI results, which are represented by the error bars (at 95% confidence interval) in Figures 4 and 5. Based on the results, the variability in the results as a result of the different testing ages was considered insignificant (i.e. a null hypothesis), a trend which can be attributed to the expected slow microstructural development in the slag-blended concretes (Beushausen et al 2012). The statistical analyses also indicated that it was not necessary to consider the DI results separately for either the four bridges or the various bridge elements in each bridge.

Outliers were manually removed from the test results (based on the coefficient of variability values) and not considered in the subsequent analyses. A summary of the DI results is presented in Figures 4 and 5. As expected, the results show that the laboratory-cured concretes had better durability potential than the as-built concretes, i.e. higher OPI, lower CCI and lower WSI (Beushausen et al 2021). The results also corroborate those of previous similar projects that showed that there is generally higher variability in the on-site DI values (Nganga et al 2017). It is also clear that the target OPI, WSI and CCI values were met, a trend that can be attributed mainly to good quality control on site, i.e. adequate compaction and curing.

Cover depth measurements

Concrete cover acts both as a physical and chemical protective layer to the embedded reinforcing steel (Broomfield 2007). It is therefore important in the implementation of a durability design that not only is adequate depth of concrete cover specified but that it is also achieved on site during construction. Therefore, measurement of the actual cover depth in the various as-built bridge elements was considered a critical component in the verification process of the deemed-to-satisfy specifications. This was done despite the prior checking of the cover depth (e.g. ensuring the correct placement of cover blocks) in each bridge element's formwork before casting. The target minimum cover depth was 50 mm. An electromagnetic cover depth measurement device (cover meter) with an accuracy ranging between ± 5.0 mm and ± 7.5 mm was used. Even though this accuracy range meets the BS 1881-204 (BS 1988) requirements for cover depth measurements < 100 mm, it was still considered significant from a durability viewpoint (i.e. service life estimation), and the cover meter was carefully calibrated before use to reduce the variability due to the inherent large accuracy range.

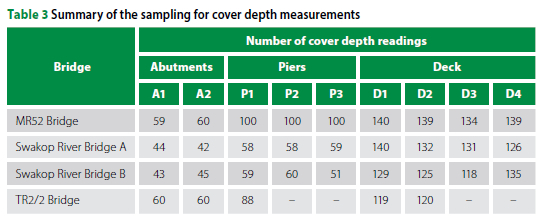

Scan surface areas of approximately 30 per m2 were selected for cover depth measurement on each face of each bridge element. Cover depth measurements were taken perpendicularly to the layer of reinforcing steel closest to the concrete surface for each scan area, i.e. linear scan method. Readings were taken to identify individual steel bars within each 1.0 m2, with 3 to 4 cover depth readings at 150 mm spacing being taken for each bar in each scan area. In instances where more than 10% of cover depth readings fell below the specified lower limit of 50 mm, the area was re-scanned to ascertain the readings. Outliers, if any, were removed manually from each of the three to four readings of each scan area by engineering judgement taking into account the accuracy of the cover meter. Table 3 presents a summary of the sample sizes for cover depth measurements for each bridge element after removal of outliers.

Reinforcing bars with inadequate (< 50 mm) concrete cover were marked on the concrete surface and, as had already been mentioned, a cementitious water-proofing and protective slurry mortar coating applied on these areas as a proactive 'corrective measure' in a bid to ensure that the durability of the bridge structure is not compromised. The durability performance of these coatings was not assessed in this study.

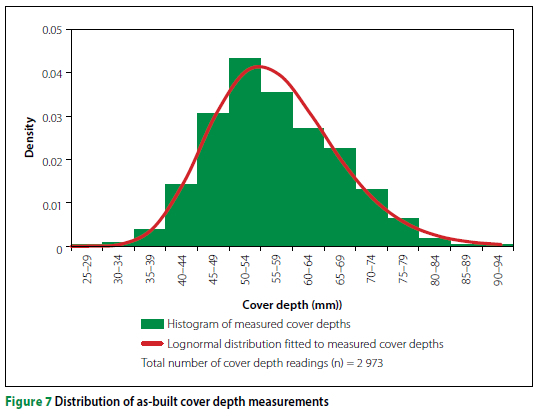

Figure 6 shows the results of the cover depth measurements, while Figure 7 shows a lognormal distribution curve fitted using MATLAB® to the histogram of the as-built cover depth measurements. Up to 30% of the cover depth readings fell below the target cover depth of 50 mm.

Service life estimation

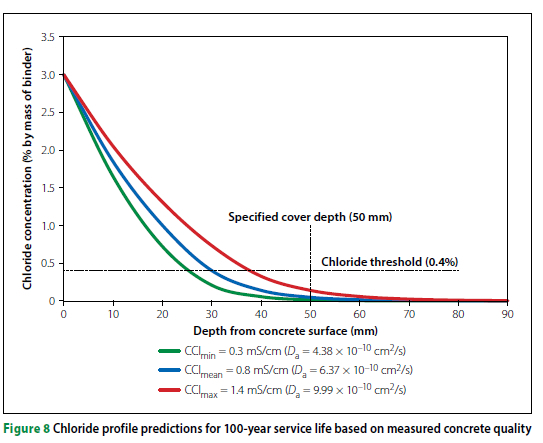

As already indicated, the dominant mode of deterioration in the post-tensioned RC bridges was identified as chloride-induced steel corrosion. Consequently, for service life estimation purposes, corrosion initiation was taken as the durability limit state, i.e. service life. This was assessed using the South African chloride ingress prediction model (Mackechnie 1996; Beushausen et al 2021) that defines the corrosion initiation limit state as 'the accumulation of a critical amount of chlorides at the level of the steel (i.e. chloride threshold) to initiate corrosion of the embedded reinforcing steel'. The service life analyses involved determining the chloride concentration at the level of the steel after 100 years of exposure (Cx t), and comparing this with the chloride threshold. The model (Equation 1) input parameters used in the analyses were as follows:

i. Cover depth (x): The cover depth measurements presented in the previous section were used in the analyses. From a service life standpoint, the minimum cover depth values were considered critical.

ii. Apparent chloride diffusion coefficient (Da): The Da value used in the analyses was obtained from the as-built chloride conductivity index values presented earlier (see Figure 4(b)) using an empirical nomogram developed for the South African chloride prediction model (Mackechnie 2001). From a service life standpoint, the maximum chloride conductivity index value was considered critical.

iii. Chloride threshold: A conservative value of 0.4% by mass of total cementitious content was adopted as the chloride threshold in the analyses (Beushausen et al 2021).

iv. Surface chloride concentration (Cs): Taking into account the exposure environment and binder type, a conservative Cs value of 3.0% by mass of total cementitious content was used in the analyses (Mackechnie 2001).

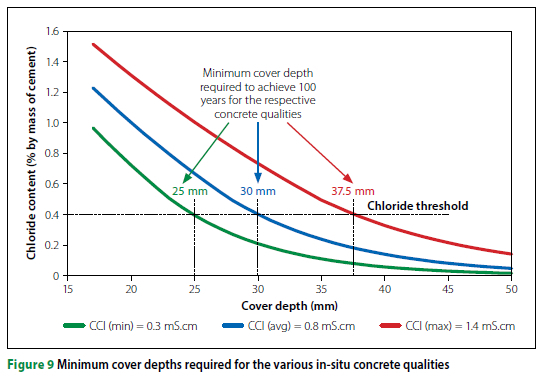

Figure 8 shows the chloride profiles determined using the aforementioned model input parameters. From this figure, two observations can be made. First, it is clear that if the specified cover depth of 50 mm was achieved in all the RC bridge elements, the desired 100-year service life would be surpassed, i.e. the chloride concentration at the steel level would be less than the chloride threshold value after 100 years' exposure. Secondly, it is also clear that even in instances where the specified cover depth of 50 mm was not achieved (see Figure 6), the 100-year service life would still be achieved as a result of increased concrete quality. This necessitated a careful look at the analyses results presented in Figure 8 to determine the minimum cover depths for the various concrete qualities (quantified using chloride conductivity index) required to achieve the desired 100-year service life. These are presented in Figure 9, which shows that even though the specified concrete cover of 50 mm may not have been achieved in some instances during construction of the various RC bridge elements, the expected loss in service life (Beushausen et al 2021) is compensated by the relatively high concrete quality achieved on site.

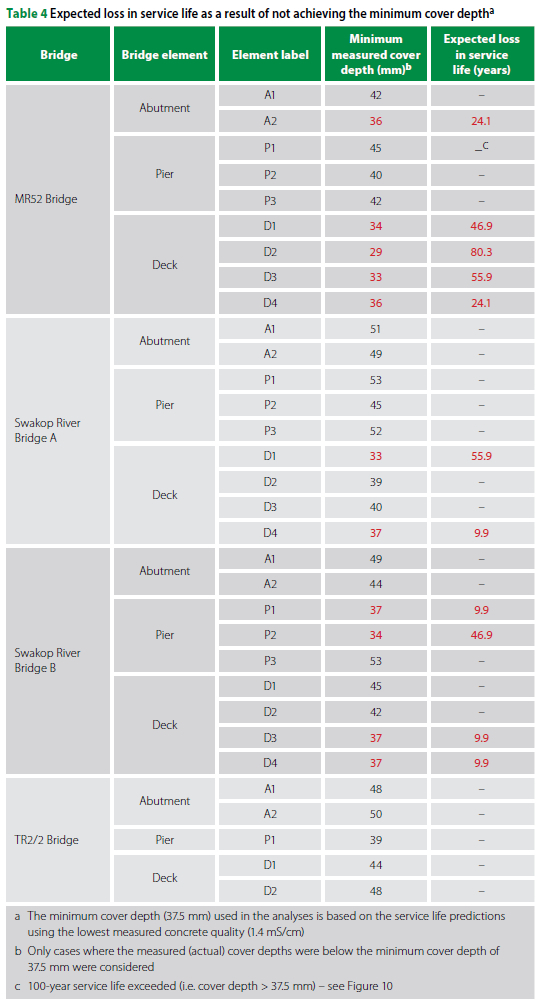

The determination of the minimum cover depths for the various concrete qualities shifts the focus to cases where the minimum cover depth (25, 30 or 37.5 mm) was not achieved. Effectively, considering the high concrete quality of the in-situ concrete achieved during the construction of the bridges, the prescriptive design cover depth of 50 mm can be viewed as an 'over-specification'. From a steel corrosion risk standpoint, two combinations of cover depth and concrete quality with the highest risk of steel corrosion were then identified, namely (i) 25 mm and 0.3 mS/cm, and (ii) 37.5 mm and 1.4 mS/cm. An analysis was therefore carried out to determine the expected loss in service life considering the corrosion risk posed by a combination of inadequate cover depth (< 37.5 mm) and concrete quality (< 1.4 mS/cm). The results are summarised in Figure 10 and Table 4.

IMPLICATIONS OF THE SERVICE LIFE ESTIMATIONS

The service life estimations presented in the previous section show that the deemed-to-satisfy concrete durability specifications adopted for the Swakopmund-Walvis Bay Freeway upgrade project were overly conservative. This outcome can be attributed to a number of factors, but it can be expected that concrete quality played a significant role. The results clearly corroborate the findings of previous studies (Otieno 2017) that highlight the importance of concrete quality (i.e. penetrability) in minimising the risk of steel corrosion in RC structures; in the project, the target penetrability, especially with respect to chloride ingress, was exceeded (see Figures 4 and 5).

The outcome of the verification of the durability performance of the bridges also highlights the need to implement more rigorous performance-based durability designs. Together with good on-site quality control in place, rigorous performance-based design and specification can help minimise wastage and ultimately contribute towards making concrete a more sustainable construction material. In this project it is clear that with the good concrete quality that was achieved on site, concrete cover could have been reduced (by up to 12.5 mm), and in effect, decrease member cross-section sizes to reduce the volume of concrete used in the project. However, the inherent challenges faced by contractors in achieving the target cover depth - as was experienced in the Swakopmund-Walvis Bay Freeway upgrade project - should be borne in mind, for example, by incorporating allowable tolerances on concrete element dimensions, reinforcing steel bending dimensions, and using good-quality, dense cover blocks. It should be pointed out that good on-site quality control is critical when cover depth is reduced as a result of increased concrete quality.

From a service life point of view, the service life estimations present the project engineers and client with an objective basis to make forward-looking decisions regarding possible actions to reduce the risk of steel corrosion in the bridges. Such actions may include setting the frequency of durability-related bridge inspections, implementation of other corrosion protection methods, e.g. sacrificial anodes (in addition to the surface coatings already in place), or a combination of these.

As mentioned earlier, a number of preventive measures were implemented on the bridge elements, including application of a cementitious surface coating in areas where inadequate cover depth (< 50 mm) to steel reinforcement was measured. However, based on the service life analyses, it is clear that such preventive measures were necessary in only 0.8% of the bridge elements (see Table 4) where cover depth was < 37.5 mm (and not < 50 mm), by virtue of the good concrete quality achieved on site (i.e. chloride conductivity values up to 36% lower than the target 2.2 mS/cm). Ultimately, this underscores the importance of good concrete quality that in most cases can be achieved if relevant steps such as compaction and curing are taken to control in-situ concrete quality. Furthermore, good concrete quality can also help in minimising the accelerating effects of cracks in concrete (Otieno 2017).

CONCLUSIONS

The objective of this paper was to present an analysis and verification of the deemed-to-satisfy design and specification approach that was used in the Swakopmund-Walvis Bay Freeway upgrade project on the Namibian coastline. The analyses showed that the deemed-to-satisfy performance targets were overly conservative. Achieving the target of 50 mm cover depth on site seemed to be a challenge, with up to 30% of the on-site measurements being < 50 mm. Nevertheless, the service life analyses showed that, taking into account the high concrete quality achieved on site, a cover depth of at least 37.5 mm was adequate. This effectively meant that only 0.8% of the cover depth measurements were inadequate. This underscores the importance of ensuring good concrete quality, which in most cases can be achieved if relevant steps such as adequate compaction and curing (method, time of commencement and duration) are taken to control in-situ concrete quality. Ultimately, the service life analyses highlight not only the critical importance of both concrete quality and cover depth in achieving durable RC structures prone to steel corrosion, but also the inherent limitations of the deemed-to-satisfy durability design and specification approach. In summary, the deemed-to-satisfy approach is still worth using if a rigorous performance-based design and specification approach cannot be used instead of not taking durability into account in the design, specification and construction of RC structures.

ACKNOWLEDGEMENTS

The authors would like to acknowledge the support of VKE Namibia, under the headship of Messrs Boshoff and Klink, in allowing the bridge projects to be used as part of this study.

REFERENCES

Alexander, M G, Ballim, Y & Stanish, K 2008. A framework for use of durability indexes in performance-based design and specifications for reinforced concrete structures. Materials and Structures, 41: 921-936. [ Links ]

Alexander, M 2018. DI-Manual: Durability Index Testing Procedure Manual, Version 4.5.1. University of Cape Town, University of the Witwatersrand & CoMSIRU. https://cemcon-sa.org.za/wp-content/uploads/2021/03/Durability-Index-Testing-Procedure-Manual-.pdf. [ Links ]

Bentur, A, Diamond, S & Berke, N 1997. Steel corrosion in concrete, Fundamentals and Civil Engineering Practice. London: E & FN Spon, 41-43. [ Links ]

Beushausen, H, Alexander, M & Ballim, Y 2012. Early-age properties, strength development and heat of hydration of concrete containing various South African slags at different replacement ratios. Construction and Building Materials, 29: 533-540. [ Links ]

Beushausen, H, Alexander, M G, Basheer, M, Baroghel-Bouny, V, d'Andrea, R, Gongalves, A et al 2016. Principles of the performance-based approach for concrete durability. Chapter 5. In Beushausen, H & Luco, L F (Eds), Performance-based Specifications and Control of Concrete Durability: State-of-the-Art Report RILEM TC 230-PSC, Dordrecht: Springer, 107-132. [ Links ]

Beushausen, H, Otieno, M & Alexander, M 2021. Durability of concrete. Chapter 12. In Alexander, M (Ed), Fulton's Concrete Technology. 10th ed. Johannesburg: Cement & Concrete South Africa, 391-468. [ Links ]

Broomfield, J P 2007. Corrosion of Steel in Concrete: Understanding, Investigation and Repair. 2nd ed. Oxford: Taylor & Francis. [ Links ]

BS (British Standard) 1988. BS 1881-204:1988. Testing Concrete: Recommendations on the Use of Electromagnetic Covermeters. London: British Standards Institution. [ Links ]

Bulley, B G 1986. The engineering geology of Swakopmund. Geologial Survey Report, 2: 7-12. [ Links ]

Callaghan, B G 1991. Atmospheric corrosion testing in Southern Africa: Results of a twenty-year national exposure programme. Pretoria: Scientia Publishers, CSIR. [ Links ]

COLTO (Committee of Land and Transport Officials) 1998. Standard Specifications for Road and Bridge Works for State Road Authorities. Midrand: South African Institution of Civil Engineering. [ Links ]

Djerbi, A, Bonnet, S, Khelidj, A & Baroghel-Bouny, V 2008. Influence of traversing crack on chloride diffusion into concrete. Cement and Concrete Research, 38(6): 877-883. [ Links ]

DoT (Department of Transport) 1981. TMH71981: Code of Practice for the Design of Highway Bridges and Culverts. Pretoria: Committee of State Road Authorities. [ Links ]

DuraCrete 1998. Modelling of degradation. In DuraCrete, probabilistic performance based durability design of concrete structures. The European Union - Brite EuRam III Project BE95-1347, Document BE95-1347/R4-5. Gouda, Netherlands. [ Links ]

Edvardsen, C 1999. Water permeability and autogenous healing of cracks in concrete. ACI Materials Journal, 96(4): 448-454. [ Links ]

Elsener, B 2005. Corrosion rate of steel in concrete: Measurements beyond the Tafel law. Corrosion Science, 47(12): 3019-3033. [ Links ]

EN (European Standard) 2013. EN-2062013. Concrete. Part 1. Specification, Performance, Production and Conformity. Brussels: European Committee for Standardisation. [ Links ]

FIB-Model-Code 2010. 3rd CEB-FIP Model Code for Concrete Structures. Comité Euro-International du Béton and Federation International de Précontrainte. London: Telford. [ Links ]

Gagné, R, Francois, R & Masse, P 2001. Chloride penetration testing of cracked mortar samples. Proceedings, 3rd International Conference on Concrete Under Severe Conditions (CONSEC), 18-20 June, University of British Columbia, Vancouver, Canada. [ Links ]

Hess, H 1996. Bringing roads to Namibia's people. Conserving our heritage: Rehabilitation of the Omaruru River Bridge B0435 at Henties Bay. The Namibian Engineer, 6: 15-16. [ Links ]

LIFE-365 2005. ACI-Committee-365. Service life prediction model. Computer program for predicting the service life and life-cycle costs of reinforced concrete exposed to chlorides. Farmington Hills, MI: American Concrete Institute. [ Links ]

Mackechnie, J R 1996. Predictions of reinforced concrete durability in the marine environment. PhD Thesis. University of Cape Town. [ Links ]

Mackechnie, J R 2001. Predictions of reinforced concrete durability in the marine environment. Research Monograph No 1, Department of Civil Engineering, University of Cape Town and University of the Witwatersrand. [ Links ]

Neville, A M 2002. Autogenous healing - a concrete miracle? Concrete International, 24(11): 76-82. [ Links ]

Neville, A M 2011. Properties of Concrete. 5th ed. Harlow, UK: Pearson Education. [ Links ]

Nganga, G W, Beuhausen, H & Alexander, M 2017. Practical implementation of durability index performance-based specifications: Current experience. Concrete Beton, 150 (September): 18-22. [ Links ]

Nilsson, L O, Poulsen, E, Sandberg, P, Sorensen, H E & Klinghoffer, O 1996. Chloride penetration into concrete, state-of-the-art. Transport processes, corrosion initiation, test methods and prediction models. HETEK Report No 53. Danish Road Directorate. [ Links ]

Olivier, J 1995. Spatial distribution of fog in the Namib. Journal of Arid Environments, 29(2): 129-138. [ Links ]

Otieno, M 2017. Sensitivity of chloride-induced corrosion rate of steel in concrete to cover depth, crack width and concrete quality. Materials and Structures, 50(9): 1-10. [ Links ]

Otieno, M B, Alexander, M G & Beushausen, H-D 2010. Corrosion in cracked and uncracked concrete: Influence of crack width, concrete quality and crack re-opening. Magazine of Concrete Research, 62(6): 393-404. [ Links ]

Otieno, M, Beushausen, H & Alexander, M 2016. Chloride-induced corrosion of steel in cracked concrete. Part I. Experimental studies under accelerated and natural marine environments. Cement and Concrete Research, 79: 373-385. [ Links ]

Pettersson, K & Jorgensen, O 1996. The effect of cracks on reinforcement corrosion in high-performance concrete in a marine environment. Proceedings, 3rd ACI/CANMET International Conference on the Performance of Concrete in a Marine Environment, 4-9 August, St Andrews, Canada, 185-200. [ Links ]

Poulsen, E & Mejlbro 2006. Diffusion of Chloride in Concrete: Theory and Application. Oxford: Taylor & Francis. [ Links ]

Richardson, M G 2002. Fundamentals of Durable Concrete. Modern Concrete Technology. London: Spon Press. [ Links ]

Robertson, T, Jarvis, A, Mendelsohn, J & Swart, R 2012. Namibia's Coast: Ocean riches and desert treasures. Windhoek, Namibia: Directorate of Environmental Affairs, Ministry of Environment and Tourism. [ Links ]

SA-Weather. Home page. https://www.weathersa.co.za. [ Links ]

SANS (South African National Standard) 2015a. SANS-3001-CO3-1 (2015), Civil Engineering Test Methods: Part CO3-1: Concrete Durability Index Testing: Preparation of Test Specimens. Pretoria: SABS Standards Division. [ Links ]

SANS 2015b. SANS-3001-CO3-2. Civil Engineering Test Methods: Part CO3-2: Concrete Durability Index Testing: Oxygen Permeability Test. Pretoria: SABS Standards Division. [ Links ]

SANS 2015c. SANS-3001-CO3-3. Civil Engineering Test Methods: Part CO3-3: Concrete Durability Index Testing: Chloride Conductivity Test. Pretoria: SABS Standards Division. [ Links ]

Schießl, P & Edvardsen, C 1993. Autogenous healing of cracks in concrete structures subjected to water pressure. Report No F361. Aachen University, Netherlands: Institute of Building Materials Research. [ Links ]

Tang, L 1996. Chloride transport in concrete: Measurement and prediction. PhD Thesis. Gothenburg, Sweden: Chalmers University of Technology. [ Links ]

Tuutti, K 1982. Corrosion of steel in concrete. Report No CBI Research 4:82. Stockholm: Swedish Cement and Concrete Research Institute. [ Links ]

Correspondence:

Correspondence:

M Otieno

School of Civil and Environmental Engineering, University of the Witwatersrand

Private Bag 3, Wits 2050, Johannesburg, South Africa

T: +27 11 717 7117

E: mike.otieno@wits.ac.za

K Walter

VKE Namibia School of Civil and Environmental Engineering

PO Box 45 University of the Witwatersrand, Windhoek Private Bag 3, Namibia Wits 2050, Johannesburg, South Africa

T: +264 61 237 642; E: kevin.walter@vkenamibia.com

PROF MIKE OTIENO is an Associate Professor in the School of Civil and Environmental Engineering, University of the Witwatersrand, Johannesburg, and is currently serving as the Head of School. He received his PhD and Master's degrees in Civil Engineering from the University of Cape Town, South Africa, and his Bachelor's degree in Civil Engineering from the University of Nairobi, Kenya. He is an Associate Member of the South African Institution of Civil Engineering. His research interests include concrete durability, service life prediction, steel corrosion in reinforced concrete structures, and repair and rehabilitation of concrete structures.

KEVIN WALTER, who is a professional engineer registered with the Engineering Council of South Africa, works as a Structural Engineer at VKE in Swakopmund, Namibia. He holds Bachelor's and Master's degrees in Civil Engineering from the University of the Witwatersrand, Johannesburg, and isa member ofthe South African Institution of Civil Engineering. His research and professional interests include bridge design and construction, structural engineering and project management.