Serviços Personalizados

Artigo

Indicadores

Links relacionados

-

Citado por Google

Citado por Google -

Similares em Google

Similares em Google

Compartilhar

Journal of the South African Institution of Civil Engineering

versão On-line ISSN 2309-8775

versão impressa ISSN 1021-2019

J. S. Afr. Inst. Civ. Eng. vol.62 no.3 Midrand Set. 2020

http://dx.doi.org/10.17159/2309-8775/2020/v62n3a2

TECHNICAL PAPER

Laboratory performance and modelling behaviour of hot-mix asphalt with recycled crushed glass

T B George; J K Anochie-Boateng; K J Jenkins

ABSTRACT

In South Africa research is currently under way to determine the suitability of using locally available recycled crushed glass as a partial fine aggregate substitute in the production of asphalt mixes. This paper characterises the laboratory performance of a dense-graded asphalt wearing course mix consisting of 15% recycled crushed glass. The influence of selected antistripping additives on moisture susceptibility was specifically assessed as a variable in the performance evaluation of the glass-asphalt mix as follows: (a) the effect of 1% hydrated lime, (b) the effect of 0.5% liquid antistripping additive, and (c) the effect without the addition of antistripping additive. The effect of these variables on the moisture susceptibility of the glass-asphalt mix was evaluated using the tensile strength ratio parameter supported with a microscopic imaging analysis. Additionally, the stiffness and permanent deformation properties of the glass-asphalt mix that demonstrated optimum resistance to moisture damage was compared to the same mix without crushed glass. The performance properties were evaluated using the Huet-Sayegh model and a polynomial model respectively, which were used particularly to develop performance characterisation models for the glass-asphalt mix. The findings of this study revealed that an anti-stripping additive is essential to meet moisture susceptibility criteria and alleviate moisture damage in dense-graded glass-asphalt mixes. In particular, moisture susceptibility was improved using hydrated lime rather than the liquid antistripping additive. Furthermore, the selected constitutive models were able to effectively characterise the laboratory performance of both mixes, with the glass-asphalt mix demonstrating improved resistance to permanent deformation when compared with the conventional asphalt mix.

Keywords: glass-asphalt, moisture susceptibility, dynamic modulus, permanent deformation, constitutive modelling

INTRODUCTION

In South Africa, the National Environmental Management Waste Act (Act 59 of 2008) commits the government to, amongst others, promote "waste minimisation, reuse, recycling and recovery of waste". However, national waste information indicates that an estimated 77% (approximately 1 000 000 tons) of waste glass generated in South Africa is being landfilled, while only 23% is recycled (Department of Environmental Affairs 2017). This data highlights that a substantial amount of waste glass could therefore potentially be recovered or diverted from landfill to be recycled or reused.

Additionally, considerable quantities of recycled crushed glass fines (less than 5 mm in size) accumulate as stockpiles at glass-packaging manufacturing plants in Gauteng and the Western Cape provinces of South Africa. These processed glass fines, which are unusable in the glass-packaging manufacturing process, are stockpiled and earmarked for disposal to landfill, thereby contributing to the waste glass that is currently being landfilled. This adds more undue pressure to rapidly depleting landfill space and has led to the necessity for adopting sustainable practices. Waste glass that is recovered to be recycled or re-used is a key component in this approach.

The road pavement industry in the international community has provided a number of alternative uses for recovered waste glass. The use of crushed glass in hot-mix asphalt (HMA) paving applications has been widely implemented in the United States and Canada since the early 1970s. Other countries that have reported using crushed glass in asphalt paving applications include the United Kingdom, Australia, New Zealand, Japan and Taiwan (Yamanaka et al 2001; Su & Chen 2002; Dane County Department of Public Works 2003; Arnold et al 2008; Australian Government 2011; Andela & Sorge n.d.).

Early applications of crushed glass in hot-mix asphalt pavements in the United States incorporated glass particles bigger than 12.5 mm, with quantities in excess of 25% (Federal Highway Administration 1998). The application of coarse glass particles (bigger than 5 mm) in large quantities was considered to be a major contributing factor to the stripping and ravelling problems reported in early glass-asphalt pavement applications. The increased susceptibility to stripping has also been attributed to the comparatively smooth surface texture of glass material, which reduces adhesion at the bitumen-glass interface (Federal Highway Administration 1998). To avoid these concerns, various studies have limited the quantity of crushed glass in the surface course, with control limits set on the grading of the glass particles used. More recently, 10 to 15% crushed glass has been specified for use in asphalt wearing courses in the United States, while some countries, e.g. New Zealand, utilise as little as 5% glass content (Federal Highway Administration 1998). Hughes (1990) demonstrated that the addition of 15% crushed glass, with a maximum particle size (MPS) of 10 mm, had a minor effect on the moisture susceptibility of a medium dense-graded glass-asphalt mix incorporating 1% hydrated lime. The Virginia Transportation Research Council (VTRC 1998) also reported on the superior stripping resistance of a fine dense-graded asphalt mix incorporating hydrated lime and consisting of up to 12% crushed glass (with an MPS of 10 mm), whereas the addition of a liquid antistripping additive demonstrated a reduction in stripping resistance with an increase in crushed glass content (VTRC 1998).

Su & Chen (2002) reported that glassasphalt pavement test sections in Taiwan, incorporating 10% of crushed glass (with an MPS of 5 mm) indicated no stripping of the glass particles, and also no rutting of the glass-asphalt pavement after one year of service. Furthermore, improved skid resistance along the longitudinal and transverse profile of the glass-asphalt pavement test sections was reported. Wu et al (2003) showed that the permanent deformation behaviour of a glass-asphalt mix incorporating 10% crushed glass (with an MPS of 5 mm) was comparable to a traditional dense-graded asphalt wearing course mix. Arabani (2010) observed an increase in stiffness modulus with an increase in crushed glass content up to 15%, above which reduced stiffness modulus was reported. Moreover, the glass-asphalt mix incorporating 15% crushed glass indicated higher stiffness moduli than a traditional dense-graded asphalt wearing course mix at elevated temperatures. Similar to the observations made by Su and Chen (2002) and Wu et al (2003), Lachance-Tremblay et al (2014) concluded that the addition of 10% crushed glass can be utilised in asphalt mixes without compromising the overall rutting performance of the asphalt mix. In South Africa, however, minimal research has been conducted on the viability of using crushed glass in asphalt pavement applications.

OBJECTIVE

The objective of this study was to determine the influence of 15% recycled crushed glass on the laboratory performance of a 10 mm nominal maximum particle size (NMPS) medium dense-graded asphalt wearing course mix. The effect of selected antistripping additives on the moisture susceptibility of three such glass-asphalt mixes (referred to as GA Mix 1, GA Mix 2 and GA Mix 3) was assessed in this study using the standard tensile strength ratio (TSR) parameter supported with a microscopic imaging method. The mentioned moisture susceptibility methods were used to select the optimum glass-asphalt mix that demonstrates least resistance to moisture damage. The stiffness and permanent deformation properties of the optimum glass-asphalt mix was then compared to a conventional medium dense-graded asphalt wearing course mix that is typically used for road construction in South Africa. The Huet-Sayegh model was used to characterise the stiffness properties of both mixes and establish an empirical stiffness characterisation model for the glass-asphalt mix tested. Additionally, an alternative mathematical model, which makes use of a polynomial modelling technique, was used to characterise the permanent deformation resistance of both mixes, which was also validated with the Francken model.

MATERIALS AND MIX DESIGN

Aggregate material and design aggregate grading

The same aggregates (i.e. andesite, granite and mine sand) that were used in the conventional mix were utilised in the production of the glass-asphalt mix. The granite crusher sand was partially substituted with 15% of recycled crushed glass due to the similar particle size distribution of both materials. The composition of recycled crushed glass was selected based on previous studies (mentioned above) indicating an optimum crushed glass content of 10 to 15%. The combined grading of the individual aggregates, crushed glass material and mineral filler was optimised to represent a similar design aggregate grading to the conventional mix by using a non-linear least-square optimisation technique in Microsoft Excel 2013.

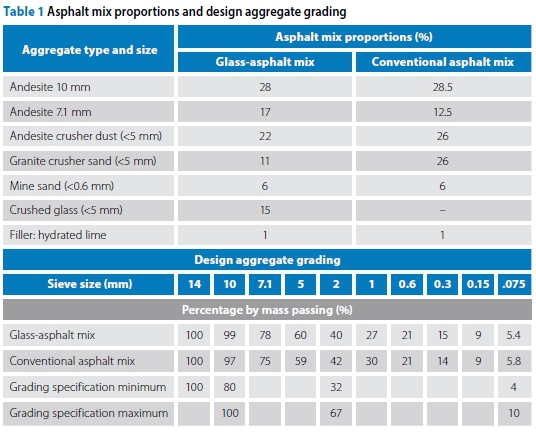

Table 1 indicates the percentage composition of each aggregate type and the mineral filler required to achieve the conventional mix design aggregate grading. It can also be observed that the design grading meets the grading control points specified for a 10 mm NMPS dense-graded asphalt mix as per standard design practices for traditional asphalt mixes in South Africa (Sabita 2016). NMPS is defined in South Africa as "one sieve size larger than the largest sieve to retain a minimum of 15% of the aggregate particles" (Sabita 2016).

Crushed glass material

The recycled crushed glass was procured from a glass manufacturing plant located in the Gauteng Province of South Africa. The type of glass that was used in this study is soda-lime glass. The general composition of soda-lime glass is as follows: 70-74% silicon dioxide (SiO2 10-14% calcium oxide (CaO) and 13-16% sodium oxide (Na2O). The chemical composition of the glass material used in this study was obtained by means of X-ray fluorescence (XRF). The analysis on a sample of the material revealed a chemical composition of 72% SiO2, 10% CaO and 13% Na2O. Other compounds were also present in smaller amounts and included 2.5% aluminium oxide (AlO3), 0.1% chromium oxide (Cr2O3) and 0.7% iron oxide (Fe2O3).

It is known that aluminium and chromium compounds are present in higher levels of amber and green-coloured glass respectively. Additionally, iron compounds, carbon and sulphur are also used as different colouring agents. The effect of these elements on long-term asphalt performance characteristics, as well as the long-term environmental impact, requires future investigation.

The particle size distribution of the crushed glass is reported in Table 2 and represents a fine continuous grading with an MPS of 5 mm.

The microscopic morphology of the crushed glass material was examined by scanning electron microscopy (SEM). The SEM examinations indicate that the crushed glass consists mainly of fine angular particles with fine-to-coarse textured features present on the surfaces of the glass particles, as shown in Figure 1. Also, due to the fine grading of the crushed glass material, reduced quantities of elongated particles and very few particles with sharp edges can be observed.

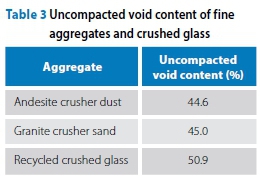

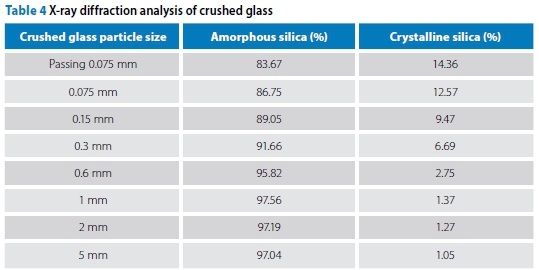

The observed angularity is also consistent with the fine aggregate angularity (FAA) test results obtained from the FAA test, which was performed on the crushed glass material and the traditional fine aggregates in accordance with ASTM C 1252 (2003). The FAA test measures the loose uncompacted void content of the fine aggregates and assumes a higher angularity with a higher uncompacted void content. The results are compared in Table 3. It can be observed that the crushed glass demonstrates increased angularity (50.9%) in comparison with the fine andesite (44.6%) and fine granite (45.0%) aggregates. This can be desirable in glass-asphalt mixes because angular particles interlock better with each other, thereby providing adequate inter-particle friction necessary to resist permanent deformation of the mix. Furthermore, the crushed glass material and fine aggregates meet the minimum criteria of 45% for a design traffic level of 30 million equivalent standard axle loads (ESALs), as specified in AASHTO M323 (2013).

An X-ray diffraction (XRD) analysis was also conducted on the entire grading of the recycled crushed glass material to identify the percentage composition of amorphous (non-crystalline) silica, i.e. glass, present in the sample. This provides an indication of the relative degree of "cleanliness or purity" of the recycled crushed glass obtained from the glass provider in South Africa.

Table 4 indicates the percentage composition of amorphous silica versus crystalline silica present in the sample of recycled crushed glass. The form of crystalline silica identified in the recycled crushed glass sample is quartz, which is the most common form of crystalline silica and is a mineral commonly found in most rocks, sands and soils.

It can be observed that on average more than 90% of the recycled crushed glass sample comprises amorphous silica, while less than 10% comprises crystalline silica. The locally available source of recycled crushed glass therefore demonstrates a high degree of purity and may hence be considered favourably for application in glass-asphalt mixes.

Antistripping additives and mineral filler

Hydrated lime (1% by mass of dry aggregate) constituted the filler component and served as an antistripping additive in GA Mix 1. The incorporation of 1% hydrated lime was selected based on the maximum specified amount allowed for inclusion in dense-graded asphalt mixes in South Africa (Sabita 2016). The hydrated lime was introduced into the mix by firstly mixing it with the cold aggregates and crushed glass, and then reheating to 165°C before mixing with bitumen.

A liquid antistripping additive (0.5% by volume of binder) was applied to GA Mix 2. The liquid additive, namely WETFIX BE, is an amine surfactant and is specially designed to improve the adhesion between the bitumen and aggregate surfaces in hot-mix asphalt. Additionally, its heat stability allows it to be stored in hot bitumen for up to five days at temperatures up to 170°C without losing its properties. This additive is often used as an adhesion promoter in hot-mix asphalt production in South Africa. The liquid additive was added to the binder according to the supplier's recommendations, and involved heating the original binder to approximately 150°C (mixing temperature), maintaining the same temperature while blending in the liquid additive, using a high-shear blender, for one hour. The blended binder was thereafter maintained at the same temperature and immediately incorporated into the mix.

To investigate the effect of the liquid antistripping additive on the moisture susceptibility of GA Mix 2, as well as similar effects on the moisture sensitivity of GA Mix 3 without an antistripping additive, the mineral filler in GA Mixes 2 and 3 consisted of 1% (by mass of dry aggregate) of baghouse fines instead of hydrated lime. Although the type of mineral filler varied, the design grading of all three mixes was not affected, due to similar particle size distribution of both filler components.

Mix design and optimum binder content

The South African mix design guideline for dense-graded asphalt mixes (Sabita 2016) was followed to determine the optimum binder content of GA Mixes 1, 2 and 3, as well as the conventional asphalt mix. In total, 80 samples were prepared for the mix design. The same binder, i.e. 50-70 penetration grade binder with penetration (25°C, 100 g, 0.1 mm) of 65 and softening point after rolling thin film oven (RTFO) aging at 47°C, that was utilised in the conventional mix was used to prepare the glass-asphalt mixes. The constituent aggregates (as per the design aggregate grading), respective mineral fillers and the binder were mixed at a temperature of 150°C and the prepared mixtures were then short-term-aged at 135°C for four hours. The mixtures were thereafter compacted at 135°C using a Superpave Servopac gyratory compactor in accordance with AASHTO T312 (2015a). Compaction was conducted at four trial binder contents (i.e. 4.0, 4.5, 5.0 and 5.5%) to dimensions of approximately 150 mm diameter by 115 mm height at 100 gyrations. The South African mix design method specifies a laboratory compaction requirement of 100 gyrations for a design traffic level of 3 to 30 million ESALs.

The bulk relative density (BRD) of three replicate compacted samples at each trial binder content was determined in accordance with SANS 3001-AS10 (SANS 2011a). Additionally, the maximum theoretical relative density (MTRD) for each asphalt mix was determined on two loose samples at each trial binder content in accordance with SANS 3001-AS11 (SANS 2011b). The average laboratory measured MTRD values and BRD values were used to determine the voids of the compacted samples, as presented in Table 5.

The South African mix design method specifies the optimum bitumen binder content to be established at 4% air voids in the mix. As per this criterion, an optimum binder content of 5.4% for GA Mixes 1, 2 and 3, and 5.2% for the conventional mix was determined. Although the particle size distribution of the crushed glass and the granite crusher sand is similar, the crushed glass is on average 15% finer between 1 mm and 2 mm particle size. It is suspected that the incorporation of finer crushed glass may have contributed to higher optimum binder content in comparison with the conventional mix, owing to a larger surface area.

LABORATORY PERFORMANCE TESTING PROGRAM

Mix sample preparation

The performance testing samples were manufactured at a mixing temperature of 150°C and a compaction temperature of 135°C. Prior to compaction, the asphalt mixtures were shot-term-aged (to simulate the ageing process that occurs during the asphalt production phase and the transportation phase) for four hours at the compaction temperature. The moisture susceptibility test samples were compacted to dimensions of 150 mm diameter by 60 mm height, and the stiffness and permanent deformation test samples were compacted to dimensions of 100 mm diameter by 150 mm height. The test samples were compacted at the determined optimum binder content to a target air void content of approximately 7% (representative of field voids). Compaction of the samples to the target height and air voids was achieved after 90 to 120 gyrations using a Superpave Servopac gyratory compactor in accordance with AASHTO T312 (2015a). In total, 30 samples were prepared to characterise and compare the performance of the glass-asphalt mix with the conventional mix.

Modified Lottman testing

The Modified Lottman test, conducted in accordance with ASTM D4867M (2009), was performed to assess the moisture susceptibility of GA Mixes 1, 2 and 3. Six gyratory compacted test samples for each glassasphalt mix were prepared and divided into two subsets. One subset was maintained dry while the other underwent a partial saturation (55% - 80% saturation) and freeze-thaw conditioning process. Although the freeze cycle is optional in ASTM D4867M (2009), this conditioning process was included since the asphalt mix contains glass particles, which makes it more prone to moisture damage than traditional aggregates (Federal Highway Administration 1998). In addition, the glass particles require additional treatment with anti-stripping additives. The aim was to therefore simulate conditioning that is more severe than conditioning expected in the field.

The indirect tensile strength (ITS) of each subset was determined by the indirect tensile splitting test. During testing, a diametrical load at 50 mm/min at 25°C was applied until the maximum load required to fracture the samples was reached. The maximum load was used to determine the ITS for each subset.

Additionally, ASTM D4867M (2009) specifies a visual assessment to be conducted on the fractured (tested) samples. This assessment entails breaking the tested samples open and reporting on the visually estimated degree of moisture damage. To eliminate visual judgement and biased interpretation associated with the current standard of visual inspection and reporting, a microscopic imaging analysis was implemented in this study to assess the degree of stripping that had occurred in each mix. One fractured sample from the wet subset of each mix was examined under a stereo microscope at a 6x zoom magnification. To obtain a representative area, several sections of dimension 22.05 mm (width) by 14.68 mm (height), each spanning over the cross-sectional area of the fractured sample, were examined under the microscope.

The microscopic sections were captured by a built-in integrated digital camera and the resulting images were imported into ImageJ 1.52a, which is the public domain Java Image processing program, inspired by the National Institute of Health (NIH). In ImageJ, the captured images were converted to 8-bit greyscale images which consist of 256 levels of grey intensity per pixel that range from 0 (black) to 255 (white). The variation in grey intensity levels is dependent on the densities of each component material in the mix. Dense materials are represented by the brighter regions, while low density materials are represented by the darker regions. As such, in this analysis the exposed aggregates correspond to the brighter regions and the bituminous-coated aggregates, mastic and voids correspond to the darker regions. Since the pixel grey values of the exposed aggregates and the remaining material phases (i.e. bituminous-coated aggregates, mastic and voids) were distinctly different from each other, a threshold value of 65 was easily selected to distinguish between the two regions. This threshold value was considered to be most accurate in identifying the areas of stripping and was consistently applied in all three mixes for realistic comparison. The applied threshold level converts the image to a binary image, where all pixels in the greyscale image greater than the threshold value are replaced with the value 255 (white) and the remaining pixels with the value 0 (black). The binary images were used to quantify the degree of stripping by measuring the area of white pixels (area of exposed aggregates) as a ratio to the area of the sum of white and black pixels (total sample surface area) for each mix. The area measurement of white and black pixels was automatically computed in the software.

Light reflection off the coated crushed glass fines was noted in particular during microscopic examinations of the glassasphalt samples. The reflection was indicated by an even and consistent distribution of bright speckles in the captured images of all three mixes and were thus identified as white pixels in the binary image. It should be noted that similar reflection was also noted in the unconditioned samples, when examined under the microscope. To avoid processing and analysis of these reflections, particles up to and including 0.15 mm for all three mixes were removed from the binary image prior to stripping area measurement. This was performed in ImageJ using the 'particle analyser' function, where only particles bigger than 0.15 mm were processed and analysed.

The steps implemented during the imaging analysis are summarised in Figure 2. One section captured per sample of each glass-asphalt mix (GA Mixes 1, 2 and 3) is illustrated, while the same steps were followed to obtain the percentage of stripping across several sections of the sample.

Dynamic modulus testing

The dynamic modulus |E*| is a performance-related parameter that is used to characterise the resilient response (stiffness) of hot-mix asphalt. The dynamic modulus is defined by the absolute value of the complex modulus, E*.

The dynamic modulus test was conducted on the optimum glass-asphalt mix and the conventional mix in accordance with the CSIR (Council for Scientific and Industrial research) protocols developed for the asphalt industry in South Africa (Anochie-Boateng et al 2010). During the test, a haversine compressive load pulse was applied on three replicate gyratory compacted samples at five test temperatures (-5, 5, 20, 40, 55°C) and six loading frequencies (25, 10, 5, 1, 0.5, 0.1 Hz) with no confining pressure. The vertical deformation of the samples was determined by recording the average measurements of three axial linear variable displacement transducers (LVDTs). The dynamic modulus of the samples tested was computed by recording the axial stresses and the resulting axial resilient strains for the last five load cycles for each test. A strain-controlled type of dynamic modulus testing was followed such that the measured strain was limited to approximately 100 micro-strain.

Flow number testing

In this study, the flow number test was conducted to evaluate the permanent deformation resistance of the glass-asphalt mix and the conventional mix. The asphalt mixture performance tester (AMPT) permanent deformation test procedure, specified in AASHTO TP 79 (2015b), was used to conduct the flow number test on three replicate gyratory compacted samples. The flow number test entails the application of a repeated compressive haversine load at 1 Hz (i.e. one cycle with a loading time of 0.1 seconds and a rest period of 0.9 seconds) and a measure of the corresponding cumulative axial permanent strain as a function of load cycles. In this study, a deviator stress level of 276 kPa with a confining pressure of 69 kPa was applied on the test samples and conducted at a test temperature of 50°C.

The cumulative permanent axial strain response is typically divided into three main phases, i.e. primary, secondary and tertiary. The cycle number at which tertiary flow (i.e. tertiary stage) of the mix commences is defined as the flow number. Thus, it is considered that the permanent deformation failure of the asphalt mix occurs at the onset of tertiary flow and is indicative of the resistance of the mix to permanent deformation.

RESULTS AND DISCUSSIONS

Moisture susceptibility evaluation

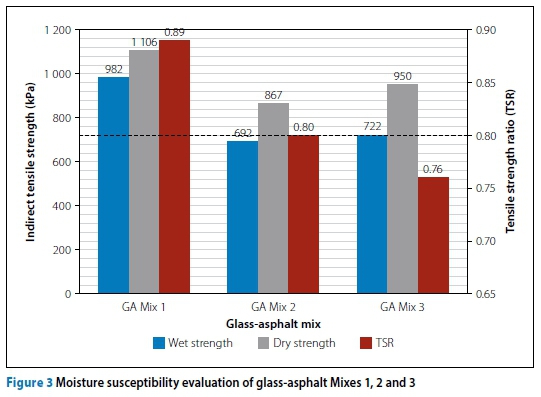

Moisture damage may occur due to the loss of strength and durability in an asphalt mix in the presence of moisture. Moisture permeates and weakens the bond between the mastic (i.e. binder and mineral filler) and the aggregates in the mix, making the mix more susceptible to moisture damage during cyclic loading. The moisture susceptibility of the mix was evaluated by the tensile strength ratio (TSR), which was determined by the ratio of the average ITS of the wet subset to the average ITS of the dry subset. The results are presented in Figure 3.

It can be observed from the results that the incorporation of hydrated lime in Mix 1 contributes towards the enhanced dry strength in comparison with Mixes 2 and 3. It is also apparent from the percentage reduction in strength of the conditioned subset of Mix 1 (i.e. 11%) in comparison with Mix 2 (i.e. 20%) that the role of the hydrated lime as an antistripping additive in the presence of water is considerably more effective than the liquid antistripping additive. Although a larger reduction in dry strength is noted for Mix 2 in comparison with Mix 3, the percentage reduction in strength of the conditioned subset of Mix 2 (i.e. 20%) is not as pronounced as in the case of Mix 3 (i.e. 24%), which is expected due to the absence of an antistripping additive in Mix 3.

It is interesting to note that Mix 2, which contains a liquid antistripping additive, indicates the lowest dry strength in comparison with Mixes 1 and 3. The liquid additive may thus have an adverse effect on the strength of asphalt mixes, although the moisture susceptibility may improve. This observation is in line with the general notion that liquid additives like these cause early pavement failures such as rutting, even although they are known to improve moisture susceptibility (Iowa Department of Transportation 2012).

In South Africa, a minimum tensile strength ratio of 0.8 for asphalt wearing courses is specified (Sabita 2016). It can be seen in Figure 3 that GA Mixes 1 and 2 meet the minimum tensile strength ratio criteria, whereas GA Mix 3 fails to comply with the specified requirement. Based on the TSR as a reliable indicator of moisture susceptibility, it is anticipated that GA Mix 1 will be less susceptible to moisture damage than GA Mix 2, while GA Mix 3 is expected to demonstrate the least resistance to moisture damage.

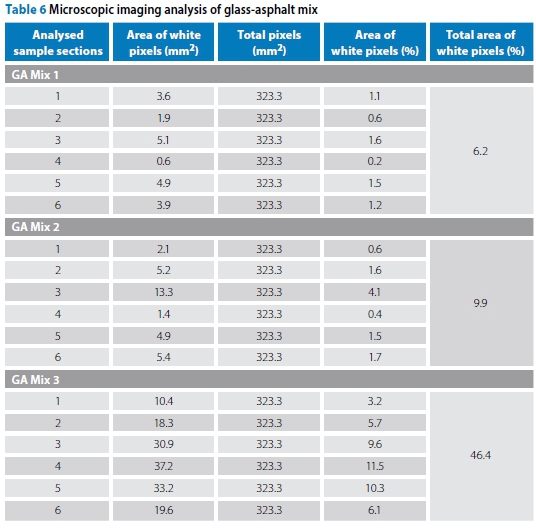

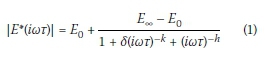

From the microscopic image analysis conducted on several sections of the fractured conditioned sample, the ratio of the area of white pixels (exposed aggregates) to the ratio of the total area of white and black pixels (exposed aggregates and bituminous-coated aggregates) was determined from the processed binary images to quantify the degree of stripping for GA Mixes 1, 2 and 3, according to the method described earlier. The results of this analysis are reported in Table 6.

The results show a clear variation in the degree of stripping with the addition of both antistripping additives. A significant reduction in the area of white pixels (stripped areas) can be observed for GA Mixes 1 and 2 compared to GA Mix 3. The total area of white pixels reduces from approximately 47% (GA Mix 3) to less than 10% (GA Mixes 1 and 2). These results confirm the effectiveness of antistripping additives in significantly improving the moisture susceptibility of glass-asphalt mixes. Moreover, the addition of hydrated lime appears to reduce the stripped areas slightly more than the liquid antistripping additive, although a major distinction was not apparent from the microscopic images.

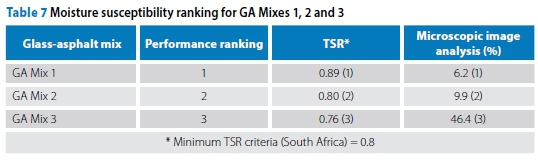

It is evident from the above evaluation that both methods appear to rank the moisture susceptibility of GA Mixes 1, 2 and 3 in the same order, as reported in Table 7. The ranking of 1 to 3 indicates least to most moisture susceptible. Based on these rankings, GA Mix 1 was selected as the optimum glass-asphalt mix on which further investigation regarding the stiffness and permanent deformation properties were conducted. It is also recommended that microscopic imaging techniques be used as a tool to validate the TSR results of mixes that are susceptible to moisture damage.

Stiffness evaluation

Dynamic modulus modelling

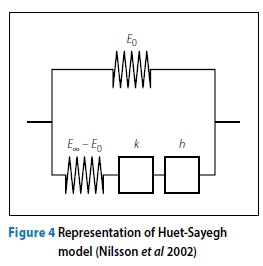

The dynamic modulus behaviour of the GA Mix 1 and conventional mix was evaluated using the Huet-Sayegh model. The Huet-Sayegh model uses physical elements to describe the dynamic modulus behaviour of HMA materials and is represented by a combination of two units connected in parallel, i.e. a spring,Eoo - E0,and two bi-parabolic dashpots, h and k, connected in series with a spring, E0, connected in parallel, as shown in Figure 4.

The associated mathematical expression of dynamic modulus for the Huet-Sayegh model is determined by Equation 1 (Nilsson et al 2002).

Where:

|E*| = dynamic modulus

i2= complex number, defined by i2= -1

w = angular frequency (Hz), w = 2rf

E0,Eoo, δ, k, h, T = model constants

In Equation 2, Eoo represents the purely elastic component (E* for the high frequency and low temperature domain) of the complex modulus, while E0 represents the longterm elastic modulus (residual E* for the low frequency and high temperature domain). δ, k, and h represent the parameters of the parabolic elements of the Huet-Sayegh model and t is the retardation time regarding the effect of temperature on the complex modulus, which is defined as per Equation 2.

Where:

T = retardation time (s)

T = temperature (°C)

a, b, c = regression constants

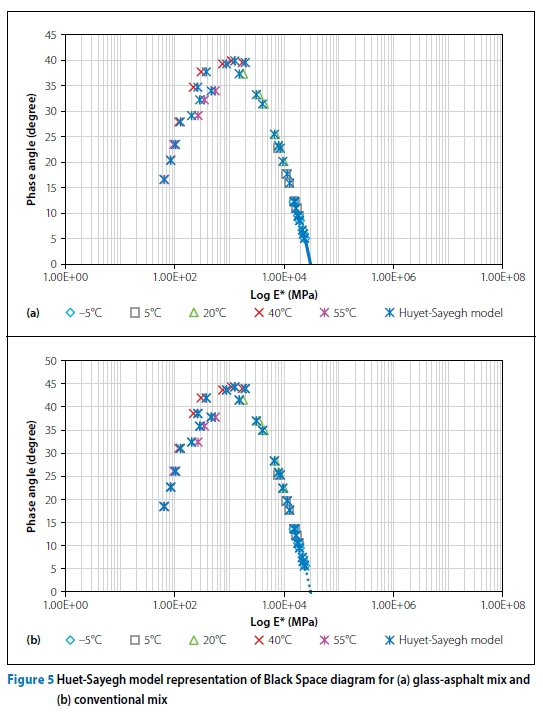

In this paper, the measured dynamic modulus data of GA Mix 1 and the conventional mix is represented by the Huet Sayegh model in the Black Space diagram shown in Figure 5 (p 18). The Black Space diagram presents a plot of the phase angles and the corresponding dynamic moduli at the tested temperature and frequency. For bituminous materials the viscous or elastic properties are indicted by the phase angle. The phase angle for a purely elastic material is 0°, while for a purely viscous material the phase angle is 90°.

The purely elastic modulus is obtained when the phase angle approaches zero, resulting in the storage modulus approaching the elastic modulus, and the loss modulus approaching zero. The purely elastic parameter Eoo was obtained from the Black diagram by extrapolating the curve to zero phase angle, as shown in Figure 5. The determination of the remaining five parameters, E0, δ, k, h and t was performed graphically such that the measured data is most accurately represented by the model in the Black diagram. This was obtained by a non-linear least-squares regression of the set of measured dynamic moduli and corresponding phase angles at the respective test frequencies and temperatures. The regression was carried out using the Solver function in Microsoft Excel 2013. It can be observed that the use of the Huet-Sayegh model provides an excellent fit for the measured dynamic modulus data. The obtained Huet-Sayegh model parameters, at a reference temperature of 20°C, are provided in Table 8.

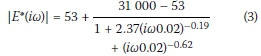

The obtained Huet-Sayegh model parameters were used to establish an empirical model for the prediction of dynamic modulus of the glass-asphalt mix tested, as described in Equation 3. Validation of the model parameters will, however, be conducted when additonal laboratory and actual field testing data becomes available.

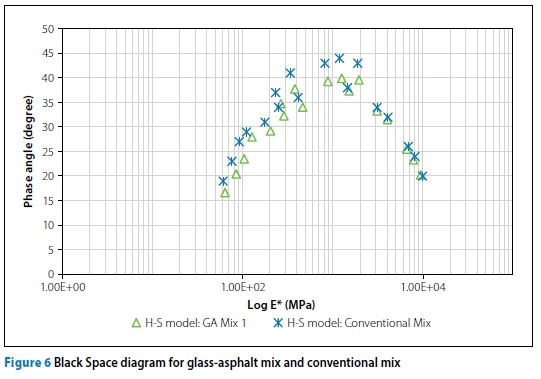

Dynamic modulus results

A comparative plot of the Huet-Sayegh model for both mixes at 20°C, 40°C and 55°C in the Black Space diagram is presented in Figure 6. Lower phase angles for GA Mix 1 in comparison with the conventional mix can be observed at 40°C and 55°C. The lower phase angles indicate a tendency towards more elastic behaviour due to the aggregate skeleton taking precedence in the mix. At elevated temperatures, the binder in the mix becomes more viscous and the load carrying capacity is gradually transferred to the aggregate skeleton, while at low temperatures it is the binder that determines the load-carrying capacity of the mix. In this regard, a stable aggregate skeleton with optimal aggregate interlock contributes to increased effective stiffness at elevated temperatures.

As previously mentioned, the glass particles utilised in this study demonstrate higher angularity than the traditional aggregates. The higher angularity in turn increases the interlock between the crushed glass particles and constituent aggregates in the mix, and could be a contributory factor towards the increased stiffness observed with the glass-asphalt mix at 40°C and 55°C. It can also be observed that the phase angles for both mixes at 20°C are comparable, reflecting comparable stiffness at intermediate temperatures.

Permanent deformation evaluation

Permanent deformation modelling

The flow number is an indicator of asphalt mix rutting resistance and was used in this study to compare the permanent deformation resistance of GA Mix 1 and the conventional mix. The flow number is defined by the number of cycles at which the rate of change of permanent strain is minimum and corresponds with the onset of tertiary flow. Inaccuracies in flow number determination may arise when the minimum permanent strain rate is merely obtained from the laboratory measured results, due to existing variation/noise in the experimental data. Additionally, there is an infinite number of cycles in the secondary stage where the constant permanent strain slope is minimum. As a result, various algorithms have been proposed for identifying the flow number in the flow number test. Most of the proposed algorithms, however, are only capable of modelling the primary and secondary phases of permanent strain and pose a challenge in representing a good-fitting three-phase permanent deformation model where the tertiary phase is also encountered. AASHTO TP 79 (2015b) refers to the Francken model as most accurate for flow number computation. The Francken model combines a power model, which describes the primary and secondary phases of permanent deformation and an exponential model, which describes the tertiary phase.

In this study, an alternative mathematical model, which makes use of a polynomial modelling technique for flow number determination, is used to compare the permanent deformation resistance of the glass-asphalt mix and the conventional mix, and the results are validated with the Francken model computation of flow number. The analysis methodology of each model used for identifying the flow number is described next.

Polynomial model

During the secondary stage of permanent deformation, the rate of change of strain (strain slope) is considered to reach a minimum after a certain number of loading cycles. The polynomial model is implemented in this region of the permanent deformation curve, whereby a second-degree polynomial curve, in the form of Equation 4, is used to model the measured rate of change of permanent strain.

Where:

Ep= permanent strain rate

N = load cycle

a, b and c = regression coefficients

The flow number is determined by setting the first derivative of Equation 4 to zero and solving for the number of load cycles (N), as described in Equation 5.

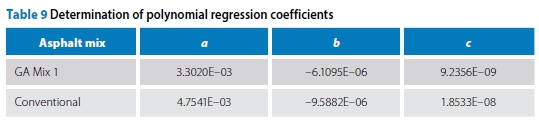

Figure 7 presents the polynomial model used to describe the average measured permanent strain rate of GA Mix 1 and the conventional mix as a function of load cycles. The coefficients of the polynomial model were obtained from a non-linear least-squares regression of the set of measured permanent deformation data. The regression was carried out using the Solver function in Microsoft Excel 2013. The determined coefficients of the model are provided in Table 9.

The obtained regression coefficients of the polynomial model were used to determine the flow number values using the approach mentioned above. The flow number (FN) obtained for GA Mix 1 and the conventional mix was determined at 331 and 257 load cycles, respectively.

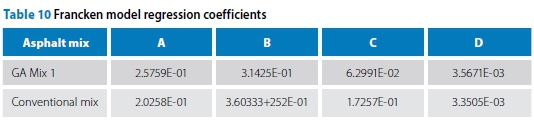

Francken model

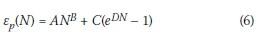

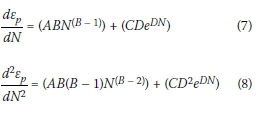

The Francken model is described by Equation 6.

Where:

Ep(N) = permanent strain (%)

N = number of load cycles

A,B, C and D = regression coefficients

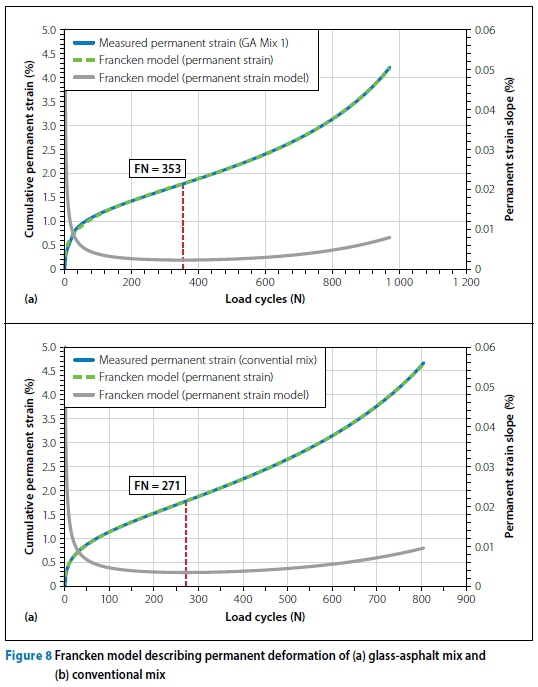

Figure 8 shows the Francken model which was used to model the permanent deformation behaviour of GA Mix 1 and the conventional mix. The coefficients of the Francken model were also obtained from a non-linear least-squares regression of the set of measured permanent deformation data. The determined coefficients of the model are provided in Table 10 and were used to determine the flow number of GA Mix 1 and the conventional mix by equating the second derivative of the model, described in Equation 8, to zero and solving for the load cycle number (N). The model coefficients were also used to plot the permanent deformation rate (strain slope) and are described by the first derivative of the model (Equation 7).

Graphically this cycle number is represented at the point where the curvature of the fitted permanent deformation curve changes from negative to positive, and is considered to be the onset of tertiary (plastic) flow in asphalt mixes. The flow number for GA Mix 1 and the conventional mix was obtained at 353 and 271 load cycles respectively.

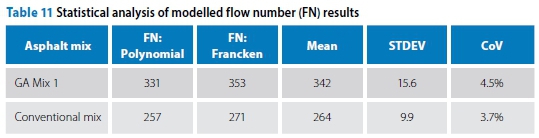

A comparison of the flow number results obtained using the polynomial model and the Francken model revealed the statistical information provided in Table 11. Very similar flow number results are obtained from both models, with a coefficient of variance (CoV) less than 5% for the glass-asphalt mix as well as for the conventional mix. It is therefore reasonable to consider the polynomial model as accurate and applicable for the determination of flow number for both glass-asphalt and conventional asphalt mixes.

Permanent deformation results

From the determined flow number values, it is apparent that the glass-asphalt mix has an increased resistance to permanent deformation than the conventional mix, as represented by a higher flow number. This observation is also consistent with the improved stiffness behaviour indicated by the glass-asphalt mix at elevated temperatures (40°C and 55°C) described earlier in this paper.

The higher flow number may be attributed to the highly angular glass particles which provide adequate interlock to generate the inter-particle friction necessary to resist permanent deformation. This was also observed through an SEM analysis conducted by Anochie-Boateng and George for the same source and grading of recycled crushed glass in an asphalt mix (Anochie-Boateng & George 2018). The SEM analysis demonstrated high angularity and in turn increased interlock between the constituent particles in comparison with a traditional asphalt mix incorporating less angular aggregates (see Figure 9).

CONCLUSIONS

The effectiveness of selected antistripping additives in resisting moisture damage was assessed as a variable in the laboratory performance evaluation of a 10 mm medium dense-graded asphalt wearing course mix consisting of 15% recycled crushed glass as follows: (1) effect of 1% hydrated lime, (2) effect of 0.5% liquid antistripping additive, and (3) effect without the addition of an antistripping additive. The effect of these variables on the moisture susceptibility of the glassasphalt mix was determined from the TSR obtained from the Modified Lottman test, supported with a microscopic imaging analysis conducted on tested Modified Lottman samples. The stiffness and permanent deformation properties of the glass-asphalt mix that demonstrated optimum resistance to moisture damage were thereafter compared to a conventional asphalt mix (without crushed glass). The Huet-Sayegh model and a polynomial model were used to characterise the stiffness and permanent deformation behaviour respectively. The following conclusions can be drawn from this research:

■ The recycled crushed glass material evaluated in this study is potentially capable of substituting traditional fine aggregates that are typically used in asphalt mixes in South Africa. This is based on the improved rutting performance demonstrated by the glass-asphalt mix in comparison with the conventional asphalt mix at elevated temperatures.

■ The polynomial model is suitable for determining the flow number of the conventional and glass-asphalt mixes, which was validated with the Francken model. Similarly, the Huet-Sayegh model is capable of accurately characterising the resilient response over the tested range of frequencies and temperatures. The determined model parameters are hence adequate to establish a dynamic modulus predictive model for the glass-asphalt mix, which would, however, require validation with additional laboratory and field performance data.

■ It was found that an antistripping additive is required to meet moisture susceptibility criteria and alleviate stripping in medium dense-graded glass-asphalt mixes. In particular, it can be concluded that hydrated lime is more effective than the liquid antist-ripping additive in alleviating stripping. In this regard, the liquid antistripping additive, which is known to be commonly used in HMA production in South Africa, may not be as effective in these non-conventional asphalt mixes. Additionally, the microscopic image analysis conducted to evaluate mix moisture susceptibility is capable of providing an accurate representation of the degree of stripping and can be used as a tool to quantitatively rank moisture-sensitive mixes. Furthermore, visual judgement and biased interpretation associated with the current standard of visual inspection and reporting are eliminated.

ACKNOWLEDGEMENTS

The authors wish to acknowledge the Council for Scientific and Industrial Research (CSIR) through its R&D office for funding this research through Parliamentary Grant (PG) Funding. The authors also wish to acknowledge Consol Glass (Pty) Ltd. for providing the recycled crushed glass material. Dr Morris de Beer from the CSIR is also acknowledged for his valuable contribution to this paper.

REFERENCES

AASHTO (American Association of State Highway and Transportation Officials) 2013. Standard specification for Superpave volumetric mix. Report M323 2013. Washington, DC: ASSHTO. [ Links ]

AASHTO 2015a. Standard method for preparing and determining the density of hot-mix asphalt (HMA) specimens by means of the Superpave Gyratory Compactor. Report R312. Washington, DC: AASHTO. [ Links ]

AASHTO 2015b. Determining the dynamic modulus and flow number for asphalt mixtures using the Asphalt Mixture Performance Tester (AMPT). Report TP 79. Washington, DC: AASHTO. [ Links ]

Andela, C & Sorge, E V (n.d.) Handbook of Alternative Uses for Recycled Glass. Richfield Springs, NY: Andela Products Ltd & and Glass Brokers, Inc. [ Links ]

Anochie-Boateng, J K, Denneman, E, O'Connell, J J, Mturi, G & Ventura, D 2010. Hot-mix asphalt testing for the South African pavement design method. Proceedings, 29th Southern African Transportation Conference (SATC), Pretoria. [ Links ]

Anochie-Boateng, J K & George, T B 2018. Investigation of the use of waste crushed glass in the production of asphalt mixes. Proceedings of the Institution of Civil Engineers - Construction Materials, 171(5): 187-194. [ Links ]

Arabani, M 2010. Effect of glass cullet on the improvement of the dynamic behaviour of asphalt concrete. Construction and Building Materials, 25: 1181-85. [ Links ]

Arnold, G, Werkemeister, S & Alabaster, D 2008. The effect of adding recycled glass on the performance of basecourse aggregate. Research Report 351. Wellington, NZ: New Zealand Transport Agency. [ Links ]

ASTM (American Society for Testing and Materials) 2003. Standard Test Method for Uncompacted Void Content of Fine Aggregate. Report C1252. West Conshohocken, PA: ASTM International. [ Links ]

ASTM (American Society for Testing and Materials) 2009. Standard Test Method for Effect of Moisture on Asphalt Concrete Paving Mixtures. Report D4867M. West Conshohocken, PA: ASTM International. [ Links ]

Australian Government 2011. National Waste Policy Case Study. Canberra: Department of Sustainability, Environment, Water, Population and Communities. [ Links ]

Dane County Department of Public Works (Wisconsin) 2003. Reuse/Recycling of glass cullet for non-container uses. Madison, WI. [ Links ]

Department of Environmental Affairs (South Africa) 2017. South Africa State of Waste Report. First Draft Report. Pretoria: DEA. [ Links ]

Federal Highway Administration 1998. User guidelines for waste and by-product materials in pavement construction. FHWA-RD-97-148, Report No 480017. Washington, DC: FHA. [ Links ]

Hughes, C S 1990. Feasibility of using recycled glass in asphalt. Richmond, VA: Virginia Department of Transportation. [ Links ]

Iowa Department of Transportation 2012. Ranking of HMA moisture sensitivity tests in Iowa. Final Report. Ames, IA. [ Links ]

Lachance-Tremblay, E, Vaillancourt, M & Perraton, D 2014. Evaluation on the performance of an asphalt mix with crushed glass. Proceedings, 59th Annual Conference of the Canadian Technical Asphalt Association, Winnipeg, Canada. [ Links ]

National Research Council (US) 1994. Permanent deformation response of asphalt aggregate mixes. Report SHRP-A-415. Washington, DC: NRC. [ Links ]

Nilsson, R N, Hopman, C P & Isacsson, U 2002. Influence of different rheological models on predicted pavement responses in flexible pavements. Road Materials and Pavement Design, 3(2): 117-149. [ Links ]

Sabita (Southern African Bitumen Association) 2016. Design and use of asphalt in road pavements. Sabita Manual 35/TRH8. Cape Town: Sabita. [ Links ]

SANS (South African National Standard) 2011a. SANS 3001-AS10: Determination of Bulk Density and Void Content of Compacted Asphalt. Pretoria: SABS Standards Division. [ Links ]

SANS 2011b. SANS 3001-AS11: Determination of the Maximum Void-Less Density of Asphalt Mixes and the Quantity Of Binder Absorbed by the Aggregate. Pretoria: SABS Standards Division. [ Links ]

Su, N & Chen, JS 2002. Engineering properties of asphalt concrete made with recycled glass. Resources, Conservation and Recycling, 35: 259-274. [ Links ]

VTRC (Virginia Transportation Research Council) 1998. Effect of glass concentration on stripping of glasphalt. Final Report. Charlottesville, VA. [ Links ]

Wu, S, Yang, W & Xue, Y 2003. Preparation and properties of glass-asphalt concrete. Wuhan University, China. [ Links ]

Yamanaka, M, Gotoh, K, Saruwatari, M & Mochishita, T- 2001. Thermal and mechanical properties of glass cullet mixed with asphalt as low-exothermic pavement material. Nagasaki University, Japan. [ Links ]

Correspondence:

Correspondence:

Theresa George

Built Environment, Council for Scientific and Industrial Research (CSIR)

P O Box 395, Pretoria 0001 South Africa

T: +27 12 841 2924 E: tgeorge@csir.co.za

Joseph Anochie-boateng

Built Environment, Council for Scientific and Industrial Research (CSIR)

P O Box 395, Pretoria 0001, South Africa

T: +27 12 841 2947 E: ja nochieboateng@csir.co.za

Kim Jenkins

Department of Civil Engineering, Pavement Engineering, Stellenbosch University

Private Bag X1, Matieland 7602, South Africa

T: +27 21 808 4379 E: kjenkins@sun.ac.za

THERESA GEORGE is a researcher in the Transport Infrastructure Engineering Division at the Council for Scientific and Industrial Research (CSIR). She holds an MEng in Civil Engineering from the University of Stellenbosch. Her field of speciality is in pavement materials, focusing particularly on bituminous materials and pavement design.

DR JOSEPH ANOCHIE-BOATENG, who holds a PhD in Civil Engineering from the University of Illinois at Urbana-Champaign, USA, joined the Council for Scientific and Industrial Research (CSIR) in 2008. He pioneered and leads the investigation into the potential utilisation of crushed glass as a substitute for natural aggregate in asphalt mixes in South Africa. He also led the development of various manuals, guidelines and test protocols to support the pavement and asphalt industries in South Africa and Tanzania. Through his research work he developed research topics for postgraduate students from the University of Pretoria, Tshwane University of Technology and University of Stellenbosch. He works closely with the South African Road Federation (SARF) on an asphalt mix design course to develop the necessary skills for southern Africa.

PROF KIM JENKINS (PrEng, MSAICE, FSAAE) leads the SANRAL (South African National Roads Agency) Chair in Pavement Engineering within the Geotechnical and Transportation Division of the Department of Civil Engineering at Stellenbosch University. Under his lead the pavement research group also collaborates internationally, amongst others with the Technische Universiteit Delft (Netherlands) and Wuhan University (China). Prof Jenkins serves on several international scientific committees and participates in international conferences, having published widely in academic journals and industry-related publications. He also chairs an international committee on recycling of road building materials linked to sustainable practice.