Servicios Personalizados

Articulo

Indicadores

Links relacionados

-

Citado por Google

Citado por Google -

Similares en Google

Similares en Google

Compartir

Journal of the South African Institution of Civil Engineering

versión On-line ISSN 2309-8775

versión impresa ISSN 1021-2019

J. S. Afr. Inst. Civ. Eng. vol.62 no.1 Midrand mar. 2020

http://dx.doi.org/10.17159/2309-8775/2020/v62n1a1

TECHNICAL PAPER

Towards predicting the buckling and crushing strength of graded SA pine with high slenderness ratios

W M G Burdzik; S Skorpen

ABSTRACT

There is an apparent increase in failure of timber truss web members or compression chords. This paper seeks to reassess buckling of the compression chords with specific focus on web members. There are two possibilities for the seemingly lower buckling strength of web members, namely that the mean modulus of elasticity is a poor predictor of buckling strength where knots and other local changes in stiffness are concerned, and secondly that the actual crushing strength of the timber is lower than the design values. This paper will investigate both of these possibilities in order to achieve a safer approach to the design of timber compression members.

Keywords: buckling strength, crushing strength, SA pine, slenderness ratios, timber trussed roofs, web members, compression chords

INTRODUCTION

The authors have seen far too many timber trussed roofs where either web members or compression chords have buckled or even snapped. If one assumes pinned ends for the web member for buckling about the minor axis, the problem is fairly simple. The effective length is defined as the distance between the ends, or conservatively the distance between intersecting centre-lines in a truss. The torsional stiffness of the chords will have a small influence on the effective length of the web if the length is assumed to be between lines of intersection. Where compression chords have buckled the problem becomes a bit more complex, as the loading is not constant over the full length and the member must be treated as a beam-column. Furthermore, the bracing system will, to a large extent, determine the buckled shape and hence the effective length. It is recognised that the torsional and bending stiffness of the web members will play a role, albeit a minor one, in the buckling of the compression chords. The authors felt it prudent, at this stage, to restrict this paper to the buckling of web members.

Determining the theoretical buckling strength of compression members is not new. Gere and Timoshenko (1997), devote a full chapter to the buckling of columns for various end conditions, out of straightness, eccentric loads and many other theories that explain why actual columns deviate from the ideal Euler equation. All the theories are based around columns that are of constant prismatic cross-section and constant mechanical properties throughout their length. These theories, together with the work done by Yura (1996), can be used for compression members that are braced by means of discrete flexible point braces, such as web members that are braced in the middle by means of runners that end at a braced bay. Salmon and Johnson (1990) give a detailed explanation and show how the stiffness of the flexible brace determines the buckling mode and strength. All the methods have as a maximum value the crushing strength of the material and a buckling equation where the modulus of elasticity plays a prominent part.

It is postulated that there are two possibilities for the seemingly lower buckling strength of web members:

1. Mean modulus of elasticity is a poor predictor of buckling strength where knots and other local changes in stiffness are concerned.

2. The actual crushing strength of the timber is lower than the design values.

This paper will investigate both of these possibilities in order to achieve a safer approach to the design of timber compression members.

BUCKLING STRENGTH

SANS 0163 - Allowable stress design 1993

Originally, South African pine was Graded 4, 6 and 8, but Knuffel (1983), after in-mill testing to the National Standards Specifications SABS 563 (1978) and SABS 1245 (1978), found that Grades 4 and 6 were not adequately separated and that Grade 8 did not have enough strength in tension. Knuffel (1984) proposed the present grading system of Grades 5, 7 and 10, with allowable compression stresses for Grades 5, 7 and 10 timber of 7.6, 9.7 and 11.0 MPa respectively for members with a slenderness ratio of Le/b = 6. The 9.7 MPa compressive stress of Grade 7 would have been obtained by dividing the characteristic value of 21.5 MPa by 2.22. It would appear from the information provided that the specimens were cut from the board in the position that was identified by the TRU (Timber Research Unit) grader as being the weakest portion of the board.

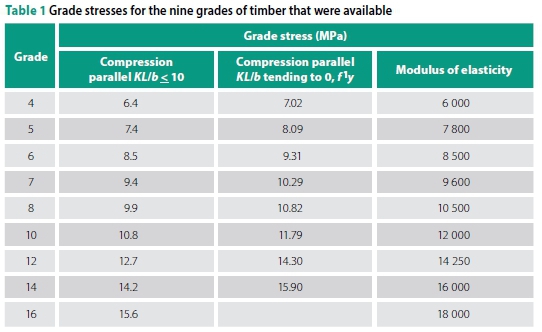

The next iteration of the permissible stress design code SABS 0163 (1993) contained a vast number of timber grades. The grade was based on the integer value of the permissible bending stress. This table was set up after numerous tests done by the National Timber Research Institute at the Council for Scientific and Industrial Research in Pretoria, South Africa. The values for the allowable compressive stress for the different slenderness ratios could be calculated, using the Perry-Robertson equation. Table 1 shows the new grading system with the allowable compression stress and the modulus of elasticity.

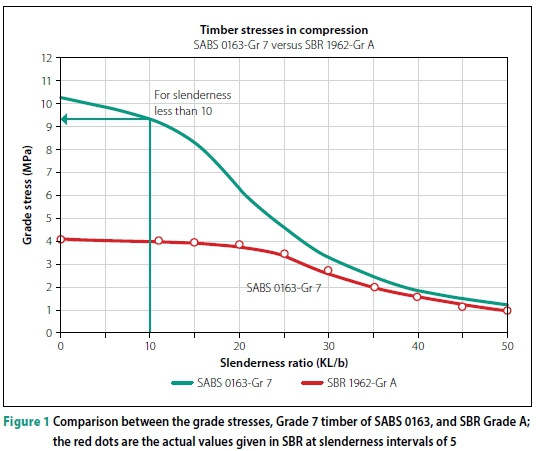

The Perry-Robertson equation that was used is in the form:

Where:

fc1 = grade compressive stress

fy1= grade compressive stress in short strut KL/b tending towards zero

fe=

E1= modulus of elasticity divided by 2.22

λ = slenderness ratio (KL/r)

n = eccentricity coefficient = 0.002 λ

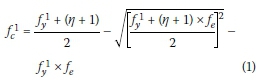

It may be of interest to compare the 1970 Standard Building Regulations (SBR) (SABS 1970) Grade A to that of the SABS 1993 Grade 7, as the MOEs are similar (see Figure 1). For higher slenderness the curve is governed by the Euler buckling stress and the authors thought it prudent to reduce the Grade 7 MOE to match that of the SBR Grade A. The graph for the SBR grade stress is a curve fit and the actual SBR values are shown as red dots. Figure 1 for SABS has been set up with the MOE for the Grade 7 reduced to 9 000 MPa, as the MOE becomes important with bigger slenderness.

The ratio of SABS 0163 (1993) values was obtained by dividing the characteristic value by the load duration factor as well as the safety factor, i.e. characteristic strength divided by 2.22. The SABS (1993) grade stresses, as well as the SBR (SABS 1970) stresses, were given for long duration loads. SBR had an increase of 25% for loads of short duration, thereby negating the factor for overloading, whereas SABS 0163 (1993) had a sliding scale that took the proportion of the imposed load into account, and for short-duration loading this would automatically be greater than one. It is possible that the way in which the compressive stress for slenderness tending towards zero was obtained or estimated in a very different way. No information could be found why the SBR Grade stress for compression members with slenderness tending to zero was so low. If one uses the short-clear specimen tests results by Otto and van Vuuren (1954) for 120 specimens of Pinus Patula, the following can be obtained for specimens with defects:

Number of specimens: 120

Mean crushing stress: 40.9 MPa

Standard error of the mean: 0.71

Standard deviation: 7.74

Basic Stress = (mean - (1.98 x Std Dev)) X long duration loss in strength. These values were based on the lower 2.5% exclusion limit. Duration of load effect = 0.56 or (9/16).

Basic Stress = (40.9 - 1.98 x 7.74) x 0.56 = 14.32 MPa.

The factor for defects is 0.5, therefore allowable stress = 14.32 x 0.5 = 7.16 MPa.

This must be adjusted for density. The mean density of the small clears was 498 kg/m3, with a lower 2.5% exclusion limit of 378 kg/m3. Assuming that this would be the lower limit on the timber density that was used, the allowable stress is reduced even further by the (378/498) = 0.76.

Allowable stress = 7.16 x 0.76 = 5.44 MPa.

Some of this may be speculation, as the source of the calculations could not be found, but it gives an indication of the reasoning that was used.

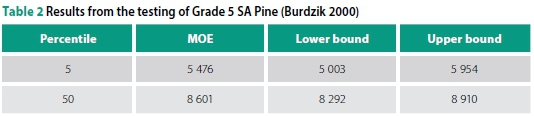

Testing of Grade 5 SA Pine 2000

The South African Lumber Miller's Association sponsored research into the compressive strength of Grade 5 SA pine, as it became evident that the actual density of the timber was lower than that of the timber on which the SABS 0163 (1993) code had been based. Burdzik (2000) tested 50 specimens of South African Grade 5, 36 mm x 111 mm with lengths of 1 902 mm (see Table 2). The documented SABS 0163 (1993) mean modulus of elasticity, MOE for the South African Grade 5 timber, was given as 7 800 MPa. No characteristic or fifth percentile value was given in SABS 0163 (1993). The mean flexural modulus of elasticity of the Burdzik test specimens was 8 601 MPa, with a characteristic or fifth percentile MOE of 5 003 MPa (lower bound at 75°% confidence index).

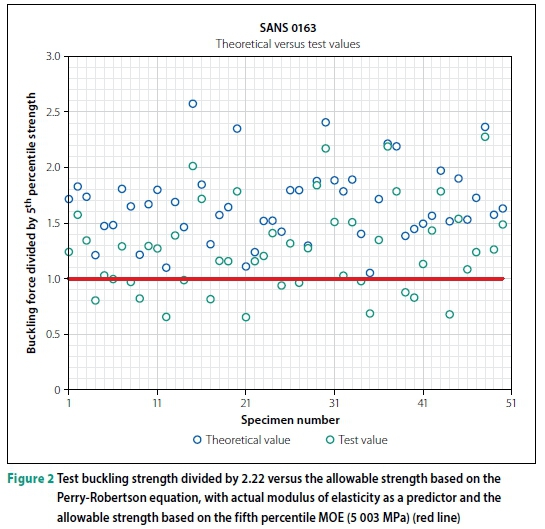

In Figure 2 the predicted allowable buckling strength based on actual MOE (blue dots) using the Perry-Robertson equation, and test values divided by 2.22 (green dots), are compared with the SABS 0163 (1993) equation, based on the sample fifth percentile MOE (red line). The red line is the unit strength line. All the tests for lengths longer than 750 mm were stopped before actual failure so that the specimens could be shortened and reused. The load that was applied was 90% of the Euler buckling strength, and an estimate of the buckling strength was made from the graphs that were obtained.

It is clear that the modulus of elasticity is an inadequate predictor of the buckling strength of the timber struts, as the difference between the predicted buckling strength (blue dots), based on the MOE, and the test value (green dots) is substantial. In his conclusion Burdzik (2000) advised that the compression strength should be based on the fifth per-centile MOE and not on the mean MOE. This amendment was included in the original draft document of SANS 10163 (2003).

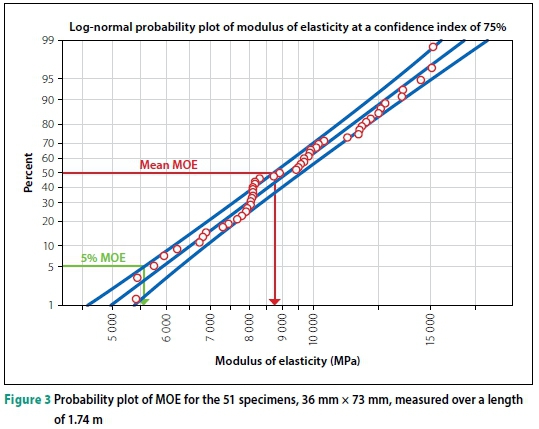

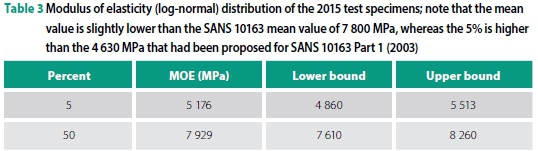

Testing of Grade 5 Struts 2015

In 2015, T-braced struts were tested in the timber laboratory at the University of Pretoria. The test results, when compared to SANS 10163 (2003) predicted values, clearly indicated that the current design equation for determining the buckling strength of Grade 5 SA pine was inadequate if the mean modulus of elasticity was used. Fifty-one specimens, 36 mm x 73 mm x 1 810 mm long, were chosen as representative of current Grade 5 web material. Some of the specimens had knots, and in some cases finger joints as well. All were tested for bending stiffness, MOE, using static third-of-span loading over a span of 1 740 m. The graph of the distribution of the modulus of elasticity is given in Figure 3 and the important values in Table 3.

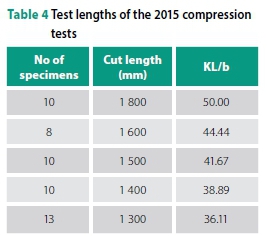

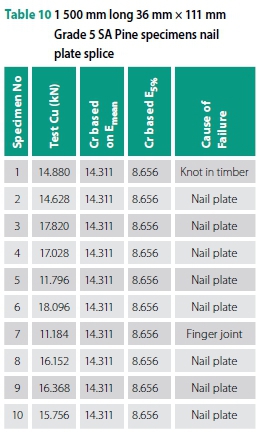

In order to cover a wider spectrum of slenderness values, the 1.82 m long specimens were then cut to lengths as given in Table 4. In addition to this, twenty, 750 mm long x 36 mm x 111 mm specimens were spliced by means of nail plates to ascertain whether failure would occur at the nail plate (see Table 10). The localised stiffness at the nail plate is less than the stiffness of the timber. The timber was butted tightly before splicing to forestall local buckling of the plates.

The SANS 10163 (2003) equation was used to predict the buckling strength of each individual strut. The strength for members with slenderness tending towards zero, is fc= 18 MPa:

Where:

ßbis the buckling factor

ßb= (1 + λ2n)-1/nwith n = 1.8 and lambda

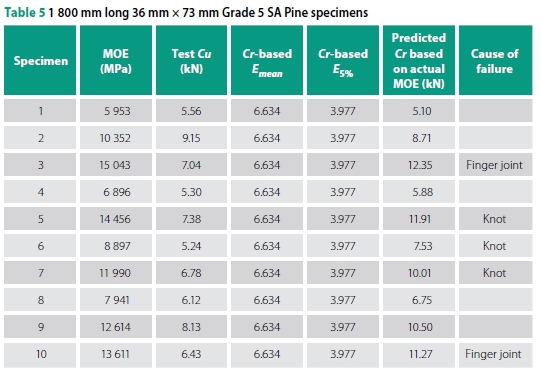

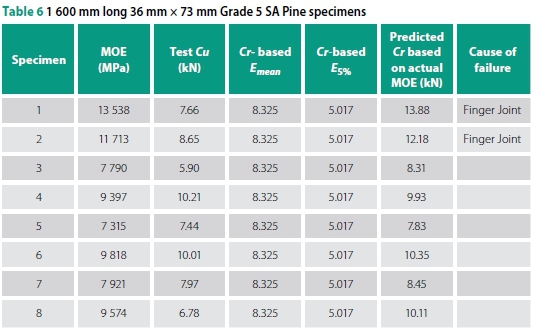

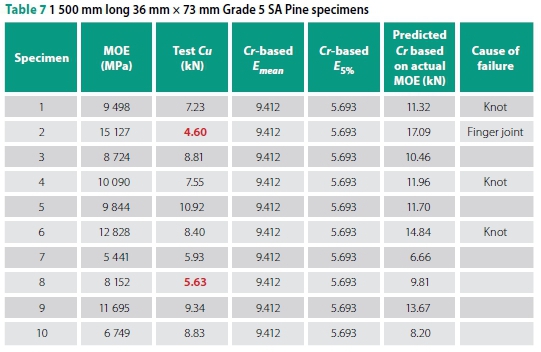

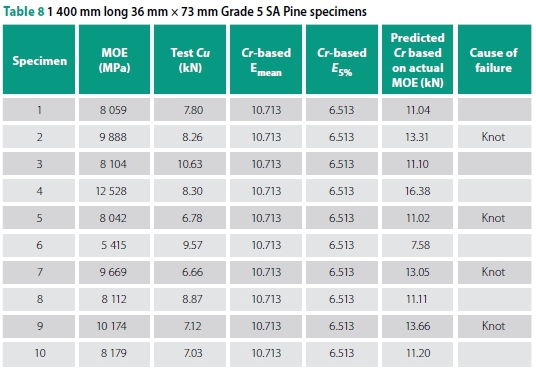

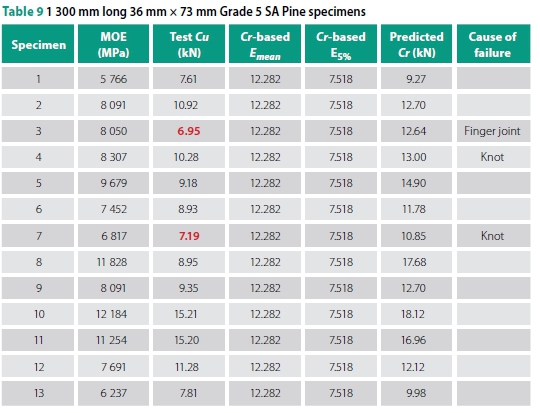

Note that provision was made for a fifth percentile modulus of elasticity in the original draft document of SANS 10163 (2003). The individual test results are given in Tables 5 to 10:

The values marked in red are stresses that do not make the strength based on 5% modulus of elasticity, MOE = 4 630 MPa.

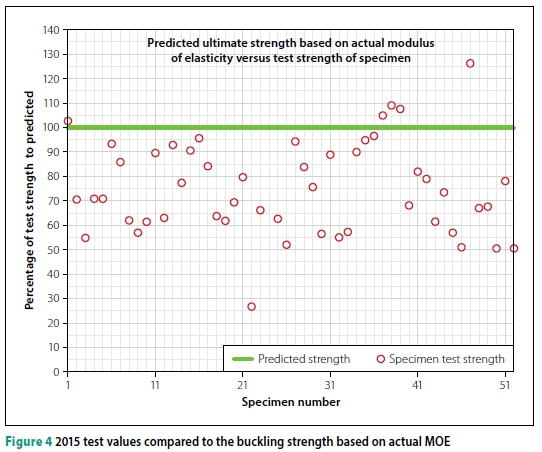

Figure 4 compares the test values (red dots) divided by the predicted values, based on the actual lateral MOE (green line) of the compression members. The numbering should not be compared with the numbering in Tables 5-10.

From Figure 4 it is clear that the vast majority of the test specimens failed at a much lower strength than the strength predicted by the actual MOE.

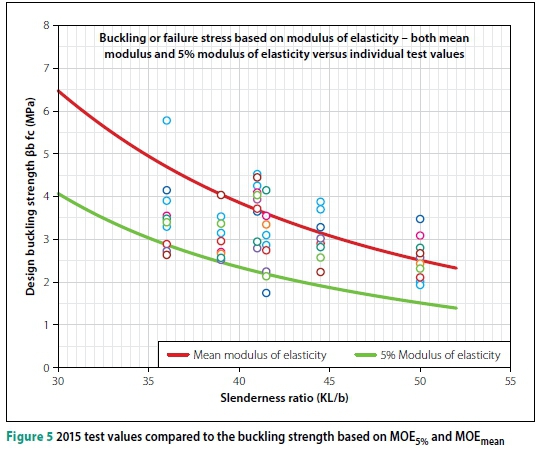

A more interesting figure can be obtained if all the test values are placed on a graph where the curves for the design stresses are based on the mean and the fifth percentile value for a Grade 5 timber, namely, Emean= 7 800 MPa and proposed 5% = 4 630 MPa. The comparison is shown in Figure 5. Not one of the test specimens had an MOE less than the proposed MOE5%. However 39 out of 51 of the test specimens had an MOE in excess of the MOEmean of SANS 10163 (2003).

Figure 5 shows that 4 out of 51 specimens have a strength less than the strength based on a 5% modulus of elasticity, even though not a single strut had a lateral MOE less than the fifth percentile MOE. The 52 specimens exclude the nail-plated specimens. There are only 17 test specimens out of 61 (including the nail plate spliced tests) that had a strength greater than the strength based on the mean MOE, even though more than 75% of the specimens had an MOE greater than the mean MOE.

CRUSHING STRENGTH

New SANS 6122 (2017)

Test Method for Compression

SANS 6122 (2017) contains the new proposed test methods for the testing of structural timber elements and is the revised document SABS STM 1122 (1993). One of the major revisions is for obtaining the compressive stress of struts that are laterally restrained at distances less or equal to ten times the thickness or depth. This value is then used to calculate the yield or crushing strength at a slenderness tending to zero. A tiled roof, with battens spaced at 320 mm and a bracing frame, would be expected to almost satisfy that condition. SABS STM 1122 (1993) specified that the weakest position in a board be identified and the test specimen cut at that position to a length of ten times the smaller dimension. The weakest position in a compression member would be identified either by using a Timber Research Unit grader or by visual grading. This was then tested in compression between two fixed steel plates. The new SANS 6122 (2017) test method (see Figure 6) has a much longer length over which it is tested, but lateral supports are still supplied at a distance of ten times either dimension.

Modified sabs 1122 test Method

Identifying the weakest portion of a compression member has proved to be problematic in many cases. Trial tests were done on a limited number of specimens to determine whether it was still feasible to use the old method, albeit modified to eliminate estimating where the weakest point in the board was to be found. The idea was to cut the long test specimens into short lengths of ten times the smaller dimension and to test each and every short piece. The weakest specimen from each long piece then defined the strength of the long piece. The idea was to compare the results to the results obtained from the SANS 6122 (2017) method with the modified SABS STM 1122 (1993) method.

Thirty specimens of 36 mm x 73 mm x 2 200 mm long, Grade 5 SA Pine were obtained. These were then divided into two samples of 15, each with a similar density profile. The similar density profiles were used, as density should be a fairly good predictor of compressive yield stress.

New Method of Testing According to SANS 6122

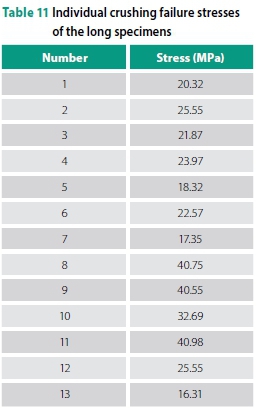

Thirteen of the fifteen specimens were tested successfully in the long length, and the values shown in Table 11 were obtained.

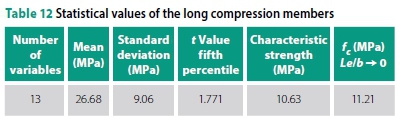

The number of test specimens are limited and any statistical interpretation would not be significant. However, a rough approximation of the statistical results could be used to ascertain whether the new SANS 6122 (2017) test method is significantly better than the modified SABS STM method. The percentage points of the t distribution were obtained from Bowker and Lieberman (1959). Table 12 refers.

Modified SABS SBR 1122

Method of Testing

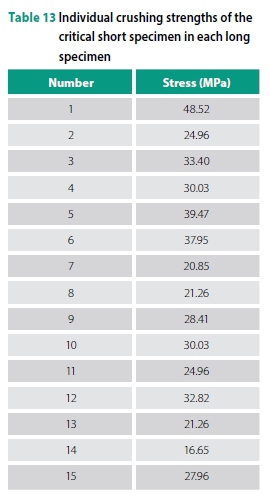

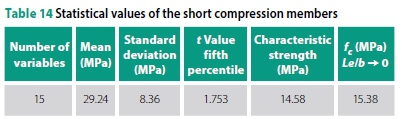

Each one of the specimens was cut into 360 mm long lengths, leading to six specimens per original specimen. Each and every short specimen was tested in compression, between two steel plates, and the lowest strength of the six was recorded as representing the original specimen's crushing strength. Tables 13 and 14 refer.

It would appear, at first glance, that the new method, Table 13, may lead to lower crushing strength values, but the limited number of tests may lead one to believe that which is not necessarily valid.

CONCLUSIONS

Buckling Strength

It is evident that the mean modulus of elasticity is a poor predictor of the failure strength of slender compression members, as shown in Figure 4, where the vast majority of the test values fall below the predicted value. In many cases, because of defects, members snapped before reaching anything close to a buckled strength. The idea of using a fifth percentile modulus of elasticity has been propagated by Burdzik since 2000 (Burdzik 2000). It is vital that the timber industry adopts a characteristic modulus of elasticity, i.e. a fifth percentile value, to ensure safe timber structures.

Crushing Strength

There may also be good reason to revisit the crushing strength of timber compression members. Based on limited tests of long specimens tested using the SANS 6122 (2017) method, two out of 13 crushing strengths fell below the accepted yield stress. The yield value of 18 MPa for a Grade 5 SA pine compression member, where the slenderness tends towards zero, may not seem to be too far off the mark; however, a bigger sample may indicate that a larger test programme needs to be undertaken. In our opinion, the bigger problem lies with defects having a large influence on the strength of members where the buckling length is greater than ten times the smaller dimension. It may be necessary to adjust the yield strength to take cognisance of the damaging effect of knots and finger joints in the transitional zone between crushing and buckling.

There is a substantial part of the strength curve for compression members that has not recently been tested, especially for slender-ness ratios between 15 and 30. It might be time to re-evaluate this portion of the graph, once testing has been done and/or the new SANS 6122 (2017) test method for determining the yield stress has been adopted and member strength tested in accordance with the SANS 6122 (2017) method.

REFERENCES

Bowker, A H & Lieberman, G J 1959. Engineering Statistics. Englewood Cliffs, NJ: Prentice-Hall. [ Links ]

Burdzik, W M G 2000. Stiffness and buckling strength of SA pine compression members. South African Forestry Journal, 189(1): 63-70. [ Links ]

Gere, J M & Timoshenko, S P 1997. Mechanics of Materials, 4th ed. Boston, MA: PWS Publishing. [ Links ]

Knuffel, W E 1983. The determination of design stresses for various grades of South African timber. Part II: In-grade testing of SA pine, Visual Grade. CSIR Special report Hout 240. Pretoria: National Timber Research Institute, CSIR. [ Links ]

Knuffel, W E 1984. An improved visual and mechanical stress grading system for SA pine timber. CSIR Report Hout 318. Pretoria: National Timber Research Institute, CSIR. [ Links ]

Otto, K P & Van Vuuren, W F J 1954. The mechanical properties of timbers with particular reference to those grown in the Republic of South Africa. Bulletin 48. Pretoria: South African Forestry Research Institute. (Banks C H 1954. Fully revised edition. [ Links ]

Schoeman J P, Marwick, P C & Van Lill 1973. Revised and metricated edition. Otto K P & Van Vuuren W F J 1976. Revised edition). [ Links ]

SABS-SBR 1970. Standard Building Regulations. Structural Timber, Chapter 7. Pretoria: South African Bureau of Standards. [ Links ]

SABS-563 1978. Standard Specification for Stress Graded Softwood General Structural Timber. Pretoria: South African Bureau of Standards. [ Links ]

SABS-0163 1993. Code of Practice for the Design of Timber Structures, Part 2: Permissible Stress Design. Pretoria: South African Bureau of Standards. [ Links ]

SABS-1122 1993. Qualification Testing of Timber Grading System for Solid Structural Timber and Laminated Structural Timber (Glulam). Pretoria: South African Bureau of Standards. [ Links ]

SABS-1245 1978. Adhesives for Wood. Parts 4-6: Test methods - Determination of pH. Pretoria: South African Bureau of Standards. [ Links ]

Salmon, C G & Johnson, J E 1990. Steel Structures, Design and Behavior, Emphasizing Load and Resistance Factor Design, 3rd ed. New York: Harper Collins. [ Links ]

SANS-10163 2003. The Structural Use of Timber. Part 1: Limit-states Design. Pretoria: SABS National Standards Division. [ Links ]

SANS-6122 2017. Structural Timber - Characteristic Values of Strength-graded Timber. Sampling, Full-size Testing and Evaluation, Draft 3rd ed. Pretoria: SABS National Standards Division. [ Links ]

Yura, J A 1996. Winter's bracing approach revisited. Engineering Structures, 18(10): 821-825. [ Links ]

Correspondence:

Correspondence:

WALTER BURDZIK

Department of Civil Engineering

University of Pretoria

Private Bag X20,Hatfield 0028, Pretoria. South Africa

T: +27 83 928 7138

E: walter.burdzik@outlook.com

SARAH SKORPEN

Department of Civil Engineering

University of Pretoria

Private Bag X20

Hatfield 0028

Pretoria

South Africa

T: +27 12 420 2196

E: sarah.skorpen@up.ac.za

PROF WALTER BURDZIK (Pr Eng) was Professor in the Department of Civil Engineering at the University of Pretoria at the time of preparing this paper (he has since retired from the university). He received his degrees from the University of Pretoria, and has been involved in timber research and structural timber design for the past 40 years. He runs one of the few recognised timber-testing facilities in South Africa, and is often involved in queries surrounding the importing of structural timber and wood-based products. He has also been involved in all the SANS (South African National Standards) committees charged with writing the South African timber design codes and specifications that have to do with wood-based structural products. His other fields of interest include analysis of structural systems, as well as steel, concrete and masonry design.

SARAH SKORPEN (Pr Eng, MIStructE) spent nine years working for the Buildings and Structures Division of SSI before joining the Structures Division of the Department of Civil Engineering at the University of Pretoria in 2011. She has obtained an MEng (Structural Eng) and recently completed her doctoral studies on integral bridges.