Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

Journal of the South African Institution of Civil Engineering

On-line version ISSN 2309-8775

Print version ISSN 1021-2019

J. S. Afr. Inst. Civ. Eng. vol.61 n.3 Midrand Sep. 2019

http://dx.doi.org/10.17159/2309-8775/2019/v61n3a3

TECHNICAL PAPER

Implementation of a performance-grade bitumen specification in South Africa

S J Bredenhann; P A Myburgh; K J Jenkins; J S O'Connell; G M Rowe; J D'Angelo

ABSTRACT

South Africa has been experiencing higher traffic volumes and heavier loads over the past several years. This has been accompanied by an increase in premature asphalt failures. Selection of the appropriate asphalt binder is critical for improving performance. Empirical bitumen testing has increasingly failed to relate test results to pavement performance, as the traffic volume and loading have changed. Moreover, empirical tests cannot effectively characterise polymer-modified bitumens that are increasingly being used in South Africa. This changing environment calls for the establishment of specifications based on fundamental engineering properties which relate to actual pavement performance. This paper discusses the fundamental principles of the performance grade (PG) specification being introduced in South Africa. It explains how these fundamental principles create a rational framework for the specification, and present a clear set of compliance criteria to ensure the optimal selection of bituminous binders. The reasons for transitioning to a PG specification are discussed, along with the basis of the specification, rheological concepts, measurements required to characterise bituminous binders, and the simulation of ageing in relation to durability. The framework of the specification, including test procedures, provisional compliance limits and mandatory reporting of test results as an interim measure, are discussed in this paper. Finally, some test results received to date for selected typical South African binders are reported and evaluated. These results indicate that current binders being used in South Africa can easily conform to the proposed PG specification in terms of deformation requirements without any disruption to the processes of the refineries or secondary manufacturers. The fatigue properties of binders are still under evaluation and thus not included in the specification framework. Only information gathered will inform the final decision.

Keywords: PG grade, bitumen performance, asphalt performance, fatigue, rutting, bitumen ageing, vlscoelastic

INTRODUCTION

The bituminous product industry endeavours to ensure quality and durability in pavement construction by pursuing mixture tests to characterise bituminous materials in pavements. Tests on bituminous layers (e.g. asphalt) are, however, not feasible for defining the binder requirements. The bituminous binder is a key component in a bituminous layer, and performance-related test methods must be developed to simulate and consider environmental factors to which the binder will be subjected over its lifetime.

Performance-related binder specifications should therefore provide a means to select an appropriate binder in an economic, unbiased and competitive way, and should classify bituminous binders on unbiased grounds, while considering possible changes in the binder rheology experienced during the production and the service life of the asphalt layer (Smith et al 2018).

The performance grade specification for South Africa was initiated at the CAPSA Conference in 2004 (Van de Ven et al 2004).

BACKGROUND

Recent developments in South Africa, such as the proposed implementation of the SANRAL-sponsored SA Road

Design System (SARDS) and the SABITA-sponsored revision of a national asphalt mix design method - introduced to practice during 2016 as SABITA Manual 35/TRH 8 - necessitated the adoption of a specification framework for bituminous binders based on engineering properties to ensure the optimal performance of flexible pavements, especially in the higher traffic categories.

In the USA the implementation of such a specification type in 1995, termed a performance grade (PG) system, was deemed to have yielded notable benefits such as:

■ Test conditions suited to specific environmental conditions of climate and traffic

■ The introduction of the measurement of the rheological properties of bituminous binder, which gave a better understanding of their behaviour in a range of operating conditions

■ The importance of assessing long-term ageing characteristics

■ Market shifts to accommodate regional requirements in terms of binder grades

■ A rational understanding of when to modify straight-run bitumen.

In developing a PG specification for bituminous binders in South Africa, it is recognised by the Road Pavement Forum (RPF) Task Group on PG specifications, that the performance parameters and compliance limits developed in the USA are based on the requirements of binder performance in asphalt layers, while a significant proportion of binders used in South Africa are applied in chip seals. As it is not feasible, given the market size, to develop distinct specifications for asphalt and seals, the decision was taken to focus on the requirements for asphalt, given the extensive progress in developing such a specification. However, the task group is mindful that, with time, some adjustments or amendments may have to be effected to the proposed specification to cater specifically for the performance requirements of binders used in chip seals. Having said that, it should be noted that there should be compelling reasons for doing so, in order not to render the specification unnecessarily complex, given the size of the bituminous product market in South Africa.

CURRENT SPECIFICATION

The current South African national standard specification (SANS 4001-BT1), which can best be described as a nominal grading system, has distinct limitations in meeting the challenges associated with the technological developments mentioned above, such as:

■ It merely defines the "consistency" (or viscosity) of the binder over a range of temperatures (from 25°C to 135°C) in terms of surrogate properties such as penetration, softening point and dynamic viscosity.

■ Compliance limits refer to neat and short-term aged binder which emulates ageing of the binder, e.g. during mixing and paving of asphalt; there is no assessment of the in-service longer-term ageing characteristics to assess the durability of the binder.

■ The specification framework does not cover critical factors related to:

■ Traffic levels and speeds

■ Climate (especially temperature ranges)

■ Critical performance characteristics such as excess viscous flow during periods of elevated temperature or crawling traffic or cracking of the binder due to traffic loading and stresses and strains originating from daily pavement temperature fluctuations, especially as the binder stiffness increases with ageing.

As a direct result of these limitations, the basis of selection of binder grades or types for specific applications is often arbitrary or conventional.

EVOLUTION OF RHEOLOGICAL TEST METHODS

The evolution of rheological test methods is summarised in Figure 1. Penetration and softening point tests allow for evaluation of binders in terms of "hardness" or "softness". The viscosity measurements that followed used kinematic and dynamic methods to evaluate the viscosity of the binder.

The following era brought the advent of advanced dynamic shear rheometry and bending beam rheometry that provided for control over shear strain levels and rates, temperature controls and a variety of loading configurations, as well as the proportions of the elastic and viscous components. Subsequently, testing has expanded into damage beyond the linear-visco-elasti (LVE) range, opening new avenues of defor mation and fracture evaluation, primarily at a research level.

DEFINITIONS, CONCEPTS AND TESTING IN PROPOSED SPECIFICATION

Bituminous layers in service are required t resist the following forms of distress:

■ Excessive visco-plasticity which may result in permanent deformation and/ or bleeding

■ Fracture due to the following factors, singly or in conjunction with each other:

■ Fatigue from repeated traffic loading

■ Fatigue induced by daily pavement temperature fluctuations

■ Low temperature cracking

■ Loss of pliability due to ageing. Asphalt layers should also be durable, i.e. maintain their properties to counter distress over a long period.

As a result, the concept of damage resistance characteristics (DRC), developed in 2010 in the USA, was introduced to provide a specification framework to gauge the binder's resistance to damage resulting from:

■ Permanent deformation (viscous flow) -at elevated temperatures and slow rates of loading

■ Cracking - at intermediate temperatures

■ Temperature fracture - at low temperatures, that would also address fatigue.

The specification framework should facilitate rational selection of binders based on:

■ Traffic volumes and speed

■ Climate (maximum and minimum temperatures)

■ Binder durability.

Further to the above performance-related properties, additional requirements need to be set in the interests of safety, storage stability and viscosity limits to facilitate handling and application at elevated temperature.

Behaviour of bituminous binders

Bituminous binders display both elastic and viscous behaviour, depending largely on temperature and loading duration or frequency. This visco-elastic character results in a variable response behaviour under varied loading times and temperatures changes.

Elastic behaviour

This behavioural characteristic can be divided into three categories:

■ At low temperature and short duration loads bitumen tends to act as an elastic solid, returning to its original position after removal of the load.

■ Excessively low temperature in conjunction with rapid loading may cause brittle failure and cracking.

■ Low temperature can cause a build-up of internal stress resulting in thermal fracture.

Viscous behaviour

At elevated temperatures and/or low frequency loads associated with slow-moving traffic, bitumen acts as a viscous fluid. It will undergo plastic deformation, i.e. the deformation is not fully recovered. Pavement layers bound with bituminous materials will tend to deform (i.e. rut or flow) under repeated applications of wheel loads, depending on the temperature and rate of loading. It is important to note, though, that this viscous behaviour of the bitumen at high temperatures can be offset by the interlocking action of the aggregate in asphalt mixtures, which serves to resist permanent deformation.

Flow in the binder takes place as adjacent bitumen molecules slide past each other, the resulting friction or resistive force being related to the relative velocity of sliding. The relationship of this resistive force and the relative velocity (of sliding) is termed "viscosity"

Dynamic viscosity, η, is thus a measure of the resistance to flow of a fluid and is expressed as:

The SI unit of dynamic viscosity is Pascal second (Pa.s)

Visco-elastic behaviour

When a bituminous binder is subjected to constant stress, an instantaneous strain and elastic response to the applied stress takes place, followed by a gradual increase in deformation (or strain) until the load is removed. This ongoing deformation is caused by the viscous behaviour of the material. Upon removal of the stress, the elastic strain is recovered instantaneously and some additional recovery occurs with time - known as delayed elasticity. Ultimately a permanent residual deformation remains, which is non-recoverable and is directly associated with the viscous behaviour of the binder.

Laboratory requirements

In the interests of resource economy, the aim was to limit specialist laboratory equipment to:

■ Dynamic Shear Rheometer (DSR)

■ Bending Beam Rheometer (BBR)

■ Rolling Thin Film Oven (RTFO)

■ Pressure Ageing Vessel (PAV).

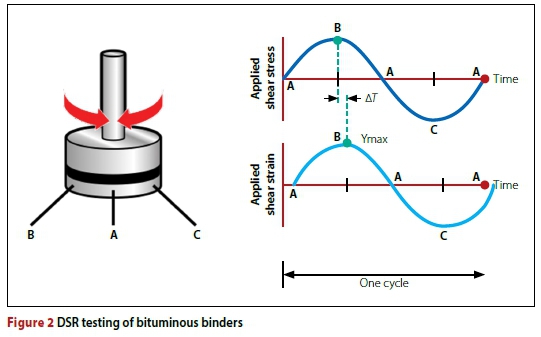

Dynamic shear rheometer

Measurements using the DSR are the cornerstone of performance grade specifications. It illustrates important components of viscoelastic behaviour and is currently being introduced in South Africa for specification purposes.

Two categories of measurement are afforded by the DSR:

■ Fundamental rheological properties

■ Creep behaviour of a bituminous binder.

Fundamental rheological properties

Both viscous and elastic behaviour is assessed by measuring the complex shearing modulus, G* (G-star) and the phase angle, δ (delta). G* is a measure of the total resistance of a material to deformation when exposed to shear load pulses. The phase angle, δ, indicates the relative proportions of recoverable and non-recoverable deformation.

When testing within the linear visco-elastic range of the bituminous binder:

The phase angle, δ, represents the time lag between the maximum applied shear stress and the maximum resulting shear strain as seen in Figure 2.

Creep behaviour

Creep behaviour of bitumen (in asphalt mixes especially) is very important. If an asphalt layer is loaded there will be an immediate elastic response followed by a delayed elastic / viscous response as long as the load is applied. As the load is removed, part of the elastic deformation will recover immediately, followed by a delayed elastic recovery with a permanent deformation due to the unrecovered deformation resulting from the viscous response under load.

Definition of minimum, maximum and intermediate temperatures

Three categories of temperature are adopted to take account of climate and operating conditions in developing a compliance framework. These are:

■ Maximum pavement temperature

■ Minimum pavement temperature

■ Intermediate pavement temperature.

Maximum pavement temperature (Tmax)

The maximum pavement temperature is the average annual seven-day maximum at 20 mm depth in the asphalt layer. The maximum pavement temperatures are adjusted to reflect a 98% statistical reliability using climatic data from a minimum of 20 years. The climatic data was converted to pavement temperatures using ThermalPads software developed by the CSIR. The ThermalPads software uses temperature prediction algorithms developed by Viljoen (2001), which are considered more accurate and consistent than the original SUPERPAVE® algorithms (Denneman 2007). The high pavement temperatures were used by the Kriging interpolation method to create a high pavement temperature map for South Africa (O'Connell et al 2015). Figure 3 illustrates the resultant isotherms, with the main isotherm bands being based on the SUPERPAVE® grading classification. Figure 3 shows that South Africa can be divided into two seven-day mean maximum temperature zones (separated by thick red line), the north-western half being 64°C max and the south-eastern half being 58°C max.

Minimum pavement temperature (Tmin)

A similar process to that described above was adopted to determine the minimum pavement temperatures in South Africa. Figure 4 indicates that the minimum temperature in South Africa rarely falls below -10°C. However, for grading purposes, considerably lower minimum temperatures were adopted for South Africa, in order to take the following into consideration:

Should actual minimum pavement temperatures be adopted in South Africa, testing associated with the minimum temperatures would not be possible, as sample temperatures would deform at such high minimum temperatures.

It was decided to maintain a temperature difference of 80°C between the maximum and minimum temperature grades in order to have good durability for South African binders.

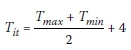

Intermediate pavement temperature (Tit)

The intermediate pavement temperature is defined as the mid-temperature between the maximum and minimum temperatures plus 4°C, thus:

Traffic classification

Traffic in the PG specification is classified both in terms of volume (or severity) and speed. This is done to take account of the fact that, for a given loading intensity, slow-moving traffic would exert more severe loading conditions. It is proposed that four levels of traffic loading be adopted, in terms of E80s and ruling speed to provide a basis for bitumen selection. Speed categories are chosen to reflect South African conditions and may differ slightly from USA definitions.

Currently it is proposed that the combined effect of traffic loading and speed will be categorised in accordance with Table 1. In this table the following nomenclature is used to describe the severity of the traffic loading:

■ S refers to Standard conditions

■ H refers to Heavy conditions

■ V refers to Very heavy conditions

■ E refers to Extreme conditions.

Bitumen ageing

Bitumen in a pavement is subjected to short-term ageing (STA) and long-term ageing (LTA). STA represents the ageing that the binder in an asphalt mix undergoes during the manufacture, storage, transport and placement of the asphalt mix. STA is a high-temperature process which would favour high-energy oxidation mechanisms.

LTA represents the ageing that the binder undergoes after placement, and over the lifetime of the pavement. However, for the purposes of defining LTA with regard to correlation with laboratory ageing, and especially with specification purposes in mind, LTA can be defined as the ageing a pavement layer undergoes during a period of five to ten years after placement. LTA is a medium-temperature process ranging between -5°C and 70°C in South Africa. It would favour lower energy oxidation mechanisms, and volatilisation would not be a major factor, unless the bituminous binder has been cut back with solvents or oils (O'Connell & Steyn 2017).

Ageing impacts pavement performance significantly. Ageing of bituminous binders manifests as an increase in bitumen stiffness, thus impacting on the fatigue life of asphalt mixes and surfacing seals. However, ageing can also have a positive effect by increasing the pavement bearing capacity due to the stiffer material. Various ageing methods are available and have been evaluated by researchers (Erkens et al 2016; Glover et al 2009; Glover et al 2005; Airey 2003).

No ageing test can simulate the actual in-field performance accurately. In the proposed South African specification, the Rolling Thin-Film Oven (RTFO) test was selected to simulate STA and the Pressure Ageing Vessel (PAV) test was selected to simulate LTA for implementation in the new South African PG Binder Specification. These two tests are considered practical to implement. In a recent study Smith et al (2018) concluded on PAV: "Based on the PAV rate at depth, the current R28 protocol of 20 hours seems on track to simulate 5 to 10 years of aging for the binder that was placed at depth."

Stiffness and relaxation parameters

In the decades preceding the SHRP research programme considerable attention was given to the relationship between ductility and pavement performance. An excellent insight into the summary of the pre-SHRP state-of-the art is described in the papers that are part of an ASTM Symposium on the Low-Temperature Properties of Bituminous Materials and Compacted Bituminous Mixtures. It was generally acknowledged that ductility is an empirical property, but it was also associated by early researchers with temperature dependency and shear rate dependency (Vallerga & Halstead 1971). Kandhal (1977) reported on ductility measurements performed at 4°C and 15.6°C and showed a strong relationship between the ductility at 15.6°C (5 cm/min) and progressive pavement deterioration, as reflected in the loss of fines, ravelling and cracking. Poor pavement performance was reported when the 15.6°C ductility for asphalt binders recovered from test sections was low, typically less than 5 cm, and the penetration was less than 30 dmm, thus higher stiffness. Poor performance was therefore related to a limiting stiffness (penetration at 25°C) and a limiting ability to relax stresses (ductility at 15.6°C). Glover et al (2005) performed an extensive study on the ageing of asphalt binders directed at "developing an improved method of screening asphalt binders for long-term pavement performance". Building upon Kandhal's (Kandhal 1977) success with 15°C ductility, Glover developed a DSR function, G'/(f{/G') as a surrogate for 15°C ductility, by consideration of a mechanical model that would best describe the ductility test, and then assessing what parameters would best describe the mechanical model with rheological tests. The function, suitable for measurements with the DSR, requires less material than the ductility test and was further verified by performing tests to establish a correlation between the function G'(η'/G') measured at 15°C and 0.005 rad/s and ductility at 15°C. Glover et al also suggested that, using time-temperature superposition, the test could be performed at the more user-friendly conditions of 44.7°C and 10 rad/s (Glover et al 2005). The DSR properties were measured on residue from a modified PAV procedure that included thinner films and a longer ageing time. Excellent correlations were found between pavement performance and the DSR function for conventional binders. The use of the viscosity function was complex for modified binders, and no general correlation could be found. Some key aspects noted in the Glover report (Glover et al 2005) included:

■ Literature reports indicate that the ductility of binders recovered from asphalt pavements correlate with cracking failure. However, ductility measurement is a time- and material-consuming process, and is subject to reproducibility difficulties, as are all failure tests.

■ From an elongation model using a Maxwell element, it was seen by Glover et al (2005) that two rheological parameters are suggested to represent the extensional behaviour of asphalt binders in a ductility test - the ratio of the dynamic viscosity to the storage modulus (η'/G') and the value of the storage modulus G'.

■ For conventional asphalts the function G'(η/G') can serve as a surrogate for ductility at 15°C, is easier to measure, and requires less material.

The Superpave PG Grading specification, AASHTO M 320, specifies a minimum stiffness and minimum m-value at the grading temperature. The Strategic Highway Research Program validation report (Leahy et al 1994) contains a plot of the BBR stiffness versus the m-value with four quadrants indicating relative pavement performance. Leahy et al (1994) concluded that "neither parameter is solely responsible for rejection of these binders", verifying the inclusion of both the stiffness and the m-value in the PG grading specification. Their conclusion is consistent with the need to include both stiffness and the relaxation characteristics (m-value) when relating binder properties to pavement performance. However, researchers have noticed that the difference between the temperatures at which the threshold stiffness and m-value requirements are met is related to pavement performance. The paper developed by Anderson et al (2011) demonstrated the linkage that exists between Glover's parameter and the parameter ATc. The ATc parameter is defined as the difference between the temperatures at which the two specification requirements are met. A method of practice for determining ATc is now standardised in ASTM D7643 (Determining the Continuous Grading Temperature and Continuous Grades for PG Graded Asphalt Binders) and AASHTO PP78-16 (Design Considerations When Using Reclaimed Asphalt Shingles (RAS) in Asphalt Mixtures) and is calculated as follows:

Where:

Ts= temperature at which the stiffness is 300 MPa

Tm= temperature where the m-value is 0.300

T1, T2= two adjacent specification grading temperatures

S1, S2 = stiffness measurements at T1, T2such that one value passes the specification requirement and one fails the requirement

m1, m2= m-values at T1, T2such that one value passes the specification requirement and one fails the requirement.

The ΔTcis now being proposed in several specifications due to the ease of its measurement. However, the information collected with this parameter does not show a universal correlation with performance. This may be due in part to it effectively defining the shape of the master curve in a similar manner to the rheological index (R-value). The ATcdefines the curvature of the S(t) master curve in the time domain (loading time = 60 seconds in the high stiffness region), whereas the R-value is typically used with DSR data to define the curvature of the master curve in the frequency domain in the high stiffness region between 100 kPa to 1 GPa. It can be argued that R defines a temperature dependency aspect, whereas the ΔTcdefines a frequency (or time) dependency.

It is intuitively obvious that a shape parameter for a stiffness curve will not be solely adequate for the definition of performance. The reason that the ΔTcshows promise (Reinke 2017), in defining performance, is postulated to be that all the materials judged with this parameter have similar low or intermediate temperature properties. Thus, for an equivalent stiffness material the ΔTcdefines the ability to relax stresses which are linked to the formation of durability cracks.

Rowe (2011) provided a discussion on the Anderson et al (2011) paper and proposed that Glover's parameter be modified to consider only the complex shear modulus (G*) and phase angle (δ). The parameter

which has been referenced as the Glover-Rowe parameter defines a complex shear modulus versus phase angle relationship within a Black space plot, and the progression of ageing of a binder can be tracked as the stiffness increases. The limits applied in the initial studies have been fixed, using the same data that Glover originally used and are 180 kPa and 600 kPa representing the onset of cracking and significant cracking. These values were developed from the initial studies in Pennsylvania, as reported by Kandhal (1977), and may not be appropriate for all temperature/climatic zones, although the initial studies reported seem to suggest they are generally about the correct level. Regardless, this parameter captures a point on the master curve of stiffness properties and is a hardness value that can assist to anchor the ΔTC values. Consequently, it may be advantageous to use both of these parameters in a specification. Other parameters of interest include the use of the crossover modulus (Gc) and or the crossover temperature at the location where the phase angle is 45°.

Thus, in the analysis of pavements in South Africa, sufficient rheology data is being captured that will allow all of these parameters to be determined and related to field performance, thus enabling specifications to be modified should a more preferable parameter emerge as being significant.

Permanent deformation parameters

The Multiple Stress Creep Recovery (MSCR) test is used to assess the creep and recovery potential of the bitumen and is performed in a DSR at the maximum pavement temperature. It is especially significant when considering the permanent deformation (rutting potential) of asphalt layers and the bleeding of spray seals.

The MSCR test uses the well-established creep and recovery test concept to evaluate the binder's potential for permanent deformation (D'Angelo 2010). Using the DSR, a one-second creep load is applied to the asphalt binder sample. After the one-second load is removed, the sample is allowed to recover for nine seconds. Figure 5 shows typical data for a polymer modified binder under repeated loading. The test is started with the application of a low stress (0.1 kPa) for ten creep/recovery cycles, then the stress is increased to 3.2 kPa and repeated for an additional ten cycles. From this test the Non-recoverable Creep Compliance (Jnrin kPa-1) for a bituminous binder is determined as follows, with reference to Figure 6:

The material response in the MSCR test is significantly different to the response in the existing USA SUPERPAVE® system tests. In the SUPERPAVE® system, the high temperature parameter, G*/sin δ, is measured by applying an oscillating load to the binder at very low strain. This is one of the reasons why the existing SUPERPAVE® high temperature parameter does not accurately represent the ability of polymer-modified binders to resist rutting. Under the very low levels of stress and strain present in dynamic modulus testing, the polymer network is never really activated. In the existing Superpave specification the polymer is really only measured as a filler that stiffens the asphalt. In the MSCR test, higher levels of stress and strain are applied to the binder, better representing what occurs in an actual pavement. By using the higher levels of stress and strain in the MSCR test, the response of the asphalt binder captures not only the stiffening effects of the polymer, but also the delayed elastic effects, that rubber-band type of effect (D'Angelo 2010).

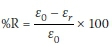

The MSCR test also gives valuable insight into the recovery behaviour of the material. The compliance value JNRfrom the MSCR test provides the rut resistance and the amount of recovered strain (Percent Recovery) from the test identifies the presence of polymer and also the quality of the blending of the polymer in the binder. The determination of Percent Recovery (%R) is illustrated in Figure 7, whereby:

Where:

ε0 = initial strain in the creep stage

εr= final strain after recovery.

PROPOSED SPECIFICATION

The proposed specification is presented in Table 2. Two main bitumen grades are envisaged for South Africa, PG58-22 and PG64-16, with the minimum temperatures maintaining the 80°C difference with the maximum grade temperature. The high pavement temperature map was created using data points which were relatively far spaced in places. In the event of higher pavement temperatures prevailing as a result of microclimates not addressed by the isotherm map in Figure 3, provision is made for a PG70-10 bitumen grade, again maintaining the 80°C temperature difference.

Requirements are specified for un-aged, RTFO-aged (short-term ageing) and PAV-aged (long-term ageing) bituminous binders.

Requirements based on an un-aged bitumen

Requirements specified, based on an un-aged binder, are related to a quick quality control measure (G*/sin δ) that relates to the old penetration parameter, a safety measure (flash point) and production measures in viscosity and storage stability.

G*/sin δ

G*/sin δ at 10 rad/sec and Tmaxhave been retained in the specification only as a quick indication of binder stiffness for quality control purposes. Whilst the G*/sin δ requirement is used as the main parameter of rutting potential in the USA Superpave specification, it is not used for this purpose in the South African specification at all. The rutting requirement in the South African specification is the JNRparameter. G* and δ must be reported separately.

Viscosity

Viscosity is the material characteristic used to describe the resistance of fluids to flow. A specification requirement is needed to make sure that a bitumen can be pumped at a certain (high) temperature. Viscosity at 165°C at a shear rate greater than 30 Hz is the specification requirement included as an indication of pumpability. Unmodified bitumen normally shows Newtonian behaviour, i.e. the viscosity is constant regardless of the shear rate; however, modified bitumens show shear thinning behaviour at an intermediate shear rate range. Figure 8 shows a schematic of the typical viscosity variation over a range of shear rates at which viscosity is measured. At very low shear rates in Figure 8, the viscosity is constant and is defined as the Zero Shear Viscosity (ZSV) or It is impracticable to test at such low shear rates. In the intermediate shear rate range, the binder displays shear-thinning behaviour and the viscosity reduces with an increase in shear rate until at a certain shear rate the Newtonian viscosity, ηΜ, is reached. Research by the CSIR (Mturi et al 2013) has shown that ηΜ is usually reached at shear rates larger than 30 Hz. Thus a test temperature of 165°C was selected to ensure that the viscosity is measured at high shear rate where the viscosity becomes constant and independent of shear rate, as is shown in Figure 8.

Storage stability at 180°C

The storage stability test is used to determine the degree of separation for a modified bitumen during storage. This test uses 30 cm high test tubes that allow separation at 180°C for a fixed period and then temperature reduction to 0°C to enable fracture of the test tube to allow separate binder specimens to be retrieved from the top and the bottom of the tube, for DSR test evaluation. It is not always guaranteed that G* from either will be the highest, therefore the storage stability is calculated as [G*high -G*low] / G*high(from top/bottom sample). The G* is measured at Tmax.

Flash point (°C)

The flash point requirement is retained in the new specification for safety purposes.

Requirements based on a RTFO-aged bitumen

Three requirements are specified for the RTFO-aged bitumen - the mass change, non-recoverable compliance (JNg) and an ageing ratio.

Mass change

The mass change specification from the current SANS BT1 is retained in the new specification with requirements of not exceeding 1.0 % m/m for all other traffic classes.

Non-recoverable compliance (JNR) from MSCR test

The non-recoverable compliance JNR is done at Tmaxwith the following requirements:

■ S-Class, JNR< 4.5 kPa-1

■ H-Class, JNR< 2.0 kPa-1

■ V-Class, JNR< 1.0 kPa-1

■ E-Class, JNR< 0.5 kPa-1

Ageing ratio

An ageing ratio requirement is specified for RTFO-aged and PAV-aged bitumens that will give an indication of the bitumen's resistance to ageing. G* and δ are measured at 10 rad/s at the intermediate temperature; an 8 mm parallel plate will be used unless the stiffness G* < 100 kPa, in which case a 25 mm parallel plate will be used. The ageing ratio is calculated as the ratio between the aged bitumen and the un-aged bitumeni.e.g*rtfo/ G*Originalfor the RTFO-aged bitumen.

Requirements based on a PAV-aged bitumen

Three requirements are specified based on the PAV-aged BBR test - the maximum creep stiffness at 60 seconds loading time, S(60), the minimum m-value at 60 seconds loading time, m(60) and the ΔTc parameter. The values are determined for Tminat two hours loading time. Because two hours were considered to be too long for testing, the principles of time-temperature superposition were used to obtain the same values at a temperature of Tmin+10°C and 60s loading time.

Maximum creep stiffness

A maximum requirement for creep stiffness, S(60), of 300 MPa at Tintafter 60 seconds of loading time is specified to limit the bitumen stiffness with ageing. It is known that stiff binders, caused by either ageing or cold temperatures, will crack. Limiting the bitumen's creep stiffness will limit cracking to cold temperatures. It is also known that fatigue is highly influenced by an increase in stiffness with ageing. The equivalency between cold temperature stiffness and ageing stiffness is therefore currently seen to be an indicator of binder relaxation properties, and hence also an indicator of fatigue resistance.

Minimum m-value

A minimum requirement for the m-value, m(60), is specified. The m(60) parameter is an indication of the bitumen's ability to relax. Increasing the relaxation parameter will ensure that the bitumen will relax after a stress application.

ΔTc

A requirement for ATcof greater than -5°C is specified. The AT*c parameter was discussed in detail above.

Ageing ratio

An age in gratio of G*pAV/G* Originalis alsospecified for the PAV-aged bitumen (LTA). Having ageing ratios for STA and LTA, bitumens can be assessed in terms of the bitumen's resistance to ageing.

DETAILS ON REPORT ONLY ITEM

A compulsory report requirement is included in the specification. This includes:

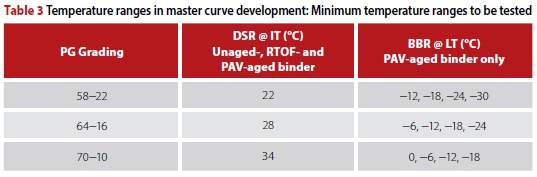

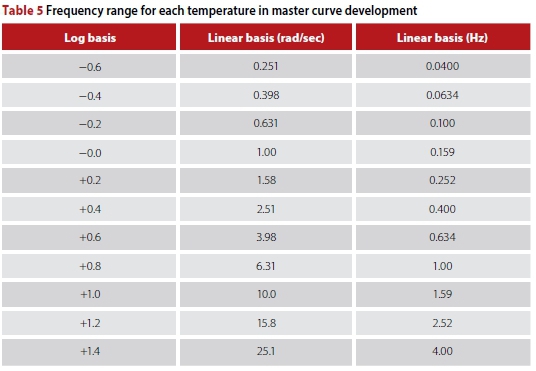

■ A single DSR frequency sweep isotherm for un-aged, RTFO- and PAV-aged bituminous binders at [(Tmax + Tmin)/2 + 4]°C (see Table 3) at an applicable strain level, as set out in Table 4, and at the frequency values set out in Table 5.

■ The specified BBR isotherms for the PAV-aged binder; the temperatures are set out in Table 3.

With the BBR isotherm of the PAV-aged bitumen at the low temperatures and the respective isotherms of the aged binders, full master curves can be developed. The procedure to follow to produce the master curves is the subject of a separate paper.

The master curves are used to calculate additional rheological parameters and build a database to investigate additional parameters for inclusion in future versions of the specification.

IMPLEMENTATION PLAN

At the Roads Pavement Forum (RPF) held in May 2016 (RPF 2016) it was decided, for a period of two years starting in July 2016, to implement the proposed Specification Framework for performance-graded bituminous binders in parallel with current binder specifications. Implementation is voluntary and will be done on selected SANRAL roads; other provincial and local government road authorities will also join forces. This implementation period is required to gather data on bitumen in terms of the new specification and build a database of typical bitumen requirements with an eventual aim of verifying the limits of all specification requirements. A draft performance-grade bitumen specification was submitted to the South African Bureau of Standards (SABS) that will be published as a SANS Technical Note, SATS 3208. A full SANS Standard Specification will follow at a later stage.

In the meantime, a few seminars to introduce the specification were held across the country, and two training courses were held - in June 2016 at SANRAL Head Office in Pretoria, followed up in April 2017 in Cape Town at the Stellenbosch University Business School, both jointly sponsored by SANRAL and SABITA.

A proficiency testing programme between the different laboratories was also launched where test results are compared on a regular basis to ensure consistency in testing and quality of results. The committee responsible for the proficiency testing programme will also develop test protocols in addition to the specifications to ensure that identical procedures are used in all participating laboratories.

Report back on progress with the implementation of the performance-grade specification is done every six months at the RPF.

RESULTS

Non-recoverable compliance results (Jnr) are reported in Table 6 for a number of typical South African binders. Softening points and penetration are added for reference and to compare to the current South African penetration specification. Reference to "1", "2" and "3" indicates different suppliers for similar products. The Jnr results shown were determined at 64°C. Results for 58°C are approximately half of the values obtained at 64°C. These results are not included in the paper for the sake of brevity.

The range of the results for Jnrindicate that the binders currently produced in South Africa would satisfy all the requirements of the proposed PG specification classes with regard to Jnr.

RESEARCH

In a further effort to verify the limits of all specification requirements in the performance-grade specification, a research project has been launched at the Stellenbosch University (SU) and the Council for Scientific and Industrial Research (CSIR), sponsored by SANRAL and Much Asphalt (Pty) Ltd. Use is also made of the laboratories of Colas and Tosas in the research. This research follows on initial research at the CSIR sponsored by SABITA. The objective is that the performance-grade specification in South Africa will be underlain by a solid knowledge base. More research will be required in future to refine the specification and possibly add more requirements, or even omit some of the current requirements where it is found that relationships with performance in the field are not as originally envisaged.

SUMMARY AND CONCLUSIONS

The current proposed format of the PG-grade specification being implemented in South Africa builds upon those implemented in the USA and the parameters considered to be of key interest in the USA for development and inclusion in future specifications. The data collection scheme being implemented allows a detailed evaluation of these parameters for the South African climate zones and traffic levels. Results to date indicate that current binders being used in South Africa can readily conform to the proposed PG specification in terms of deformation requirements without any disruption to the refineries or secondary manufacturers.

Should more appropriate parameters emerge for controlling cracking behaviour than those currently being specified, some minor modifications can easily be made within the existing specification framework. It should be noted that the climatic zones for South Africa are not vastly different from some other parts of the world where extensive data collection is taking place and we can build upon the experience being captured in these climatic zones.

ACKNOWLEDGEMENTS

This paper is presented with the approval of the South African National Roads Agency Limited SOC. The contents of the paper reflect the views of the authors who are responsible for the facts and accuracy of the data presented herein. The contents do not necessarily reflect the official view or policies of the South African National Roads Agency Limited SOC. The authors also wish to express their thanks to SABITA who initiated the research that eventually culminated in the specifications discussed in this document.

REFERENCES

Airey, G D 2003. State of the art report on ageing test methods for bituminous pavement materials. International Journal of Pavement Engineering, 4(3): 165-176. [ Links ]

Anderson, R M, King, G N, Hanson, D I & Blankenship, P I 2011. Evaluation of the relationship between asphalt binder properties and non-load related cracking. Journal of the Association of Asphalt Paving Technologists, 80: 615-649. [ Links ]

D'Angelo, J 2010. New high-temperature binder specification using multistress creep and recovery, development in asphalt binder specifications. Transportation Research Circular, No. E-C147. Washington, DC: Transportation Research Board. [ Links ]

Denneman, E 2007. The application of locally developed pavement temperature prediction algorithms in performance grade (PG) binder selection. Proceedings, 26th Southern African Transport Conference, 9-12 July 2007, Pretoria. [ Links ]

Erkens, S, Porot, L, Glaser, R & Glover, C 2016. Review of asphalt (concrete) aging tests in US and Europe. Proceedings, 95th Annual Meeting of the Transportation Research Board, Compendium of Papers, pp 1-8. [ Links ]

Glover, C J, Davison, R R, Domke, C H, Ruan, Y, Juristyarini, P, Knorr, D B & Jung, S H 2005. Development of a new method for assessing asphalt binder durability with field validation. Report 0-1872-2. Austin, TX: Texas Department of Transportation. [ Links ]

Glover, C J, Martin, A E, Chowdhury, A, Han, R, Prapaitrakul, N, Jin, X & Lawrence, J 2009. Evaluation of binder aging and its influence in aging of hot mix asphalt concrete: literature review and experimental design. Report 0-6009-1. Austin, TX: Texas Department of Transportation. [ Links ]

Kandhal, P S 1977. Low-temperature ductility in relation to pavement performance. In Marek, C R (Ed.). Compacted Bituminous Paving Mixtures. Philadelphia, PA: American Society for Testing and Materials. [ Links ]

Leahy, R B, Harrigan, E T & Von Quintus, H 1994. Validation of relationships between specification properties and performance. Report SHRP-A-409. Washington, DC: Transportation Research Board. [ Links ]

Mturi, G A J, O'Connell, J & Anochie-Boateng, J K 2013. Limitations of current South African test methods for bituminous binders. Construction and Building Materials, 45: 314-323. [ Links ]

O'Connell, J, Mturi, G A J & Zoorob, S 2015. A review of the development of the non-recoverable compliance for use in South Africa. Proceedings, 11th Conference on Asphalt Pavements for Southern Africa (CAPSA 2015), 16-19 August 2015, Sun City. [ Links ]

O'Connell, J & Steyn, W J vd M 2017. an overview of the ageing of bituminous binders. Proceedings, 36th Southern African Transport Conference, 13-17 July, Pretoria. [ Links ]

Reinke, G 2017. The relationship of binder delta Tc (ATc) to mixture fatigue. Presentation to the SEAUPG Meeting, Florida, USA. [ Links ]

Rowe, G R 2011. Prepared discussion following the Anderson AAPT paper - Evaluation of the relationship between asphalt binder properties and non-load related cracking. Journal of the Association of Asphalt Paving Technologists, 80: 649-662. [ Links ]

RPF (Roads Pavement Forum) 2016. Minutes of the 31st Road Pavements Forum Resolutions, Resolution 4. Available at: https://rpf.csir.co.za/road-pavements-forum-rpf/31st-road-pavements-forum. [ Links ]

Smith, B T, Howard, I L, Jordan III, W S, Daranga, C & Baumgardner, G L 2018. Comparing pressure aging vessel time to field aging of binder as a function of pavement depth and time. Transportation Research Record, 2672(28): 1-17. [ Links ]

Vallerga, B A & Halstead, W J1971. Effects of field aging on fundamental propereties of paving asphalts. Highway Research Record, 361: 71-92. [ Links ]

Van de Ven, M F C, Jenkins, K J & Bahia, H U 2004. Concepts used for the development of bitumen specifications. Proceedings, 8th Conference on Asphalt Pavements for Southern Africa (CAPSA '04), September 2004, Sun City, South Africa. [ Links ]

Viljoen, A W 2001. Estimating asphalt temperatures from air temperatures and basic sky parameters. Internal report, Pretoria: Transportek, CSIR. [ Links ]

Correspondence:

Correspondence:

STEPH J BREDENHANN

SANRAL (at the time of writing this paper)

1 Havenga Street, Oakdale Bellville, Bellville 7530, South Africa

T: +27 21 854 6927, E: steph@enpave.net

PIETER A MYBURGH

Specialist Consultant

1 Rosenheim, Robinson Street, Durbanville 7550, South Africa

T: +27 82 883 5960, E: pmyburgh@ffg.net

PROF KIM J JENKINS

SANRAL Chair in Pavement Engineering

Department of Civil Engineering, Stellenbosch University

Private Bag X1, Matieland 7600, South Africa

T: +27 21 808 4379, E: kjenkins@sun.ac.za

JOHAN O'CONNELL

CSIR

PO Box 395, Pretoria 0001, South Africa

T: +27 12 841 2295, E: joconnell@csir.co.za

DR GEOFFREY ROWE

Abatech Inc

PO Box 356, Blooming Glen, PA 18911, USA

T: +1 267 772 0096, E: growe@abatech.com

DR JOHN D'ANGELO

D'Angelo Consulting, LLC

8528 Canterbury Drive, Annandale, VA, 22003, USA

T: +1 571 218 9733, E: johndangelo@dangeloconsultingllc.com

STEPH J BREDENHANN (Pr Eng, Pr CPM) matriculated at Upington High School in 1972, graduated in 1977 from Stellenbosch University and completed his Master's degree in 2000. He started his career at the Sishen Iron Ore Mine in the industrial engineering field, and later joined the Kimberley City Council before he moved to a consulting engineering firm, Entech Consultants, in Stellenbosch, where he was a director. He became a regional director of WSP Consulting Engineers, then joined Goba Consulting Engineers as technical director before he joined SANRAL as the Western Region Project Manager for Research. He specialises in pavement and materials engineering. He is a Fellow ofthe South African Institution of Civil Engineering, as well as ofthe Society for Asphalt Technology.

PIETER A MYBURGH graduated from the University of Cape Town in 1965, following which he was employed by the Provincial Government of the Cape Province as engineer in their Roads Department. From 1982 he was Chief Executive Officer of the Southern African Bitumen Association (SABITA) until his retirement in 2006. Since then he has acted as specialist consultant in pavement and materials engineering. He is a Fellow of the South African Institution of Civil Engineering, as well as of the Society for Asphalt Technology. His other interests include music and wild-life photography.

PROF KIM J JENKINS (Pr Eng) started his career as a geotechnical engineer (investigation and design), and later expanded his sphere of activities into pavement engineering. Kim found a niche in road rehabilitation and focused on technology development in cold recycling of pavements using sustainable technologies. His research is captured in more than 100 publications. In his tenure he has served to graduate in the order of 100 Master's and Doctoral candidates. He is currently the incumbent of the Research Chair in Pavement Engineering at Stellenbosch University, sponsored by the South African National Roads Agency Limited (SANRAL).

JOHAN O'CONNELL is currently a Senior Researcher at the CSIR, Smart Mobility, within the Transport Infrastructure Engineering Group. He obtained an MSc in Organic Chemistry from the University of Port Elizabeth in 1988. He joined the transportation industry in 1992 when he started working for Petrocol. His research interests focus on the introduction of a new performance-graded binder specification for southern Africa for pavement construction, as well as the establishment of bituminous binder ageing models which can be linked to asphalt pavement life expectancy and pothole development (this is also the topic of his PhD studies at the University of Pretoria).

DR GEOFFREY ROWE has been working with asphalt materials for 43 years and is currently the President of Abatech, providing consultancy services on projects around the world. He has implemented significant technology for pavements, including pavement structural design, analysis of FWD data, materials property analysis and rheology. He is a Past President of the Association of Asphalt Paving Technologists. He serves on many other groups advising research that impacts on specifications in North America, Europe, Asia and Africa. He is a licensed Professional Engineer in the USA and a Chartered Engineer in the UK.

DR JOHN D'ANGELO (PE) is the Chief Operating Officer of a small consulting firm specialising in asphalt materials testing, pavement design, construction operations, construction quality assurance and pavementforensic analysis. He has worked on paving projects in various countries around the world for over 45 years, including 32 years at the US Federal Highway Administration. He has worked in the areas of construction management, pavement design, materials testing and quality control. He has also worked extensively in asphalt binders, mixture design, warm-mix asphalt and recycling. He was instrumental in the implementation and continued development ofthe Superpave Binder and mixture tests and specifications. He is a member ofthe Transportation Research Board, the Association of Asphalt Pavement Technologists, the Canadian Technical Asphalt Association, the International Society for Asphalt Pavements and ASTM.