Serviços Personalizados

Artigo

Indicadores

Links relacionados

-

Citado por Google

Citado por Google -

Similares em Google

Similares em Google

Compartilhar

Journal of the South African Institution of Civil Engineering

versão On-line ISSN 2309-8775

versão impressa ISSN 1021-2019

J. S. Afr. Inst. Civ. Eng. vol.60 no.2 Midrand Jun. 2018

http://dx.doi.org/10.17159/2309-8775/2018/v60n2a3

TECHNICAL PAPER

Modelling manpower and equipment productivity in tall residential building projects in developing countries

M K Parthasarathy; R Murugasan; Ramya Vasan

ABSTRACT

This study is aimed at developing productivity models based on the combined usage of manpower and equipment resources in construction for tall residential building projects in India. Data was collected from 52 tall residential building projects in different locations for a consecutive period of 18 months for the five basic activities of construction: concreting, reinforcement, formwork, blockwork and plastering. Multiple linear regression analysis was used to develop 15 models - three models each in different conditions for the five basic construction activities for manpower and equipment productivity, and were validated with independent field data. In addition, the factors affecting productivity of manpower and equipment were analysed through a qualitative study by collecting and examining responses to questionnaires from 96 respondents involved in the 52 projects. The study found that improper planning of work was the most important factor affecting the productivity in tall residential building projects. The models developed in the study, and the analysis of factors affecting productivity will be useful to cost engineers and project managers to estimate the productivity of resources in tall residential building projects in India and other developing countries where similar conditions prevail.

Keywords: construction, residential buildings, tall buildings, productivity, modelling

INTRODUCTION

The construction industry plays a vital role in the development of India, one of the steadiest and fastest growing countries in the world (Economic Report of the President 2016). Being the second largest contributor to Gross Domestic Product (GDP) after agriculture, construction employs a workforce of nearly 35 million in addition to a variety of equipment. In fact, its market size is worth about $126 billion, according to the Department of Industrial Policy and Promotion, Government of India in 2016. A Financial Express report predicted that more than 40% of the population would be residing in urban areas by 2030, and suggested that approximately 400 million people would be migrating to cities in a period of 15 years from 2016 to 2030 (Gulati 2016). Consequently, urbanisation and increased demand for space in developing countries like India have led to large-scale construction of tall residential buildings, and impacted the basic activities of construction like concreting, reinforcement, formwork, blockwork and plastering. In developing countries these basic activities are executed with a combination of manpower and equipment resources, due to the easy availability of manpower and the high cost of equipment. Such a combined approach to construction requires a scientific approach to the planning and execution of projects. This problem can be addressed primarily by tall building residential projects, a solution of great potential for the development of cities and urban spaces worldwide (Elbakheit 2012).

As in other developing countries, India is faced with the challenge of affordable and comfortable tall building construction projects to meet the high demand for space in urban localities. Studies on productivity in construction projects in the Indian context by Attar et al (2014), Patil (2015), Santosh and Apte (2014), and Shashank et al (2014) highlighted the productivity measurement, as well as the methods. They also discussed the large quantum of manpower and equipment resources involved, but did not suggest any models which could be used for tall building projects. On the other hand, the models developed by Antunes and Gonzalez (2015), Gundecha (2012), Jrade et al (2012), Wang (2005) and others in other countries for construction productivity mainly focused on work methods, the factors affecting the productivity, productive time of trade, etc. A careful study of these models indicated that they were area-specific and could not be used as prediction models for construction in developing countries, the major reason being that construction in developing countries involves a combination of equipment usage and manual labour, unlike in developed countries where the activities are predominantly mechanised.

This study is therefore aimed at developing scientific models to estimate the productivity of manpower and equipment in tall residential building projects with a height of 30 m or more in India, bearing in mind the seasonal variances in monsoon and non-monsoon periods, as well as factors affecting the productivity of manpower and equipment.

LITERATURE REVIEW

A few studies on the modelling of manpower and equipment productivity for tall residential building projects which have direct relevance to the current study are discussed in this section.

Zayed and Halpin (2005) estimated the productivity and cost of pile construction using the regression technique in the United States. They designed 52 regression models to assess piling process productivity and cycle time. They validated the models to assure their appropriateness in the assessment process by developing several sets of charts that represented productivity, cycle times and cost. They concluded that productivity was directly related to the achievement of cycle time using piling equipment. They further observed that variation happened if the cycle time of piles on one piece of equipment was not achieved.

Al-Zwainy et al (2013) used the Multivariable Linear Regression Technique for modelling productivity of construction, with a focus on marble finishing works in Iraq. They used parameters like age, experience, number of assisting workmen, height of the floor, size of the marble tiles, security conditions, health status of the work team, weather conditions, site condition and availability of construction materials as independent variables. They developed a model based on 100 sets of data collected in Iraq from different types of construction, such as residential, commercial and educational projects. They concluded that the size of finished marble blocks had the most significant effect on the productivity of marble finishing works for floors, while the other input variables had a moderate impact on the productivity.

Gupta and Kansal (2014) examined the factors affecting labour productivity in construction sites in India. They invited professionals such as project managers, project engineers, site engineers, architects, assistance project managers, assistance project engineers and others who worked on the project, from management to execution level, to participate in a questionnaire survey. The questionnaire had four primary groups of factors, i.e. management, technological, human/labour and external. They found that ten factors of clarification in technical specifications (labour supervision, method of construction, delay in payment, labour fatigue, lack of construction managers' leadership, extent of variations/change in order during execution, late arrival, early quitting and frequent unscheduled breaks, labour skill, and availability of experienced labour) affected construction labour productivity in the Chambal Region.

An examination of the available literature indicated that very few studies had developed models for estimating productivity on tall building projects. It further showed that research was not carried out in the context of a combination of both manpower and equipment resources. Finally, it was observed that the research outcomes were based on area-specific studies and had no scope for application in tall residential building projects. Hence, this study explored the options of developing models for estimating productivity in tall residential building projects. In addition, it attempted to examine various factors influencing productivity when construction was carried out with a combination of manpower and equipment resources.

OBJECTIVES OF THE STUDY

The objectives of this research are:

-

To develop prediction models for manpower and equipment productivity, using multiple linear regression for the main activities of tall residential building construction like concreting, reinforcement, formwork, blockwork and plastering, considering the resources as independent variables, and for conditions prevailing in developing countries.

-

To validate the developed models by comparing theoretical and actual quantities of each item, so that the models can be used for planning and utilisation of resources in projects.

-

To examine and classify the factors affecting productivity of manpower and equipment in tall residential building projects.

-

To rank the factors affecting productivity in descending order of their intensity in terms of frequency indices.

RESEARCH METHOD

This is an empirical study of tall residential building projects in India. First, it identified the tall buildings located in different parts of India and prepared a database for the selection of projects and the collection of data. It regularly collected data pertaining to the five basic activities over a period of 18 months. Multiple linear regression analysis was used to develop manpower and equipment productivity models. Independent field data was used to validate the models developed in this study. Thereafter questionnaires were used to collect information regarding the factors affecting tall building projects from 96 respondents involved in 52 projects.

DATA BASE DEVELOPMENT

Project selection criteria

A set of criteria was employed to select the 52 tall building projects:

-

The final height of the building should be more than or equal to 30 m.

-

The building should be a framed Reinforced Cement Concrete (RCC) structure with column-slab design and it should not involve any composite construction.

-

All the five selected basic activities should be on-going at various height levels in the project.

-

The floor height in each level should be 3 m - 4 m, which is the normal floor to floor height in India.

-

The project sites should be distributed throughout the country.

Based on these criteria, 52 tall residential building construction projects were chosen for the study. This in turn determined the distribution of two sets of questionnaires to 130 persons involved in different trades among consultants, execution teams, planning personnel, etc.

Data collection

Once the activities and projects had been selected, the manpower input and equipment usage for each activity were recorded on a monthly basis for every project. In the case of equipment like tower cranes and hoists, which were shared for many activities in the given project, a percentage of time allocation was considered for different activities. For example, tower crane time was distributed as 35% for concrete, 35% for reinforcement and 30% for formwork. Similarly, the distribution of time for all equipment was determined for this study. The distribution of percentages of equipment time to different activities was based on the experience of the project personnel and the allocation log sheets maintained by the plant and equipment (P&E) departments in the 52 project sites.

The heights of the building, i.e. the point from where the work commenced at the start of the month to the point to where work had progressed by the end of the month, were recorded. The mean of these two heights was considered as the height at which the activity was carried out during the month.

The range of data collected from the 52 tall building construction projects is given in Table 1

Factor selection for factor analysis

Twenty-one factors affecting the productivity of manpower and 20 factors affecting equipment productivity were identified for this study from various sources:

-

Studies available from construction industry and other projects.

-

The opinion of personnel involved in the construction of tall building projects, based on their experience.

-

Empirical data on losses due to productivity from a multinational organisation in the area of study.

-

The opinions of contract managers while estimating the costs of tall residential building projects.

The list of factors considered for this study, with their classification in respective categories, is shown in Table 2(a). The critical literature review of the factors affecting manpower and equipment productivity is given in Table 2(b).

QUANTITATIVE ANALYSIS AND DEVELOPMENT OF MODELS

The data from the 52 projects was collected and sorted for each of the five basic construction activities. Data pertaining to every third month from the start date of data collection was separated as out-of-sample for the purpose of validation, and the remaining months' data was used as sample for the formulation of the models. Models were developed in this study for estimating productivity of the five activities: concrete, reinforcement, formwork, blockwork and plastering. Further, the effect of monsoon was also studied, and models were developed for each activity in monsoon and non-monsoon periods separately. According to the Indian Meteorological Department, India receives rain from two monsoons, namely the Southwest Monsoon from the end of May to the beginning of September every year, and the Northeast Monsoon from the beginning of October to the end of December. Four categories/areas of monsoon were considered, with reference to the onset of the two monsoon periods in India:

A. Northern and western regions - June, July and August

B. Eastern region - July, August and September

C. Southeastern region - October and November

D. Southwestern region - May, June and July

The data was separated as sample for modelling and as out-of-sample for validation. Overall, the data separated for the purpose of validation was 30% of the total data set.

Concrete quantity model

In this model, concrete quantity was the dependent variable, whereas the parameters of height (H), man-days (MD), tower crane hours (TCH), pump hours (CPH), transit mixer hours (TMH) and batching plant hours (BPH) were independent variables.

The best model obtained using multiple linear regression analysis is:

Conc = -448.751 - 1.249 H + 0.402 MD

+ 0.902 TCH + 1.371 CPH

+ 2.155 TMH + 5.735 BPH (R2 = 0.953; N = 624; SE = 528.58) (Model 1)

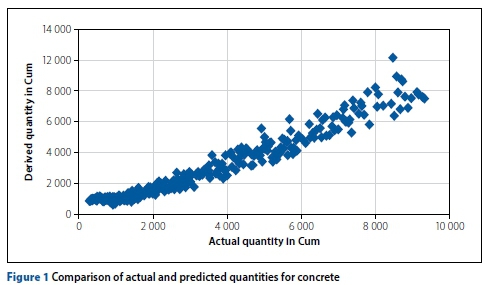

The plot between actual quantity (from out-of-sample data) and the derived quantity (sample data) for concrete validates the model, as shown in Figure 1 The alignment of plotted points along the line of equality indicates the robustness of the model.

The model for concrete quantity in the monsoon period is:

Conc monsoon = -674.443 - 0.322 H

+ 0.328 MD + 1.127 TCH + 1.291 CPH +2.804 TMH

+ 5.262 BPH

(R2 = 0.957; N = 136; SE = 520.34) (Model 2)

The model for concrete quantity in the non-monsoon period is:

Conc non-monsoon =

-266.949 - 2.229 H + 0.358 MD

+ 0.809 TCH + 1.328 CPH + 2.181 TMH + 5.610 BPH (R2 = 0.946; N = 486; SE = 569.22) (Model 3)

Reinforcement quantity model

In this model, reinforcement quantity was the dependent variable, whereas the parameters of height (H), man-days (MD), tower crane hours (TCH), bar cutting hours (BCH) and bar bending hours (BBH) were independent variables.

The best model obtained using multiple linear regression analysis is:

Rft = -210.221 - 0.119 H + 0.047 MD

+ 0.997 TCH + 0.438 BCH - 0.370 BBH

(R2 = 0.932; N = 624; SE = 106.69) (Model 4)

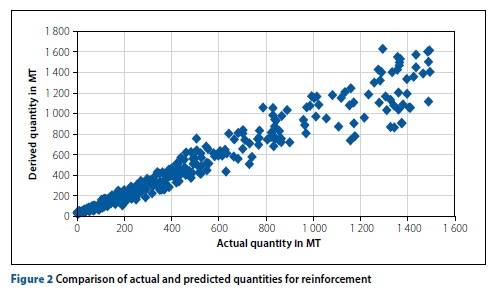

The plot between actual quantity (from out-of-sample data) and the derived quantity (sample data) for reinforcement validates the model, as shown in Figure 2 The alignment of plotted points along the line of equality indicates the robustness of the model.

The model for reinforcement quantity in the monsoon period is:

Rft monsoon = -303.834 - 0.120 H

+ 0.039 MD + 1.355 TCH

+ 0.430 BCH - 0.341 BBH

(R2 = 0.959; N = 136; SE = 87.38) (Model 5)

The model for reinforcement quantity in the non-monsoon period is:

Rft non-monsoon = -188.669 + 0.005 H

+ 0.052 MD + 0.872 TCH + 0.391 BCH - 0.339 BBH

(R2 = 0.931; N = 486; SE = 112.54) (Model 6)

An examination of the reinforcement models (Models 4, 5 and 6) exhibits a negative sign on the resource of bar bending machine hours, implying that the increase in bar bending hours reduces the quantity of reinforcement. In most cases, reinforcement is provided as straight bars or cut to length. Bending is required in all the bars. Hence, this negative sign implies that, with increase in bar bending instead of being laid straight, there will be a reduction in quantity. On the other hand, Model 6 for reinforcement work in the non-monsoon period shows a positive sign towards the independent variable height. This is due to the use of a higher quantity of long bars on three floors, as a 12 m bar is useful for floors of 4 m height in specific cases.

Formwork quantity model

In this model, formwork quantity is the dependent variable, while the parameters of height (H), man-days (MD), tower crane hours (TCH) and hoist hours (HH) are independent variables.

The best model obtained using multiple linear regression analysis is:

FW = -519.279 + 0.192 H + 0.454 MD

+ 7.223 TCH + 4.856 HH (R2 = 0.950; N = 624; SE = 2609.25) (Model 7)

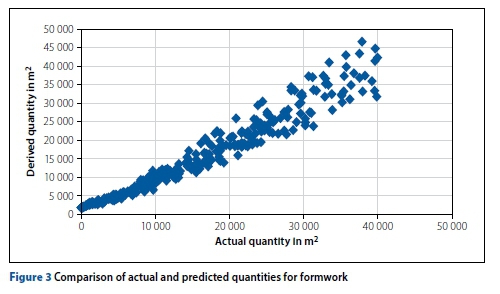

The plot between actual quantity (out-of-sample data) and the derived quantity (sample data) for formwork validates the model, as shown in Figure 3 The alignment of plotted points along the line of equality indicates the robustness of the model.

The model for formwork quantity in the monsoon period is:

FW monsoon = 41.864 + 1.828 H + 0.437 MD

+ 5.974 TCH + 5.373 HH (R2 = 0.950; N = 136; SE = 2438.09) (Model 8)

The model for formwork quantity in the non-monsoon period is:

FW non-monsoon = -313.592 - 2.609 H

+ 0.417 MD + 7.879 TCH

+ 4.795 HH

(R2 = 0.961; N = 51; SE = 2056.62) (Model 9)

It is observed from the coefficients of the variables in formwork models (Models 8 and 9) that the formwork quantity is higher for the monsoon period than for the non-monsoon period. This may be due to the fact that major quantities of formwork are being done with system formwork and climbing formwork, which involve a continuous process of work, even in the monsoon period but with protection against the rains.

Blockwork quantity model

In this model, blockwork quantity is the dependent variable, whereas the parameters of height (H), man-days (MD), tower crane hours (TCH), and hoist hours (HH) are independent variables.

The best model obtained using multiple linear regression analysis is:

BW = 49.662 - 0.514 H + 0.183 MD

+ 2.887 TCH + 1.221 HH (R2 = 0.932; N = 480; SE = 374.08) (Model 10)

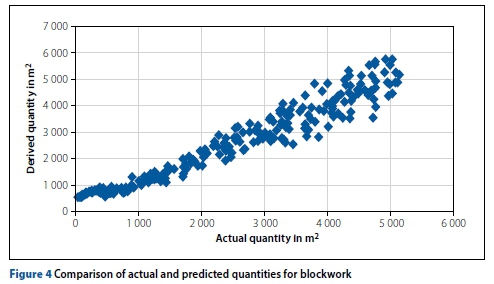

The plot between actual quantity (out-of-sample data) and the derived quantity (sample data) for blockwork validates the model, as shown in Figure 4 The alignment of plotted points along the line of equality indicates the robustness of the model.

The model for blockwork quantity in the monsoon period is:

BW monsoon = 15.621 - 1.263 H + 0.176 MD

+ 2.529 TCH + 1.404 HH

(R2 = 0.936; N = 103; SE = 370.76) (Model 11)

The model for blockwork quantity in the non-monsoon period is:

BW non-monsoon = -61.466 + 0.572 H +

0.234 MD + 2.753 TCH

+ 1.213 HH

(R2 = 0.933; N = 376; SE = 385.63) (Model 12)

Plastering quantity model

In this model, plastering quantity is the dependent variable, while the parameters of height (H), man-days (MD) and hoist hours (HH) are independent variables.

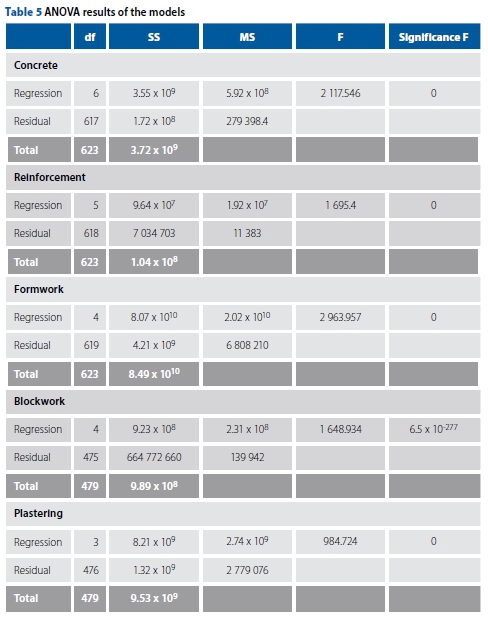

The best model obtained using multiple linear regression analysis is:

P = 929.613 - 0.491 H + 0.430 MD + 1.863 HH (R2 = 0.861; N = 480; SE = 1667.05) (Model 13)

The plot between actual quantity (out-of-sample data) and the derived quantity (sample data) for plastering validates the model, as shown in Figure 5 The alignment of plotted points along the line of equality indicates the robustness of the model.

The model for plastering quantity in the monsoon period is:

P monsoon = 591.723 + 7.521 H + 0.571 MD

+ 1.607 HH (R2 = 0.865; N = 103; SE = 1546.55) (Model 14)

The model for plastering quantity in the non-monsoon period is:

P non-monsoon = 901.529 + 1.739 H

+ 0.385 MD + 1.881 HH (R2 = 0.854; N = 376; SE = 1688.85) (Model 15)

Statistical validity of the models

Table 3 shows the statistical validity of the models and the significance of the variables, verified through validity checks with reference to the standard parameters of "t" values, "P values" and variance influencing factor (VIF) for each independent variable considered in the models.

The acceptable "student's t" statistic value for 95% confidence level is 1.645, but Table 3 reveals "student's t" values of more than 1.645 for all the resource parameters, implying a normal distribution across observations. The acceptable P values is 0.05 but the table shows that "P values" are less than 0.05, implying that the variables included for model development are significant to the model.

Interestingly, the coefficient of the variable height in each activity, except formwork, is negative, i.e. for activities concrete, reinforcement, blockwork and plastering. The negative value of height indicates that, as height increases, productivity decreases. This is logical and understandable, given the increased time for lifting materials from the base for each additional floor. In the four activities the materials have to be lifted from the bottom every time for an additional height, and hence the productivity decreases with increase in height. However, in formwork activity we have a positive coefficient, which defies the above logic. The increase of formwork productivity with height is due to the increased number of repetitions from floor to floor, with the same material being lifted without disturbing the standard configuration. This increase in productivity is attributed to the specialisation that the resources imbibe, due to repetitive nature of the work.

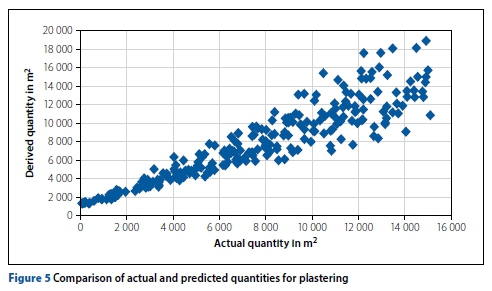

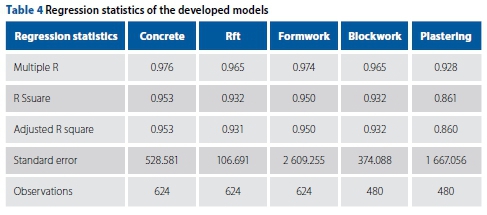

The results of regression statistics and ANOVA for the models are shown in Tables 4 and 5, respectively.

It is observed from Table 4 that multiple 'R' is more than 0.9 for all five the models, implying correlation between the observed and predicted value, which is adequate to comply with construction requirements.

The value of significance 'F' in Table 5 is less than 0.05 for all five the models, which implies that the developed models are significant. The collinearity statistics for all the independent variables is established indicating that the variance influencing factor (VIF) is greater than '1' in each case. However, multi-collinearity between the independent variables exists, as the VIF is more than '2'. For example, in concrete work the two independent variables of concrete pump hours and transit mixer hours have strong multi-collinearity because, without a transit mixer to deliver concrete, the concrete pump resource will not be useful.

Inference from quantitative analysis

In all the above models, the variables such as man hours, tower crane hours, hoist hours and other equipment hours appear with positive coefficients, indicating that an increase in these variables leads to an increase in productivity. On the other hand, the variable height appears with a negative coefficient, showing that, with the increase in height, the production decreases, except for the formwork model. In all the models the plotted lines aligned along the line of equality, indicating the robustness of the models.

QUALITATIVE ANALYSIS

Questionnaire responses

Questionnaires with the factors presented in Table 2 were distributed to 130 persons and responses collected from 96 persons who were involved in the execution of the 52 selected tall residential building projects. The responses were tabulated in order to understand the importance of various factors affecting productivity. The responses to the factors affecting manpower productivity and equipment productivity have been separately analysed and are shown in Tables 6 and 7, respectively.

The relative important index (RII) was calculated for the summary of responses for both manpower and equipment productivity. The RII in Tables 6 and 7 indicates that planning factors are the most important, followed by human factors in both cases.

Frequency indices

Based on the responses about factors affecting manpower productivity collected from 96 persons, the frequency index for each factor was worked out. The frequency indices for manpower and equipment productivity are depicted in Figures 6 and 7, respectively.

The frequency indices can be used as a measure to ascertain whether the factors considered for this study influence the manpower and equipment productivity. Based on the questionnaire survey and responses in this study, it is observed that 22 out of 41 factors have a frequency index of more than 0.70, and 38 out of 41 factors have a frequency index of more than 0.60. These indices of 0.70 and 0.60 clearly show that the factors affect productivity and should be taken up for further study.

DISCUSSIONS OF THE FINDINGS

The quantitative and qualitative studies of the research, based on the data collected from 52 tall residential building construction projects across India and various analyses conducted on them, reveal several findings.

A. Quantitative study

1. Fifteen multiple linear regression models, three for each of the five basic activities of tall building construction (concreting, reinforcement, formwork, blockwork and plastering) were developed in this study for the productivity of manpower and equipment for tall residential building construction projects covering the monsoon season and the non-monsoon season.

2. The 15 developed models were evaluated and proven, with reference to the out-of-sample data, and were found to satisfy resource estimation requirements adequately.

3. In all the models, man-days are found to be the most significant explanatory variable influencing the quantity of different activities.

4. Tower crane hours and hoist hours are the next significant explanatory variables influencing the quantities.

5. The effect of monsoon on the quantities of different activities taken for the study is not significant, with a reduction of 2.15% for concreting quantity, 3.58% for formwork quantity and 3.90% for plastering quantity.

6. These models can be used as an effective tool in the estimation and monitoring of manpower and equipment resources in tall building construction projects at different stages of work in India and other South Asian developing countries.

B. Qualitative study

1. Based on expert opinion, 21 factors affecting manpower productivity were identified and were segregated into four groups: human factors, planning factors, system factors and environmental factors. Twenty factors affecting equipment productivity were identified and were segregated into five groups: human factors, planning factors, system factors, environmental factors and resource/ equipment factors.

2. The frequency indices for the 21 factors affecting manpower productivity, and the 20 factors affecting equipment productivity were calculated from the responses received from 96 respondents to two questionnaires. The range of frequency indices for manpower productivity is between 0.555 and 0.820, and the range of frequency indices for equipment productivity is between 0.535 and 0.805.

3. The three important factors affecting manpower productivity are improper planning of work with a frequency index of 0.82, non-availability of materials with a frequency index of 0.80, and lack of skill of workman with a frequency index of 0.80.

4. The three important factors affecting equipment productivity are improper planning of work with a frequency index of 0.81, lack of skill of operator with a frequency index of 0.79, and equipment breakdown with a frequency index of 0.78.

CONCLUSIONS

Productivity of manpower and equipment resources in construction projects is usually calculated using empirical methods, experience of personnel and in some cases the manufacturer's recommendation. Using models for the estimation and monitoring of productivity provides leverage to the project team to scientifically estimate and monitor productivity for a given set of resources and a given set of conditions in construction projects, particularly tall buildings. In this study, 15 robust models were developed for the five basic activities of construction for three conditions, and these models were validated using out-of-sample data. These models cover the resources to be used for each activity in tall building residential projects. Similarly, this study also identifies the factors affecting manpower and equipment productivity, and also the intensity of their effect. The planning factors affect the productivity more than other factors and need to be addressed in construction projects, particularly tall residential building projects.

LIMITATIONS AND SUGGESTIONS FOR FURTHER STUDY

Firstly, the models developed in this study can be used for tall residential buildings with RCC framed structure of column-beam-slab construction. However, they cannot be used for the construction of composite structures with structural steel.

Secondly, these models will be useful in construction involving a combination of resource input in the form of manpower and equipment. However, these will not be useful for fully mechanised projects or fully manpower-oriented projects without equipment.

Thirdly, these models can be best applied in South Asian developing countries which follow a certain pattern of construction, with a combination of manpower and equipment resources in similar environmental and climatic conditions, especially with similar periods of monsoon and non-monsoon. If the operational and climatic conditions are different, then they may not have much applicability. Further, it is possible to extend the benefit of the models to other construction activities like fagade work, interior works, etc, for which the equipment and labour requirement will be different from those of the activities covered in this study.

CONFLICT OF INTEREST

The authors declare that there is no conflict of interest regarding the publication of this paper.

REFERENCES

Al-Zwainy, F M S, Abdulmajeed, M H & Aljumaily, H S M 2013. Using multivariable linear regression technique for modelling productivity construction in Iraq. Open Journal of Civil Engineering, 3(3): 127-135. [ Links ]

Antunes, R & Gonzalez, V 2015. A production model for construction: A theoretical framework. Buildings, 5(1): 209-228. [ Links ]

Attar, A A, Gupta, A K & Desai, DB 2014. A study of various factors affecting labor productivity and methods to improve it. IOSR Journal of Mechanical and Civil Engineering, 14(1): 11-14. [ Links ]

Chigara, B & Moyo, T 2014. Factors affecting labor productivity on building projects in Zimbabwe. International Journal of Architecture, Engineering and Construction, 3(1): 57-65. [ Links ]

Dai, J, Goodrum, P M, Maloney, W F & Srinivasan, C 2009. Latent structures of the factors affecting construction labor productivity. Journal of Construction Engineering and Management, 135(5): 397-406. [ Links ]

Economic Report of the President 2016. Report submitted to the US Congress, February 2016. Available at: http://www.presidency.ucsb.edu/economic_reports/2016.pdf. [ Links ]

Elbakheit, A R 2012. Why tall buildings? The potential of sustainable technologies in tall buildings. International Journal of High-Rise Buildings, 1(2): 117-123. [ Links ]

Enhassi, A, Mohamed, S, Mustafa, Z A & Mayer, P E 2007. Factors affecting labor productivity in building projects in the Gaza Strip. Journal of Civil Engineering and Management, 13(4): 245-254. [ Links ]

Gulati, A 2016. Building cities for tomorrow. Available at: http://www.financialexpress.com/economy/building-cities-for-tomorrow/242301. [ Links ]

Gundecha, M M 2012. Study offactors affecting labor productivity at a building construction project in USA - Web survey. MSc dissertation. Fargo, ND: North Dakota State University. [ Links ]

Gupta, V & Kansal, R 2014. Improvement of construction labor productivity in Chambal Region. International Journal of Research in Engineering and Technology, 3(10): 34-37. [ Links ]

Jrade, A, Markiz, N & Albelwi, N 2012. An economical operation analysis optimization model for heavy equipment selection. International Journal of Social, Behavioral, Educational, Economic, Business and Industrial Engineering, 6(1): 146-151. [ Links ]

Mistry, S & Bhatt, R 2013. Critical factors affecting labor productivity in construction projects: Case study of South Gujarat Region of India. International Journal of Engineering and Advanced Technology, 2(4): 583-591. [ Links ]

Nguyen, D L & Nguyen, T H 2013. Relationship between building floor and construction labor productivity. Engineering, Construction and Architectural Management, 20(6): 563-575. [ Links ]

Patil, R 2015. Estimating construction equipment productivity and economics using stochastic methods. International Journal of Research in Engineering, Science and Technologies, 1(8): 341-346. [ Links ]

Robles, G, Stifi, A, Jose, L, Ponz-Tienda & Gentes, S 2014. Labour productivity in the construction industry: Factors influencing the Spanish construction labour productivity. International Journal of Civil, Environmental, Structural, Construction and Architectural Engineering, 8(10): 1061-1070. [ Links ]

Santosh, V & Apte, M R 2014. Productivity in building construction. IOSR Journal of Mechanical and Civil Engineering, 10(5): 64-71. [ Links ]

Shashank, K, Hazra, S & Pal, K N 2014. Analysis of key factors affecting the variation of labour productivity in construction projects. International Journal of Emerging Technology and Advanced Engineering, 4(5): 152-160. [ Links ]

Wang, F 2005. On-site labour productivity estimation using neural networks. Available at: http://spectrum.library.concordia.ca/8516/1/MR10224.pdf(accessed on 13 March 2016). [ Links ]

Zayed, T M & Halpin, D W 2005. Productivity and cost regression models for pile construction. Journal of Construction Engineering and Management, 131(7): 2-12. [ Links ]

Correspondence:

Correspondence:

Dr M K Parthasarathy

Department of Civil Engineering Anna University Chennai

600025, India

T: +91 44 2259 7377

E: balaji_parth@hotmail.com

Drr Murugasan

Department of Civil Engineering Anna University Chennai

600025, India

T: +91 44 2235 8178

E: murugasanr@rediffmail.com

Ramya Vasan

Larsen & Toubro Limited Construction Division

Chennai 600089, India

T: +91 44 2259 7378

E: ramya.vasa@gmail.com

DR M K PARTHASARATHY works as Senior Deputy General Manager in the Construction Division of Larsen & Toubro Limited, an Indian multinational engineering company. He is currently Head, Project Controls, for the construction of a 220 m high-rise building comprising a Hotel Tower (350 keys) and Residential Tower (150 high-end apartments) in Colombo, Sri Lanka; the project has a contract value of USD 354 million. He is a civil engineer by profession and has more than 25 years' experience in construction and project management. His interests include management information systems, procurement and execution of major construction engineering projects. He also conducts in-house training programmes in the aforementioned areas for the knowledge enhancement of company employees.

DRR MURUGASAN works as Associate Professor in the Institute of Remote Sensing, Department of Civil Engineering, College of Engineering Guindy, Anna University College of Engineering, one of the premier institutions in India, established in 1794. His teaching interests include highway engineering, construction management and remote sensing. He is a civil engineer by profession and has more than 30 years' experience in the aforementioned fields. He has done more than 16 000 hours of teaching to under- and post-graduates in engineering, and has guided 11 PhD research scholars. He is also a consultant for many private and government agencies in the field of coastal zone management, using satellite remote sensing.

RAMYA VASAN works as Manager, Procurement in the Construction Division of Larsen & Toubro Limited, an Indian multinational engineering company. She specialises in the procurement of civil and architectural items. She has good knowledge of construction management, and also of management information systems related to construction management. She is also an expert in costing and the review of costing in construction projects. A civil engineer by profession, she has accumulated 11 years' experience, working for the same company.