Serviços Personalizados

Artigo

Indicadores

Links relacionados

-

Citado por Google

Citado por Google -

Similares em Google

Similares em Google

Compartilhar

Journal of the South African Institution of Civil Engineering

versão On-line ISSN 2309-8775

versão impressa ISSN 1021-2019

J. S. Afr. Inst. Civ. Eng. vol.60 no.2 Midrand Jun. 2018

http://dx.doi.org/10.17159/2309-8775/2018/v60n2a2

TECHNICAL PAPER

Performance of thermoplastic road-marking material

S Naidoo; W J vd M Steyn

ABSTRACT

The most important aspect of road markings is that they must be retroreflective. The minimum night-time visibility (retroreflectivity) (RL) for white and yellow road markings must be 100 mcd/m2/lx and 70 mcd/m2/lx respectively. There are also other important parameters to which road markings should conform, such as the day-time visibility (luminance) (Qd), colour and skid resistance. The South African Bureau of Standards (SABS) regulations on plastic road-marking materials are insufficient, and therefore road-marking applicators could be applying inferior quality plastic road-marking materials. Since the European specifications are widely adopted by many countries, the BS EN 2007 specification was used in conjunction with the available South African standards in this study to determine the performance of thermoplastic road-marking materials. Retroreflectivity testing is important in controlling the final road-marking product.

The objectives of this study were:

■ To determine the RL and Qd service lives of various road-marking paints and road-marking materials on asphalt and chip seal road surfaces.

■ To determine if there are significant differences in RL, Qd and the colour of the road markings when washed with liquid soap mixed with water and hard brooms.

■ To check if the colour and skid resistance of the applied road markings comply with the specification.

Based on the data obtained from the study, the following conclusions were drawn:

■ The RL and Qd service lives of various road-marking paints and road-marking materials on asphalt and chip seal road surfaces were determined as between 1 and 48 months, and 1 and 30 months respectively.

■ There was no significant increase in RL or colour compliance of the washed road markings, while there was generally an increase in Qd after washing the test markings.

■ White road markings generally complied with the colour specification, while yellow road markings did not comply with the specification.

■ The initial skid resistance of white and yellow 1.2 mm thermoplastic road markings complied with the specification, while all other road markings did not comply with the specification.

Keywords: retroreflectivity, luminance, skid resistance, colour

INTRODUCTION

Public roads without road markings, especially roads carrying high traffic volumes, would lead to chaos and accidents resulting in injuries and loss of life. The road authorities need to ensure that all signage, i.e. horizontal (road markings) and vertical (traffic signs), are well maintained and conform to the Southern African Development Community Road Traffic Signs Manual (SADC RTSM) (SADC 1997) and the South African Road Traffic Signs Manual (SARTSM) (1999).

According to Letsoalo (2012), there are approximately 27 road accident fatalities per 100 000 in South Africa, while globally it is approximately 10.3 road accident fatalities per 100 000. Approximately 14 000 people are killed annually on the roads in South Africa. Middle and low-income countries with low vehicle ownership experienced high road fatality rates compared with high-income countries with high vehicle ownership (Letsoalo 2012). This could be attributed to the lack of road safety awareness campaigns, and the lack of maintenance of roads and roadside furniture. The contributing factors to the high number of road accident fatalities are human factors, vehicle factors, road factors and environmental factors (Letsoalo 2012). The highest percentage of road accidents occur at night, and this is the main reason for road markings to be retroreflective in order to guide the road user. It may not necessarily be that the road accidents have occurred as a result of defective road markings, but as road authorities have a certain degree of control over road markings, the authorities should ensure that the markings are continuously maintained to the required standards to eliminate road markings as a possible cause of accidents. According to Martin et al (1996), an effective road-marking system facilitates driver guidance, improves traffic flow, contributes to driving comfort and enhances traffic safety.

BACKGROUND

The most important aspect of road markings is that it must be retroreflective (brightness at night under headlights). The minimum RL for white and yellow road markings must be 100 mil-licandelas/m2/lux (mcd/m2/lx) and 70 mcd/m2/lx respectively (SADC RTSM) (SADC 1997). There are other important parameters that road markings should conform to, such as Qd, colour, and skid resistance. There are various types of road-marking paints and road-marking materials, namely solvent-borne, waterborne, cold plastic, thermoplastic and preformed tape applied universally. In South Africa, solvent-borne paints, waterborne paints and thermoplastic materials are widely used, with cold plastic materials being increasingly used of late. There are SABS standards on solvent-borne and waterborne road-marking paints covering a wide range of aspects. However, there are insufficient standards on plastic road-marking materials, and road-marking applicators could therefore be applying inferior quality plastic road-marking materials.

The Committee of Land Transport Officials (COLTO) (1998) specifications refer to the use of hot melt thermoplastic as a possible road-marking material, subject to its specification in the project specifications. No further guidance or specifications for this material are given. Thermoplastic road-marking material is a 100% solid, environmentally and user-safe compound which consists of binder, pigment, filler and intermix glass beads. There are various suppliers of raw materials from countries such as the UK, US, China, India, Singapore and Saudi Arabia. Some of the local suppliers in South Africa are importing the constituents and formulating the mix, which is sold to road-marking applicators who then apply it on the road network. It is important to draw up a specification and establish testing systems to ensure that imported road-marking materials are suitable for the environment and climate, and that it should perform to at least a certain degree. There is little published information specific to South African road-marking practices and materials, and it remains necessary that on-going attention be given to the development of the local road-marking materials and their application. It is advised in the SARTSM (1999) that each road authority should develop its own estimated service life based on local conditions and experience, due to the variations in the parameters associated with the service life of road-marking paints and materials.

Although thermoplastic road markings have been in use for a number of years, there is little agreement on their service life. The problem arises in attempting to establish an expected service life of a particular material on a given roadway. There are too many factors influencing performance to permit an average life to be predicted with any confidence without carrying out research. The South African National Roads Agency Limited (SANRAL) has adopted a performance-based specification in its road-marking contracts. The specification indicates only the required RL, but experience has shown that some of the important performance standards may not be satisfactory. For example, yellow road markings tend to look white at night and in South Africa yellow road markings have a different meaning to white road markings, and as such could lead to the wrong action taken by the driver. In the City of Tshwane (CoT) the current road-marking maintenance programme is determined mostly by the visibility of the road marking. This is not objective, since each engineer may view the road markings differently, and as such there may be inconsistencies in the road-marking maintenance programme over the city roads.

TYPES OF ROAD-MARKING PAINTS AND MATERIALS

There are various types of road-marking materials available which vary in price and performance. Commonly used road-marking materials include solvent-borne and waterborne paints, thermoplastic (including preformed tape) and cold plastic. The most common road marking applied in South Africa for many years has been the solvent-borne paint, as it has been the cheapest in the market and readily available, being locally manufactured. Solvents contain volatile organic compounds (VOCs) which are carcinogenic. Concern over carcinogens prompted research to develop other pavement marking materials that contain no or lesser quantities of carcinogens, hence the introduction of thermoplastic road-marking materials (Martin et al 1996).

Although South Africa does not have a thermoplastic road-marking material standard, there are good EN standards that could be written into contract documents to ensure quality control of the road-marking product.

ROAD-MARKING STANDARDS

The standards commonly used for road-marking materials worldwide are:

-

American Association of State Highway and Transportation Officials (AASHTO) Standards

-

British Standards (BS)

-

European Standards (EN). Almost all national standards are based on one or the other of these standards. BS has merged with EN and thus the current BS for thermoplastic road markings is BS EN 2007. The original road-marking standard (BS 3262) was what is known as a "recipe" standard. It specified the percentage of each material to be included in the thermoplastic. Recipe standards have been discontinued for two decades in Europe, but are still widespread elsewhere in the world. Many countries are now switching to performance-based standards.

A recipe-based specification dictates to the manufacturer what has to be included in the material in terms of the ingredients. Any particular thermoplastic made to this specification may perform well or badly, depending on the quality of the raw materials used, the skill with which they are blended and the application, but poor performance is not the manufacturer's problem, as the manufacturer has met the specification. A performance-based specification, on the other hand, allows the manufacturer to use whatever raw materials he chooses, but it lays down the performance standards that the thermoplastic road marking must meet in use.

THERMOPLASTIC ROAD-MARKING MATERIAL

Thermoplastic road-marking material is a mixture of glass beads, binder, pigment and filler material. Dry thermoplastic compound is generally heated in a thermostatically controlled pre-heater or boiler to a temperature of 220°C and agitated continuously until a homogenised liquid is achieved, before transferring it to an application vehicle (AASHTO 2016). The hot, melted liquid is applied onto the road surface with drop-on glass beads added on top to produce high initial RL as may be stipulated in the specifications of the road authority. The material usually dries within a short space of time.

Glass beads

Road markings must be applied with glass beads on roads where RL is required. The retroreflection of road markings in wet or rainy conditions is much lower than in dry conditions, and as such the road markings should be enhanced with special properties to improve the RL (BS EN 2007).

Drop-on glass beads are applied to the surface of both thermoplastic markings and liquid paint markings through a bead dispenser which should be an integral part of any paint sprayer. Glass beads are fed onto the paint by means of a mechanical process or by gravity. Thermoplastic road markings also contain intermix beads which become exposed as the surface of the thermoplastic wears off, thereby producing Rl throughout most of its service life. The added advantage of glass beads is that it provides skid resistance. The important properties of glass beads to be analysed in order for the beads to perform optimally include gradation, refractive index, roundness and clarity, and coating (Gates et al 2003; Miglets et al 1994).

Binder

Binder (resin) is the constituent that provides adhesion to the road surface and the other constituents (the pigments, fillers and glass beads (SS 2002a). An effective road marking system requires not only quality glass beads, but also a quality binder. If either part of the road marking system is not good, or they are not installed properly, then the road marking system will not perform as well as it could.

Pigment

Pigment is a fine powder added primarily to impart colour and opacity to the mixture. Titanium dioxide (TiO2) is a common reflective pigment used in white road markings, and higher levels in RL can be achieved by adding more TiO2 (Smadi et al 2013). Too much used in yellow road markings may result in the road markings appearing a lighter yellow, and this is usually observed on road markings where a high initial RL is specified.

Filler

Filler is a powder added to assist the dispersion of the pigment, thereby providing colour uniformity throughout the mix (SS 2002a). Fillers are made up of a mixture of calcium carbonate, sand and other inert materials to impart body to the mixture. The filler is also an important constituent to ensure that RL is achieved, as well as for the daylight appearance of the road markings.

APPLICATION OF THERMOPLASTIC ROAD-MARKING MATERIALS

Thermoplastic road-marking materials can be applied in either a liquid or a solid form. Liquid thermoplastic is applied in three ways, namely by spraying, extruding or by screed (TMRS 2012). Thermoplastic in a solid form is commonly referred to as preformed thermoplastic.

Spray thermoplastic

Spray thermoplastic is applied by mobile equipment at a rapid application rate and dries almost instantly. This results in the requirement for minimal traffic accommodation and shorter periods of road closures, which reduce travel time delays. Spray thermoplastic is usually applied at a thickness of 1.2 mm in South Africa, while in most European countries the minimum application thickness is 1.5 mm, and 2 mm in the US. In Australia spray thermoplastic is applied at 2 mm (TMRS 2012). One of the reasons for thermoplastic road marking being applied thicker in Europe and the US is due to the scraping away of some of the thermoplastic under the action of the snowplough where snow has settled on the road. The other reason is that the US, Australia and Europe consider road safety as a high priority and allocate sufficient budgets for road-marking maintenance.

Extruded thermoplastic

Extruded thermoplastic is also applied by mobile equipment, but the mix design of the material is different and the viscosity is also higher than spray thermoplastic. The applied product takes a longer time to dry than spray plastic, as it is usually applied at a thickness of 3 mm in South Africa. In Singapore extruded thermoplastic is applied between 2.5 mm and 3 mm, while in Europe and the US it is applied up to 5 mm and 4.8 mm respectively (SS 2002b; AASHTO 2016).

Screed thermoplastic

Screed thermoplastic is generally applied by manual hand-push equipment for small road markings, such as transverse road markings, arrows, words and symbols. Thermoplastic that is required to be applied thicker than 2 mm for small markings is usually applied by the screed method.

Preformed thermoplastic

Preformed thermoplastic which is manufactured in sheets (commonly 600 mm χ 900 mm) will have to be cut up into the road marking size required before application (TMRS 2012). The road surface must be cleaned and then the cut-up preformed thermoplastic is placed in its final position and heated with the flame of a blow torch to between 150°C and 180°C (TMRS 2012). It is usually manufactured to a thickness of 3 mm, and the dry film thickness is approximately 2 mm after application onto the road surface. It can be seen that, due to the manufactured sheet size, preformed thermoplastic will be more conducive as road marking arrows and symbols. It is also an ideal product to be used as Control of Speed by Illusion (COSBI) lines for traffic calming purposes.

METHODOLOGY

Road trials of permanent road markings should be conducted over the full climatic cycles of at least one year (BS EN 2011; SANS 2006a; SANS 2006b). The SABS conducts road trials only on transversely applied test markings (SANS 2006a; SANS 2006b). According to BS EN (2011), the test markings are applied transversely and longitudinally on a flat asphalt road which has been established for at least a year.

RESEARCH DESIGN

The following activities were undertaken as part of this study:

-

Nine roads were selected, which included asphalt roads and chip seal roads, both new and long established. The roads were categorised into "clean asphalt surfaced roads" (roads that are self-cleansing, for example when it rains and sand from the edge of the road is washed onto the road, the sand will flow into the stormwater system due to the effective gradient and efficient storm-water system), "dirty asphalt surfaced roads" (sub-standard roads resulting in sand remaining on the roads due to the ineffective gradient and also due to a lack of stormwater systems), "clean sealed roads" and "dirty sealed roads".

-

A link of the road, as can be seen in Figure 1, was selected, and at least two blocks of transverse markings were applied, depending on the length of the link. A set of transverse markings comprised various types of road markings, namely waterborne road-marking paints, cold plastic and thermoplastic road-marking materials.

-

A block of transverse test road markings was made up of three sections of various white and yellow road-marking paints and materials, as can be seen in Figure 2. Each road marking was applied to a width of 150 mm, as recommended in SANS (2006a) with a gap of 200 mm over the width of a lane selected.

-

The positions of the longitudinal test road markings were also broken up into blocks, similar to that of the transverse test road markings.

-

The test road markings were applied on clean, dry surfaces and the temperature of the road surface was greater than 10°C, as recommended in COLTO (1998).

-

The test road markings were applied on the road surface as follows: waterborne road-marking paints (0.42 l/m2), cold plastic (1 mm), and thermoplastic (1.2 mm and 3 mm). The road-marking paints and materials were applied on test plates at the same time when applying the test road markings on the road surface to ensure that the correct application rates were achieved.

-

Initially five service providers agreed to provide road-marking paints and road-marking materials. At the time of applying the road-marking paints and materials, only four service providers kept to the arrangements. The acronym SP1 means service provider one, SP2 means service provider two, and so on.

-

The traffic counting system was set up such that the traffic counts were obtained from the lane where the transverse test road markings were applied. The counts were obtained over 14 consecutive days during a period while schools were operational, and converted into Annual Average Daily Traffic (AADT).

The following road-marking paints and materials (both white and yellow) were applied on the test sites:

-

Waterborne road-marking paint which conformed to SANS (2006b)

-

Imported waterborne road-marking paints

-

Cold plastic road-marking material blended in South Africa

-

Imported cold plastic road-marking material

-

Thermoplastic road-marking material blended in South Africa

-

Imported thermoplastic road-marking material.

DATA ANALYSIS AND FINDINGS

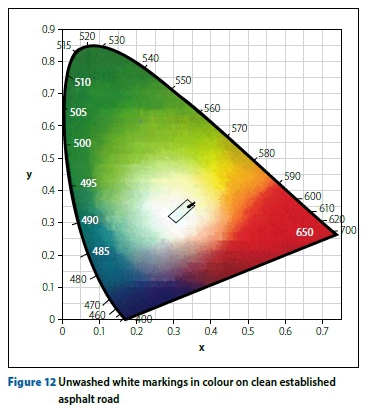

According to the SADC RTSM (SADC 1997), the minimum RL for used white and yellow road markings must be 100 mcd/m2/lx and 70 mcd/m2/lx respectively. These values were used to determine the Rl service life of the test road markings in this study. There is no standard published by the SABS with regard to Qd on road markings, hence the BS EN (2007) specification was used to analyse this parameter. According to BS EN (2007), the minimum Qd for white and yellow road markings must be 100 mcd/m2/lx and 80 mcd/m2/lx respectively. These values were used to determine the Qd service life of the test road markings in this study. There is a possible error with the colour coordinates indicated in Table 7.2 of the SADC RTSM (SADC 1997), as the coordinates indicated for the yellow road-marking colour specification do not form a logical envelope when plotted on the chromaticity diagram.

Therefore the BS EN (2007) specification was used to analyse the colour parameter. For the colour test, the calculated values of the actual measurements of the test road markings were plotted on the graph to determine if the white and yellow test road markings conformed to the colour range. According to Table 7.2 of the SADC RTSM (SADC 1997), the minimum skid resistance of white and yellow road markings must be 50 Skid Resistance Test (SRT) units.

Although the markings were analysed in the unwashed and washed condition, the service lives of the test markings in RL, Qd and colour are that of the markings in the unwashed condition, as road markings are generally viewed by road users in the dirty condition. Both unwashed and washed road marking graphs are presented to indicate the differences in the decline of RL, Qd and colour.

The use of non-parametric methods was applied to compare group means of the various types of road-marking paints and materials due to the small sample size.

When comparing between two groups, Friedman's Chi Square Test was used. Descriptive statistics were used to indicate the mean, Standard Deviation (SD) and Coefficient of Variation (CV).

EXAMINATION OF THE TEST ROAD MARKINGS

Four sets of RL, Qd and colour measurements were conducted over at least one year on the applied test road markings. The first set of measurements on RL and Qd was conducted within a month of application of the test road markings, and the remaining three sets of measurements were conducted more or less evenly, depending on the availability of the testing equipment and weather conditions. The first set of colour measurements was conducted approximately four months after the application of the test markings, due to the unavailability of the machine. The measurements were conducted during the day under appropriate traffic accommodation according to the SARTSM (1999). Only one set of skid-resistance measurements was conducted on the test plates in a laboratory. White and yellow test markings were applied on nine different roads, but the detailed analysis of the long-established clean asphalt road (Middel Street in the City of Tshwane (Figure 3)) is presented in this paper.

Measuring retroreflectivity

The LTL-X retroreflectometer (Figure 4) was used to measure RL. Nine measurements were conducted on each test road-marking line applied. Three measurements each were conducted in the region of the left and right wheel part of each transverse test road-marking line painted, and three measurements were conducted towards the centre of each of the transverse road-marking lines painted. Two sets of measurements were conducted during the same day on transverse lines. The first set of measurements was conducted on the test road markings as found on that day, and the second set of measurements was conducted after washing the test road markings with liquid soap added into clean drinkable water with brooms and left to dry. Nine measurements were conducted over the length of the white and yellow longitudinal test road markings. The measurement points were distributed more or less evenly over the length of the longitudinally applied test road markings. The longitudinal lines were only measured in the dirty condition, as the washing of only the transverse markings was sufficient to identify if there were significant differences in the various parameters in the "dirty" and "washed" condition. The Rl value was established as the average of a number of measurements conducted with shifts of the instrument in steps along the marking.

Measuring luminance

The LTL-XL (Figure 5) was used to measure Qd. The number of Qd measurements conducted was equal to the number of RL measurements conducted in the dirty and washed condition. Similar to RL, the Qd value was established as the average of a number of measurements conducted with shifts of the instrument in steps along the marking.

Measuring colour

An X-Rite Model SP60 colour machine (Figure 6) was used to conduct the measurements of the test road markings. When conducting measurements with this machine, the tristimuli values of X, Y and Z are obtained and converted into chroma-ticity coordinates x and y which are plotted on the chromaticity diagram. According to the X-Rite manual, the formulae to calculate x and y are as follows:

Measuring skid resistance

A British Portable Pendulum skid resistance tester (Figure 7) was used to measure the skid resistance of the test markings applied on the test plates. A pendulum fitted with a spring-loaded slider at its free end was released from a fixed position, and the frictional energy loss caused by the dragging motion of the rubber rear edge of the slider over the markings was measured and expressed in SRT units. The test method used was in accordance with SANS 6260 (SANS 2007).

DISCUSSION OF THE FOUR PARAMETERS

Retroreflectivity

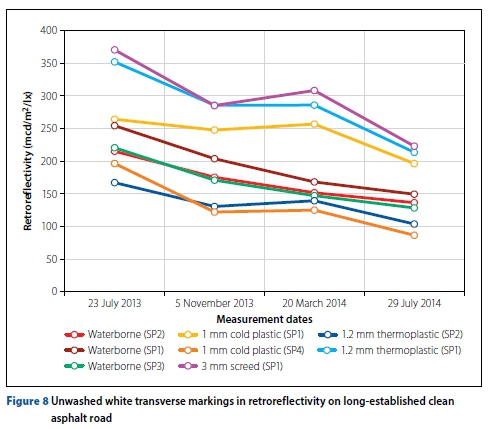

There was generally no significant increase in the RL service life of the washed test road markings, as can be seen in Table 1, and Figures 8 and 9. Some of the unwashed white test road markings had a longer RL service life than washed markings. There could be a few possible reasons for this, namely:

-

The measurements of the washed markings could have been conducted before the road markings were completely dry, which possibly reduced the RL measurements after washing.

-

The method of washing the markings was not very effective.

-

The measurements might not have been conducted at the exact spot before washing and after washing the markings.

A certain amount of dirt on road markings do not make a significant difference in the RL.

Possible removal of glass beads could have happened while washing the markings with hard brooms.

Luminance

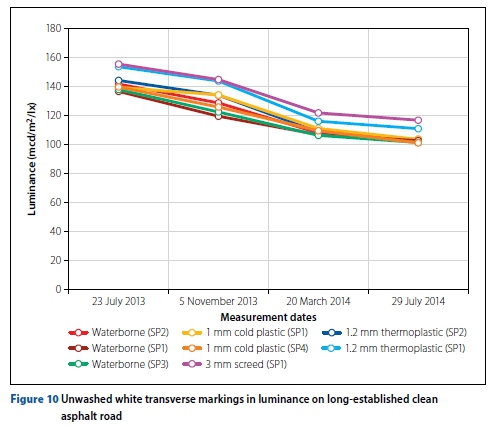

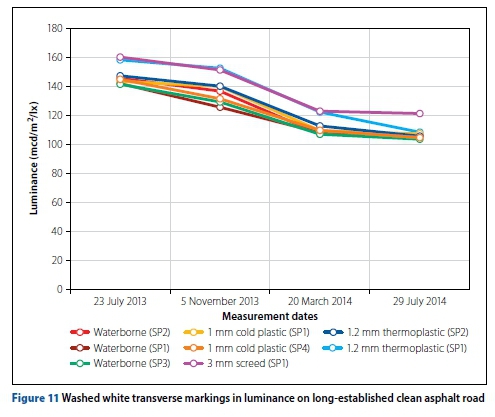

There was generally an increase in the Qd measurement values of the washed test road markings, as can be seen in Table 2, and Figures 10 and 11. As a result of this, some of the washed markings produced a longer Qd service than the unwashed markings. The possible reasons for the increase in the Qd after washing are:

-

The fines from the sand particles which had been stuck to the test road markings were removed to a certain extent, exposing more of the actual area of the road marking.

-

Some of the oils and exhaust fumes were removed from the test road markings

Colour

Higher percentages of the later measurements in some instances fell into the compliance regions, as can be seen in Table 3, and Figures 12 and 13. The possible reasons are:

-

The measurements might not have been conducted on the exact spot, as the machine measures only approximately 1 cm in diameter.

-

The rains might have cleaned the markings.

The washing of road markings generally did not positively contribute to colour compliance. Although the colour of road markings complied in a few instances with the specification after being washed, road markings are generally not washed by the road authorities, and also the rainy season is usually of limited duration.

Skid resistance

The skid resistance of the test road markings was conducted on test plates in the laboratory, which might not be a true reflection of the road markings on the road surface. It is likely that the skid resistance of the road markings applied on the road surface will be higher due to the roughness of the road surface, especially road markings applied onto chip seal surfaces. The skid resistance of road markings is important, especially for motor cyclists in urban areas (De Witt et al 2000). The high percentage of area that is covered with road markings ahead of intersections is extremely dangerous for motor cyclists if the skid resistance is not up to standard (De Witt et al 2000).

RETROREFLECTIVITY SERVICE LIFE OF WHITE TRANSVERSE MARKINGS

All the test road markings, except for 1 mm cold plastic (SP4), applied on the long-established clean asphalt road, were higher than the minimum specification of 100 mcd/m2/lx over the four measurement periods, as can be seen in Table 1 and Figure 8. In the fourth measurement period, the Rl mean of 1 mm cold plastic (SP4) was 86.7 mcd/m2/lx.

The cold plastic and thermoplastic road marking materials generally declined over the year. However, it can be seen in Table 1 and Figure 8 that the RL mean of some of the measurements conducted later were higher than the Rl mean values of the measurements conducted earlier. For example, the Rl mean of unwashed 1.2 mm thermoplastic (SP2) was 130.7 mcd/m2/lx on 5 November 2013, and the same marking was 139.4 mcd/m2/lx on 20 March 2014, which is 4.5 months later. The intermix beads in the plastic road marking materials became exposed over time as a result of the wheels of the vehicles passing over the road markings, which contributed positively to the RL.

Waterborne (SP1, SP2 and SP3), 1 mm cold plastic (SP1), 1.2 mm thermoplastic (SP1 and SP2) and 3 mm thermoplastic (SP1) produced Rl service lives of more than 12 months. The average decline in RL of all test markings over the year was approximately 40%, and if the decline continues at the same rate, then thermoplastic materials will produce a Rl service life of approximately two years. Although most of the test road markings applied on Middel Street complied with the specification for more than a year, the Rl means of 1.2 mm thermoplastic (SP1) and 3 mm thermoplastic (SP1) were in the region of 200 mcd/m2/lx after a year. This is an indication that thermoplastic road marking materials are much more durable on clean asphalt roads, compared with waterborne road marking paints, which seem to start getting closer to the minimum RL of 100 mcd/m2/lx after a year.

The fact that there is no overlap between the 95% CIs of the first and last measurements, as can be seen in Figure 14, is an indication that the difference between them is statistically significant. Friedman's Chi Square Test revealed that there is at least one pair of measurements over time that is significantly different within each of the different road-marking paints and materials, and referring to Figure 14 it seems as though these differences exist at least between the first and last repetitions.

LUMINANCE SERVICE LIFE OF WHITE TRANSVERSE MARKINGS

All the test road markings applied on the long-established clean asphalt road were higher than the minimum specification of 100 mcd/m2/lx over the four measurement periods, as can be seen in Table 2 and Figure 10. The average decline in Qd of all test markings over the year was approximately 26%. If the decline in Qd continues at the same rate, 1.2 mm thermoplastic (SP1) and 3 mm thermoplastic (SP1) will produce Qd service lives of approximately 15 months and 17 months respectively. All the other road marking paints and materials produced Qd service lives of approximately one year.

The fact that there is no overlap between the 95% CIs of the first and last measurements, as can be seen in Figure 15, is an indication that the difference between them is statistically significant. Friedman's Chi Square Test revealed that there is at least one pair of measurements over time that is significantly different within each of the different road marking paints and materials, and referring to Figure 15 it seems as though these differences are at least between the first and last repetitions.

SKID-RESISTANCE ANALYSIS OF MARKINGS ON THE TEST PLATES

Only white waterborne (SP3), 1 mm cold plastic (SP1 and SP4), white 1.2 mm thermoplastic (SP1) and yellow 1.2 mm thermoplastic (SP1) complied with the minimum specification of 50 SRT units. All other test markings were between 35 and 45 SRT units. It is likely that the skid resistance of road markings will be higher on the road surface due to the combined effect of the road surface and the markings. Road-marking applicators need to consider increasing the amount of antiskid aggregates to improve the skid resistance of the markings.

COLOUR ANALYSIS OF MARKINGS

The white test road markings generally complied with the BS EN (2007) specification except for 1.2 mm thermoplastic (SP2) after one-and-a-half years of application. Figures 12 and 13 indicate the graphical positions of the white test road markings on the chromaticity diagrams.

PERFORMANCE OF THERMOPLASTIC ROAD MARKING MATERIAL

Based on the data obtained from the study, the performance of thermoplastic road-marking materials in RL, Qd, colour and skid resistance is summarised in Table 4. It can be seen that even though the traffic volumes were higher on some of the clean roads than on the dirty roads, the service life of thermoplastic was higher on the clean roads than on the dirty roads. For example, on the long-established clean asphalt road, 1.2 mm thermoplastic produced an RL service life of more than 12 months while it produced between one and six months on the long-established dirty asphalt road, as can be seen in Table 4. Although thermoplastic road-marking materials are generally known to produce high RL over long periods of time, the outcome of the study indicates that RL is not maintained for long periods on dirty type roads. It can be seen that road authorities are applying thermoplastic road marking materials that do not comply with the yellow colour specification. It can be further seen that the skid resistance of 3 mm thermoplastic road-marking material did not comply with the specification.

CONCLUSIONS

Based on the data obtained from the study, the following conclusions are drawn:

-

The Rl and Qd service lives of various road-marking paints and road marking materials on asphalt and chip seal road surfaces were determined as between 1 and 48 months and 1 and 30 months respectively. The range in service lives were wide, due to the low service lives of waterborne road-marking paints on dirty roads and high service lives of plastic road-marking materials on clean roads.

-

There was no significant increase in RL or colour compliance of the washed road markings, while there was generally an increase in Qd after washing the test markings.

-

White road markings generally complied with the colour specification, while yellow road markings did not comply with the specification.

-

The initial skid resistance of white and yellow 1.2 mm thermoplastic complied with the specification, while all other road markings did not comply with the specification.

As RL is the most critical parameter in road markings, the type of road-marking selection should be mainly based on the RL service life, but due consideration should be given to the other three parameters, namely the luminance, colour and skid resistance. For example, specifying a very high RL on yellow road markings may result in the service provider applying lighter shade yellow markings, which may cause confusion at night, because the markings will tend to look white in colour. There can be a certain degree of compromise, as all parameters cannot be easily achieved together, as indicated in BS EN (2007). Retroreflectivity measurements should not simply be rejected, especially if the values are close to the specification on thermoplastic road-marking material, since the values can increase when the road-marking material is worn away by the action of the tyres. More test points should be considered, or measurements should be conducted a few days later.

Although thermoplastic road-marking materials generally produced the longest service life, especially in respect of RL, it might not be cost-effective to apply them on roads where they will have similar service lives to those of cheaper road-marking paints, such as waterborne. After classifying the roads into the dirty and clean categories, and using the tendered rates, a more realistic road-marking budget can be requested. The outcome of the results on the applied test road markings was not affected by extraordinary weather conditions, as the rainfall and temperature were similar to those of previous years.

The SABS should seriously consider continuing the work it started in developing a national thermoplastic road-marking standard, which will offer much guidance to all stakeholders involved.

ACKNOWLEDGEMENT

The authors would like to thank the City of Tshwane for the funding made available to execute this research project.

DISCLAIMER

This paper reflects the views of the authors, who are responsible for the facts and the accuracy of the data presented herein.

REFERENCES

AASHTO (American Association for State and Highway Transportation Officials) 2016. M249-12 2012. Standard Specification for White and Yellow Reflective Thermoplastic Striping Material (Solid Form). Washington, DC: AASHTO. [ Links ]

BS EN (British Standard) 2007. BS EN 1436:2007. Road Marking Materials: Road Marking Performance for Road Users. London: British Standards Institution. [ Links ]

BS EN (British Standard) 2011. BS EN 1824 2011. Road Marking Materials - Road Trials. London: British Standards Institution. [ Links ]

COLTO (Committee of Land Transport Officials) 1998. Standard Specifications for Road and Bridge Works for State Road Authorities. Halfway House, South Africa: SAICE. [ Links ]

De Witt, A J, Smith, R A F & Visser, A T 2000. Durability and cost effectiveness of road marking paint. Paper presented at the Nineteenth South African Road Transport Conference, 17-20 July, Pretoria. [ Links ]

Gates, T J, Hawkins, H G & Rose, E R 2003. Effective pavement marking practices for sealcoat and hot-mix asphalt pavements. Report No. 0-4150-4. College Station, TX: Texas Transportation Institute, Texas A&M University. [ Links ]

Letsoalo, C P 2012. State of the road safety report. Paper presented at the Second South African Road Federation / Road Traffic Management Corporation Conference, 23-24 October, Johannesburg. [ Links ]

Martin, P T, Perrin, J, Jitprasithsiri, S & Hansen, B 1996. A comparative analysis of the alternative pavement marking materials for the State of Utah. Report prepared for the Utah Department of Transportation Salt Lake City, UT: University of Utah, Civil and Environmental Engineering Department. [ Links ]

Miglets, J, Fish, J K & Graham, J L 1994. Roadway Delineation Handbook. Publication No. FHWA-SA-93-001. Washington, DC: Federal Highway Administration. [ Links ]

SADC (Southern African Development Community) 1997. Uniform traffic control devices. In: Road Traffic Signs Manual, Vol 1, Chapter 7. Pretoria: Department of Transport. [ Links ]

SANS (South African National Standard) 2006a. SANS 731-1 2006. Road Markings: Single-pack Solvent-borne Paints. Pretoria: SABS Standards Division. [ Links ]

SANS (South African National Standard) 2006b. SANS 731-2 2006. Road Markings: Single-pack Water-borne Paints, Pretoria: SABS Standards Division. [ Links ]

SANS (South African National Standards) 2007. SANS6260 2007. Paints and Varnishes: Determination of Skid Resistance. Pretoria: SABS Standards Division. [ Links ]

SARTSM (South African Road Traffic Signs Manual) 1999. Regulatory and warning signs and markings applications, Vol 2, Chapter 3. Pretoria: Department of Transport. [ Links ]

Smadi, O, Hawkins, N, Bektas, B A, Carlson, P, Pike, A & Davies, C 2013. Predicting the initial retroreflectivity of pavement markings from glass bead quality. Report 743: Washington, DC: National Cooperative Highway Research Program, Transportation Research Board. [ Links ]

SS (Singapore Standard) 2002a. SS498: Part 1. Hot-applied thermoplastic road marking material, constituent materials and mixture. Spring, Singapore. [ Links ]

SS (Singapore Standard) 2002b. SS498: Part 2. Hot-applied thermoplastic road marking material, road performance. Spring, Singapore. [ Links ]

TMRS (Transport and Main Roads Specification) 2012. Technical Specification MRTS45 2012. Road Surface Delineation. Cairns, Queensland, Australia: Department of Transport and Main Roads. [ Links ]

Correspondence:

Correspondence:

Soma Naidoo

PO Box 1290, Pretoria 0001, South Africa

T: +27 12 358 4870

E: soma@tshwane.gov.za

Prof Wynand Steyn

Department of Civil Engineering, University of Pretoria

Private Bag X20, Hatfield 0028, South Africa

T: +27 12 42 0 2171

E: wynand.steyn@up.ac.za

SOMA NAIDOO (Pr Tech Eng) is a Deputy Director in the Roads and Transport Department at the City of Tshwane Metropolitan Municipality. He has a BSc (Hons) degree in Civil Engineering and an MSc degree in Transportation Planning, both obtained at the University of Pretoria. He has experience in the construction of roads and bridges, and is currently involved in infrastructure asset management. He is also a Professional Member of IMESA (Institute of Municipal Engineering of Southern Africa),

PROF WYNAND STEYN (Pr Eng, MSAICE) Is Head of the Department of Civil Engineering and full professor (focusing on road pavement related subjects) at the University of Pretoria. His research interests centre on vehicle-pavement interaction, accelerated pavement testing, pavement engineering, pavement materials and instrumentation. He has authored, co-authored and edited 27 journal papers, 20 book chapters (author / co-author / editor) and 97 conference papers. He is Associate Editor of the International Journal for Pavement Engineering and has a B3 National Research Foundation (NRF) rating. He is a Member of the South African Institution of Civil Engineering.