Servicios Personalizados

Articulo

Indicadores

Links relacionados

-

Citado por Google

Citado por Google -

Similares en Google

Similares en Google

Compartir

Journal of the South African Institution of Civil Engineering

versión On-line ISSN 2309-8775

versión impresa ISSN 1021-2019

J. S. Afr. Inst. Civ. Eng. vol.56 no.1 Midrand ene. 2014

TECHNICAL PAPER

Evaluation of the strength behaviour of unpaved road material treated with electrochemical-based non-traditional soil stabilisation additives

R J Moloisane; A T Visser

ABSTRACT

Travel along unpaved roads is not always assured, because of their low standards, poor riding quality, impassability in wet weather, and the danger in the quantity of dust that is generated by moving vehicles and wind. Stabilisation with electrochemical-based non-traditional soil stabilisation additives (chemical additives) may offer a solution to this continual problem.

The objective of this paper is to report on the strength behaviour of a typical marginal quality weathered quartz gravel material treated with two electrochemical-based non-traditional soil stabilisation additives, enzyme and sulphonated oil to assess their potential value for unpaved road construction under wet and dry conditions. These treated panels were trafficked under 100 vehicles per day. The evaluation was done by means of laboratory tests and field investigations for three years. The characteristics of the natural material and the binding ability of the non-traditional soil stabilisation additives were established from the laboratory testing. Density and moisture, and the strength development of the treated material were determined from field investigations.

These two non-traditional soil stabilisation additives appear to have affected the particles and their water component, hence an increase in densities was achieved. The degree of formation and paste surrounding the particles appeared to have varied with time and differed between the additives. An increase in density in the sulphonated oil additive treated panel occurred three months after construction, and a further increase was again noticed eight months after construction (five months thereafter). Up to eight months after construction, the enzyme additive treated panel showed a significant decrease in density, but showed a slight increase thirty-one months after construction. This increase in densities might probably be because of further densification by traffic. The variations in density were attributed to testing variability.

In the in situ and soaked DCP-CBR strength measurements, the sulphonated oil additive treated panel reached its maximum in situ strength at two months after construction, while the enzyme additive treated panel reached its maximum in situ strength at five months after construction. Up to eight months after construction, both treated panels indicated a significant decrease in both the in situ and soaked DCP-CBR strength conditions. The decrease was attributed to rain. There was, however, little evidence to show that the additives had improved the material, with the control panel being consistently stronger in both the in situ and soaked DCP-CBR conditions.

The importance of considering the time factor in the strength development of non-traditional stabilisation test techniques, as well as the number of tests, was highlighted in the results of this study. The natural variability of the materials used in this type of study is generally high, and the precision of the test method is typically quite low. On this basis, it is usually difficult to draw definite conclusions.

Keywords: Unpaved road material, electrochemical stabilisation, bonding, dry density and moisture content, strength development

INTRODUCTION

Unpaved roads make up a significant portion of the rural and urban road network, and by promoting access, this network is one of the key factors contributing to economic growth. Travel along unpaved roads is, however, not always assured because of their low standards, poor riding quality, impassability in wet weather, and the danger in the quantity of dust that is generated by moving vehicles and wind. This dustiness of unpaved roads reduces visibility and hinders traffic safety. Many unpaved roads do not have the ideal range and distribution of particle sizes to give a good load-bearing capacity when wet (coarser particles) or sufficient plastic capability (clay) when dry to prevent material from breaking loose. All unpaved roads, when dry, suffer from surface abrasion loss resulting in dust because the adhesion between the particles is reduced. The loss of road construction material also leads to the formation of ruts and potholes that could collect/retain water, and this may decrease the natural durability and strength properties of the unpaved road system, making the road uncomfortable and dangerous to drive on.

The quality of most unpaved road materials can be improved with traditional chemical additives, such as cement and lime, to improve strength and durability properties, but stabilisation with electrochemical-based non-traditional soil stabilisation additives (chemical additives), such as enzyme and sulphonated oil (also referred to as ionic additive) may offer a more cost-effective and practical solution to address these ongoing problems. Chemical additives used for strength improvement are referred to as stabilisers or additives, and for dust suppression are referred to as dust palliatives (Jones & Ventura 2004).

The objective of this paper is to report on the strength behaviour of a typical marginal quality unpaved road material treated with two electrochemical-based non-traditional soil stabilisation additives, enzyme and sulphonated oil, to assess their potential value for unpaved road construction. This work is based on the laboratory and field testing of panels reported in Moloisane (2009). Although the field experiment included traditional soil stabilisation additives, the focus of this paper is the non-traditional soil stabilisation additives.

The Moloisane (2009) study was undertaken to evaluate the strength behaviour of unpaved road materials treated with non-traditional soil stabilisation additives and included short-term to medium-term investigations as part of the main study, as well as longer-term studies of a previous investigation by Van Veelen (2005). The experimental sections by Van Veelen (2005), built in the same area as those of the Moloisane (2009) study, were monitored for about eight months in 2005. Data collected in 2009, i.e. 48 months after construction, were used to investigate certain technical issues, including the non-traditional stabilisation additive properties and the in situ strength development behaviour. The Van Veelen (2005) study panels seldom received traffic, because they were constructed on the shoulder area of the existing surfaced road, whereas the panels in this study were constructed on an existing unpaved road and were trafficked at least under 100 vehicles per day. Since the Van Veelen (2005) study served as an effort in building sound guidelines on the long-term strength behaviour of the use of non-traditional soil stabilisation additives, it was used for comparison in the Moloisane (2009) study. The results of the tests are reported in this paper. Comparative strength of the treated unpaved road material and control (untreated) sections was also investigated during the testing. Both laboratory and field tests indicated that the application of enzyme and sulphonated oil increased the strength of the unpaved road material, provided that they are used properly.

OVERVIEW OF CHEMICAL STABILISATION OF UNPAVED ROAD MATERIAL

The main objective of chemical stabilisation on unpaved road material, as explained by among others Kézdi (1979) and Ballantine & Rossouw (1989), is to maintain the characteristics of the material, favourable from the aspects of the given engineering target, regardless of the moisture in its environment. As a result of chemical stabilisation, the bearing capacity and strength of the unpaved road material should be increased; and water-tightness, resistance to erosion and other properties should also be improved.

Stabilisation of unpaved road material with electrochemical-based non-traditional soil stabilisation additives (chemical additives) such as enzyme and sulphonated oil (ionic additive) has been investigated in a number of studies, and is on-going in the form of experimental, trial, control and demonstration sections and laboratory performance testing. Enzyme is defined as an organic catalyst that rapidly carries a chemical reaction to completion without becoming a part of the end product and being the reaction that would normally take place at a much slower rate (Burns 1978; Chang 1984; Tolleson et al 2003; Marasteanu et al 2005; Velasquez et al 2006; Pacific Enzymes Incorporated 2007). Enzyme catalyses very specific chemical reactions if conditions are conducive to the reaction (Tingle et al 2007). The manufacturers claim that this liquid additive, which is also non-hazardous and environmentally friendly, lowers the surface tension of water, hence aiding compaction, and that it creates the crystalline structures amongst individual soil particles through biologically catalysed reactions. Enzyme additives also help the soil bacteria to release hydrogen ions, resulting in pH gradients at the surfaces of the clay particles, which assist in breaking up the structure of the clay (Velasquez et al 2005). Sulphonated oil consists primarily of strongly acidic sulphur-based organic mineral oils (Paige-Green & Groenewald 1993; Van Zyl et al 1993; Paige-Green & Coetser 1996; Savage 1998; Ali et al 1999; Tingle et al 2007; Van Veelen & Visser 2007). The manufacturer claims that this liquid anionic additive which is non-hazardous, non-flammable, non-corrosive when diluted, non-toxic, environmentally safe and user friendly, is a synthetic compound with surface-active properties, which has been devised to change the hydrophilic (water adsorption) properties of clay materials to those of hydrophobic nature (water repellent) (Con-Aid International 1998). Performance of the electrochemical-based non-traditional soil stabilisation additives depends on the clay mineralogy, and sufficient time to react with the clay fraction (Austroads 1998; Bergmann 2000; Gauteng Provincial Government 2004; Jones & Ventura 2004).

Studies concerning enzyme utilisation for unpaved road material have been conducted in the past years by Scholen (1992; 1995), Funk (1993), Wright-Fox et al (1993), Brownfield (1994), Weedon & Croeser (1996), Bolander (1997), Petry (1997), Birst & Hough (1999), Bolander (1999), Bergmann (2000), Santoni et al (2001), Layrea (2003), Tingle & Santoni (2003), Tolleson et al (2003), Brazetti & Murphy (2004), Marasteanu et al (2005), Van Veelen (2005), Velasquez et al (2005; 2006), Tingle et al (2007); Van Veelen & Visser (2007) and Visser (2007). Studies concerning sulphonated oil utilisation for unpaved road material have also been conducted in the past years by Van Zyl et al (1993), Scholen (1995), Weedon & Croeser (1996), Bolander (1997), Petry (1997), Savage (1998; 2005; 2006), Birst & Hough (1999), Bolander (1999), Santoni et al (2001), Tingle & Santoni (2003), Brazetti & Murphy (2004), Harris et al (2005), Van Veelen (2005), Tingle et al (2007), Van Veelen & Visser (2007) and Visser (2007).

Scholen (1992) presented positive results for soil-aggregate stabilisation with three commercial enzymes. Those enzymes included a bacterial culture with enzymes' solution that multiplied rapidly when exposed to air, and produced the organic molecules which were necessary to attract to the clay minerals. Well-graded aggregates with high clay contents were found to have performed best by "locking'' the larger aggregate particles within the matrix, hence the creation of a rigid surface and reduced ravelling. Stabilisation performance results from the study done by Wright-Fox et al (1993), using two enzyme additives on a highly plastic fat clay material, indicated that the unconfined compressive strengths (UCS) of the enzyme-treated products were 21% higher than the control (untreated) samples. The conclusion by Wright-Fox et al (1993) that enzymes might provide some additional shear strength for some soils, led to the recommendation that soil stabilisation with enzymes must be considered for various case-by-case applications. Funk (1993) reported that after seven years of using the enzyme in unpaved road stabilisation, blading was only required four times a year, compared with every one to three weeks prior to application, hence an enzyme was considered an extremely cost-effective product. Brownfield (1994) reported that roads treated with enzyme have maintained a hard and stable road surface.

In the study conducted by Bolander (1997), the laboratory tests met the expectations of the field performance. This also concurred with other laboratory studies conducted by Petry (1997), Santoni et al (2001) and Tingle & Santoni (2003) in which enzymes and sulphonated oils used in unpaved roads provided increased strength. The laboratory tests of expected field performance study of various additives, which included enzymes and sulphonates on densegraded aggregate evaluated by Bolander (1999), included indirect tensile strength (ITS) and durability testing. Enzymes and sulphonates provided some tensile strength, but lost it with increasing moisture content. Based on the experiences of Bolander (1999) it is clear that thorough preparation, sufficient mixing and curing time all had a marked effect on the efficiency, durability and service life of the structures treated with enzymes and sulphonates.

Performance-based field testing using non-traditional soil stabilisation additives, which included an enzyme and ionic additive (sulphonated oil) conducted by Weedon & Croeser (1996), indicated that sections constructed with ionic additives did not reveal a marked difference compared with the control (untreated) section. The increased in situ strength was attributed to the reduction of in situ moisture content. In the laboratory experiment, using various non-traditional soil stabilisation additives which included enzymes and sulphonates conducted by Tingle & Santoni (2003), to evaluate the stabilisation of low- and high-plasticity clay soils, the focus was on increased load-bearing capacity as the basis of performance characterisation as indicated by the UCS. Sulphonates provided excellent UCS improvement under both dry and wet test conditions, and also provided the greatest strength improvements for the low-plasticity soil. Sulphonates further provided the best resistance to moisture, and this indicated excellent waterproofing characteristics. Enzymes showed a slight increase in the UCS for the low- and high-plasticity soils under both dry and wet test conditions. Consistent road enhancement and better performance from enzyme and sulphonated oil-treated roads based on records of the road performance were found by Brazetti & Murphy (2004).

Locally, the strength behaviour of four different soils treated with four different non-traditional soil stabilisation additives, which included an enzyme and sulphonated oil under dry and wet conditions, was evaluated by Van Veelen (2005). The enzyme-treated materials showed an improvement on the gravel and ferricrete materials, with a significant increase in soaked strength for the gravel material. Sulphonated oil treated materials showed an improvement on all materials with a significant increase in soaked strength for the clay material. The good performance of the sulphonated oil additive on the clay material was attributed to the fact that the reactive clay mineral in the clay material produced a permanent association between the additive and the clay particles. Both enzyme and sulphonated oil showed an increase in strength over the eight-month test period. The in situ California Bearing Ratio (CBR) strengths that were gained eight months after construction of the experiment indicated that the enzyme, which had no significant improvement in strength during the five months of testing, showed a significant improvement in strength on the ferricrete and gravel materials. This revealed that the additives needed a curing time of a few dry months to reach their maximum strength. Experimental field investigation study to evaluate stabilisation of road materials with non-traditional soil stabilisation additives, which included a sulphonated oil-based product, conducted by Visser (2007) revealed gain in strength in the material with active clay. It was also found that the product had no benefit when used on inert sand with low plasticity index (PI).

There is thus ample evidence that improvement in material characteristics occurred with the use of both non-traditional soil stabilisation additives, although the effect of increased strength caused by drying out of the treated materials is probably not always fully considered.

EXPERIMENTAL PROGRAMME

Construction of the experimental panels

The chosen experimental site was an existing unpaved road called Larch Road, which is in the Benoni Agricultural Holdings in the Ekurhuleni Metropolitan Municipality, South Africa. This road is used by both local light and heavy-duty agricultural traffic. The test pavement construction was initiated on 8 May 2008. About 150 mm depth of the existing wearing course was ripped and mixed after spraying with potable water to about optimum moisture content and compacted to 93% Modified AASHTO density.

A new 150 mm thick layer was imported on top of this reworked layer, which acted as subgrade. The pavement was then divided into panels 5 m long and 6 m wide. Panels that used untreated material were also constructed between the treated panels and used as controls. These control (untreated) panels were also used to prevent contamination between the treated panels. For consistency and good quality control, only one control (untreated) panel was used throughout the testing. Water was not applied to the road surface before mixing for fear of exceeding optimum moisture. A rotavator machine was used to pulverise the gravel-wearing course into workable material. The mixed treated wearing course material was compacted to 95% of Modified AASHTO density and then shaped by means of a motor grader to a crown-shape to allow for easier drainage.

Unpaved road material characterisation

The natural weathered gravel material used in the construction of the experimental panels was obtained from a commercial source, Benoni Sands Quarries. The following properties of this material were determined in the laboratory: sieve analysis, consistency limits, maximum dry density (MDD) and optimum moisture content (OMC), and California Bearing Ratio (CBR). Tests were conducted in accordance with TMH1 (CSRA 1986) standard methods and compared to the TRH14 (CSRA 1985) classification guidelines, and the COLTO (COLTO 1998) performance specifications. The material was also characterised according to TRH20 (CSRA 1990) shrinkage product (Sp) and the grading coefficient (Gc). Sp is the product of linear shrinkage and the percentage passing the 0.425 mm sieve, while the Gc is the difference between the percentage passing the 26.5 and 2.00 mm sieves multiplied by the percentage passing the 4.75 mm sieve, all divided by 100. The material was also classified according to the American Association of State Highway and Transportation Officials (AASHTO)'s M145 classification system as described by AASHTO (1998). X-ray diffraction (XRD) was used for the mineralogical analysis.

Sieve analysis test results indicated that the dark-reddish brown material was sandy gravel. The soil mortar analysis test results showed that the material consisted of an average of 49% coarser particles, an average of 24% finer particles, and an average of 27% very fine particles. The average grading modulus of the material was 1.70. Consistency limit test results showed that the material had an average plasticity index of 8%. The laboratory testing showed an average MDD of 2 100 kg/m3 at an average OMC of 8%, and average CBRs at 95% and 90% Modified AASHTO density of 15% and 11% respectively. The compacted density of the panels was determined after construction to assess future densification that might occur due to traffic and the stabilisation process. The panels were constructed on an existing unpaved road and it was deemed that there were no differences in the supporting layer for all the panels.

Performance-based material criteria of the untreated material as per COLTO (COLTO 1998), i.e. Sp and Gc results, indi-cated that the material was relatively good, but with some potential for ravelling and corrugating. The material was classified as A-2-4 according to the AASHTO M145 classification system (AASHTO 1998). The A-2-4 materials are deemed poorer because of their inferior binding characteristics, poor grading, or a combination of the two (AASHTO 1998; 2000).

From the XRD diffraction patterns of the untreated material, quartz was the main constituent (49%) in addition to traces of the other crystalline phases, namely, plagioclase (albite series) (26%), microcline (10%) and muscovite (illite) (5%). In the clay mineral phases, montmorillonite was the main constituent (7%) in addition to a trace of kaolinite (3%). The natural material was classified as weathered quartz gravel.

The four unpaved road materials of the Van Veelen (2005) study were also classified according to the AASHTO M145 Classification System for comparison with the unpaved road material of the Moloisane (2009) study. A summary of the critical properties of the unpaved road materials of these two studies is presented in Table 1.

The Putfontein clay material of the Van Veelen (2005) study was also classified as A-2-4. This unpaved road material closely matched the dark-reddish brown gravel material of this study physically - it is not known whether the mineralogical compositions also match closely.

Non-traditional soil stabilisation additives used

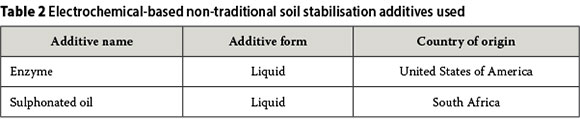

The origins of the commercial non-traditional soil stabilisation additives used in the study are presented in Table 2.

Because of the proprietary nature of these commercial additives, their exact chemical compositions are not disclosed. The enzyme additive used in the study is a water-based additive (produced from fermenting sugar beet) which consists mainly of organic compounds (hence biodegradable) and surfactants. The sulphonated oil additive used in the study is a viscous, deep red or dark brown liquid anionic additive with no smell or taste, with the active agent being an organic acid, produced from a blend of synthetic-chemical products that originated from petrolcum.

Methodology

The enzyme additive was applied at a rate of 0.005 ℓ/m2 (0.033 ℓ/m3 or 0.15ℓ in the 4.50 m3 panel) and the sulphonated oil additive at 0.01 ℓ/m2 (that is 0.015 ℓ/m3 for the 4.50 m3 panel) to the newly imported 150 mm layer of imported natural quartz gravel material. The application rates were recommended by the suppliers/manufactures, and thus adhered to and used as such. The long-term strength behaviour of enzyme and sulphonated oil additives on the unpaved road material (new wearing course) performance was observed after 14 days, one month, two months, three months, four months, five months, six months and eight months by means of the laboratory testing and field investigations, and after 31 months (almost three years) by field investigations only. The laboratory testing included scanning electron microscopy (SEM), while the field investigations assessed the in situ dry density and moisture content determined by a nuclear density meter, and the in situ and soaked strength was determined by a dynamic cone penetrometer (DCP).

The scanning electron microscope (SEM) is an electron microscope capable of producing high-resolution images of a sample surface morphology (Locquin & Langeron 1983). SEM uses electrons to illuminate and create an image of a specimen. The binding ability of the particles of the untreated natural material and the additives' interactions in the panels were assessed using the SEM. The JEOL (JSM-840) model, which performs morphological and micro-structural assessment, was used for the analysis to obtain the micrographs or images that showed surface morphology information of the treated materials. The specimens were prepared by breaking off small pieces from the samples in order to look at a freshly exposed surface that broke along a natural plane of weakness.

The nuclear density measurement test was performed to determine the compaction of the treated material. This test compares the field density with the laboratory compaction density in order to determine the percent compaction achieved. The nuclear density meter measures the mass of the wet soil per volume and the mass of the water present in a unit volume of soil within a few minutes. This was used to compare and correlate the DCP results with the CBR at an appropriate Modified AASHTO density on treated material determined in the laboratory.

The DCP-CBR of the in situ material from the panels was compared with the CBR determined from the laboratory tests. This made it possible to compare the CBR values of the material from the tests conducted in a controlled environment (that is in the laboratory) with those obtained from the field investigations.

For the DCP testing in the soaked condition the procedure made use of a cleaned open-quarter of a 200ℓ steel oil drum being placed on the panel surface and sealed with soil to reduce the water leaking out. This open-quarter drum was then filled with water to a depth of 50 mm, which was maintained for two hours. The amount of water added should soak the material to a depth of about 150 mm (assuming about 30% voids). In practice, a significant amount of water flows laterally and the material is probably not fully soaked to the full depth of 150 mm. The DCP test was then carried out in the middle of the wetted spot to test for the 'soaked CBR'. The aim of the soaked DCP test was to determine the conditions comparable with the soaked CBR in the laboratory and to reflect the weakest road condition.

RESULTS AND DISCUSSION

Scanning electron microscopy (SEM) analysis

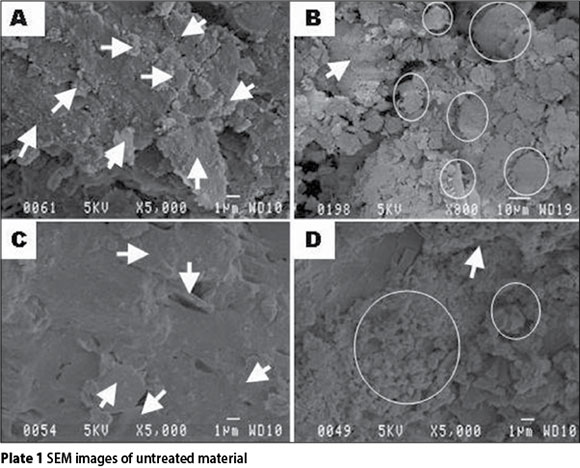

SEM analysis was carried out to identify the changes of the phase composition and microstructure. The images represent the general observed features.

Untreated material

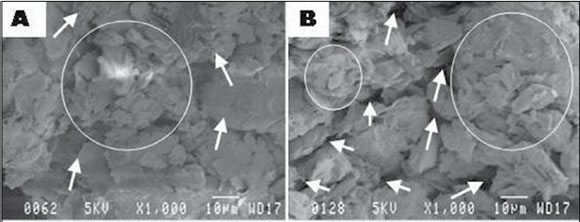

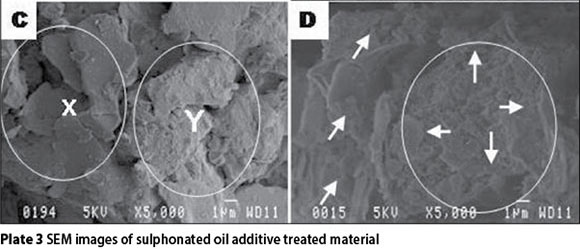

Plate 1 depicts the SEM images of the micro-structure characteristics of the weathered quartz gravel material. Plates l(A) and (B) are images of well-crystallised morphology of flaky arrangements of clay particles, which is montmorillonite and kaolinite as matrix between the fine grains. The concentration and the distribution of the clay particles (about 1 µm) are not regular; some parts contain more clay particles and less grains and other contain more grains and less clay particles. Individual quartz particles are more difficult to identify due to the amount of clay, but these quartz particles, which are free of clay coating, are clearly seen (indicated by ellipses, circles and arrows in images (B) and (C)). The quartz particles in the images seem more rounded. This means that the particles have been transported further, allowing more erosion of the particles. The image in (D) shows the individual clay particles against the background of a quartz particle. This matrix can be related to the plasticity characteristics of the quartz material. The SEM images show a clear crystallised surface morphology of the untreated material.

Enzyme additive treated material

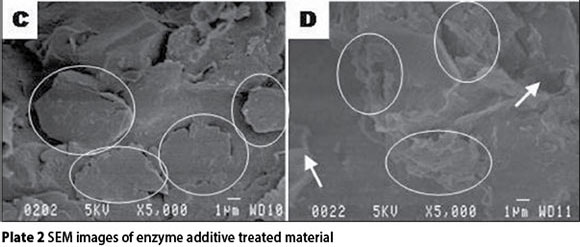

Plates 2(A), (B) and (C) are images of the enzyme additive treated material at one, three and five months respectively; after construction and despite the different magnifications, they all appear generally similar. All these images show cornflake-like grains (indicated by arrows, circles, and ellipses) dispersed throughout the images. The enzyme additive seems to have coated the surface of the soil particles, though it is difficult to identify the inter-particle bonding. Plate 2(D) is the image at eight months after construction and shows bonding along the edges of clay flakes (indicated by ellipses). This confirmed the enzyme additive characteristics of forming inter-particle bonding. A homogeneous microstructure is developed which may indicate increase in strength. Micro cracks were not evident.

Sulphonated oil additive treated material

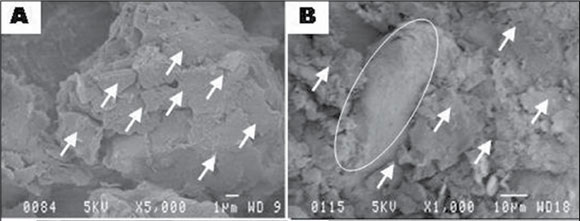

Plates 3(A) and (B) are the images of the sulphonated oil additive treated material at one and three months after construction respectively, and show the inter-particle bonding (indicated by arrows) forming a dense microstructure. Larger quartz particles seemed not to have bonded (indicated by ellipse), but smaller particles indicated the tiny forms of dense matrix (indicated by arrows), thus resulting in the occurrence of a homogeneous microstructure. Plate 3(C) is the image at five months after construction and shows a heterogeneous structure that consists of larger bonded particles (indicated by zones X and Y in the ellipses). This resulted in the occurrence of a homogenous microstructure, thereby (an indication of) increasing strength. Plate 3(D) is the image eight months after construction and shows a complete bonded matrix to increase the strength (indicated by arrows). Micro cracks were also not evident.

During sample preparation for the SEM, a small specimen is broken from a larger mass of material. This can affect the surface morphology observed under the SEM. Surface morphology was predominant in the microstructure of the treated material of the study.

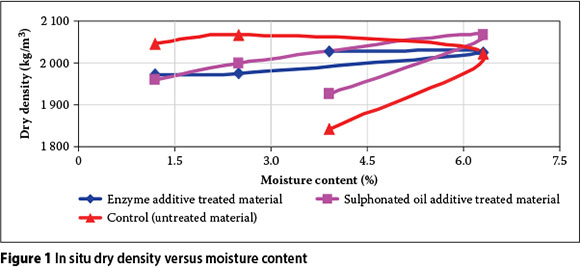

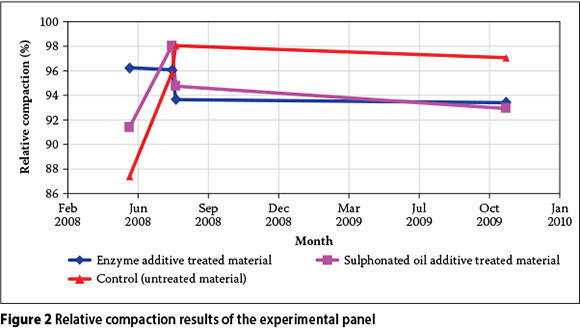

Analysis of the in situ density according to relative compaction obtained

The in situ dry density, or field density, and in situ moisture tests, where the oven-dried moisture was used, are presented in Table 3 and graphically depicted in Figure 1. Relative compaction results of the experimental panels are depicted graphically in Figure 2.

The purpose of the density tests was to ensure that the treated panels were compacted to the recommended target of 95% of Modified AASHTO density as per TRH20 (CSRA 1990) recommendation guidelines. The same compaction was applied to all the panels during construction. The Modified AASHTO density of the treated panels of the study ranged from 91% to 94%. The additives may have had an effect on the relative compaction obtained, and this may indicate that these additives may possibly be used as compaction aids.

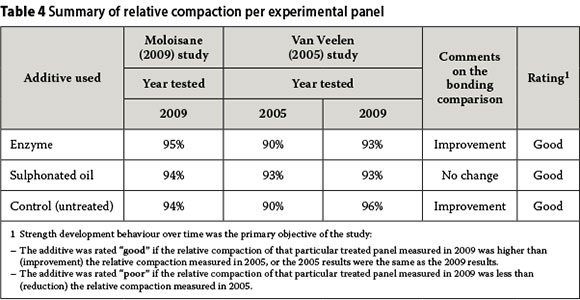

The in situ dry density tested on 24 July 2008, almost three months after construction, showed a slight decrease of 0.2% in the enzyme additive treated panel, and an increase of 6.8% in the sulphonated oil additive treated panel. Further compaction in the sulphonated oil additive treated panel may be attributed to traffic. The average relative compaction density test results (Modified AASHTO density) eight months after construction revealed that enzyme additive and sulphonated oil additive treated panels had densities of 93.5% (a decrease of 2.91%) and 93.0% (a slight increase of 1.75%) respectively. The control (untreated) panel had a density of 97.1% (a significant increase of 11.1%). Both studies of Moloisane (2009) and Van Veelen (2005) were compared for the treated in situ and soaked strength behaviour. The dark-reddish brown gravel material of the Moloisane (2009) study was compared with the Putfontein clay material of the Van Veelen (2005) study. These two unpaved road materials were characterised to be closely matching physically. A summary of the comparison of the in situ relative compaction of the treated panels is presented in Table 4.

Though the data was limited, the enzyme additive treated materials indicated that there might be an on-going improvement, and the sulphonated oil additive treated materials indicated that there would be no change. The best improvement was in the control (untreated) panel.

Analysis of the in situ CBR of the control (untreated) panel

The in situ CBRs of the control (untreated) panel were assessed in terms of the density obtained during the laboratory tests. The in situ CBRs of the control (untreated) panel and CBR at 90% and 95% of Modified AASHTO density of the pavement material are presented in Table 5.

The control (untreated) panel reached its maximum in situ CBR at five months after construction (at the end of the dry season). The soaked CBR of the control (untreated) panel was much higher than the CBR at the corresponding Modified AASHTO density during the laboratory tests. This was attributed to the fact that the panel could not have been thoroughly soaked through. Soaking in the field took place over a period of two hours and the water depth was 50 mm in the cleaned open-quarter oil drum. The surface may have been well-sealed by traffic preventing ready water ingress. Furthermore the density was greater than 95% Modified AASHTO. In the laboratory test material larger than 19 mm is discarded, whereas in the field the coarser material provides strength. Two soaked CBR values of 51% and 84% obtained in February 2012 were higher than the in situ CBR values of the same month. This unlikely situation was attributed to the fact that the panels were tested under relatively wet climatic conditions, because February is in the rainy summer season (mid-October to mid-February). The DCP results, when converted to the CBR, only give an indication of the CBR of the material and not the exact CBR, hence there was poor correlation between the field and the laboratory testing.

In situ strength development analysis

The laboratory CBR-test quantitatively determines the bearing capacity of the material, where the shearing resistance of a material under carefully controlled conditions of density and moisture is measured. The strength of the treated panels in both in situ and soaked conditions was measured by means of the DCP to yield the correlated CBR values. The DCP has been increasingly used in many parts of the world in soil, granular material and lightly treated soils to assess the in situ pavement strength conditions (Scala 1956; Van Vuuren 1969; Kleyn 1975; Kleyn & Savage 1982; De Beer et al 1989; Burnham & Johnson 1993; Newcomb et al 1995; Salgado & Yoon 2003; Van Veelen 2005; Van Veleen & Visser 2007).

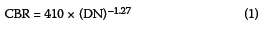

The theory behind the DCP is that the resistance to penetration of a steel 60° cone through the material is an indication of the in situ strength of the material, as measured by the CBR. The output of the DCP test is a penetration rate, expressed in millimetres per blow (DN), which is also called Dynamic Cone Penetration Index. Both the in situ and soaked CBRs were measured each month on the panels, with the exception of the two months before the eighth month (last month of the study) due to rainfall. The DCP tests were again carried out after three years. The in situ CBR was also tested next to the wetted area to provide the in situ DCP. The existing panels constructed by Van Veelen (2005) were only measured parallel with the new ones of the Moloisane (2009) study in the eighth month. The field data was reduced in terms of penetration versus corresponding number of blows. The number of blows was plotted horizontally along the x-axis and the penetration reading was plotted vertically along the y-axis. The plots were divided into 'best fit' straight lines. The slope values were calculated by the change in penetration versus the change in the number of blows observed over the range for that particular straight-line section. The DCP value was converted to CBR by the corresponding DCP slope value by means of the expression in Equation 1 as given by Kleyn et al (1989). The DCP represent multiple point measurements of the road-bearing strength, which are averaged.

Where:

CBR = In situ CBR strength (%)

DN = Penetration rate (mm/blow)

Strength development behaviour analysis five months after construction

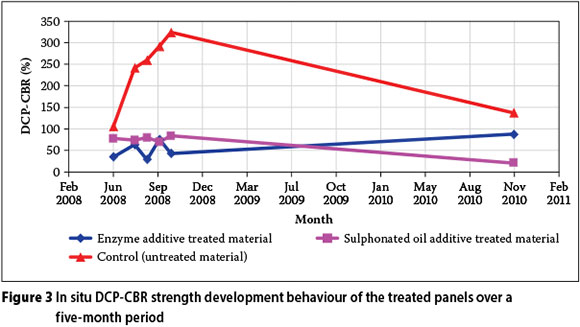

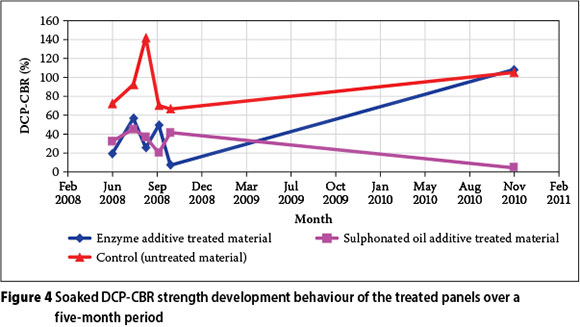

The DCP-CBR results of the panels' strength behaviour over five months after construction are presented in Table 6 and graphically depicted in Figures 3 and 4 for trend observation.

The enzyme additive treated panel had a higher in situ DCP-CBR value of 76% in September 2008 at four months after construction, while the sulphonated oil additive treated panel had higher in situ DCP-CBR value of 80% in August 2008 at three months after construction, and had approximately the same value in the fifth month. In July 2008 at two months after construction, the enzyme additive treated panel reached its maximum soaked DCP-CBR value of 57% compared to the sulphonated oil additive treated panel with a maximum soaked DCP-CBR value of 45%, and had approximately the same value in the fifth month. Although in July 2008 at two months after construction, the enzyme additive treated panel had the soaked DCP-CBR value of 57%, which was regarded as maximum in the five-month period, the in situ DCP-CBR value in the same month was 64%, higher than the soaked. The results are consistent as the in situ DCP-CBR is higher than the soaked value. In November 2010 at approximately 31 months after construction, the enzyme additive treated panel had a significant increase in both the in situ and soaked DCP-CBR strength, while the sulphonated oil additive treated panel had a significant decrease in both the in situ and soaked DCP-CBR strength.

The control (untreated) panel indicated the highest in situ DCP-CBR strength in October 2008, five months after construction, while the maximum soaked DCP-CBR strength was indicated in August 2008, three months after construction. In November 2010, approximately 31 months after construction, the in situ DCP-CBR strength was higher than the treated panels, while the soaked DCP-CBR strength was approximately the same as that of the enzyme additive treated panel, and much higher than that of the sulphonated oil additive treated panel. From the time series it does appear as if the additives have a negative influence on strength over time. From the time sequence the DCP-CBR strength values were variable; an individual result should not be used to draw conclusions. These 'actually very similar' values were attributed to the conditions, density and moisture variations, and the fact that the results are based on single tests.

The on-going strength developed during the first five months was ascribed to the fact that from June to September 2008 there was no rainfall and therefore the testing was conducted under dry conditions. It only rained about 17 mm in June 2008, with the most (about 14 mm) measured on 3 and 4 June; the remaining 3 mm fell on the 20th. During the eighth month the panels indicated a significant decrease in the in situ and soaked DCP-CBR strength (it should be noted that the road was probably nearing its wettest condition at that time of the year). That was attributed to the amount of rain that fell on the panels from October to December 2008, which prevented the panels from drying out to reach their maximum strength. During the period October to December 2008, about 285 mm of rain fell on the panels, which was high for the area. According to South African Explorer (2008), the area normally receives an average of about 116 mm of rain during this period. The experimental panels were constructed in May 2008, when about 185 mm of rain fell. According to South African Explorer (2008), the area normally receives about 579 mm of rain per year, but in 2008 it received about 785 mm of rain. The panels were therefore constructed and tested under relatively wet climatic conditions. The only testing that was conducted under dry conditions was during July to September 2008 (months two to four when no rain fell).

Strength development behaviour of the treated experimental panels versus the control (untreated) panel

The maximum in situ and soaked DCP-CBR of each treated panel were compared with the in situ and soaked DCP-CBR of the control (untreated) panel for the same months. The comparison procedure was such that even if the control (untreated) panel may have had a higher strength in another month, that value was not considered for the comparison. That was done to compare the true conditions of the same month, because conditions vary. With reference to the studies conducted by Van Veelen (2005) and Van Veelen & Visser (2007), an improvement was considered when the treated panels had a DCP-CBR of more than 10% greater than the control (untreated) panel. A summary of the maximum in situ and soaked DCP-CBR of the treated panels, compared with the maximum in situ and soaked DCP-CBR of the control (untreated) panel for the same month in the year 2008 is presented in Table 7.

In the 2008 results, both enzyme and sulphonated oil additive treated panels showed a decrease in strength compared with the control (untreated) panel in both in situ and soaked conditions. A summary of the maximum in situ and soaked DCP-CBR of the treated panels, compared with the maximum in situ and soaked DCP-CBR of the control (untreated) panel for the same month in the year 2010 is presented in Table 8.

In the 2010 results, the enzyme additive treated panel showed a decrease in strength compared with the control (untreated) panel in in situ conditions only and a slight increase in soaked conditions. The sulphonated oil additive treated panel showed a decrease in strength compared with the control (untreated) panel in both in situ and soaked conditions. This decrease in strength is evidence that those additives did not perform well under wet conditions. The panels were constructed and tested during the rainy season. It is hypothesised that this poor performance may be attributed to the fact that none of the panels had time to dry out sufficiently for substantial strength improvement to occur after construction. It may also be concluded that the additives performed poorly because they are not totally compatible with the specific type of material, although the material did contain a small amount of the necessary smectite clays. It may also be considered that the low application rates (typically 0.03 ℓ/m2 for stabilisation and 0.01 ℓ/m2 as a compaction aid) were insufficient to treat the material.

Comparison of the strength development behaviour of the treated experimental panels

Both the studies of Moloisane (2009) and Van Veelen (2005) were compared for the treated in situ and soaked strength behaviour. The dark-reddish brown gravel material of the Moloisane (2009) study was compared with the Putfontein clay material of the Van Veelen (2005) study. These two unpaved road materials were characterised to be closely matching physically. A summary of the comparison of the in situ strength behaviour of the treated panels is presented in Table 9.

From the comparative information of the "in situ strength behaviour" the enzyme and sulphonated oil additive treated panels indicated that the strength development would deteriorate. A summary of the comparison of the "soaked strength behaviour" of the treated panels is presented in Table 10.

From the comparative study of the "soaked strength behaviour", the enzyme additive treated panel indicated that the strength would improve, while the sulphonated oil additive treated panel indicated that the strength development would deteriorate. This does not necessarily mean that the sulphonated oil additive performed poorly. The rating was just an indication of comparison, based on the conditions that existed during the monitoring.

Overall performance of the treated experimental panels

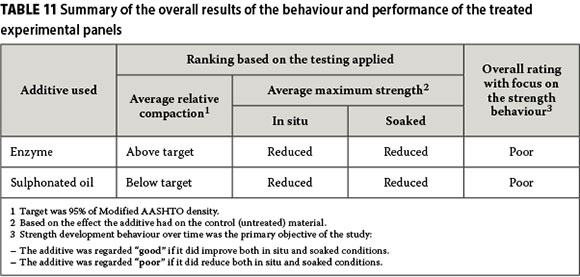

A summary of the overall behaviour and performance of the treated panels based on all the tests conducted over the 8 and 31 months period of the studies is provided in Table 11.

From the summary information of the results and rating of the general behaviour and performance, enzyme and sulphonated oil additive treated panels were rated as "poor". The rating was just an indication of comparison, based on the conditions that existed during the monitoring. The variability and inconsistency of the results is typical of this type of study. It should be noted that limited testing is generally carried out (example, single DCP and density tests per panel) during this type of work. The natural variability of the materials used in this type of study is generally high and the precision of the test method is typically quite low. On this basis, it is usually difficult to draw definite conclusions, but general indications of trends emerged.

CONCLUSIONS

The degree of formation and paste surrounding the particles appeared to have varied with time and differed between the enzyme and sulphonated oil additives. It was hypothesised from the SEM images that the increase in strength was due to cementation and pore filling by the additives. An increase in density in the sulphonated oil additive treated panel occurred three months after construction, and a further increase was again noticed eight months after construction (five months thereafter). Up to eight months after construction, the enzyme additive treated panel showed a significant decrease in density, but showed a slight increase 31 months after construction. The variations in density were attributed to testing variability. In the comparison per additive, the enzyme and sulphonated oil additive treated panels did not indicate much difference in relative compaction. This is because both additives are effectively compaction aids. The overall conclusion was that an increase in the densities of the Van Veelen (2005) study over the eight and 40 months periods occurred, although the panels were not trafficked. The Moloisane (2009) study of eight months duration, which was trafficked, also had an increase in the densities. This increase in densities in the latter case might probably be because of further densification by traffic.

In the in situ and soaked DCP-CBR strength measurements, the sulphonated oil additive treated panel reached its maximum in situ strength at two months after construction, while the enzyme additive treated panel reached its maximum in situ strength at five months after construction. Both treated panels indicated a significant decrease in both the in situ and soaked DCP-CBR strength conditions at eight months after construction. The decrease was attributed to the rain. In the comparison of the treated versus control (untreated) of the panels, the control showed the maximum in situ DCP-CBR strength in the fourth month, while the maximum soaked DCP-CBR strength was shown in the second month. The fact that the "control (untreated) panel" varied in performance is indicative of problems arising from the limited amount of testing typically allocated to projects of this type. In the comparison per additive, the in situ long-term DCP-CBR strength development behaviour of both the enzyme and sulphonated oil additive treated panels rated deterioration. The rating was just used as an indication of comparison. There was, however, little evidence to show that the additives improved the material, with the control panel being consistently stronger in both the in situ and soaked DCP-CBR conditions.

The results highlighted the importance of considering the time factor in the strength development of non-traditional soil stabilisation. It is clear that the variability and inconsistency of the results are typical of this type of study. It should be noted that limited testing is generally carried out (example, single DCP, and density tests per panel) during this type of study. The natural variability of the materials used in this type of study is generally high and the precision of the test method is typically quite low. On this basis, it is usually difficult to draw definite conclusions.

ACKNOWLEDGEMENTS

This paper is based on the first author's MSc in Applied Science project report submitted to the University of Pretoria. The National Department of Transport's Northern Transportation Centre of Development and Tshwane University of Technology are fully thanked for financial support. Ekurhuleni Metropolitan Municipality and its personnel from the Roads, Transport and Civil Works (RTCW) Department of the Benoni Roads Depot who assisted in the construction of the experimental panels are greatly thanked, especially Mr Fanie Erasmus for all the hard work he put in to see this study succeed. Manufacturers and suppliers of the additives are also thanked for the supply of the chemical additives and for the provision of data.

REFERENCES

AASHTO (American Association of State Highway and Transportation Officials) 1998. Manual on subsurface investigations. Washington D.C., USA. [ Links ]

AASHTO (American Association of State Highway and Transportation Officials) 2000. Classification of soil and soil-aggregate mixtures for highway construction purposes (AASHTO M-145-91). Washington D.C., USA. [ Links ]

Ali, G, Taha, R, Muscati, M & Al-Rasheidi, A 1999. Evaluation of treated bases, double sand seal, and slurry seal pavement sections in the sultanate of Oman. Transportation Research Record: Journal of the Transportation Research Board (TRB), No 1652, pp 32-42. [ Links ]

Austroads 1998. Guide to stabilisation in roadworks. Sydney, Australia: Austroads Inc, Publication No AP-60/98. [ Links ]

Ballantine, R W & Rossouw, A J 1989. Stabilisation of soils. Johannesburg: Pretoria Portland Cement (PPC) Lime Ltd. [ Links ]

Bergmann, R 2000. Soil stabilisers on universally accessible trails. Department of Transportation, Federal Highway Administration (FHWA), USA. [ Links ]

Birst, S & Hough, J 1999. Chemical additive usage on unpaved roads in the mountain plain states. Fargo, North Dakota: North Dakota State University, Upper Great Plains Transportation Institute, USA. [ Links ]

Bolander, P W 1997. Chemical additives for dust control: What we have used and what we have learned. Transportation Research Record: Journal of the Transportation Research Board (TRB), No 1589, pp 42-49. [ Links ]

Bolander, P W 1999. Laboratory testing of non-traditional additives for stabilisation of roads and trial surfaces. Transportation Research Record: Journal of the Transportation Research Board (TRB), No 1652, pp 24-31. [ Links ]

Brazetti, R & Murphy, S 2004. Results and conclusions from a comprehensive World Bank study of the performance of roads rehabilitated with soil stabilisers in Paraguay, South America. Paper presented at the 83rd Annual Meeting of the Transportation Research Board (TRB), Washington D.C., USA.

Brownfield, B J 1994. Perma-Zyme. Alaska Transportation Technology Transfer Programme, Planning Design, Fairbank, Alaska, USA, Field Notes No 33. [ Links ]

Burnham, T & Johnson, D 1993. In-situ foundation characterisation using the Dynamic Cone Penetrometer (DCP). Minnesota Department of Transportation, Maplewood, USA, Report No MN-93/05. [ Links ]

Burns, R G 1978. Soil enzymes. New York: Academic Press, pp 298-305. [ Links ]

Chang, R 1984. Chemistry. New York: Random House. [ Links ]

COLTO (Committee of Land Transport Officials) 1998. Standard specifications for road and bridge works for state road authorities. Pretoria: Department of Transport. [ Links ]

Con-Aid International (Pty) Ltd 1998. Guidelines for the Con-Aid/CBR Plus soil stabiliser. Roodepoort, South Africa. [ Links ]

CSRA (Committee of State Road Authorities) 1985. TRH14 - Guidelines for road construction materials. Pretoria: Department of Transport, Technical Recommendations for Highways. CSRA (Committee of State Road Authorities) 1986. TRH 1 - Standard methods of testing road construction materials. Pretoria: National Institute for Transport and Road Research, CSIR, Technical Methods for Highways.

CSRA (Committee of State Road Authorities) 1990. TRH 20 - The structural design, construction and maintenance of unpaved roads. Pretoria: Department of Transport, Technical Recommendations for Highways. [ Links ]

De Beer, M, Kleyn, E G & Savage, P F 1989. Advances in pavement evaluation and overlay design with the aid of the Dynamic Cone Penetrometer (DCP). Paper presented at the 2nd International Symposium on Pavement Evaluation and Overlay Design, Rio De Janeiro, Brazil, September. [ Links ]

Funk, R 1993. Letter to Emery County Road Supervisor. Jerome, Idaho, USA, provided by Idaho Enzymes Inc, 5 November. [ Links ]

Gauteng Provincial Government 2004. Stabilisation manual: Manual L2/04. Pretoria: Department of Public Transport, Roads and Works, Directorate Design, Subdirectorates: Materials and Quality Control and Technical Measurements. [ Links ]

Harris, P, Von Holdt, J & Scullicon, T 2005. Recommendations for stabilisation of high-sulfate soils in Texas. College Station, Texas, USA: Texas Transportation Institute, Report No 0-4240-3. [ Links ]

Jones, D & Ventura, D F C 2004. A procedure for fit-for-purpose certification of non-traditional road additives. Pretoria: CSIR, Report No CR-2004/45. [ Links ]

Kézdi, A 1979. Treated earth roads. Amsterdam: Elsevier Scientific. [ Links ]

Kleyn, E G 1975. The use of the Dynamic Cone Penetrometer (DCP). Pretoria: Transvaal Provincial Administration (TPA) (now Gauteng Provincial Government), Roads Department, Report No L2/74. [ Links ]

Kleyn, E G & Savage P F 1982. The application of the pavement Dynamic Cone Penetrometer (DCP) to determine the bearing properties and performance of road pavements. Proceedings, International Symposium on Bearing Capacity of Roads and Airfields, Trondheim, Norway, June. [ Links ]

Kleyn, E G, De Wet, L F & Savage, P F 1989. Towards a classification system for the strength-balance of road pavement structures. The Civil Engineer in South Africa, 31(2). [ Links ]

Layrea, S 2003. Soil stabilisation with Perma-Zyme 11X. MSc dissertation, Nottingham: University of Nottingham, UK (unpublished). [ Links ]

Locquin, M V & Langeron, M 1983. Handbook of microscopy, English edition. Oxford, UK: Butterworth-Heinemann. [ Links ]

Marasteanu, M O, Hozalski, R M, Clyne, T R & Velasquez, R A 2005. Preliminary laboratory investigation of enzyme solutions as a soil stabiliser. Minnesota, USA: Minnesota Department of Transportation, Report No MN/RC-2005-25. [ Links ]

Moloisane, R J 2009. Evaluation of the long-term strength behaviour of unpaved roads treated with non-traditional stabilisers. MSc dissertation, Pretoria: University of Pretoria, (unpublished). [ Links ]

Newcomb, D E, Chabourn, B A, Van Deusen, D A & Burnham, T R 1995. Initial characterisation of subgrade soils and granular base materials at the Minnesota Road Research Project. Saint Paul, Minnesota, USA: Minnesota Department of Transportation, Report No MN/RC-96/19. [ Links ]

Pacific Enzymes Incorporated 2007. Enzymes - the catalyst for Perma-Zyme 11X. Available at: www. pacificenzymes.com (accessed on 13 August 2007). [ Links ]

Paige-Green, P & Coetser, K 1996. Towards successful sulphonated petroleum products treatment of local materials for road building. Pretoria: South African Roads Board, Department of Transport, Research Report No RR 93/286. [ Links ]

Paige-Green, P & Groenewald, M 1993. Stabilisation of materials, including soil stabilisers. Pretoria: CSIR, Division of Roads and Transport Technology, Bulletin 20. [ Links ]

Petry, T M 1997. Performance-based testing of chemical stabilisers. Transportation Research Record: Journal of the Transportation Research Board (TRB), No 1589, pp 36-41. [ Links ]

Salgado, R & Yoon, S 2003. Dynamic Cone Penetration Test (DCPT) for subgrade assessment. West Lafayette, Indiana, USA: Purdue University, Report No FHWA/IN/JTRP-2002/30. [ Links ]

Santoni, R L, Tingle, J S & Webster, S 2001. Non-traditional stabilisation of silty-sand. Vicksburg, USA: U.S. Army Engineer Research and Development Centre. [ Links ]

Savage, P F 1998. Some experiences on the use of Con-Aid: A water-soluble ionic additive. Proceedings, 17th Annual Transportation Convention (ATC), Pretoria, 7-9 March, Paper 7, pp 1-11. [ Links ]

Savage, P F 2005. Compaction and stabilisation of soils. Pretoria: University of Pretoria, Faculty of Engineering, Built Environment and Information Technology, Supplementary Class Notes: SGC788 (unpublished). [ Links ]

Savage, P F 2006. Towards a better understanding of soluble adsorbed water displacing ionic additives. Proceedings, 25th Southern African Transport Conference (SATC), Session 1B, Infrastructure Engineering, Pretoria, July, pp 17-25. [ Links ]

Scala, A J 1956. Simple methods of flexible pavement design using the Cone Penetrometer. New Zealand Engineering, 11(2). [ Links ]

Scholen, D E 1992. Non-traditional stabilisers. Federal Highway Administration (FHWA), USA, Report No FHWA-FLP-92-011. [ Links ]

Scholen, D E 1995. Stabiliser mechanisms in nonstandard stabilisers. Conference Proceedings 6: Conference on Low-Volume Roads, Vol 2, Transportation Research Board (TRB), Washington, D.C., June, pp 252-260. [ Links ]

South African Explorer 2008. Benoni climate. www. saexplorer.co.za/south-africa/climate/benoni_ climate.asp (accessed on 25 November 2008). [ Links ]

Tingle, J S, Newman, J K, Larson, S L, Weiss, C A & Rushing, J F 2007. Stabilisation mechanisms of non-traditional additives. Transportation Research Record: Journal of the Transportation Research Board (TRB), No 1989, Vol 2, pp 59-67. [ Links ]

Tingle, J S & Santoni, R L 2003. Stabilisation of clay soils with non-traditional additives. Transportation Research Record: Journal of the Transportation Research Board (TRB), No 1819, pp 72-84. [ Links ]

Tolleson, A R, Shatnawi, F M, Harman, N E & Mahdavian, E 2003. An evaluation of strength change on subgrade soils treated with an enzyme catalyst solution using CBR and SSG comparisons. Orangeburg, USA: South Carolina State University, University Transportation Centre, Final report, pp 1-12. [ Links ]

Van Veelen, M 2005. Strength behaviour of unpaved roads using soil stabilisers. MEng dissertation, Pretoria: University of Pretoria, South Africa, (unpublished). [ Links ]

Van Veelen, M & Visser, A T 2007. The performance of unpaved road material using soil stabilisers. SAICE Journal, 49(4):2-9. [ Links ]

Van Vuuren, D J 1969. Rapid determination of the California Bearing Ratio (CBR) with the portable Dynamic Cone Penetrometer (DCP). The Rhodesian Engineer, Paper No 105, September. [ Links ]

Van Zyl, G D, Jordaan, P W, Bofinger, H E, Curtayne, P C, De Beer, E et al 1993. Towards appropriate standards for rural roads: Discussion document. Pretoria: South African Roads Board, Department of Transport, Report No RR 92/466/1. [ Links ]

Velasquez, R A, Marasteanu, M O & Hozalski, R M 2006. Investigation of the effectiveness and mechanisms of enzyme products for subgrade stabilisation. International Journal of Pavement Engineering, 7(3):213-220. [ Links ]

Velasquez, R A, Marasteanu, M O, Hozalski, R M & Clyne, TR 2005. Preliminary laboratory investigation of enzyme solution as a soil stabiliser. Minnesota, USA: Minnesota Department of Transportation, Final Report 2005-25. [ Links ]

Visser, A T 2007. Procedure for evaluating stabilisation of road materials with non-traditional soil stabilisers. Transportation Research Record: Journal of the Transportation Research Board (TRB), No 1989, pp 21-26. [ Links ]

Weedon, M E & Croeser, M E C 1996. Upgrading of existing gravel roads to a blacktop standard using sub-standard base material modified with various soil stabilisers. IMESA Journal, 21(4):3-6. [ Links ]

Wright-Fox, R, Macfarlane, J G & Bibbens, R F 1993. Alternate chemical soil stabilisers. Los Angeles, California: California Department of Transportation (CalTrans), minor research report. [ Links ]

Contact details

Contact details

Jones Moloisane

Department of Civil Engineering

Tshwane University of Technology

Private Bag X680 Pretoria, 0001

T: +27 12 382 5221

F: +27 12 382 5226

F to E: +27 86 297 5679

E: moloisanerj@tut.acza

Contact details

Contact details

Alex Visser

Department of Civil Engineering

University of Pretoria

Pretoria, 0002

T: +27 12 420 3168

E: alex.visser@up.ac.za

JONES MOLOISANE (PrTech Eng, MSAICE) is a lecturer (focusing on transportation engineering technology, and construction contract managementand administration related subjects) In the Department of Civil Engineering atthe Tshwane University of Technology, South Africa. He Is also a director and shareholder at Delta Built Environment Consultants (Pty) Ltd, Virtual Consulting Engineers (Pty) Ltd and Science Ignite. He Is the deputy chairman (2013-2015) of the International Engineering Technologist Agreement (IETA) under the auspices ofthe International Engineering Alliance (IEA). He holds the qualifications MTech (Civil) cum laude (Technikon Pretoria) and MSc (Appl Sci) (Pretoria). In 2009 he received the SAICE Award for the best postgraduate student in transportation engineering in South Africa (Northern Region) for his Project Report submitted in partial fulfilment of the requirements for the MSc (Appl Sci) degree on the evaluation of the long-term strength behaviour of unpaved roads treated with non-traditional soil stabilisation additives. In both 2009 and 2012 he received the Engineering Council of South Africa (ECSA) Merit Award for his significant contribution towards furthering the objectives of ECSA and the engineering profession beyond the call of duty. He is a council member of ECSA and also serves on various ECSA sub-committees, the South African Qualifications Authority's Foreign Qualifications Evaluation Committee and the South African Bureau of Standards' SC 59E: Construction Standards-Pavement Materials Testing Committee.

EMERITUS PROF ALEX VISSER (Pr Eng, FSAICE) recently retired as the SA Roads Board Professor in Transportation Engineering in the Department of Civil Engineering at the University of Pretoria, South Africa. He holds the degrees BSc (Eng) (Cape Town), MSc (Eng) (Wits), PhD (University of Texas at Austin) and BComm (SA). His fields of research Interests are primarily low-volume road design and maintenance, roads for ultra-heavy applications, interlocking block paving, and road management systems. He has performed extensive research on non-traditional soil stabilisation additives for improving road materials, and has published extensively and lectured internationally on these topics. Since retiring he has also provided advice on projects around the world. Prof Visser is a Fellow and Past-President of the South African Institution of Civil Engineering (SAICE) and a Fellow of the South African Academy of Engineering. In 1998 he was awarded the SAICE Award for Meritorious Research for his contributions to low-volume road technologies, and in 2004 he received the Chairman's Award from the Transportation Division for contributions to transportation engineering. He was awarded emeritus membership of the US Transportation Research Board for Low-Volume Roads Committee in 2006 for lifelong services rendered.