Serviços Personalizados

Artigo

Indicadores

Links relacionados

-

Citado por Google

Citado por Google -

Similares em Google

Similares em Google

Compartilhar

Journal of the South African Institution of Civil Engineering

versão On-line ISSN 2309-8775

versão impressa ISSN 1021-2019

J. S. Afr. Inst. Civ. Eng. vol.55 no.2 Midrand Jan. 2013

TECHNICAL PAPER

Relationship between creep time dependent index and Paris Law parameters for bituminous mixtures

M Mostafa Hassan

Contact details

ABSTRACT

Bituminous mixtures undergo cracking, either top-down or bottom-up, as a consequence of the repeated application of traffic loads, thermal cycling or a combination of the two mechanisms. Cracking is considered as one of the major distress modes in asphalt pavements.

This study presents a method to characterise crack resistance of asphaltic mixtures containing waste materials using a semi-circular bending (SCB) fracture test. Three different bituminous mixtures containing incinerator bottom ash waste and one control mix, containing limestone, were tested under cycling SCB loading conditions at 5°C and the results were interpreted using Paris Law. The same mixtures were also tested under controlled stress creep conditions at the same temperature. This paper examines the link between the time dependent index from creep tests with the n parameter from the Paris Law model, based on visco-elastic continuum damage mechanics analysis and linear elastic fracture mechanics principles.

Keywords: cracking, bottom ash, visco-elasticity, SCB, Paris Law, creep

INTRODUCTION

Burning municipal solid waste, results in a few by-products, the most common of which is bottom ash. It was not uncommon to dump this in landfills. However, due to European Union restrictions imposed in 2004 on landfill sites, alternative usage has become necessary. One such alternative is using bottom ash waste in asphalt for roads. Its properties have been studied mechanically, physically and environmentally (Hassan & Khalid 2010a). These properties have linked bottom ash to lightweight aggregates.

Numerous successful trials have been conducted worldwide to study its usage as a road construction material. However, a better understanding of its usage and behaviour is still required. It was found that substitution of virgin aggregate with up to 80% incinerator bottom ash aggregate (IBAA) waste resulted in mixtures with a higher binder content of up to 1.2%, lower resilient modulus values and satisfactory use in binder course and base layers on major roads (Hassan & Khalid 2010a&b; Ogunro et al 2004; Vassiliadou & Amirkhanian 1999). An IBAA content of up to 80% was found to improve the leaching properties and rutting resistance of bituminous mixtures (Hassan & Khalid 2010a). With regard to the crack resistance properties of mixtures containing bottom ash waste, there are very few previous studies (Hassan & Khalid 2010b) that have explored this area. In the latter study, it was shown that elasto-plastic material properties can be derived from elastic parameters using a correspondence visco-elastic principle and creep compliance of mixtures. This work examines the relationship between the Paris Law constant, n, and the creep compliance time exponent, m, for mixtures containing different bottom ash waste quantities.

MATERIALS

Two aggregates were used in this study -limestone to produce control bituminous mixtures, and bottom ash waste to replace limestone. The binder used was 100/150 Pen bitumen sourced from Venezuelan crude. These materials were utilised to produce hot bituminous mixtures containing 0%, 30%, 60% and 80% (named as OA, AA, BA and CA in sequence) bottom ash waste by weight. The composition and volumetric parameters of each mixture and details of the mix design procedure were published elsewhere (Hassan & Khalid 2007).

SAMPLING AND TESTING

Cylindrical cores of nominal 150 mm diameter and 65 mm thickness were cored from 300 mm square asphalt slabs compacted in the laboratory using a roller segment. Each cylinder was then cut in half to obtain semicircular samples. These were then sharply notched at mid-point in the direction of the load using a diamond-tip tile cutter. The notch length was 15 mm to produce a notch to a radius ratio of 0.2. Samples were then stored in an incubator at 5°C until test commencement. Cyclic semi-circular bending (SCB) tests were conducted in which the mixtures were tested under a cyclic load of 1.5 kN under a haversine load frequency of 1 Hz and a temperature of 5°C. For all tests, triplicate samples were used. Figure 1 shows the SCB test schematically.

Alternatively, cylindrical asphalt mixture samples of 67 mm diameter and 134 mm height were manufactured. Firstly, a laboratory roller compactor was used to produce 305 mm x 305 mm asphaltic slabs of 100 mm height. The slabs were compacted at four different pressures, namely 175 kPa, 275 kPa, 345 kPa and 495 kPa. Each pressure was applied for 10 passes over each slab. The slabs were then cut into two halves. Each half was turned on its side and cored to produce cylinders of 67 mm diameter and 150 mm height. Each cylinder was then trimmed from both ends to 134 mm height. Three samples were used for each creep test.

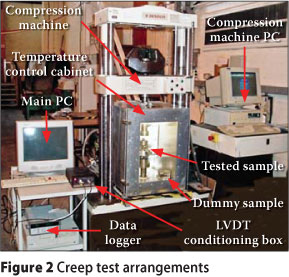

Figure 2 shows the equipment arrangement for the creep tests, comprising a temperature controlled cabinet (-20°C to 50°C) mounted on a loading frame, an axially mounted 10 tonne load cell, the specimen and its instrumentation, and a linear variable deferential transducer (LVDT) with its conditioning box connected to a data logger.

Specimens were tested at 5°C. To ensure uniformity of temperature, samples were conditioned in a temperature control cabinet, at the testing temperature, for at least 12 hours preceding the test. Specimens were then placed between two steel plates, smeared with silicon grease to reduce friction, and a small pre-load was applied to take out any relaxation in the system.

Specimens were then allowed to deform under a uniaxial compression stress. The cross-head was allowed to apply a constant load over samples for 1 800 seconds. This time was found to be adequate for mixtures to reach steady state conditions. In each test, the axial and radial strains over time were recorded.

For each applied stress, the stress-strain relationship was captured and recorded by a computer. The axial deformation of the specimens was measured by recording the cross-head movement.

RESULTS AND DISCUSSION

SCB results

Figure 3 shows the measured crack lengths against the number of cycles, for the four tested mixtures, in which it is shown that each mixture had a stable crack growth phase. It is evident that adding bottom ash waste up to a certain amount has led to an increase in the number of cycles to failure.

These results were obtained based on the average of triplicate samples with R2 values of 0.112, 0.235, 0.135 and 0.256 for mixes OA, AA, BA and CA respectively.

LEFM analysis has been used to characterise crack growth rate by means of the well-known Paris Law (Paris & Erdogan 1963) in which the rate of crack propagation is a function of the stress intensity factor. This law is given by the following expression:

where:  is the crack growth rate; ΔΚ1 is mode I stress intensity factor range (Kmax -Kmin); A and n are constants that depend on the material and test conditions; a is the crack length; and N is the number of load cycle applications.

is the crack growth rate; ΔΚ1 is mode I stress intensity factor range (Kmax -Kmin); A and n are constants that depend on the material and test conditions; a is the crack length; and N is the number of load cycle applications.

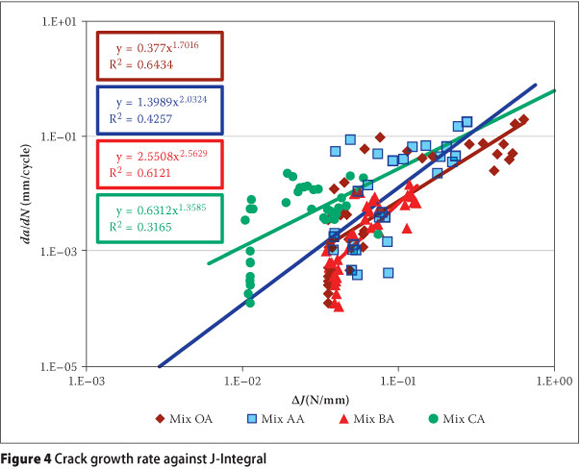

As asphalt is a visco-elastic material. Its fracture behaviour can be characterised by means of the J-Integral parameter. Thus, the Paris Law can be expressed in terms of the J-integral as follows (Rice 1986):

To calculate J, Schapery (1984) integrated a non-linear visco-elastic constitutive equation and presented the result in Equation 3.

where: wj is the strain energy density; Tj is the stress vector acting on the contour; u is the displacement vector; ds is the increment along contour i; and x and y are coordinates normal to the crack front.

For linear elastic conditions, J represents the energy made available at the crack tip, whereas for visco-elastic conditions, J no longer represents the available energy because of its dissipation. However, the corresponding principle of visco-elasticity, demonstrated by Schapery (1984), makes it possible to define a generalised time-dependent J-Integral by forming a Je, which is a pseudo-elastic J-Integral, with the linear elastic case as shown in Equation 3 (Kuai et al 2009). It has been shown (Kuai et al 2009) that the visco-elastic problem can be converted to an elastic problem with the pseudo stress and strain parameters. Then the generalised J-Integral is given as follows:

where: We is the pseudo strain energy density; ue is the pseudo displacement vector;

ER is a reference modulus; τ is the retardation time for the ith element; and D(t) is the creep compliance.

Parameters were determined to be used in Equation 5 (Hassan & Khalid 2010b) and the results were presented as in Figure 4, from which new Paris Law constants, AJ and nJ, were determined and presented as in Table 1.

Creep results

For all mixtures, axial and radial strains were recorded over time. Figure 5 shows creep compliance curves obtained at 5°C and stress of 1 000 kPa. The creep compliance, D(t), in Equation 5 is typically described in a power law form as follows:

where D0 is the material's glassy compliance; D1 is the compliance coefficient of time; m is the compliance exponent; and t is loading time. The m values for the four mixtures can be seen from the power law equations in Figure 5 to be 0.3757, 0.3972, 0.3336 and 0.2850 for mixtures OA, AA, BA and CA respectively. Schapery (1981) derived a relationship between the exponent nJ from Equation 2 and m from Equation 6 under different scenarios.

Schapery (1981) found that, if the tensile strength of the material and bond energy of fracture surface were constant during the fracture process, then nJ = 1 + 1/m. From regression analysis (Figure 6) the two parameters are related as in Equation 7.

The nature of the relationship differs from that reported by Schapery and its shape does not change when any outliers are deleted from the regression analysis, demonstrating that the relationship in Equation 7 is representative between the two parameters for the bottom ash waste mixtures.

CONCLUSIONS

From the work conducted in this study, it can be concluded that:

- Paris Law was found suitable to characterise crack growth properties of bottom ash waste bituminous mixtures using the J-Integral. The J-integral was evaluated from elastic fracture analysis using Schapery's correspondence principle.

- Adding up to 60% bottom ash waste led to a significant increase in the number of cycles to failure in the cyclic SCB test.

- The Paris Law constant, nJ, has been related to the creep compliance exponent of time, m, through a linear regression equation that differs from that reported by Schapery for constant tensile strength and bond energy of the fracture surface.

REFERENCES

Hassan, M M & Khalid, H A 2007. Incinerator bottom ash aggregates in bituminous mixtures. Proceedings, 4th International Conference on Bituminous Mixtures and Pavements, Thessaloniki, Greece, April, pp 489-498. [ Links ]

Hassan, M M & Khalid, H A 2010a. Mechanical and environmental characteristics of bituminous mixtures with incinerator bottom ash aggregate. International Journal of Pavement Engineering, 11(2): 83-94. [ Links ]

Hassan, M M & Khalid, H A 2010b. Fracture characteristics of asphalt mixtures containing incinerator bottom ash aggregate. Transportation Research Record, 2180: 1-8. [ Links ]

Kuai, H D, Lee, H J, Zi, G S & Mun, S H 2009. Application of generalized J-integral to crack propagation modelling of asphalt concrete under repeated loading. Proceedings, 88th Annual Meeting of the Transportation Research Board, Paper No 09-2324 (DVD). [ Links ]

Ogunro, V H, Inyang, H, Young, D & Oturkar, A 2004. Gradation control of bottom ash aggregate in super-pave bituminous mixes. Journal of Materials in Civil Engineering, 16: 604-613. [ Links ]

Paris, P C & Erdogan, F J 1963. A critical analysis of crack propagation laws. Transactions of the ASME, Journal of Basic Engineering, Series D, 85(3): 528-534. [ Links ]

Rice, J R 1986. A path independent integral and the approximate analysis of strain concentration by notches and cracks. Journal of Applied Mechanics, 35: 379-386. [ Links ]

Schapery, R A 1981. Visco-elastic deformation and failure behaviour of composite materials with distributed flaws. In Wang S S & Renton W J (Eds), Advances in Aerospace Structures and Materials, Washington DC: American Society of Mechanical Engineers, pp 5-20. [ Links ]

Schapery, R A 1984. Correspondence principles and a generalized J-integral for large deformation and fracture analysis of viscoelastic media. International Journal of Fracture, 25: 195-223. [ Links ]

Vassiliadou, E & Amirkhanian, S 1999. Coal ash utilization in asphalt concrete mixtures. Journal of Materials in Civil Engineering, 11(4): 295-301. [ Links ]

Contact details:

Contact details:

Mohamed Mostafa Hassan

Department of Civil Engineering

Central University of Technology

Private Bag X20539

Bloemfontein, 9300, South Africa

T: +27 51 507 3454

E: mmostafa@cut.ac.za

DR MOHAMED MOSTAFA HASSAN (C Eng, M ASCE) is a senior lecturer in Civil Engineering at the Central University of Technology (CUT) in Bloemfontein, South Africa. He has been actively involved in civil engineering research in the United Kingdom, Egypt and South Africa for more than fifteen years. His research career started in early 1997 as a researcher in railway engineering at the Suez Canal University in Egypt. From 2005 to 2009 he worked at Liverpool University until the completion of his PhD studies in pavement engineering. After lecturing transportation and highway engineering in Egypt for a while, he joined CUT in 2010 with the aims of teaching and establishing a research team on transportation and highway engineering. Dr Mostafa Hassan is actively involved in professional and scholastic activities (he is a member of the Transportation & Development Institute), and is a reviewer for a number of accredited journals, among others the Journal of Transportation Engineering and the International Journal of Pavement Engineering.