Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

South African Journal of Chemistry

On-line version ISSN 1996-840X

Print version ISSN 0379-4350

S.Afr.j.chem. (Online) vol.67 Durban Jan. 2014

RESEARCH ARTICLE

Analysis of Volatile Compounds in Khadi (an Unrecorded Alcohol Beverage) from Botswana by Gas Chromatography-Flame Ionization Detection (GC-FID)

Renameditswe Mapitse; Harriet Okatch*; Eniah Moshoeshoe

Department of Chemistry, University of Botswana, Private Bag UB 00704, Gaborone, Botswana

ABSTRACT

Chemical analysis of volatile compounds from khadi, an unrecorded alcoholic beverage from Botswana, was carried out using gas chromatography-flame ionization detection (GC-FID). Ten samples of khadi from two different locations were analyzed. All samples had pH values in the range of 2.87-3.16. Overall the samples contained ethanol, higher alcohols and esters. Ethanol was observed to be the dominant volatile compound with concentrations ranging from 1.66-5.71 % vol. Other volatiles determined were 2-methyl-1-propanol (9.12-29.0 mg L-1) and 2/3-methyl-1-butanol (14.5-124.7 mg L-1), ethyl lactate (27.4-110.9 mg L-1) and ethyl acetate (28.3-48.5 mg L-1).

Keywords: Unrecorded alcohols, volatiles, ethanol, gas chromatography.

1. Introduction

The International Centre for Alcohol Policies (ICAP) which defines unrecorded (non-commercial) alcohols as (a) traditional drinks produced, whether legally or illegally, for home consumption or limited trade, (b) unregistered drinks or counterfeit products and (c) non-beverage or surrogate alcohols derived from medicinal products, automobile products or cosmetics1 realizes that although these drinks may adhere to standards of quality, some of them may be contaminated and toxic, thereby posing public health threats of unknown magnitude and necessitating the need for analysis. A collation of literature illustrates the presence of alcoholic beverages obtained from several ingredients including melons,2 oranges,3 mango,4 agave plants.5,6 Analyses of some unrecorded alcohols from India, Mexico, Russia, Tanzania, Zambia,7 Nigeria, Lithuania, Hungary, Guatemala, Poland and Vietman 8 have shown the beverages to contain ethanol (as major component), methanol, n-propanol, 2-butanol, 2-methyl-1-propanol, acetic acid, ethyl acetate, ethyl-2-hydroxypropanoate, phenyl ethyl alcohol, dodecanoic acids, naphthalene, furfural, 1-methyl-napthalene, large-chain fatty acids, ethyl esters, 5-methyl-furfuraldehyde, terpenes and a mixture of 2-methyl-1-butanol and 3-methyl-1-butanol.6,9,10

Several types of unrecorded and unlicensed traditional home-brewed alcoholic beverages exist in Botswana and are usually sold by home-based liquor traders in locations locally known as Spoto and Shebeens. Amongst these home-brewed alcohols are beer-type fermented beverages like khadi and bojalwajwa Setswana, which are the most common due to their availability, accessibility and affordability. These home-brewed alcoholic beverages are usually cheaper than the western-type counterparts (beers, lagers, wines and spirits). In Botswana, the brewing and sale of these traditional home-brewed alcoholic beverages is not regulated by the National Alcohol Policy11 and therefore the composition and quality are not monitored. Previous studies11,12 identified several social and health problems associated with alcohol consumption, including malnutrition, selfneglect, poor hygiene, pale skin, weight loss, hallucinations, incoherence and cirrhosis whilst Finlay and Jones,13 in addition noted an increase in traffic accidents. Khadi is obtained from the fermentation of a base or 'mash' consisting of any of the following ingredients: wild berries, fruits, wild pumpkins, wild tuberous roots, sugar, sorghum or maize.14 In some cases, substances such as tobacco, yeast, dagga, car battery acid (sulphuric acid) are added to khadi during preparation to give it 'strength' and 'enhance its capacity' to intoxicate.15 Therefore, the composition and taste of the resulting khadi is dependent on the ingredients, both base and addi-tives16 and the brewing style. The quality of khadi can be determined by several tests including conducting chemical analysis of the volatile compounds which would indicate the flavour and the aroma profiles.610 However, some volatiles such as methanol are toxic and have the potential to cause nausea, headaches, blindness and even death.1718 For the sake of consumer protection, it is necessary to determine the chemical composition of the alcoholic beverages and to identify any potential toxins.

While khadi has existed for centuries, in the culture and tradition of the Batswana people, its composition and quality remain unknown. Therefore, the aim of this study is to determine the volatile compounds present in khadi from Botswana employing gas chromatography-flame ionization detection (GC-FID).

2. Materials and Methods

2.1. Samples

Ten khadi samples were obtained from Nkoyaphiri and Gabane on different dates. Both these locations are peri-urban and within a 20 km distance from the capital city of Botswana, Gaborone. The ingredients used to brew khadi included sugar, water and kgalola tuber as per information obtained from the brewers. The samples were stored at 4 °C and pH and volatile compounds analysis was conducted within a week of sampling.

2.2. Chemicals

Acetaldehyde, methyl acetate, 2-butanol, 1-butanol, ethyl benzoate, methanol, ethyl acetate, benzyl alcohol, benzaldehyde, 1-hexanol, 1-propanol, ethyl lactate, ethyl octanoate, 2-methyl-1-butanol, 1-phenyl-1-butanol, benzyl acetate, 2-methyl-1-propanol and 2-pentanol standards used in this study were obtained from Sigma Aldrich (St. Louis, Missouri, USA) and were of HPLC grade and 99 % purity. The ethanol was 95 % purity and obtained from Merck (Johannesburg, South Africa). 2-Pentanol was employed as the internal standard.

2.3. Standards

Working standards were made by serial dilutions (24.97399.54 mg L-1) in 40 % ethanol. Standard solutions were prepared by serial dilutions (24.97-399.54 mg L-1 ). Ethanol standards concentrations ranged from 40-200 parts per thousand. It was necessary to use different concentrations for the ethanol standards to avoid excessive dilutions which could have resulted in significant error. Ethanol was assumed to be the main ingredient in the khadi samples.

2.4. Determination of pH

The pH of the khadi samples were measured with a pH meter (pH 209) obtained from HANNA Instruments (Johannesburg, South Africa).

2.5. Gas Chromatography-Flame Ionization Detection

An Agilent 6820 gas chromatograph equipped with polyethylene glycol TPA modified column (ZB-FFAP 30 m x 0.32 mm id x 0.25 µm: Chrompak, Middleburg, Netherlands) and a flame ionization detector was used. A split/splitless injector was used. The injection and detection temperatures were set at 300 °C. Nitrogen was used as a carrier gas at a flow rate of 2 mL min-1. The initial column temperature was set at 35 °C and held for 3 min. The temperature was then ramped to: 40 °C at 2.5 °C min-1 and held for 2 min; 80 °C at 20 °C min-1 and held for 4 min; 140 °C at 20 °C min-1 and held for 5 min; 220 °C at 20 °C min-1 with a final hold of 1 min. The total run time was 26 min. Calibration curves were constructed using the peak area ratios of analytes in different standard concentrations to that of the internal standard.

2.6. Sample Preparation

About 1.5 mL of each sample was filtered into a vial using 0.45 cellulose acetate microfilters (Merck Millipore, South Africa). 5 ^L of 3500 ppm of 2-pentanol was placed into a graduated vial and made up to the 0.5 mL mark with the filtered sample. The mixture was mixed and introduced into the GC-FID. The unknown components of the sample were tentatively identified by comparing the retention times of the chromatogram of the samples to that of the standards. Quantitative analysis was conducted using generated calibration curves.

3. Results and Discussion

3.1. Analysis of pH

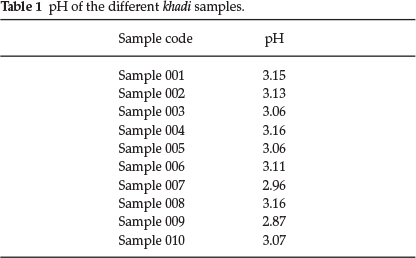

The pH of the khadi samples ranged between 2.87 to 3.16 as shown in Table 1, indicating that khadi beverage is acidic. The average pH was 3.08 with a standard deviation of 0.09. The difference in pH may be due to the quality and ripeness of the tuber or inconsistencies in the method of brewing. The pH of khadi (2.87 to 3.16) is close to that of white wines (pH 2.95-3.9)19 although slightly more acidic. It is also similar to that of orange wine (pH 3.03) obtained from moro oranges. This low pH inhibits growth of microorganisms but may also be associated with tooth corrosion amongst populations that frequently consume such beverages. Corrosive effects of common beverages and acidic soft drinks have been observed on teeth and enamel.20,21

3.2. Volatile Composition of Khadi Beverages

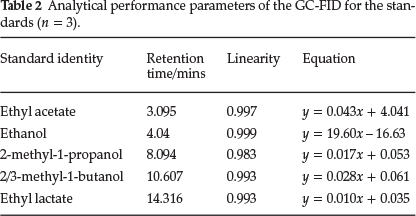

For determination of volatiles in the khadi samples, GC-FID analysis of the samples was conducted. GC-FID was chosen owing to its accurate quantitative and qualitative analysis of many organic substances.22 Figures 1 and 2 show a chromatogram of the standards and a typical chromatogram obtained for the khadi samples respectively. Table 2 shows the analytical parameters for each of the standards of detected constituents used for quantification: good r values were obtained, all greater that 0.99. Table 3 shows a summary of the constituents of the khadi samples and their corresponding concentrations. Khadi samples were found to contain ethanol, higher alcohols; 2-methyl-1-propanol and 2/3-methyl-1-butanol, ethyl lactate and ethyl acetate.

In addition, the khadi samples contained other constituents that were not identified. All the identified compounds have been reported to exist in some alcoholic beverages.4,610'23'24

Figure 1 shows that the 20-component standard was separated efficiently within a 25-min time period. With the exception of 2-methyl-1-butanol and 3-methyl-1-butanol, all the standards were separated with good resolution. The analytical parameters for the detected compounds show that for the concentration ranges that were selected, the standards showed a good linear relationship between the concentration and the detector response and allowed for quantification.

Like other alcoholic beverages, the most abundant constituent of all khadi samples was ethanol as shown in Table 3. The ethanol content was calculated to range between 1.66 % vol to 5.71 % vol and with an average of 3.92 % v/v. This falls within the estimate range of 2-20 % vol13. This ethanol content is within the same range of beers (2.92-15.66 % vol) and is lower than that of wines (12-16 % vol) and spirits (40-54 % vol).25,26 The local commercialized sorghum-based alcohol beverage in Botswana (Chibuku) has an alcoholic strength of 3.5-4 % vol. The average alcohol strength (3.92 % vol) of the analyzed khadi samples falls within this range. However, the wide range of alcohol content for the same alcoholic beverage suggests variations in preparation which should be considered in the event of standardization. This wide range of alcohol strength may also suggest that further analyses need to be conducted to determine if the alcohol strength varies per location. These samples were obtained at various locations which might explain the variation in ethanol content.

Higher alcohols found in khadi were 2-methyl-1-propanol (9.13-29.0 mg L-1) and 2/3-methyl-1-butanol (14.5-124.7 mg L-1) which are produced by catabolism of amino acids6 and play an important role in the flavour which varies depending on the types of compounds present and their content.4 Soufleros and co-workers23 state that if the total composition of higher alcohols is less than 600 mg L-1, the quality of wine is positively affected. In this study, as with other studies,24,27 the structural isomers 2-methyl-1-butanol and 3-methyl-1-butanol were not successfully separated. Hence the quantification reported here is for the total amount of both isomers. The respective contribution of each isomer was not determined. The determined average value of 2/3-methyl-1-butanol, 42.5 mg L-1 was comparable to that determined in Bavarian wheat beers, 58.3 mg L-1.28

The identified esters in the khadi samples were ethyl acetate and ethyl lactate. Esters in alcohol are associated with a fruity smell, and ethyl acetate was one of the major esters identified in pineapple wines4 and in Mezcal,6 an alcoholic drink related to Tequila and obtained from Agave plants. Ethyl acetate was detected in only four of the ten samples and the content ranged between 28.3 and 45.8 mg L-1 The ethyl acetate content of distilled spirits such as Mezcals (103-182 mg L-1) appears to be higher than that of beer-type fermented beverages as obtained in this study and in a study by Charry-Parra29 who analyzed volatile components of beer and determined the ethyl acetate content as 18.7 ppm. Ethyl lactate was detected in all samples except one. The difference in ethyl lactate and ethyl acetate composition of khadi samples may be a result of the use of different ingredients during the beverage preparation. Khadi prepared predominantly from fruits will have a larger component of ethyl esters compared to non-fruity bases. Table 3 shows the quantities of the identified components.

The chromatograms of the samples showed peaks with retention times that did not correspond to those of any of the standards, indicating that some significant components have not been identified and suggesting the inclusion of more standards in subsequent studies to fully characterize the components of the khadi beverages

Although fears exist regarding the health effects of unrecorded alcoholic beverages, the analysis conducted in this study suggest that the contents of the unrecorded alcoholic beverages are similar to those of commercial alcoholic beverages and implicitly suggest the same health effects.

4. Conclusion

Ten samples of a locally brewed alcoholic beverage, khadi, were sampled and analyzed using GC-FID. The analysis shows that khadi contains ethanol (1.66-5.71 % vol), 2-methyl-1-propanol (9.12-29.0 mg L-1) and 2/3-methyl-1-butanol (14.5-124.7 mg L-1), ethyl lactate (27.4-110.9 mg L-1) and ethyl acetate (28.3- 48.5 mg L-1). These compounds have been reported in other alcoholic beverages including wines, beer and spirits. Khadi is acidic with pH 2.87-3.16.

Acknowledgements

The authors are grateful for the assistance from the International Center for Alcohol Policies (ICAP) and the University of Botswana. ICAP is a not-for-profit organization supported by major international producers of beverage alcohol. This study was partially financed by ICAP.

References

1 www.icap.org (accessed December 2012). [ Links ]

2 L.F.H. Gomez, J. Ubeda and A. Briones, Int. J. Food Sci. Technol., 2008, 43, 644-650. [ Links ]

3 S. Selli, J. Food Quality, 2007, 30, 330-341. [ Links ]

4 J.A. Pino and O. Queris, Food Chem., 2011,125, 1141-1146. [ Links ]

5 D.W. Lachenmeier, E-M. Sohnius, R. Attig and M.G. Lopez, J. Agric. Food Chem., 2006, 54, 3911-3915. [ Links ]

6 A.D. Leon-Rodriguez, L. Gonzalez-Hernandez, A.P. Barba De La Rosa, P. Escalante-Minakata and M.G. López, J. Agric. Food Chem., 2006, 54, 1337-1341. [ Links ]

7 V Nuzhnyi, Chemical composition, toxic, and organoleptic properties of noncommercial alcohol samples, in Moonshine Markets. Issues in Unrecorded Alcohol Beverage Production and Consumption, (A. Haworth and R. Simpson, eds.), Brunner-Routledge, New York, 2004, pp. 177-199. [ Links ]

8 J. Rehm, F. Kanteres and D.W. Lachenmeier, Drug Alcohol Rev., 2010, 29, 426-436. [ Links ]

9 M.G. López, Tequila aroma, in Flavour Chemistry of Ethnic Foods, (F. Shahidi and C.T. Ho, eds.), Kluwer Academic Plenum Publishers, New York, 1999, pp. 211-217. [ Links ]

10 A. Pena-Alvarez, L. Diáz, A. Medina, C. Labastida, S. Capella, L.E. Vera, J. Chromatogr. A, 2004,1027, 131-136. [ Links ]

11 J.M.N. Pitso, Afr. J. Drug Alcoholic Studies, 2007, 6, 89-102. [ Links ]

12 L. Molamu and D. Macdonald, Drugs: Education, Prevention and Policy, 1996, 3, 145-152. [ Links ]

13 J. Finlay and R.K. Jones, P ULA; Botswana J. Afr. Studies, 1983,3(2), 1-13. [ Links ]

14 Global Status Report on Alcohol 2004. World Health Organisation, http://www.who.int/substance_abuse/publications/en/botswana.pdf (accessed 15/06/12). [ Links ]

15 A. von Rudloff, L. Mogkatlhe and G. Mookodi, Botswana: Summary of nationwide research, in International Center for Alcohol Policies (ed.), Producers, Sellers, and Drinkers: Studies of Noncommercial Alcohol in Nine Countries, ICAP Monograph, Washington DC, 2012, pp. 13-18. [ Links ]

16 J. Denbow and PC. Thebe, Culture and Customs of Botswana. Greenwood Press, USA, 2006, p. 108. [ Links ]

17 K. Ahmad, The Lancet, 2000, 356, 1911. [ Links ]

18 F. Bindler, E. Voges and P. Laugel, Food Addit. Contam. 1988,5,343-351. [ Links ]

19 B. Willershausen, A. Callaway, B. Azrak, C. Kloß and B. Schulz-Dobrick, Nutr. Res., 2009, 29, 558-567. [ Links ]

20 K.W. Seow and K.M. Thong, Aust. Dent. J., 2005, 50(3),173-178. [ Links ]

21 T. Attin, K. Weiss, K. Becker, W. Buchalla and A. Wiegand, Oral Dis. 2005,11, 7-12. [ Links ]

22 M. Caldeira, F. Rodrigues, R. Perestrelo, J.C. Marques,\ and J.S. Cämara, Talanta, 2007, 74, 78-90. [ Links ]

23 E.H. Soufleros, I. Pissa, D. Petridis, K. Lygerakis, K. Mermelas, G. Boukouvalas, E. Tsimitakis, Food Chem., 2001, 75, 487-500. [ Links ]

24 S. Cortes, R. Rodriguez, J.M. Salgadu and J.M. Dominguez, Food Control, 2001, 22, 673-680. [ Links ]

25 B.K. Logan, G.A. Case and S. Distefano, J. Forensic Sci., 1999, 44(6), 1292-1295. [ Links ]

26 L.J. Jones and PG. Markow, Determining the Alcohol Content of Beers and Wines, Brooks/Cole, Thomson Learning, Chemical Education Resources, 2004. [ Links ]

27 K.M. Namara, R. Leardi and A. Sabuneti, Anal. Chim. Acta, 2005, 542, 260-267. [ Links ]

28 D. Langos, M. Granvogl and P. Schieberle. J. Agric. Food Chem., 2013, 61, 11303-11311. [ Links ]

29 G. Charry-parra, M. DeJesus-Echevarria and F.J. Perez, J. Food Sci., 2011, 76(2), c205-c211. [ Links ]

Received 12 February 2013

Revised 13 September 2014

Accepted 26 September 2014.

* To whom correspondence should be addressed. E-mail: okatchh@mopipi.ub.bw