Serviços Personalizados

Artigo

Indicadores

Links relacionados

-

Citado por Google

Citado por Google -

Similares em Google

Similares em Google

Compartilhar

South African Journal of Animal Science

versão On-line ISSN 2221-4062

versão impressa ISSN 0375-1589

S. Afr. j. anim. sci. vol.53 no.5 Pretoria 2023

http://dx.doi.org/10.4314/sajas.v53i5.08

Extrusion of canola oilcake meal and sweet lupins on the production performance of Meatmaster lambs under feedlot conditions

T.S. BrandI, II, #; O.DreyerII; J.H.C. van ZylII

IDirectorate: Animal Sciences, Department of Agriculture, Western Cape Government, Private Bag X1, Elsenburg, 7607, South Africa

IIDepartment of Animal Sciences, University of Stellenbosch, Private Bag X1, Matieland, 7602, South Africa

ABSTRACT

Increasing commodity prices of plant proteins pressure farmers to start exploring alternative methods to optimize utilization of these dietary sources; heat treatment (extrusion) is tested in this study. Canola oilcake meal and sweet lupins were extruded to attempt to increase the amount of rumen undegradable protein. Meatmaster lambs were kept under feedlot conditions and fed four different diets: canola oilcake meal, control (CC); canola oilcake meal, extruded (CE); sweet lupins, control (LC); and sweet lupins, extruded (LE) to determine the effect of extrusion on growth performance. Performance parameters such as average daily gain, feed conversion, and feed intake were compared. A feed conversion ratio of 4.62 vs. 4.85 kg feed/kg weight gain was determined for the extruded diet vs. the control diet (not extruded). An average daily gain of 0.310 and 0.320 kg/day were obtained for the control and extruded diets, respectively. Daily feed intake was similar on the extruded (1.440 kg) and control diets (1.437 kg).The performance parameters of lambs on canola oilcake meal (17.4% inclusion) or sweet lupins (26.6% inclusion) were similar. An average fat level of 4 mm (7-9 mm back fat thickness) was achieved, with no effect of processing or protein source. Sweet lupins were identified as an inexpensive, locally-produced alternative plant protein source to canola oilcake meal, with similar performance parameters obtained in feedlot lambs.

Keywords: canola oilcake meal, lambs, performance, rumen undegradable protein, sweet lupins

Introduction

For 60 years, commercial extrusion processing has actively been used in the food and feed sectors (Rahman et al., 2015). Extrusion can be defined as a high-temperature, short-time (HTST) process entailing heat and pressure to create a mechanical shear (Risk et al., 2021), which changes the texture and nutritional quality of the product. Along with increasing competitiveness in the food and feed sectors (Brand, 2007; Brand & Jordaan, 2020) and the decreasing popularity of the use of animal-derived and genetically-modified products in the feed industry (Masoero et al., 2006), the opportunity presented itself to explore affordable, locally-produced plant protein sources, which could be used as an alternative protein sources.

Canola oilcake meal and sweet lupins are identified in a variety of research studies as high-quality protein sources that can be used in ruminant nutrition (Dickinson et al., 2004; Kriel, 2014; Brand & Jordaan, 2020). Canola oilcake is a good source of protein containing 17-24% CP on a DM basis (Heuzé et al., 2020), with a well-balanced amino acid profile that stimulates the growth of rumen microorganisms. Subsequently, the microorganisms are supplied with all the required nutrients; a greater quantity of microbial protein is produced (Kriel, 2014), which results in better animal performance. Mustafa et al., (2003) stated that extrusion protects oilseeds and oilseed meals against rumen degradation, enhancing the amount of amino acids available for intestinal digestion.

Lupins, specifically sweet lupins (Lupinus angustifolius) are a less expensive, high-quality plant protein source, containing 37.5% CP on a DM basis (Brand, 2007). They are highly degradable in the rumen, resulting in insufficient rumen bypass protein being supplied to the animal (Brand & Jordaan, 2020). Brand & Jordaan (2020) established that extrusion at 116 °C effectively decreased the effective rumen degradability of CP by 28%, without affecting the rate of degradation, resulting in potentially more use of lupin in the ruminant diet. Studies have proven that extrusion decreases the ruminal degradability of legume seeds and oilcake (Mustafa et al., 2003). Claassen (2011) from ExtruAfrica also stated that extrusion was a more affordable, environmentally-friendly process that was energy-efficient and produced a smaller quantity of waste products relative to other heating processes. Extrusion processing can be applied to decrease rumen degradation, ultimately increasing the amount of bypass protein supplied to the small intestines for further absorption by the animal, resulting in better performance.

The aim of this study was to determine the effect of the extrusion of canola oilcake meal and sweet lupins on the performance of lambs under feedlot conditions. The effect of processing (extrusion) and protein sources on average daily gain (ADG), feed intake (FI), and feed conversion ratio (FCR) were determined in this study.

Materials and Methods

Ethical clearance for this study was granted by the Animal Care and Use Research Ethics Committee of Stellenbosch University (#21726) and DAEC (TB103) (Departmental Evaluation Committee) of the Agricultural Department of the Western Cape Government at Elsenburg, South Africa. Sixty-nine Meatmaster lambs at an average live weight of -22.9 kg from Langgewens Research Farm were used for this study. Lambs were housed at the metabolism facilities at Elsenburg, where they were placed in individual paddocks (1.75 m × 1.2 m), each supplied with ad libitum feed and water.

Before the feeding trial, the lambs were preventatively treated for all internal and external parasites. A 7-d adaptation period was in place to ensure gradual adaptation of the rumen to a concentrated diet. During this period, the lambs were supplied with ad libitum chopped lucerne hay and 300 g pellets per lamb for the first 3 d. After the first 3 d, there was no restriction on the concentrated pellets supplied to the lambs. Feeding commenced twice a day, in the morning (08:00) and in the afternoon (16:00). Each lamb was supplied with a specific concentrated feed, based on the treatment group allocated to them. Fresh feed and water were supplied on a daily basis.

The four treatment groups were: canola oilcake meal control (CC); canola oilcake meal, extruded (CE); sweet lupin, control (LC); and sweet lupin, extruded (LE). Lambs were randomly allocated to these groups, with each group consisting of 16 lambs (seven ewes and nine rams per group). Weekly weighing of lambs took place every Wednesday morning and feed refusals were weighed back to determine weekly feed intake. The duration of the trial was approximately 4 m (from September until January). When a live weight of -40 kg was reached (the ideal slaughter weight of Meatmaster lambs is -35.2 kg to achieve A2 grading; van der Merwe et al., 2019), lambs were transported and slaughtered at DeliCo Abattoir in Riebeeck Kasteel, Western Cape, South Africa. A Mitutoyo Absolute Digimatic Calliper was used to measure the carcass fat thickness in millimetres.

Canola oilcake meal and sweet lupins were purchased from SOILL in Moorreesburg, Western Cape, South Africa. Both these plant protein sources were extruded using an InstaPro single screw extruder, situated at Mariehndal experimental farm of the University of Stellenbosch, under the custodianship of ExtruConsultancy services. A single screw extruder was used, which is conventionally used in producing livestock and aquatic feed and successfully converts mechanical energy to heat by means of friction (Rahman et al., 2015). The material is heated to a specific temperature due to a combination of moisture/steam and pressure and exits the barrel as extrudate. The discharge pressure is 30-60 atm (Serrano, 1979). In the current experiment, the extrusion conditions were at factor 30 for water, 17 for feed, and a motor amp of 30-31 and at a temperature of 113 °C.

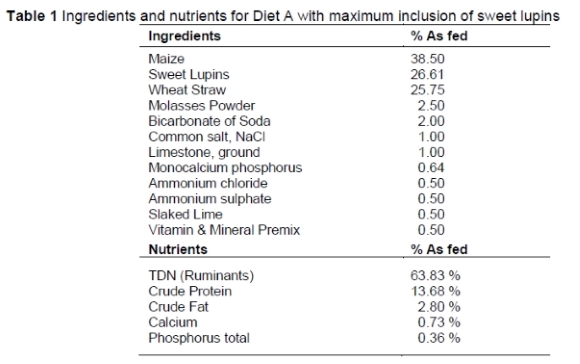

Canola oilcake meal and sweet lupins, together with Kalori 3000 (molasses powder) were extruded together in order to obtain the Maillard reaction, also known as the browning effect, at a temperature of approximately 113 °C. After extrusion was completed, the extrudates were laid out on a net to dry and regularly turned over to prevent the possible moulding. This procedure was followed until a moisture content of 10-12% was obtained in the extruded feed. The moisture content of samples was measured utilizing a Moisture Analyzer MC2000. The extruded product was milled at Kromme Rhee Research Farm and used in producing the formulated concentrate diets (Tables 1 and 2).

Results were statistically analyzed according to a 2 × 2 factorial design with extrusion and protein source as main factors; sex was used as the block factor using SAS 9.4 software (SAS Institute Inc., Cary, USA, 2016). The number of rams and ewes was balanced within each treatment to prevent gender effects. Mean values are accompanied by standard errors where applicable.

Results and Discussion

Statistical analysis of the production data revealed no statistical interaction between extrusion and protein source. Results of the main effects (extrusion and protein source) are therefore presented in Tables 3 and 4. The effect of extrusion of the protein source on the production performance of Meatmaster lambs is presented in Table 3. No significant differences in any of the measured production parameters were detected. These findings were in contrast to results obtained by Serrano et al. (1998), who obtained an improved FCR with extruded feed fed to calves during their transition phase (monogastric to ruminant), relative to calves fed a control diet (2.63 vs 3.29). Similar feed intakes for extruded (1.44 kg/day) and non-extruded feed (1.43 kg/day) were found. This result is supported by the study of Amirteymoori et al. (2021) on male Kermani lambs, where the DMI of extruded linseed was comparable to the DMI of ground linseed (1383 vs 1323 g/day).

Previous results (Brand & Jordaan, 2020) indicated an increase in the rumen undegradable protein (RUP) fractions of sweet lupins and canola oilcake meal. These findings were not corroborated by the production results obtained in the current study. Meatmaster lambs are an early maturing breed (van der Merwe, 2020a & b), indicating a possibly lower requirement for bypass protein (van der Merwe et al., 2020). Results with later maturing breeds fed from an earlier age may present different results.

Lambs fed extruded feed obtained an ADG of 0.310 kg/day vs. 0.300 kg/day obtained by lambs fed non-extruded feed. Comparable weight gains throughout the trial for the extruded and control diets were evident (12.60 kg vs. 12.65 kg). Mendowski et al. (2019) also found similar body weights and body condition scores in dairy cows fed normal or extruded lupins. A lower body weight in lambs fed extruded linseed relative to ground linseed (38.60 kg vs. 40.40 kg) was observed by Amirteymoori et al. (2021).

Results found in this study may be due to the extrusion conditions not being optimal in terms of temperature and duration spent in the extruder barrel. Deacon et al. (1988) proved that the crude protein (CP) digestibility of protein sources extruded at 121 °C was not affected by extrusion conditions. Deacon et al. (1988) also suggested that insufficient response to extrusion may be due to extrusion temperatures that are too low and insufficient time of the material spent under pressure. As stated by both Serrano (1979) and Rahman et al. (2015), variation in extrusion results can be dependent on a variety of factors, including the type of extruder used, different extrusion conditions, and also the particle size and composition of the feed being extruded. It is clear from current results as well as results from the literature that the ideal extrusion conditions for different protein sources are not defined yet. The role and amount of sugar needed to provide the ideal conditions for the Maillard reaction to occur without the irreversible binding of the protein sources are similarly uncertain.

Table 4 represents the effect of protein sources (canola oilcake meal and sweet lupins) on the production performance of Meatmaster lambs. The feed intakes of canola oilcake meal and sweet lupins were relatively similar (1.39 vs. 1.47 kg/day), and animals spent a comparable amount of days in the feedlot (41.8 vs 42.3 d for canola oilcake meal and sweet lupins, respectively). No differences in FCR between lupins (4.87 kg feed/kg weight gain) or canola oilcake meal were observed. The results clearly indicate no statistical differences in the production performance of lambs fed a diet with sweet lupins or canola oilcake meal as the protein source.

In theory, canola oilcake meal is classified as a moderate source of rumen undegradable protein (McKinnon et al., 1995) relative to sweet lupins, being 81% degradable in the rumen (Mendowski et al., 2019). Unextruded canola oilcake meal supplies more microbial protein to the small intestine (Gous, 1998; Dickinson et al., 2004; Kriel, 2014). In conclusion, differences between the performance parameters of protein sources were similar (P <0.05), which suggests the potential of sweet lupins as a protein source for lambs.

The chemical composition of the treatment groups (CC, CE, LC, and LE) is summarized in Table 5. Extrusion did not seem to have an effect on the chemical composition of canola oilcake meal and sweet lupins in respect of the CP content. Solanas et al. (2008) stated that extrusion has little effect on the chemical composition of feed mixtures.

No differences (P <0.05) were present for either protein source (canola oilcake meal and sweet lupins) or processing method (extrusion) on the carcass fat thickness of Meatmaster lambs (Table 6). The carcass fat thickness of Meatmaster lambs that were fed canola oilcake meal, sweet lupins, the extruded diet, and the control diet were 8.72 mm, 7.14 mm, 8.34 mm, and 7.52 mm, respectively. Regardless of processing, an average fat level of 4 (7-9 mm, with 11.6-14.6% subcutaneous fat) (van der Merwe et al., 2020) were achieved during the feeding trial. This is due to the Meatmaster being an earlier maturing breed. Thus the onset of adipose tissue starts earlier than in late maturing sheep breeds. This is a result of the elevated blood leptin, which regulates intake by stimulating or suppressing appetite (van der Merwe et al., 2019). Plaisance et al. (1997) also stated that extrusion processing does not have any influence on carcass classification and composition.

Although there was no statistical interaction between protein source and extrusion, further improvement of performance parameters is possible by application of more precise extrusion conditions in order to optimize the RUP fractions. Serrano (1979) stated that the processing conditions in previous research are not always well defined. Nevertheless, the current study demonstrated that similar performance parameters could be achieved using canola oilcake meal and sweet lupins as alternative protein sources. With lupin costing R4 800/ton (R1 278 contribution to diet costs), relative to canola oilcake at R9 264/ton (R1 611 contribution to diet costs) (Trust & Committee, 2022), the study identifies sweet lupins as a less expensive plant protein source in comparison to canola oilcake meal and obtains similar performance parameters in lambs under feedlot conditions. Availability and price of protein sources will ultimately determine utilization in feed formulations (Brand, 2007). As pressure increases on the use of oilseed meals globally, this will promote lupin production in South Africa (Brand & Jordaan, 2020).

Future recommendations would be to test the precise temperature application and time period for raw materials spent in the extruder barrel. The addition of maize could increase the stability of the extrudates by increasing gelatinization (Solanas et al., 2008b). Lastly, an alternative source of molasses powder could be explored to prevent possible crystallization in the extruder barrel, which ultimately delays the extrusion process.

Conclusion

With increasing commodity prices, animal feed protein sources are becoming more expensive. The need arises to explore more affordable, locally-produced plant protein sources for animal feed. No differences in production performance of Meatmaster lambs were found with regards to processing (extrusion) of sweet lupins or canola oilcake meal in this study. Although previous results indicated a clear increase in RUP in protein sources due to extrusion, the time of feeding of the products with the amino acid requirements of the animal at a specific stage may play an important role in the results obtained. The ideal extrusion conditions and the amount of molasses added may also be critical and certain processing conditions may include an irreversible binding of the amino acid in the protein source.

Nonetheless, sweet lupins are a less expensive plant protein source than canola oilcake meal in the diets of Meatmaster lambs under feedlot conditions at this growth stage. Lupins are easily adaptable to poor soil and require less N fertilization and may therefore be an alternative protein source for lambs in feedlots in South Africa.

Acknowledgements

The Western Cape Department of Agriculture is acknowledged for providing facilities to do the study, as well as for joint funding of the study. The Western Cape Agricultural Research Trust is thanked for the joint funding of the study.

Author contributions

Concept and design: TSB; Source of funding: TSB; data collection and analysis: TSB & OD; drafting of initial paper: OD; critical revision and final approval of the version to be published: TSB. This statement is to certify that all the authors of this paper made substantial contributions to the conception and design, acquisition of data, and analysis and interpretation of data. All the authors have seen and approved the manuscript being submitted.

Conflict of interest declaration

The authors certify that they have no affiliations with or involvement in any organization or entity with financial or non-financial interests in the subject matter and materials discussed in this manuscript

References

Amirteymoori, E., Khezri, A., Dayani, O., Mohammadabadi, M., Khorasani, S., Mousaie, A., Kazemi-Bonchenari, M., 2021. Effects of linseed processing method (ground versus extruded) and dietary crude protein content on performance, digestibility, ruminal fermentation pattern, and rumen protozoa population in growing lambs. Ital. J. Anim. Sci. 20, 1506-1517 https://doi.org/10.1080/1828051X.2021.1984324. [ Links ]

Brand, T.S., 2007. Research performed in the Western Cape area of South Africa on alternative plant protein sources in pig diets. Elsenbg J. 2007, 5-9. [ Links ]

Brand, T.S., Jordaan, L., 2020. Effect of extrusion on the rumen undegradable protein fraction of lupins. Arq. Bras. Psicol. 50, 779-785 https://doi.org/10.4314/sajas.v50i6.2. [ Links ]

Cary, N.C., 2016. SAS/SHARE® 9.4: User's Guide, Second Edition. SAS Institute Inc., United States of America. [ Links ]

Claassen, V., 2011. ExtruAfrica shows potential of extrusion in feed production. https://www.allaboutfeed.net/animal-feed/feed-processing/extruafrica-shows-potential-of-extrusion-in-feed-production/. Accessed June 2022. [ Links ]

Deacon, M.A., De Boer, G., Kennelly, J.J., 1988. Influence of Jet-Sploding® and extrusion on ruminal and intestinal disappearance of canola and soybeans. J. Dairy Sci. 71, 745-753. https://doi.org/10.3168/jds.S0022-0302(88)79614-9. [ Links ]

Dickinson, E.B., Hyam, G.F.S., Breytenbach, W.A.S., Metcalf, W.D., Basson, W.D., Williams, F.R., Scheepers, L.J., Plint, A.P., Smith, H.R.H., Smith, P.J., van Vuuren, P.J., Viljoen, J.H., Archibald, K.P., Els, J.N., 2004. Lupiene. In: Kynoch Pasture Handbook. Kejafa Knowledge Works, Maanhaarrand. [ Links ]

Gous, R.M., 1998. Evaluation of canola and lupins for pig and poultry feeding. Protein Research Trust. Project No. 10/99, 1998-1999, University of KwaZulu-Natal, Pietermaritzburg. [ Links ]

Heuzé, V., Tran, G., Sauvant, D., Lessire, M., Lebas, F., 2020. Rapeseed meal. Feedipedia, a programme by INRAE, CIRAD, AFZ and FAO. [ Links ]

Kriel, G., 2014. Kanola: Oliekoek puik proteTen vir vee. Landbouweekblad, 30. [ Links ]

Masoero, F., Moschini, M., Fusconi, G., Piva, G., 2006. Raw, extruded, and expanded pea (Pisum sativum) in dairy cow diets. Ital. J. Anim. Sci. 5, 237-247. https://doi.org/10.4081/ijas.2006.237. [ Links ]

McKinnon, J.J., Olubobokun, J.A., Mustafa, A., Cohen, R.D., Christensen, D.A., 1995. Influence of dry heat treatment of canola meal on site and extent of nutrient disappearance in ruminants. Anim. Feed Sci. Technol. 56, 243-252. [ Links ]

Mendowski, S., Chapoutot, P., Chesneau, G., Ferlay, A., Enjalbert, F., & Germain, A., 2019. Effects of replacing soybean meal with raw or extruded blends containing faba bean or lupin seeds on nitrogen metabolism and performance of dairy cows. J. Dairy Sci. 102(6), 5130-5147. doi: 10.3168/jds.2018-15416. [ Links ]

Mustafa, A.F., Gonthier, C., Ouellet, D.R., 2003. Effects of extrusion of flaxseed on ruminal and postruminal nutrient digestibilities. Arch. Anim. Nutr. 57, 455-463. https://doi.org/10.1080/0003942032000161036. [ Links ]

Plaisance, R., Petit, H.V., Seoane, J.R., Rioux, R., 1997. The nutritive value of canola, heat-treated canola and fish meals as protein supplements for lambs fed grass silage. 68, 139-152. [ Links ]

Rahman, M. A. U., Rehman, A., Chuanqi, X., Long, Z. X., Binghai, C., Linbao, J., & Huawei, S., 2015. Extrusion of feed/feed ingredients and its effect on digestibility and performance of poultry: A review. Int. J. Curr. Microbiol. Appl. Sci. 4, 48-61. [ Links ]

Risk, A., Team, A., Directorate, P.H., & Zealand, B.N., 2021. Technical review of animal feed processing methods. Processing parameters for retorting, extrusion-cooking, baking, and chemical treatment in the production of animal feed from animal-derived raw material. [ Links ]

Serrano, X., Baucells, M.D., Barroeta, A.C., Puchal, F., 1998. Effects of extruded diet on the productive performance of weaning and post-weaned calves. Anim. Feed Sci. Tech. 70(3), 275-279. https://doi.org/10.1016/S0377-8401(97)00082-5. [ Links ]

Serrano, X., 1979. The extrusion-cooking process in animal feeding: Nutritional implications. Lipids. 26, 107-114. [ Links ]

Solanas, E.M., Castrillo, C., Jover, M., De Vega, A., 2008b. Effect of extrusion on in situ ruminal protein degradability and in vitro digestibility of undegraded protein from different feedstuffs. J. Sci. Food Agric. 88, 2589-2597 https://doi.org/10.1002/jsfa.3345. [ Links ]

Trust, O.P.S.D., Committee, O.A., 2022. Statistics and Estimates: Crops, Reports, and Bulletins. [ Links ]

van der Merwe, D.A., 2020. Modelling the growth, feed intake, and backfat deposition of different South African sheep breed types. Thesis (PhD. Agric.), Stellenbosch University, South Africa. 178, 70-78. [ Links ]

van der Merwe, D.A., Brand, T.S., Hoffman, L.C., 2020a. Premium lamb production of South African sheep breed types under feedlot conditions. S. Afr. J. Anim. Sci. 50, 578-587. https://doi.org/10.4314/sajas.v50i4.9. [ Links ]

van der Merwe, D.A., Brand, T.S., Hoffman, L.C., 2019. Application of growth models to different sheep breed types in South Africa. Small Rumin. Res. 178, 70-78. https://doi.org/10.1016/j.smallrumres.2019.08.002. [ Links ]

van der Merwe, D.A., Brand, T.S., Hoffman, L.C., 2020b. Precision finishing of South African lambs in feedlots: A review. Trop. Anim. Health Prod. 52, 2769-2786. https://doi.org/10.1007/s11250-020-02282-x. [ Links ]

Submitted 21 July 2022

Accepted 29 August 2023

Published 25 October 2023

# Corresponding author: Tertius.Brand@westerncape.gov.za