Serviços Personalizados

Artigo

Indicadores

Links relacionados

-

Citado por Google

Citado por Google -

Similares em Google

Similares em Google

Compartilhar

South African Journal of Science

versão On-line ISSN 1996-7489

versão impressa ISSN 0038-2353

S. Afr. j. sci. vol.120 no.1-2 Pretoria Jan./Fev. 2024

http://dx.doi.org/10.17159/sajs.2024/16626

RESEARCH ARTICLE

Use of sulfur dioxide to reduce postharvest decay and preserve the quality of fresh tomatoes

Chanel K. Daniei-SwartiandI, II; Julia C. Meitz-HopkinsI; Filicity A. VriesII; Cheryl L. LennoxI

IFruit and Postharvest Pathology Research Programme, Department of Plant Pathology, Stellenbosch University, Stellenbosch, South Africa

IITessara (Pty) Ltd, Cape Town, South Africa

ABSTRACT

Tomatoes are an important and versatile crop with a short shelf life. Postharvest losses due to fruit decay and handling are reportedly as high as 30-50% globally; therefore, the agricultural sector would benefit from solutions that target the preservation of crops such as tomatoes. In this study, we investigated the potential use of sulfur dioxide (SO2) to provide postharvest protection against fungal decay in tomatoes whilst maintaining the quality of tomato fruit. Three tomato varieties packed as bulk (3-5 kg) cartons were exposed to SO2-generating sheets applied as either a top sheet over the fruit or a bottom sheet placed on the base of the carton before packing the fruit on the top. The results show that the application of SO2-generating sheets reduced the natural progression of decay on 'Roma' tomatoes by up to 60% and up to 80% on 'Rosa' tomatoes. Only marginal decay control was observed on 'Round' tomatoes. The top sheet application rendered the best results, as the application of the bottom sheet resulted in phytotoxicity in the form of SO2 damage. SO2 application reduced fruit shrivelling, especially when tomatoes were stored at higher temperatures during their shelf life. The application of SO2 on the tomatoes did not have any negative effects on fruit firmness. The results of this study provide a case to further explore the use of SO2-generating sheets on tomatoes to prevent postharvest decay. Differences in varietal physiology may be key to the successful application of this technology.

SIGNIFICANCE:

Tomatoes are a crop that is highly susceptible to postharvest decay. These effects lie mainly with the end consumer. Besides the monetary loss of buying a commodity that rots quickly, pathogens infecting tomatoes are known to produce mycotoxins that pose a risk to human health. With food availability and safety concerns, the application of a product that could reduce these concerns would be beneficial to the agricultural sector.

Keywords: sulfur dioxide, Roma tomatoes, Rosa tomatoes, Round tomatoes, postharvest decay

Introduction

Tomatoes are a lucrative crop globally, with production exceeding one billion tons in 2021.1 Unfortunately, total production does not translate to total consumption due to losses that occur along the distribution chain.2 In South Africa, tomatoes rank second in relation to potatoes as important commodities; they contribute approximately 24% of the country's annual vegetable production.3 Commercial tomato-growing regions in South Africa include the provinces of Limpopo, Mpumalanga, KwaZulu-Natal, Eastern Cape and Western Cape, but the Limpopo region remains the largest grower of tomatoes. In 2021, the estimated production of tomatoes was around 530 834 tons1, with an estimated gross production value of about ZAR3 031 644.1 Tomatoes in South Africa are sold as fresh produce through direct sales and exported to neighbouring African countries like Mozambique, Angola and Zambia.4

Tomatoes ripen and deteriorate quickly. Ripe tomatoes could last for as long as 2 weeks, but the shelf life is further reduced by decay, injuries and general poor handling.5 Tomatoes are prone to postharvest decay caused by a complex of fungi such as Rhizopus stolonifer (Ehrenb.) Vuill. 1902, Botrytis cinerea Pers. 1797, Alternaria alternata (Fr.) Keissl. 1912 and Colletotrichum coccodes (Wallr.) S. Hughes.6 Bacterial and viral infections are also common. Statistics relating to postharvest decay of tomatoes are rarely reported as it mostly appears at consumer level. Studies that have investigated the progression of the disease over time report that 74% of ripe fruit will exhibit decay after 2 weeks of storage.7 Due to quick deterioration, tomatoes cannot be stored for long periods, which puts pressure on producers and retailers to get the fruit to the market as soon as possible. This limits market access and the potential revenue that could be generated if the fruit was able to stay fresh for longer.

Current postharvest handling of tomatoes in South Africa involves handpicking in the early to mid-mornings and then transporting the tomatoes in open plastic crates to the packhouse. Where infrastructure allows, bins are tipped into a dump tank where the tomatoes are washed in chlorinated water at a dose of about 50-200 ppm. Tomatoes then pass over rollers with light brushes that dry the fruit before being tipped onto the packing tables to be packed either as loose or bagged product, as per retail requirements. Postharvest decay control with fungicides is rare, because application of any product would have to comply with maximum residue levels for safe human consumption. The short shelf life of tomatoes makes it difficult to identify such a postharvest chemical. The chlorine wash provides an effective sanitation method to prevent new infections; however, it does not prevent the proliferation of pathogens which may have already been established through the stem scar.8

Sulfur dioxide (SO2) is extensively used in the food and beverage industry as an antioxidant and preservative9 in dried fruits, soft drinks and alcoholic beverages. SO2 applications to prevent enzymatic browning in bananas, lemons and apples have been reported.10 SO2 application is also used on fresh fruit such as table grapes to inhibit fungal growth caused by B. cinerea.11,12Cantin et al.12 reported good inhibition of various postharvest pathogens on fresh figs when SO2 was applied via fumigation or using SO2 pads. Efficacy of SO2 in conjunction with controlled atmosphere storage has also shown promising results in reducing decay, extending the shelf life and maintaining the nutritional value of fresh blueberries.13

The most common drawback of using SO2 on soft fruit is the bleaching that may occur. Some studies report that SO2-generating pads increased the occurrence of bleaching on the skins of figs12 and grapes10. Usually this happens at wound sites or fresh abscission sites, but excessive exposure can also cause SO2 damage in the form of sunken areas on fruit surfaces, as well as contribute to premature browning of the grape stems.12

SO2 has long been considered an acceptable food additive; however, with the recent trends of moving away from chemical usage in foodstuffs, SO2 usage is questioned. Although mostly harmless, exposure to SO2 could be problematic for people who have sulfite allergies.9,14 As requested by the European commission, the European Food Safety Authority published a review that re-evaluated the use of SO2 and other sulfites as food additives.15 The panel noted that the current acceptable daily intake of 0.7 mg/kg of body weight could be subjected to review as the actual intake was higher amongst population groups. The panel did not express any concerns of harmful genotoxic, chronic, carcinogenic or negative reproductive effects based on studies done regarding oral exposure; however, a later review in 2022 reported a lower acceptable daily intake of 0.38 mg/kg of body weight.15

Currently, there are no SO2 products registered for postharvest use on tomatoes, globally. The preharvest application of sulfur as a nutrient for tomato plant growth is known. The exposure of tomato plants to SO2 gas has been studied16 with negative findings17, but research on the postharvest application of SO2 on fresh tomatoes is a novel concept. In this study, we investigated the potential use of SO2-generating sheets to provide postharvest protection against fungal organisms that cause decay on tomatoes, whilst maintaining the quality of tomato fruit.

Materials and methods

Fruit

Two varieties of long-life tomatoes, 'Round' and 'Roma', and one variety of specialty tomato, 'Rosa', were procured from packhouses in the Western Cape, South Africa. The fruit was picked and packed into 5 kg cartons for the larger varieties and 3 kg cartons for the smaller 'Rosa' tomatoes. Normal packhouse procedures of fruit washing and grading per class and variety were followed. As per these normal procedures, the variety 'Rosa' was not subjected to postharvest fruit washing. Class 1 fruit was used for the study.

Sulfur dioxide and decay control

The ability of SO2 to reduce the decay that occurs naturally in tomatoes was investigated. A SO2-generating sheet was manufactured by Tessara (Pty) Ltd, Cape Town, South Africa, to be used in these experiments. The sheet provided for testing was formulated as a dual-release sheet, with a high first phase of SO2 emissions (gas levels), followed by a second low-emission phase.

Treatments applied in this trial were as follows: (1) Top sheet - SO2-generating sheet positioned over the tomatoes in the carton, (2) Bottom sheet - SO2-generating sheet placed inside on the base of the carton with fruit packed on the top, and (3) Control - without any SO2 sheets in the cartons. A total of six cartons were packed for each treatment group to satisfy statistical requirements. The cartons were stored at 10 °C for either 14 or 21 days, after which quality evaluations were done. For both these time intervals, fruit boxes were evaluated, the decayed and poor-quality fruit was removed, and the remaining good fruit was moved to 18 °C for a further 7 days to mimic shelf-life storage. The trials were done in duplicate for the 'Round' and 'Roma' tomatoes and in triplicate for the 'Rosa' tomatoes over a space of 2 years.

At each evaluation, the amount of fungal decay, SO2 damage and shrivel was recorded by fruit count for 'Round' and 'Roma' tomatoes and by fruit weight for the 'Rosa' tomatoes. Symptomatic fruits were subjected to isolation and molecular identification of a subset of isolates by sequencing the ITS gene region as described in the literature.18 Percentage defects were calculated relative to the original numbers of fruit in the carton or the total box weight. In addition, a sample of 10 fruits was taken from each treatment group to evaluate firmness, which was done using a fruit texture analyser. The firmness test was conducted using an 11-mm probe for the large tomatoes and a 3-mm probe for the small tomatoes. Each fruit was pierced once at opposite ends to render a total of two readings per fruit. Average firmness is reported.

Statistical analysis

The analysis was conducted independently by the Agricultural Research Council (ARC)-Infruitec Nietvoorbij, Stellenbosch, South Africa. The experimental design was randomised with six replicates for each treatment combination. An analysis of variance (ANOVA) was applied on continuous variables and the output evaluated using sAs19 statistical software. The four main parameters evaluated were fungal decay, shrivel, fruit firmness and SO2 damage. A Shapiro-Wilk20 test was used to determine deviation from normality. A Fisher's least significant difference was used to compare treatment means, where a probability level of 5% was deemed significant.21

Results

A combined average over two trials was calculated for fungal decay, shrivel, fruit firmness and SO2 damage for the 'Round' and 'Roma' tomatoes. Three trials were conducted for the 'Rosa' tomatoes, with all being statistically different; therefore, the results are discussed separately. Varieties were not compared and will be discussed separately. All data reported for shelf life are cumulative.

Decay control

ANOVA interactions were significant for parameters of decay (p <0.0001) and decay inhibition (p = 0.04) in 'Roma' tomatoes (Table 1). The control sets throughout the storage period had significantly higher decay incidence (21-67%) than tomatoes treated with the SO2 sheets (8-55% decay incidence; Figure 1). The effect of the treatments continued for up to 7 days after cold storage, even after the sheets had been removed, indicating that the initial SO2 application has an ongoing effect and that the protection against decay will continue in the absence of SO2 exposure, thereby extending the shelf life of 'Roma' tomatoes. With regard to sheet placement, it was noted that both the top and bottom placed sheets effectively reduced the decay. The results infer that a bottom sheet will be more beneficial with longer storage time, as at 21 days of cold storage, tomatoes treated with a bottom placed sheet had significantly less decay than the tomatoes treated with a top sheet.

An ANOVA for 'Round' tomatoes indicated no significant differences in decay (Table 1). The 'Round' tomatoes were presented with high decay levels throughout the trial. After 14 days at 10 °C, decay recorded on the 'Round' tomatoes was between 22% and 25% (Figure 1). At this point, there was no statistical difference between the treated and control fruit. When moved to shelf life, the tomatoes treated with a top placed sheet had significantly lower decay than the control fruit; however, the decay was high (62%). After extended storage (21 days) at 10 °C, the fruit treated with the bottom sheet showed the least amount of decay, but this was not statistically different to the other groups.

The ANOVA for 'Rosa' tomatoes showed that all three trials conducted were different; therefore, the results could not be combined, and the trials need to be discussed separately (Table 1). In the first trial, there was no significant interaction between all parameters evaluated during initial storage; however, the interaction was significant when tomatoes were moved to shelf life. In the second and third trials, interactions were not significant for both initial storage and shelf life.

The trials for 'Rosa' tomatoes differed significantly with the amount of decay observed (Figure 2). The first trial showed a fair amount of decay with the controls reaching up to 30% decay during the initial storage, whilst Trials 2 and 3 recorded between 0.9% and 7% decay during the same time. In Trial 1, there was no significant difference in decay between SO2 treatments and the control during the initial 7-day storage evaluation and subsequent shelf life, although tomatoes treated with SO2 had about 10% less decay than the control during initial storage. Exposure to SO2 sheets for up to 14 days showed that treated tomatoes had significantly less decay than the control. The bottom sheet proved to be the best treatment, differing significantly from the top sheet. The results for the 14 days plus shelf life evaluation were not different to the initial evaluation, as decay did not develop further.

In Trial 2, after 7 days in storage, the control had less than 1% decay. Still, the results indicate a significant reduction in decay when the tomatoes were treated with SO2 sheets. The sheet placements did not differ from each other. Decay was so low that no further development occurred during shelf life. In this trial, there were no significant differences between SO2 treatments and controls after 14 days in storage. Decay recorded in the third trial was less than 10% in the control, and for both storage periods and the respective shelf life, the treatments and controls did not differ significantly, although the top sheet treatment did have less actual decay than the control.

Percentage decay inhibition was calculated for all varieties. This determines which concentrations would be necessary to kill off at least 50% of the fungal growth on tomatoes. After 14 days at 10 °C and subsequent shelf life at 18 °C, decay on 'Roma' tomatoes was inhibited by approximately 63% and 58%, respectively, when a top sheet was applied (Table 2). A bottom sheet application resulted in an inhibition range of 54-65% over the same period. Long-term cold storage (21 days) with a top sheet shows that decay is inhibited by about 30% and 17% inhibition at shelf life. The bottom sheet resulted in 60% inhibition after 21 days in cold storage and 38% after shelf life.

For 'Round' tomatoes, there was a negative correlation when percentage decay inhibition was calculated (Table 2). Only marginal inhibition was noted with the application of the bottom sheet over the long-term storage period. This value is less than 50%; therefore, SO2 treatments on 'Round' tomatoes cannot be recommended as a viable treatment option at present.

Decay inhibition differed between trials conducted on 'Rosa' tomatoes. In the first trial, application of a top sheet inhibited decay after 7 days by 22% and by 28% after 14 days. A bottom sheet inhibited decay after 7 days by 33% and by 68% after storage for 14 days. In the second trial, SO2 application was most successful during the 7-day storage period. During this time, a top sheet reduced decay by 81% relative to the control and a bottom sheet reduced decay on 'Rosa' tomatoes by 78%. The sheets did not seem to be effective after 14 days. In the third trial, the top sheet SO2 application was most successful, inhibiting decay during the first 7 days by 48% and then by 80% when used for a period of 14 days (Table 3). Isolates from all three varieties that were subjected to molecular identification were found to be identical to GenBank references of Alternaria spp. (KP125281).

SO2 damage

When the concentration of SO2 gas in the carton is too high, or the gas becomes localised to certain areas, it can cause SO2 bleaching or damage to the fruit.22 The percentage of SO2 damage that was recorded on 'Roma' and 'Round' tomatoes after the 14- and 21-day cold storage periods and subsequent shelf life is presented in Figure 3. A significant amount of SO2 damage was recorded in cartons with a bottom sheet when compared to other treatments. Although significantly higher than the top sheet treatments, it must be noted that the overall value of SO2 damage at its highest was a mere 5.4% on 'Roma' tomatoes.

The SO2 damage was more pronounced on the 'Round' tomatoes (Figure 3). After 14 days, the incidence of SO2 damage ranged from 0.89% for the top sheet application to 16.21% for the bottom sheet application. A significant increase in SO2 damage was noted on tomatoes that were treated with a bottom sheet. Inexplicably though, the continued exposure to the bottom pads after 21 days in cold storage yielded less SO2 damage on fruit than at 14 days.

The results for SO2 damage on 'Rosa' tomatoes echo that of the other two varieties. Minimal SO2 damage was observed with application of a top sheet, and high SO2 damage (up to 18%) was observed when a bottom sheet was used across the three trials (Figure 4). For all varieties, the SO2 damage that was observed during the initial storage did not develop further after shelf life. In cases where increased amounts during shelf life are noted, this could be due to inadequate sorting during the initial inspection.

Shrivel

Following the 2 weeks at a 10 °C storage regime, the amount of shrivel on 'Roma' tomatoes did not differ between treatments; however, when moved to shelf life, the SO2-treated tomatoes had more shrivel than the control tomatoes (Figure 5). Over the 21-day storage period, however, SO2-treated tomatoes had significantly less shrivel than the control fruit; and during the respective shelf life, tomatoes treated with a top sheet showed significantly less shrivel than the bottom sheet treated tomatoes and the control tomatoes.

For 'Round' tomatoes, the results were mostly insignificant except for the 21-day shelf-life period, where tomatoes treated with SO2 applied as a top sheet were significantly less shrivelled than the bottom sheet treated and control tomatoes. Overall, the shrivel on 'Round' tomatoes was minimal throughout the trial (Figure 5).

For 'Rosa' tomatoes, the results varied between trials (Figure 6). In the first trial, no significant difference in shrivel was observed among treatments after the first 7 days; however, during the shelf life, tomatoes treated with a top sheet had significantly less shrivel than the bottom sheet treated and control tomatoes. After 14 days, the converse was shown, with the controls having the least amount of shrivel. In Trial 2, there was no difference in shrivel between SO2 treatments and the respective controls throughout the trial period. In the third trial, tomatoes treated with SO2 consistently had less shrivel than the controls throughout the trial.

Firmness

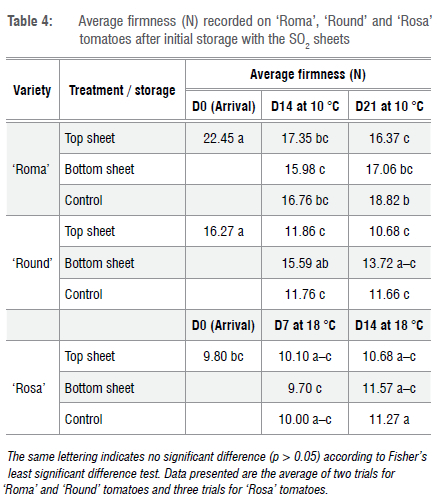

Prior to the initial cold storage, samples were taken for firmness testing to establish a baseline representing the firmness of the fruit on arrival. Measurements at each initial evaluation were then compared to this baseline. For all varieties, a natural decline in firmness was observed when comparing the readings for the control to the arrival reading (Table 4).

For 'Roma' tomatoes, firmness values for all treatments were similar throughout the trial; however, in the 21-day cold storage, tomatoes treated with a top sheet were significantly less firm than the controls. For the 'Round' tomatoes, there was also a natural decline in firmness relative to the arrival readings, as noted in the controls. However, it was observed that tomatoes treated with a bottom sheet maintained readings relative to that of the arrival quality for up to 21 days in cold storage. 'Rosa' tomatoes held their firmness throughout the trial period of 14 days. There was no significant drop in firmness relative to the baseline reading, and there was no difference between the control and SO2-treated tomatoes.

Discussion

Tomatoes are picked, packed, and distributed to retailers within a period of 2 to 3 days. This is primarily due to tomatoes ripening and deteriorating quickly. This quick turnaround time puts pressure on the packhouse and retailer to get the fruit out. Based on information gathered from industry stakeholders on preferred storage times, the 'Roma' and 'Round' tomatoes were stored for up to 14 and 21 days in cold storage. The 'Rosa' tomatoes were stored for up to 7 and 14 days. These time frames could open opportunities for transporting tomatoes to new markets located further away than those currently supplied, or even for storing tomatoes for longer when production volumes are high.

Spoilage of tomatoes in storage due to pathogens is an important aspect to consider for the postharvest preservation of the crop. The resulting postharvest diseases contribute to losses in both quantity and quality of the crop.23 The application of SO2 as a postharvest decay control strategy was investigated in this study to prevent pathogen proliferation and preserve the quality of tomatoes. For years, SO2 has been successfully applied to grapes. In the USA, it is a widespread practice to first fumigate harvested grapes with a high dosage (1000-5000 ppm) of SO2, followed by lower dosages over time, gradually decreasing the dose with each application.24 Grape farmers in the USA still use SO2 fumigation; however, fumigation during storage is now being done by treatment with a SO2 pad within the grape carton. The idea around this methodology is that the initial high SO2 dosage will sterilise the surface of the grapes, and the in-package treatment will allow for a lower dose of SO2 to be constantly released to offer added protection against decay development over the storage period. In other areas of the world, like South Africa, table grape farmers rely solely on the SO2 packaging insert to control decay development in their grapes.

In this study, we used a dual-release SO2 sheet. The active ingredient, sodium metabisulfite (Na2S2O5), is encapsulated between layers of non-woven material and plastic. The layers that make up the dual-release system are designed such that when the Na2S2O5 encounters moisture from the respiration of the fruit and humidity of the environment, SO2 gas is released. The first stage releases a high dose (mimicking fumigation), and the second stage releases a lower dose of SO2 to keep the fruit surface sterile and prevent decay.

Decay symptoms observed in these trials were presented primarily as water-soaked and black sunken lesions that are consistent with black mould infection caused by Alternaria spp. Decay on 'Roma' tomatoes was reduced by both the top and bottom sheet applications. The results suggest that short-term storage (14 days) of 'Roma' tomatoes benefits from using a top SO2 sheet, whilst for long storage periods (21 days), a bottom sheet would be better. However, use of a bottom sheet does present complications because of SO2 damage that can occur. The 'Round' tomatoes used in this study seemed to be sensitive to pathogen attack. Considerable amounts of decay were observed throughout storage and shelf life. Decay on 'Round' tomatoes was not shown to be statistically reduced with the application of a SO2 sheet, even though numerical values of the treatments were lower than the control. Decay on 'Rosa' tomatoes differed between trials conducted. This shows the natural variation that occurs throughout the year and between seasons. Due to the availability of tomatoes, the trials were conducted over a period of 1 year (2020-2021). Tomatoes for the first trial were sourced in November, which is the start of rising summer temperatures. The conditions in the Western Cape over this time are often conducive to pathogen development, which could be what was observed. The second trial was conducted in September (early spring). These were early season fruit and may have been more steady and less prone to pathogen attack. The third trial was conducted in November 2021, and whilst decay was present, the overall inoculum level was low. Literature suggests that the time of harvest has a significant impact on fruit quality and that there are definitive differences between tomatoes harvested in autumn and spring.25 In addition to the timing of harvest, the reduced inoculum pressure over the course of the year could be attributed to preharvest practices on the farm. Natural variation in decay over time is a possibility, and played a role in these trials. Overall, though, when looking at the effect of an SO2-generating sheet on the reduction of natural decay on 'Rosa' tomatoes, both the top and bottom SO2 sheet applications were useful in reducing decay, with results favouring the use of a top sheet application for this variety.

We have shown that the application of a SO2 sheet during storage also had an impact on the decay that developed after shelf life when the SO2 sheet was removed. This was consistent for all varieties. Whilst decay did develop, it was much less than what was recorded on the controls. This is explained in that SO2 sterilises the fruit surface and can kill off spores and mycelia on the fruit surface; however, it has less impact on latent infections26 which come into play in the absence of SO2 (removal of sheets). The further development of decay during the shelf life indicates that residue left on the fruit surface after sheets are removed is not adequate to prevent the proliferation of fungi.

We did not directly compare varieties; however, the variations were apparent. Variations in decay amongst tomato varieties have been previously reported. Sinha et al.23 reported that, under ambient conditions after 16 days, the variety 'Sofol' showed 21% decay whilst the variety 'Roma' had 43% decay. 'Sofol' is a round-type tomato, and with that in mind, we see the opposite occurrence with regard to decay patterns in this study, perhaps due to differences in cultivation practices and climatic regions.

An accumulation or localisation of SO2 gas can cause SO2 bleaching or damage to the fruit.22 Through the sorting process, all defects observed at the cold storage evaluation were removed before placing the fruit at shelf life. When the fruit is still cold, the condensation that forms on the fruit surface makes it hard to see slight SO2 damage. Therefore, any SO2-damaged tomatoes observed during the shelf life can be attributed to improper sorting at the initial cold storage evaluation.

A key finding from these trials is that the bottom sheet yielded more SO2 damage than the top sheet. The damage observed from the bottom sheet could be attributed to the increased pressure of fruits sitting on top of each other and pressing onto the bottom sheet. This is the most obvious explanation, as damage seen with the top sheet application was not as pronounced. With the application of a top sheet, the fruits are not pressing onto the sheet, even if contact is made. For all varieties, the amount of SO2 damage observed with the application of a top sheet was negligible (less than 1%); in comparison, SO2 damage from a bottom sheet was up to 5% on 'Roma' tomatoes, up to 16% on 'Round' tomatoes and up to 18% on 'Rosa' tomatoes. SO2 damage can have various manifestations on fruit, the most common being bleaching (discolouration) and fruit pitting.27 Both these symptoms were observed on tomatoes to varying degrees. In some instances, only a slight discolouration around the stem scar was visible; however, where pressure was applied, as with the application of a bottom sheet, the fruit showed signs of pitting. Unfortunately, whilst a slight discolouration can be overlooked, pitting would render the tomatoes unmarketable due to appearance.

Tomatoes have a high water content and are prone to shrinkage due to moisture loss after harvest.28 Of the three varieties used in this trial, 'Roma' and 'Rosa' tomatoes were most affected by shrivelling, during the shelf-life storage phase. In contrast, shrivel on 'Round' tomatoes was minimal. This could be due to the initial water content of the varieties and the respective respiration rates. With 'Roma' tomatoes, short-term exposure to SO2 had no effect on shrivelling; however, long-term exposure to SO2 did reduce the incidence of shrivel. A similar pattern was observed with the 'Round' tomatoes. 'Rosa' tomatoes benefitted from SO2 exposure throughout the trial period.

In conclusion to a study on the firmness of tomatoes, Batu29 proposed two firmness readings for large tomatoes. The first is for fruit marketed at retail level, which should render a firmness reading greater than 1.45 N/mm (0.15 kg), and the second value is for tomatoes for home consumption, which should be greater than 1.28 N/mm (0.13 kg). The firmness of both large tomato varieties recorded in this study was well above these readings, even for the control fruit; the 'Roma' tomatoes were firmer than the 'Round' tomatoes. This finding corresponds with the literature that states that processing tomatoes like 'Roma' tend to be firmer and last longer than fresh market tomatoes. Varietal differences in firmness are accounted for by properties such as cell wall composition.30 A gradual decline in firmness was observed across all three varieties used in this study, and the results obtained show that SO2 exposure did not negatively affect this quality parameter.

Conclusion

The results confirm that a SO2 sheet applied as a top sheet can be used to effectively reduce decay by a minimum of 58% on 'Roma' tomatoes when refrigerated at10 °C for up to 14 days and then exposed to ambient temperatures for another 7 days. Alternatively, a bottom sheet application can reduce decay by 60% if tomatoes are kept refrigerated for 21 days, but the potential SO2 damage must be considered. 'Round' tomatoes in this study only benefitted from a marginal reduction in decay by the application of a bottom sheet. Continuous refinement of this product for use on 'Round' tomatoes will need to focus on reducing the SO2 damage. The potential for decay control in 'Rosa' tomatoes is high because, even though trials differed, a decay inhibition of up to 80% was obtained at different intervals.

The outcome of this study builds a strong case for the use of SO2-generating sheets to be used on certain tomato varieties under commercial conditions for the purpose of decay reduction during storage. As an added benefit, the use of SO2-generating sheets may assist with reduced shrivelling of tomatoes during storage. Furthermore, SO2 does not negatively affect the firmness of tomatoes during storage.

Acknowledgements

We acknowledge Tessara (Pty) Ltd for project funding and bursary contributions; Marieta vd Rijst at the Agricultural Research Council for statistical analysis; Anel Botes and team at the Agricultural Research Council for firmness testing; and the pathology team at Tessara R&D department for assistance with trial evaluations.

Competing interests

We have no competing interests to declare.

Authors' contributions

C.K.D.-S.: Conceptualisation; methodology; data collection; sample analysis; validation; writing; project management. J.C.M.-H.: Student supervision; editing of manuscript. F.A.V.: Student supervision; project leadership; funding acquisition. C.L.L.: Student supervision.

References

1. Food and Agriculture Organization of the United Nations (FAO). FAOSTAT - The Food and Agriculture Organization Corporate Statistical Database [webpage on the Internet]. c2021 [cited 2023 Aug 05]. Available from: https://www.fao.org/faostat/en/#data/Q [ Links ]

2. Bahammou N, Cherifi O, Bouamama H, Cherifi K, Moubchir T, Bertrand M. Postharvest control of gray mould of tomato using seaweed extracts. J Mater Environ Sci. 2017;8(3):831-836. http://www.jmaterenvironsci.com/ [ Links ]

3. South African Department of Agriculture, Forestry and Fisheries (DAFF). Production guidelines for tomato [document on the Internet]. c2014 [cited 2023 Aug 05]. Available from: https://www.dalrrd.gov.za/Portals/0/Brochures%20and%20Production%20guidelines/Production%20Guidelines%20Tomato.pdf [ Links ]

4. South African Department of Agriculture, Forestry and Fisheries (DAFF). Trends in the agricultural sector 2017: Tomatoes. Pretoria: DAFF; 2017. p. 59-60. [ Links ]

5. Pinheiro J, Goncalves EM, Silva CLM. Alternative technologies for tomato postharvest quality preservation. CAB Rev. 2013;8:61. https://doi.org/10.1079/PAVSNNR20138061 [ Links ]

6. Bartz JA, Sargent SA, Scott JW. Postharvest quality and decay incidence among tomato fruit as affected by weather and cultural practices. UF/IFAS Extension; 2015. Available from: http://edis.ifas.ufl.edu/ [ Links ]

7. Moneruzzaman KK, Hossain ABMS, Sani W, Saifuddin M. Effect of stages of maturity and ripening conditions on the physical characteristics of tomato. Am J Biochem Biotechnol. 2008;4(4):329-335. https://doi.org/10.3844/ajbbsp.2008.329.335 [ Links ]

8. Hurst W. Harvest, handling and sanitation. In: Commercial tomato production handbook. University of Georgia Extension Bulletin 1312. 2017. p 38-42. https://extension.uga.edu [ Links ]

9. Freedman BJ. Sulphur dioxide in foods and beverages: Its use as a preservative and its effects on asthma. Br J Dis Chest. 1980;74(2):128-134. https://doi.org/10.1016/0007-0971(80)90023-6 [ Links ]

10. Sandarani MDJC, Dasanayaka DCMCK, Jayasinghe CVL. Strategies used to prolong the shelf life of fresh commodities. J Agri Sci Food Res. 2018;9(1):206. [ Links ]

11. Gabler FM, Mercier J, Jimenez JI, Smilanick JL. Integration of continuous biofumigation with Muscodor albus with pre-cooling fumigation with ozone or sulfur dioxide to control postharvest gray mold of table grapes. Postharvest Biol Technol. 2010;55:78-84. https://doi.org/10.1016/j.postharvbio.2009.07.012 [ Links ]

12. Cantin CM, Palou L, Bremer V Michailides TJ, Crisosto CH. Evaluation of the use of sulfur dioxide to reduce postharvest losses on dark and green figs. Postharvest Biol Technol. 2011;59:150-158. https://doi.org/10.1016/j-postharvbio.2010.09.016 [ Links ]

13. Cantin CM, Minas IS, Jimenez M, Manganaris GA, Michailides TJ, Crisosto CH. Sulfur dioxide fumigation alone or in combination with CO2 - enriched atmosphere extends the market life of highbush blueberry fruit. Postharvest Biol Technol. 2012;67:84-91. https://doi.org/10.1016/j.postharvbio.2011.12.006 [ Links ]

14. Garcia-Fuentes AR, Wirtz S, Vos E, Verhagen H. Short review of sulphites as food additives. Eur J Nutr Food Saf. 2015;5(2):113-120. https://doi.org/10.9734/EJNFS/2015/11557 [ Links ]

15. EFSA Panel on Food additives and Nutrient Sources added to Food (ANS). Scientific Opinion Follow up on the re-evaluation of sulfur dioxide (E 220), sodium sulfite (E 221), sodium bisulfite (E 222), sodium metabisulfite (E 223), potassium metabisulfite (E 224), calcium sulfite (E 226), calcium bisulfite (E 227) and potassium bisulfite (E 228) as food additive. EFSA J. 2022;14(4):4438. https://doi.org/10.2903/j.efsa.2022.7594 [ Links ]

16. Leone IA, Brennan E. Modification of sulfur dioxide injury to tobacco and tomato by varying nitrogen and sulfur nutrition. J Air Pollut Control Assoc. 1972;22(7):544-547. https://doi.org/10.1080/00022470.1972.10469677 [ Links ]

17. Padhi SK, Dash M, Swain SC. Effect of sulphur dioxide on growth, chlorophyll, and sulphur content of tomato (Solanum lycopersicum L.). Eur Sci J. 2013;9:36. [ Links ]

18. Basson E, Meitz-Hipkins JC, Lennox CL. Morphological and molecular identification of fungi associated with South African apple core rot. Eur J Plant Pathol. 2019;153:849-868. https://doi.org/10.1007/s10658-018-1601-x [ Links ]

19. SAS Institute, Inc. SAS version 9.4. Cary, NC: SAS Institute Inc.; 2023. [ Links ]

20. Shapiro SS, Wilk MB. An analysis of variance test for normality (complete samples). Biometrika. 1965;52:591-611. https://doi.org/10.1093/biomet/52.3-4.591 [ Links ]

21. Ott R. An introduction to statistical methods and data analysis. Belmont, CA: Duxbury Press; 1998. p. 807-837. [ Links ]

22. Ahmed S, Roberto SR, Domingues AR, Shahab M, Chaves Junior OJ, Sumida CH, et al. Effects of different sulfur dioxide pads on Botrytis mold in 'Italia' table grapes under cold storage. Horticulturae. 2018;4:29. https://doi.org/10.3390/horticulturae4040029 [ Links ]

23. Sinha SR, Singha A, Faruquee M, Jiku MAS, Rahaman MA, Alam MA, et al. Post-harvest assessment of fruit quality and shelf life of two elite tomato varieties cultivated in Bangladesh. Bull Natl Res Cent. 2019;43:185. https://doi.org/10.1186/s42269-019-0232-5 [ Links ]

24. Smilanick JL, Henson DJ. Minimum gaseous sulphur dioxide concentrations and exposure periods to control Botrytis cinerea. Crop Prot. 1992;11:535-540. https://doi.org/10.1016/0261-2194(92)90171-Z [ Links ]

25. Kasampalis D, Tsouvaltzis, P Siomos A. Tomato fruit quality in relation to growing season, harvest period, ripening stage and postharvest storage. Emir J Food Agric. 2021;33(2):130-138. https://doi.org/10.9755/ejfa.2021.v33.i2.2176 [ Links ]

26. Smilanick JL, Hartsell PI, Henson D, Fouse DC, Assemi M, Harris CM. Inhibitory activity of sulfur dioxide on the germination of spores of Botrytis cinerea. Phytopathology. 1990;80(2):217-220. https://doi.org/10.1094/Phyto-80-217 [ Links ]

27. Zaffoli JP Latorre BA, Naranjo P Hairline, a postharvest cracking disorder in table grapes induced by sulfur dioxide. Postharvest Biol Technol. 2008;47:90-97. https://doi.org/10.1016/j.postharvbio.2008.06.013 [ Links ]

28. Arah IK, Amaglo H, Kumah EK, Ofori H. Preharvest and postharvest factors affecting the quality and shelf life of harvested tomatoes: A mini review. Int J Agron. 2015;2015, Art. #478041. http://dx.doi.org/10.1155/2015/478041 [ Links ]

29. Batu A. Determination of acceptable firmness and colour values of tomatoes. J Food Eng. 2004;61:471-475. https://doi.org/10.1016/S0260-8774(03)00 141-9 [ Links ]

30. Tigist M, Workneh TS, Woldetsadik K. Effects of variety on the quality of tomato stored under ambient conditions. J Food Sci Technol. 2013;50(3):477-486. https://doi.org/10.1007/s13197-011-0378-0 [ Links ]

Correspondence:

Correspondence:

Chanel Daniel-Swartland

Email: ChanelD@tessara.co.za

Received: 05 Aug. 2023

Revised: 01 Nov. 2023

Accepted: 01 Nov. 2023

Published: 30 Jan. 2024

Editor: Teresa Coutinho

Funding: Tessara (Pty) Ltd