Serviços Personalizados

Artigo

Indicadores

Links relacionados

-

Citado por Google

Citado por Google -

Similares em Google

Similares em Google

Compartilhar

South African Journal of Science

versão On-line ISSN 1996-7489

versão impressa ISSN 0038-2353

S. Afr. j. sci. vol.118 spe Pretoria 2022

http://dx.doi.org/10.17159/sajs.2022/12652

REVIEW ARTICLE

Considerations on bio-hydrogen production from organic waste in South African municipalities: A review

Andrea Dell'Orto; Cristina Trois

NRF SARChI Research Chair in Waste and Climate Change, Discipline of Civil Engineering, University of KwaZulu-Natal, Durban, South Africa

ABSTRACT

Organic waste disposal contributes to 3.8% of GHG emissions to the atmosphere, yet 68.8% of this putrescible waste fraction is still disposed of, untreated, to landfills in South Africa. The implementation of a ban on disposal of organic waste to landfills at provincial level opens up the need to research best technology pathways and waste minimisation strategies to valorise and promote the circularity of diverted waste streams. The SARChI Chair in Waste and Climate Change has developed the WROSE™ (Waste Resource Optimization Scenario Evaluation) model to assist municipalities in selecting the most appropriate waste management solutions. A research gap has been identified in the lack of information on full-scale applications of two-stage anaerobic digestion (2-stage AD) for combined bio-hydrogen and bio-methane production from organic waste. In this review, we explore drivers and barriers to the implementation of 2-stage AD in South Africa and propose possible scenarios using the WROSE™ model for its insertion into an Integrated Waste Management System at municipal level. A literature analysis suggests that 2-stage AD is a potentially viable solution to recover the inherent value of organic waste and promote circularity using bio-hydrogen and bio-methane. However, the currently available organic fraction in the municipal solid waste streams is not a suitable feedstock, as it requires high levels of pre-treatment. Suitable scenarios using the WROSE™ model are proposed for South African municipalities, paving the way for future research towards the scale-up of this technology.

SIGNIFICANCE:

• Organic waste is not managed adequately in South Africa, contributing to greenhouse gas emissions without recovering the intrinsic value of the material.

• 2-stage AD is a potentially viable solution to recover the inherent value of organic waste and promote circularity using bio-hydrogen and bio-methane. Several barriers must be overcome before carrying out the technology at full-scale.

• A 2-stage AD scenario can be implemented at full-scale into an Integrated Waste Management System using appropriate decision-making tools such as WROSE™.

Keywords: 2-stage AD, bio-hydrogen, organic waste, Integrated Waste Management System, WROSE™ model

Introduction

In a world that has always prioritised the extraction of new materials, our resources and energy demand have skyrocketed because of overpopulation and improved living standards in developing countries. Consequently, the contribution from anthropogenic greenhouse gas (GHG) emissions to climate change has increased greatly.1 Therefore, the new circular economy concept is gaining ground to tackle this issue. This idea considers a novel approach synthesised by the 4 Rs: reduce, reuse, recycle and recover.2

Africa has immense potential for recovering materials from waste, which is now mostly dumped or burned outside of proper waste management facilities.3,4 However, African countries focus predominantly on passive and inexpensive treatment methods such as landfilling, which do not recover the added value inherent in waste materials but do contribute to environmental pollution. While only 4% of the yearly African organic waste production (71 million tonnes) is recovered, incrementing recycling rates to 25% would yield over USD243 million in additional monetary value, originating from the by-products of proper treatment.5 Landfill disposal has commonly been the preferred method due to very affordable gate fees (in most cases fees are USD10-15 per tonne of waste in South Africa - up to 10 times lower than in Europe) and, in the past, abundance of space.6 However, landfills are rapidly filling up, raising the need for an effective diversion of organic fractions such as food waste, garden refuse, the organic fraction of municipal solid waste (OFMSW), and agricultural waste. Another downside of landfilling of organic waste is the substantial impact on human health and the environment, including the uncontrolled GHG emissions to the atmosphere, due to the high biodegradability of organic waste.7,8

The South African government is working on the gradual diversion of solid waste from landfills.9 Moreover, South African provinces, starting from the Western Cape, are progressively implementing organics-to-landfill bans to increase landfills' lifespans, reduce carbon emissions and valorise the economic potential of waste.10 The new regulatory acts, along with the new law on extended producer responsibility11, are raising the need to find an alternative treatment option for this putrescible waste stream.

Biological methods such as composting achieve proper stabilisation of organic matter, but they do not facilitate energy production or the recovery of valuable material, given the low commercial potential of compost.12 On the other hand, anaerobic digestion (AD) partially sacrifices the stabilisation of biodegradable matter to recover a biogas mostly made of methane and carbon dioxide that can be burned to produce electricity or to fuel gas systems.13 Moreover, if AD is performed in a two-stage configuration (2-stage AD), hydrogen gas could also be recovered after the first stage, thus increasing the energy recovery of the system and reducing the impact of organic waste treatment in terms of GHGs.13

Anaerobic biodigesters have successfully been implemented across rural South Africa on a micro-scale level, mainly using agricultural waste, animal manure and even sewage waste as feedstocks.14 However, there is a lack of studies on their implementation in urban and peri-urban areas at a larger scale, where different feedstocks, such as OFMSW, food waste and garden refuse, are available.15 Moreover, biological hydrogen production from such waste fractions has been investigated worldwide16 as well as in South Africa17, but mainly in a standalone configuration called dark fermentation, and not to optimise the successive production of hydrogen and methane. In contrast, 2-stage AD still needs to be improved and advanced from lab-scale to micro-scale and, possibly, full-scale, to make it applicable both at the household and municipal level. For this purpose, we investigated the drivers for and barriers to the implementation of such technology and explore the possibility of introducing a 2-stage AD scenario in an Integrated Waste Management System in South African municipalities using the Waste Resource Optimization Scenario Evaluation (WROSE™) model, which is an essential tool to assist municipalities in selecting the most appropriate and sustainable treatment method for organic waste management.18,19

2-stage AD for bio-hydrogen and bio-methane in South Africa

Recovering the inherent value of organic waste would be the ideal realisation of the circular economy concept, in which every material becomes a resource at the end of its life cycle. However, this approach requires adopting the most appropriate treatment methods, such as AD, to fulfil and maximise such a goal.

AD is a biological process that occurs spontaneously in natural environments devoid of oxygen, such as soil, sediments and ruminants' stomachs, and the waste body of landfills. A series of anaerobic bacteria degrade and convert organic matter into a biogas mostly made of methane and carbon dioxide.13

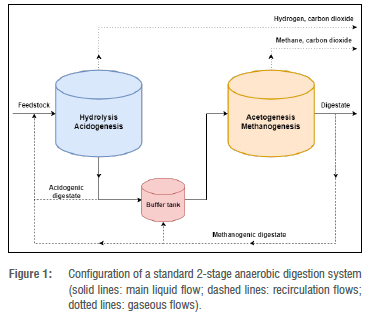

Conventional AD is a well-established process that allows for the recovery of energy from biogas. However, recovery efficiency can be further increased if the process is performed in two stages to prevent the degradation of hydrogen during acetogenesis.13 In this new configuration, the first reactor hosts the first two phases (hydrolysis and acidogenesis) in a process called dark fermentation (as it occurs in the absence of light), while the second stage consists of a combined acetogenesis-methanogenesis on the digestate that emerges from the first stage. As shown in Figure 1, the second reactor might be preceded by a buffer tank that can be used to remove matter recalcitrant to hydrolysis, increase control on operational pH and organic load, or even dilute inhibiting compounds.20

The first stage hosts both hydrolytic microorganisms and fermentative species. Hydrolytic bacteria (Bacteroidetes and Firmicutes phyla21) secrete extracellular enzymes that break down complex organic matter into simpler molecules, generating monosaccharides, amino acids and fatty acids from carbohydrates, proteins and fats, respectively. Those smaller compounds are then degraded into volatile fatty acids (VFAs), ethanol and low molecular weight alcohols, gaseous hydrogen and carbon dioxide by microorganisms such as Clostridium sp., Enterobacter sp., Escherichia coli and Bacillus sp. (mesophilic), thermophilic Clostridium (C. thermocellum) and Thermoanaerobacterium sp. and extremely thermophilic Caldicellulosiruptor sp. and Thermotoga sp.22

Hydrolytic species prefer a pH of 6-8 but are more adaptable to different environmental conditions than are acidogenic microorganisms, which thrive at a pH of 5.5-6.5.20 Consequently, as the goal of 2-stage AD is to maximise both hydrogen and methane production, the optimal pH for the first stage is in the 5.5-6 range, thus preventing hydrogen consumption by methanogenic bacteria, which are inhibited at acidic pH.23,24

In the second stage, methanogenesis is preceded by acidogenesis, the transformation of VFAs into acetic acid and hydrogen operated by propionate-oxidisers such as Syntrophus and Syntrophomonas sp., Pelotomaculum sp., Smithllela sp., and Syntrophobacter sp.21 These acetate-producing bacteria perform reactions that are not thermodynamically favoured, and therefore they have to rely on the hydrogenotrophic methanogens to consume the hydrogen immediately. This syntrophic partnership is essential to keep the H2 partial pressure sufficiently low (<10-4-10-5 atm) to guarantee favourable conditions for acetogenesis.25 A second methanogenic pathway, called acetoclastic methanogenesis, consists of the transformation of acetic acid into methane and carbon dioxide and accounts for about 70% of the global methane production.26 Unlike hydrogen-producing bacteria, methanogens cannot sporulate to withstand extreme environmental conditions and are limited to a pH range of 6.2-7.8, with best performances at pH 7-7.2.20,24 Typical bacterial species responsible for methanogenesis are Desulfobacterium sp., Methanoculleus sp., Methanospirillum sp. and Methanococcus sp. (mesophilic), Methanothermobacter sp. and Methanosarcina sp. (thermophilic), and Methanothermus sp. and Methanothermococcus sp. (extremely thermophilic).22

Control of operational pH is paramount to maximise biogas yields and maintain the stability of the process, especially in the first stage, given the production and accumulation of acidic compounds. While chemicals can be used as buffering agents to avoid excessive acidification and prevent bacterial inhibition from VFAs build-up, their continued use is not sustainable from an economic standpoint. Therefore, recirculation of methanogenic digestate into the acidogenic reactor has been investigated, and has proved to be a feasible method to provide sufficient residual ammonia and bicarbonate to preserve the stability of the first stage, while reducing the cost of pH buffering.24 Because an excess of ammonia can lead to bacterial inhibition, it is essential to keep the VFAs/alkalinity ratio in the 0.3-0.5 range.27 As a consequence, the optimal recirculation ratio has been investigated. Depending on the feedstock, optimal values for the ratio are between 0.3 and 0.65, which leads to an increase in biogas production of up to 75%.28-30 Recirculation of digestate can also be performed in the same reactor to increase the hydraulic retention time and enhance the removal of volatile solids (VS) and biogas production.20

Hydrolysis is usually the rate-limiting step of anaerobic digestion due to the recalcitrant compounds that make up lignocellulosic feedstocks.31,32 Therefore, a 2-stage configuration can be carried out using two different operational temperatures: a thermophilic (50-60 °C) first stage that enhances the breaking down of refractory molecules, and a mesophilic (30-40 °C) second stage that maintains advantageous conditions for methanogenesis while reducing energy consumption.20,24 When using a lignocellulosic substrate, the first stage is usually operated in a continuous stirred-tank reactor that can facilitate mixing, while the second stage can be carried out in different reactors, such as a continuous stirred-tank reactors, upflow anaerobic sludge blanket reactors (high loading rates, low retention times), anaerobic fluidised bed reactors (efficient, with high recycle rate but high energy costs) or expanded granular sludge bed reactors (modified anaerobic fluidised bed systems, with a lower upflow velocity and partial bed fluidisation).20,33

Energy expenditures are a significant operational cost for an anaerobic digestion system. In comparison with a single-stage reactor, a 2-stage configuration can potentially result in a twofold energy generation from biogas.34 However, using two reactors increases the electricity and heating costs, thus hindering the system's energy balance. A recent study highlighted that, although the 2-stage configuration recovered up to 12.25 kJ/g-VS from biomethane production, its energy balance remained negative at -2.16 kJ/g-VS, despite being an improvement from the -3.41 kJ/g-VS achieved by the single-stage reactor.34 Therefore, combining the energy recovery from both hydrogen and methane can potentially help obtain a net energy gain and needs further investigation.

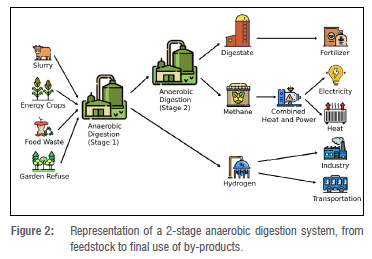

Figure 2 highlights the role of a standard 2-stage AD system in transforming organic waste into valuable by-products that can be reintroduced into a circular economy or used to produce electricity and heat. However, because the demand for household heating is not widespread across South Africa, the combined heat and power unit could be replaced with a simpler combustion engine or gas turbine for electricity production in order to reduce costs.

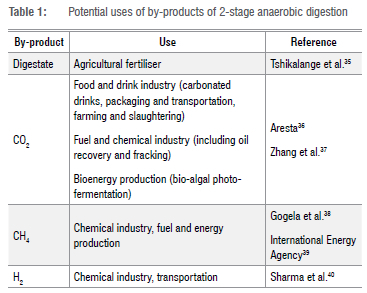

When a 2-stage AD system is fed with organic waste such as slurry, energy crops, food waste and garden refuse, this new configuration becomes a perfect realisation of the idea of a circular economy, as all the possible outputs can find some application in the economy as secondary materials (Table 1).

AD digestate has been successfully used as a cheaper and environmentally friendly alternative to inorganic fertilisers without affecting the quality and quantity of the final agricultural product, especially if the feedstock is source-separated organic waste.35,41 In fact, the residual sludge coming from an AD process that partially stabilised the organic matter, with a VS reduction of between 60% and 90%, is a fluid with a low total solid content (3-15%) which contains macronutrients (N, R K, Ca, S and Mg) and micronutrients (B, Cl, Mn, Fe, Zn, Cu, Mo and Ni) needed for plant growth.42

Carbon dioxide (CO2) has extensive application in different sectors, such as the food and drink industry, fuel and chemical industry, and bioenergy production.36,37 It is usually produced as a by-product of several industrial processes (methane steam reforming, fertiliser synthesis) but can be captured, utilised and sequestered from atmospheric emissions in order to limit its global warming potential. In fact, cO2 is the main component of anthropogenic greenhouse gas emissions, and therefore the leading cause of climate change.43

The same consideration applies for methane, as its global warming potential over 100 years is 28-36 times higher than that of CO244, even if its concentrations in the atmosphere are significantly lower (410 ppm for CO2 versus 1.866 ppm for CH4)43. However, combustion of methane generates more energy per unit mass (55.7 kJ/g) than any other solid fuel, as a consequence of its high hydrogen content45, while also originating less CO2. Therefore, methane is routinely used in many chemical industrial processes to produce fuel and electricity, primarily through steam generators and gas turbines.38,39

On the other hand, hydrogen is a non-toxic gas that can generate more heat per mass (142 kJ/g) than any other fuel46, without generating any polluting emissions because the only by-product of its combustion is water vapour47. H2 is generally produced from fossil fuels, most commonly through steam methane reforming, thus cancelling all the advantages of its clean combustion.48 New renewable production methods have been investigated, and water electrolysis supplied with solar and wind power is a promising alternative, but is heavily reliant on weather conditions.48 In contrast, producing hydrogen and methane through 2-stage AD using a constantly available feedstock such as OFMSW would ensure a clean, reliable and sustainable production that would also valorise the energy potential of organic waste.49

Availability and suitability of organic waste as feedstock for 2-stage AD

In South Africa, organic waste is most commonly landfilled, contributing to GHG emissions without recovering the intrinsic value of the material.15 However, drivers such as the consistent increase in waste production could induce municipalities to endorse alternative treatment methods.5

The generation of municipal solid waste (MSW) is strictly connected to several demographic and monetary drivers, such as population growth, urbanisation, economic development, global trade, expansion of middle class and modified consumption habits.7 Despite the declining population growth in South Africa, which dropped from 2.3% in 2013 to 1.0% in 2021, the population number continues to increase, surpassing 60 million people for the first time in 2021.15,50 South Africa is experiencing a shift from a rural to a more urbanised population, especially in provinces such as KwaZulu-Natal.50 The largest cities have doubled growth rates compared to smaller towns and contribute to a vast majority (over 80%) of the national gross value added.50 Therefore, the number of people moving to urban areas will grow with time, leading to an increased MSW generation due to the enhanced lifestyle and the augmented accessibility to store-bought goods.15 It has been projected that, in African countries, the growth in the production of MSW, estimated at 30% in the 2012-2025 timeframe, will not even out before 2100, therefore posing critical challenges in terms of waste management.5 Furthermore, recent studies foresee that, in South Africa, the collection rate for MSW will increase to 66-75% in 2025 from 43-55% in 2012, posing an ulterior challenge in terms of proper management of the additional waste produced and collected.3

According to the South Africa State of Waste Report15, in 2017, organic waste made up 56.3% of the total general waste in the country, for an estimated amount of about 30.5 million tonnes, of which 68.8% was landfilled. However, this fraction mainly consists of by-products of agricultural and industrial processing (sugar and sawmills, paper and pulp industry), while there is a lack of specific data for the OFMSW. Nonetheless, the totality of MSW, which made up 8.9% (4.8 million tonnes) of the national waste production, was still sent to landfill in 2017, therefore raising a need for a separate treatment of its putrescible fraction - the main contributor to the production of harmful leachates and the emission of GHGs from landfills.51

In South African municipalities, garden refuse is generally collected separately from municipal waste and then landfilled or, in some cases, composted to reduce the quantity of waste disposed of in a landfill.52 It has been estimated that, in 2017, this fraction accounted for about 30% of MSW generated in South Africa.15 The diversion of garden waste from landfills could unlock different beneficial effects, such as monetary savings (reduction of leachate production that will require treatment; landfill airspace savings and extension of the landfill lifespan) and reduction of GHG emissions in the atmosphere.15

These arguments are even more compelling when discussing the other major organic fraction currently landfilled in South Africa: food waste. South Africa produces about 31 million tonnes of food every year, but about one third is lost mainly during supply.53 55 However, food wastage is not experienced only in the supply chain but also at a household level.56 A study of the domestic waste habits in Rustenburg, in the North West Province, found that food waste production is strictly related to income levels. While food waste accounts for 13% and 17% of total waste production in middle-income and high-income households, respectively, a higher percentage (27%) is observed in low-income households, possibly because of inadequate refrigeration and proper storage facilities.53,57

Several characterisation studies investigating food waste production in major South African municipalities confirm that the amounts fluctuate within a 3-33% range.58,59 Such food wastage has considerable financial repercussions. It has been calculated that, in 2012, food loss and waste directly amounted to ZAR61.5 billion (2.1% of South Africa's GDP), while the cost related to food wasted by households was worth ZAR21.2 billion (0.8% of national GDP).53,60 In addition, indirect costs, such as diesel and electricity costs utilised in the food processing and supply chain, were estimated at about ZAR1 billion.53

Besides the economic aspects, proper management of food residues would also be beneficial from an environmental standpoint. There are two levels of emissions that are strictly associated with food waste: direct emissions from disposal of organic waste into landfills and indirect emissions linked to every step of the food production and supply chain. Recent studies show that, globally, the yearly direct emissions from food loss have more than tripled in the 1961-2011 period, mainly as a consequence of the contribution of developing countries, where people have switched to a diet richer in fresh food, while food waste related emissions from developed regions have contracted from half to a quarter of the global contributions.61 In the UK, it has been calculated that food wastage at the household level accounts for about 3% of national GHG emissions.53

In South Africa, there is a lack of data on direct and indirect emissions, which still require better understanding and adequate quantification, particularly at the municipal level.51,62,63 However, the South African Department of Forestry, Fisheries and the Environment has recently published the 2017 National GHG Inventory Report64 to help quantify the actual emissions related to each sector. While the coal-fuelled energy sector is still responsible for the vast majority (80.1%) of South Africa's carbon footprint, the waste sector accounts for 3.8% (21 249 Gg CO2e) of the national GHG emissions (excluding 'FOLU - Forestry and Other Land Use'), with disposal of solid waste contributing over four-fifths (81.7%) of the total emissions related to waste management.64 Even though total national emissions decreased by 2.8% between 2015 and 2017, the contribution from the waste sector increased by 4.4% - an increase which was mainly driven by the disposal of solid waste.64 Therefore, it is essential to develop a sustainable alternative to landfilling of putrescible waste, which is the main waste responsible for GHG landfill emissions, to reverse the trend while producing by-products that can promote circularity of the secondary materials in the economy.62 AD, especially in its 2-stage configuration, can solve this problem, but several gaps still need to be addressed.

Barriers to the implementation of 2-stage AD in South Africa

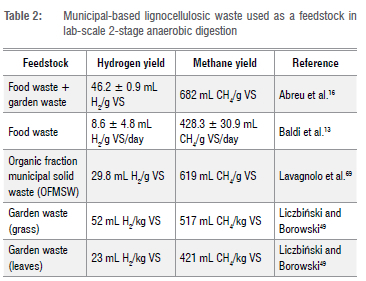

A wide variety of organic materials can be used as a feedstock for AD, but most are not suitable for mono-digestion and require co-digestion to guarantee the right conditions for the bacterial species involved in AD.65-67 For instance, it has been determined that the municipal-based lignocellulosic biomasses available in the eThekwini Municipality are the organic fraction of municipal solid waste, food waste, garden waste, and, potentially, energy crops cultivated on the topsoil of closed landfills according to a technique called phytocapping.68 Similar feedstocks have been used worldwide to produce hydrogen and methane at a laboratory scale (Table 2).

However, most of these studies focused on the co-digestion of solids with liquid feedstocks, such as sewage sludge, that could act as an inoculum. Additionally, there is only a handful of studies that considered co-digesting two different solid waste streams, and most of them focused on a conventional single-stage AD.16,65-67,70 Therefore, there is a clear need to determine the best operational conditions to perform 2-stage AD using lignocellulosic feedstocks that differ in nature and which can offset their differences in terms of nutrients and guarantee a more stable and efficient digestion. For the same purpose, the pre-treatment of lignocellulosic waste, necessary to enhance solids' biodegradability and biogas yields, needs to be further investigated.65,66

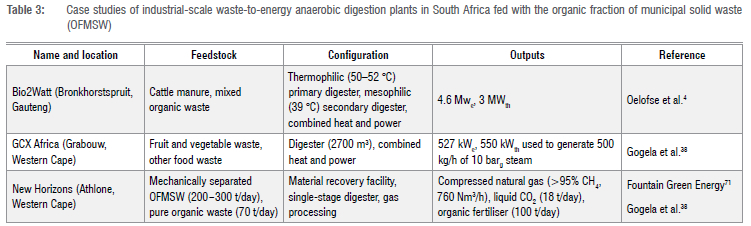

Subsequently, the potential for up-scaling 2-stage AD must be assessed, following the successful example of industrial plants that already produce biogas in South Africa using OFMSW (Table 3).

In addition to the technology gaps, several barriers must be overcome before successfully applying 2-stage AD in South Africa. For instance, 2-stage AD requires a clean feedstock that can only be achieved by implementing a separate collection of the OFMSW.69 Moreover, there is a need to change the perception of alternative waste treatment methods from more high-priced to more cost-effective than landfilling when environmental benefits are considered. Finally, there are limited opportunities for a market for secondary materials.4,5 However, the political will to back up hydrogen projects through South Africa's Hydrogen Society Roadmap72, which has been extended until 2031, can drive investments and demand for hydrogen. Another political driver is the implementation of organics-to-landfill bans at both national and provincial levels.9,10 In addition, 2-stage AD can benefit from several socio-economic drivers, such as the potential for poverty alleviation and social development of disadvantaged people, through job creation, entrepreneurial opportunities, and women empowerment.4,5

Considerations on the insertion of 2-stage AD in an Integrated Waste Management System

The scaling-up of 2-stage AD is a necessary but insufficient step to prepare its insertion in an Integrated Waste Management System. The technology must be investigated under a life cycle assessment, environmental impact assessment, or sustainable/environmental technology assessment approach to recognise all the flows and impacts related to the system.73 Additionally, selection and quantification of the most appropriate indicators is required to perform a proper assessment of 2-stage AD.19,74

In this context, several waste-management models can provide decision-makers, such as industrial companies or municipal officials, with the tools to make informed decisions on the most suitable technology. For instance, the Waste Reduction Model (WARM) was developed by the US Environmental Protection Agency (US-EPA) to determine the implications of baseline and alternative waste management scenarios in terms of GHG emissions and energy and monetary savings.75 Similarly, WRATE is a UK-based life cycle assessment model that focuses primarily on the environmental impacts of waste management strategies.76

Unfortunately, these models target environmental and technological aspects without including social and institutional indicators. Moreover, they rely on GHG emission factors suited to industrialised countries, and therefore they are not entirely reliable and applicable in developing nations. Other models developed specifically for South Africa, like SAScOST77, are focused on highlighting the advantages deriving from the implementation of source-separation of waste, a preferable option that does not represent the current situation of waste management in most of the country15.

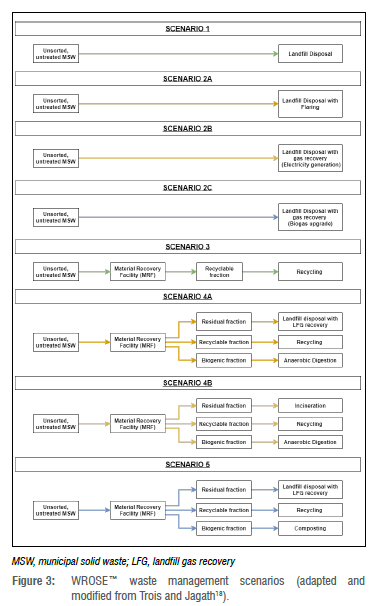

Consequently, the SARChI Chair in Waste and Climate Change at the University of KwaZulu-Natal developed the Waste Resource Optimization and Scenario Evaluation (WROSe™) model.18 The initial goal of WROSE™ was to compare several treatment methods, such as landfill disposal (with or without gas recovery), recycling and composting, with the current baseline scenario and quantify their GHG emissions, energy use, techno-economic feasibility, and monetary and landfill airspace savings, which would predict the extension of the lifespan of a landfill when each alternative scenario was applied. In order to make accurate calculations, WROSE™ needs a proper waste stream characterisation that precedes the determination of GHG emissions. Such outputs are obtained by modifying US-EPA/IPCC emission factors to consider both direct emissions and emissions/savings related to transportation, digestate application, and energy production from biogas.18 Since 2010, the model has been progressively developed and made more accurate by expanding its dataset with more case studies and then including social (job creation potential, health risks, public participation) and institutional indicators (environmental and energy legislation, financial and administrative regulation, licence required), while also broadening the range of examined scenarios (Figure 3) in order to make it more relevant for the South African context.19,74

Social and institutional indicators are particularly appropriate to elevate the WROSE™ model as one of the most powerful decision-making tools for South African municipalities to provide a solution that is both environmentally sound and highly impactful on people's lives. For example, it has been estimated that, while landfilling creates about 1 job/kt managed, recycling of waste would create 6-13 jobs/kt in Africa.4

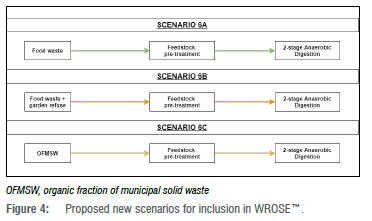

Nonetheless, the WROSE™ model still needs to be further enhanced by developing accurate South African based emission factors and including 2-stage AD in its technology portfolio. One of the critical aspects is that the organic fraction separated in a material recovery facility is not suitable for 2-stage AD but only for stabilisation due to its impurities.78 Hence, new scenarios (Figure 4) cannot be derived directly from the closest existing scenarios (4A-4B) because they need to consider the few clean organic waste fractions available in South Africa: food waste, garden refuse and OFMSW.

Future research must focus on defining detailed material and energy flows to determine the fate of each waste fraction and facilitate the integration of these scenarios in an Integrated Waste Management System. Each scenario should be investigated by testing the following set of identified indicators, comparing 2-stage AD with conventional AD18,74:

• GHG emission reduction (determined using both IPCC emission factors79, in line with the nationally determined contributions of South Africa, and scenario-specific South African emission factors determined using the WROSE model62,80)

• Technical feasibility (available feedstocks, development of pre-treatments tailored to each feedstock, bio-hydrogen and bio-methane potential, scaling-up of 2-stage AD)

• Economic feasibility (proper localisation of plant, investment costs, market profitability of by-products and potential short- and long-term savings)

• Diversion from landfill (extension of lifespan, monetary and airspace savings)

• Job creation potential (tonnes of waste or MW of electricity per job)

• Health risks (direct and indirect risk factors)

• Public acceptance and social perception (participation in source separation of waste, involvement in environmental impact assessment processes)

• Institutional indicators (environmental and energy legislation, financial and administrative regulation)

In particular, it is paramount to investigate the techno-economic feasibility and environmental impact of 2-stage AD in the context of a South African municipality.

With the inclusion of these new scenarios in WROSE™, the model will become paramount in advising municipalities on the feasibility of the new technology, paving the way for a potential insertion in an Integrated Waste Management System.

Conclusions and recommendations for future research

Landfill disposal of organic waste, still a common practice in South Africa, is associated with several deleterious impacts and many lost opportunities. Mismanagement of biodegradable waste contributes to carbon emissions and climate change, while its proper valorisation would guarantee energy and materials recovery according to the circular economy principle and create social and economic opportunities. For these reasons, 2-stage AD for the combined production of bio-hydrogen and bio-methane has been identified as a promising treatment method to achieve these goals. However, the technology needs to be researched and enhanced to address several barriers before the upscaling of 2-stage AD. Moreover, its insertion in an Integrated Waste Management System can be facilitated by determining material and energy flows and evaluating the new technology through a specific set of techno-economic, environmental, social and institutional indicators. To this end, the insertion of new 2-stage AD scenarios in the WROSE™ model would provide South African municipalities with a powerful tool to determine the environmental, economic, and social benefits of the new technology while minimising the impacts of a new plant.

Acknowledgements

We acknowledge the South African Department of Science and Innovation and the National Research Foundation for funding the SARChI Chair in Waste and Climate Change (UID 115447) through the Council for Scientific and Industrial Research (CSIR) Waste RDI Roadmap. We also acknowledge SANEDI for their contribution. This study forms part of the SANEDI/UKZN Waste to Energy Roadmap for South Africa.

Competing interests

We have no competing interests to declare.

Authors' contributions

A.D.: Conceptualisation; literature review; methodology; data collection; writing - the initial draft; writing - revisions. C.T.: Conceptualisation; methodology; writing - revisions; student supervision; project leadership.

References

1. Ellen MacArthur Foundation. Completing the picture: How the circular economy tackles climate change [webpage on the Internet]. c2019 [cited 2021 Oct 27]. Available from: https://www.ellenmacarthurfoundation.org/publications/completing-the-picture-climate-change [ Links ]

2. Kirchherr J, Reike D, Hekkert M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour Conserv Recycl. 2017;127:221-232. https://doi.org/10.1016/j.resconrec.2017.09.005 [ Links ]

3. Gebremedhin KG, Gebremedhin FG, Amin MM, Godfrey L. State of waste management in Africa. In: Africa waste management outlook. Nairobi: United Nations Environment Programme; 2018. https://wedocs.unep.org/handle/20.500.11822/25514 [ Links ]

4. Oelofse S, Nahman A, Godfrey L. Waste as resource: Unlocking opportunities for Africa. In: Africa waste management outlook. Nairobi: United Nations Environment Programme; 2018. https://wedocs.unep.org/handle/20.500.11822/25514 [ Links ]

5. Oelofse S, Nahman A. Waste as a resource : Opportunities in Africa. Resource. 2019;21(2):23-27. https://hdl.handle.net/10520/EJC-166b369632 [ Links ]

6. Godfrey L, Oelofse S. Historical review of waste management and recycling in South Africa. Resources. 2017;6(4), Art. #57. https://doi.org/10.3390/resources6040057 [ Links ]

7. Katima JHY Godfrey L. Introduction: Waste management as a priority in Africa. In: Africa waste management outlook. Nairobi: United Nations Environment Programme; 2018. https://wedocs.unep.org/handle/20.500.11822/25514 [ Links ]

8. Godfrey L, Ahmed MT, Gebremedhin KG, Katima JH, Oelofse S, Osibanjo O, et al. Solid waste management in Africa: Governance failure or development opportunity? In: Edomah N, editor. Regional development in Africa. London: IntechOpen; 2019. Available from: https://www.intechopen.com/chapters/68270 [ Links ]

9. South African Department of Environment, Forestry & Fisheries (DEFF). National Waste Management Strategy 2020. Pretoria: DEFF; 2020. Available from: https://www.environment.gov.za/sites/default/files/docs/2020nationalwaste_managementstrategy1.pdf [ Links ]

10. Western Cape Department of Environmental Affairs and Development Planning (DEA&DP). Western Cape Integrated Waste Management Plan 2017-2022. Cape Town: DEA&DP; 2017. Available from: https://www.westerncape.gov.za/eadp/files/atoms/files/Western_Cape_Integrated_Waste_Management_Plan_2017-2022.pdf [ Links ]

11. South African Department of Forestry, Fisheries and the Environment (DFFE). Draft amendments to the Regulations and notices regarding Extended Producer Responsibility. Pretoria: DFFE; 2021. Available from: https://www.environment.gov.za/sites/default/files/gazetted_notices/nemwa_extendedproducerresponsibilty202regulationsnotices_g44295gon239.pdf [ Links ]

12. Couth R, Trois C. Cost effective waste management through composting in Africa. Waste Manage. 2012;32(12):2518-2525. https://doi.org/10.1016/j.wasman.2012.05.042 [ Links ]

13. Baldi F, Pecorini I, Iannelli R. Comparison of single-stage and two-stage anaerobic co-digestion of food waste and activated sludge for hydrogen and methane production. Renew Energy. 2019;143:1755-1765. https://doi.org/10.1016/j.renene.2019.05.122 [ Links ]

14. Mutungwazi A, Mukumba P, Makaka G. Biogas digester types installed in South Africa: A review. Renew Sust Energ Rev. 2018;81:172-180. https://doi.org/10.1016/j.rser.2017.07.051 [ Links ]

15. South African Department of Environmental Affairs (DEA). South Africa state of waste: A report on the state of the environment. First draft report. Pretoria: DEA; 2018. Available from: http://sawic.environment.gov.za/documents/8641.pdf [ Links ]

16. Abreu AA, Tavares F, Alves MM, Cavaleiro AJ, Pereira MA. Garden and food waste co-fermentation for biohydrogen and biomethane production in a two-step hyperthermophilic-mesophilic process. Bioresour Technol. 2019;278:180-186. https://doi.org/10.1016/j.biortech.2019.01.085 [ Links ]

17. Sekoai PT, Gueguim Kana EB. Semi-pilot scale production of hydrogen from organic fraction of solid municipal waste and electricity generation from process effluents. Biomass Bioenergy. 2014;60:156-163. https://doi.org/10.1016/j.biombioe.2013.11.008 [ Links ]

18. Trois C, Jagath R. Sustained carbon emissions reductions through zero waste strategies for South African municipalities. In: Kumar S, editor. Integrated waste management. Volume II. London: IntechOpen; 2011. https://doi.org/10.5772/17216 [ Links ]

19. Kissoon S, Trois C. Advancement of the Waste Resource Optimization and Scenario Evaluation (W.R.O.S.E) model to include social indicators for waste management decision making in developing countries. In: Proceedings of the Sixteenth International Waste Management and Landfill Symposium; 2017 October 2-6; Sardinia, Italy. Padua: CISA Publisher; 2017. p. 8. [ Links ]

20. Pham Van D, Fujiwara T, Leu Tho B, Song Toan PP, Hoang Minh G. A review of anaerobic digestion systems for biodegradable waste: Configurations, operating parameters, and current trends. Environ Eng Res. 2020;25(1):1-17. https://doi.org/10.4491/eer.2018.334 [ Links ]

21. Wang P Wang H, Qiu Y Ren L, Jiang B. Microbial characteristics in anaerobic digestion process of food waste for methane production - A review. Bioresour Technol. 2018;248:29-36. https://doi.org/10.1016/j.biortech.2017.06.152 [ Links ]

22. Shanmugam S, Mathimani T, Rene ER, Geo VE, Arun A, Brindhadevi K, et al. Biohythane production from organic waste: Recent advancements, technical bottlenecks and prospects. Int J Hydrogen Energy. 2021;46(20):11201-11216. https://doi.org/10.1016/j.ijhydene.2020.10.132 [ Links ]

23. Pandey AK, Pilli S, Bhunia P Tyagi RD, Surampalli RY Zhang TC, et al. Dark fermentation: Production and utilization of volatile fatty acid from different wastes - A review. Chemosphere. 2022;288, Art. #132444. https://doi.org/10.1016/j.chemosphere.2021.132444 [ Links ]

24. Hans M, Kumar S. Biohythane production in two-stage anaerobic digestion system. Int J Hydrogen Energy. 2019;44(32):17363-17380. https://doi.org/10.1016/j.ijhydene.2018.10.022 [ Links ]

25. Zhu Y Zhao Z, Yang Y Zhang Y Dual roles of zero-valent iron in dry anaerobic digestion: Enhancing interspecies hydrogen transfer and direct interspecies electron transfer. Waste Manage. 2020;118:481-490. https://doi.org/10.1016/j.wasman.2020.09.005 [ Links ]

26. Srisowmeya G, Chakravarthy M, Nandhini Devi G. Critical considerations in two-stage anaerobic digestion of food waste - A review. Renew Sust Energ Rev. 2020;119, Art. #109587. https://doi.org/10.1016/j.rser.2019.109587 [ Links ]

27. Scano EA, Asquer C, Pistis A, Ortu L, Demontis V Cocco D. Biogas from anaerobic digestion of fruit and vegetable wastes: Experimental results on pilot-scale and preliminary performance evaluation of a full-scale power plant. Energy Convers Manage. 2014;77:22-30. https://doi.org/10.1016/j.enconman.2013.09.004 [ Links ]

28. Qin Y Wu J, Xiao B, Cong M, Hojo T, Cheng J, et al. Strategy of adjusting recirculation ratio for biohythane production via recirculated temperature-phased anaerobic digestion of food waste. Energy. 2019;179:1235-1245. https://doi.org/10.1016/j.energy.2019.04.182 [ Links ]

29. Wu C, Huang Q, Yu M, Ren Y Wang Q, Sakai K. Effects of digestate recirculation on a two-stage anaerobic digestion system, particularly focusing on metabolite correlation analysis. Bioresour Technol. 2018;251:40-48. https://doi.org/10.1016/j.biortech.2017.12.020 [ Links ]

30. Bolzonella D, Battista F, Cavinato C, Gottardo M, Micolucci F, Lyberatos G, et al. Recent developments in biohythane production from household food wastes: A review. Bioresour Technol. 2018;257:311-319. https://doi.org/10.1016/j.biortech.2018.02.092 [ Links ]

31. Zamri MFMA, Hasmady S, Akhiar A, Ideris F, Shamsuddin AH, Mofijur M, et al. A comprehensive review on anaerobic digestion of organic fraction of municipal solid waste. Renew Sust Energ Rev. 2021;137, Art. #110637. https://doi.org/10.1016/j.rser.2020.110637 [ Links ]

32. Ferraro A, Massini G, Mazzurco Miritana V Rosa S, Signorini A, Fabbricino M. A novel enrichment approach for anaerobic digestion of lignocellulosic biomass: Process performance enhancement through an inoculum habitat selection. Bioresour Technol. 2020;313, Art. #123703. https://doi.org/10.1016/j.biortech.2020.123703 [ Links ]

33. Ersahin ME, Ozgun H, Dereli RK, Ozturk I. Anaerobic treatment of industrial effluents: An overview of applications. In: Waste water - Treatment and reutilization. London: IntechOpen; 2011. Available from: https://www.intechopen.com/chapters/14547 [ Links ]

34. Parra-Orobio BA, Donoso-Bravo A, Torres-Lozada P. Energy balance and carbon dioxide emissions comparison through modified anaerobic digestion model No 1 for single-stage and two-stage anaerobic digestion of food waste. Biomass Bioenergy. 2020;142, Art. #105814. https://doi.org/10.1016/j.biombioe.2020.105814 [ Links ]

35. Tshikalange B, Bello ZA, Ololade OO. Comparative nutrient leaching capability of cattle dung biogas digestate and inorganic fertilizer under spinach cropping condition. Environ Sci Pollut Res. 2020;27(3):3237-3246. https://doi.org/10.1007/s11356-019-07104-8 [ Links ]

36. Aresta M. Carbon dioxide utilization: Greening both the energy and chemical industry: An overview. In: Liu C, Mallinson RG, Aresta M, editors. Utilization of greenhouse gases. Washington DC: American Chemical Society; 2003. p. 2-39. https://doi.org/10.1021/bk-2003-0852.ch001 [ Links ]

37. Zhang Z, Pan S-Y Li H, Cai J, Olabi AG, Anthony EJ, et al. Recent advances in carbon dioxide utilization. Renew Sust Energ Rev. 2020;125, Art. #109799. https://doi.org/10.1016/j.rser.2020.109799 [ Links ]

38. Gogela U, Pineo C, Basson L. The business case for biogas from solid waste in the Western Cape [document on the Internet]. Cape Town: GreenCape; 2017. Available from: https://www.greencape.co.za/assets/Uploads/GreenCape-Biogas-Business-Case-Final.pdf [ Links ]

39. International Energy Agency (IEA). Outlook for biogas and biomethane: Prospects for organic growth. Paris: IEA; 2020. Available from: https://www.iea.org/reports/outlook-for-biogas-and-biomethane-prospects-for-organic-growth/an-introduction-to-biogas-and-biomethane [ Links ]

40. Sharma SK, Goyal IP Tyagi and RK. Hydrogen-fueled internal combustion engine: A review of technical feasibility. Int J Performability Eng. 2015;11(5):491-501. https://doi.org/10.23940/ijpe.15.5.p491.mag [ Links ]

41. Angouria-Tsorochidou E, Thomsen M. Modelling the quality of organic fertilizers from anaerobic digestion - Comparison of two collection systems. J Clean Prod. 2021;304, Art. #127081. https://doi.org/10.1016/j.jclepro.2021.127081 [ Links ]

42. Peng W, Lü F, Hao L, Zhang H, Shao L, He P. Digestate management for highsolid anaerobic digestion of organic wastes: A review. Bioresour Technol. 2020;297, Art. #122485. https://doi.org/10.1016/j.biortech.2019.122485 [ Links ]

43. IPCC. Climate change 2021: The physical science basis. Contribution of Working Group I to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change. Cambridge, UK: Cambridge University Press. Forthcoming 2021 [cited 2021 Aug 09]. Available from: https://www.ipcc.ch/report/ar6/wg1/ [ Links ]

44. US Environmental Protection Agency. Understanding global warming potentials [webpage on the Internet]. c2016 [cited 2021 Oct 27]. Available from: https://www.epa.gov/ghgemissions/understanding-global-warming-potentials [ Links ]

45. Schmidt-Rohr K. Why combustions are always exothermic, yielding about 418 kJ per mole of O2. J Chem Educ. 2015;92(12):2094-2099. https://doi.org/10.1021/acs.jchemed.5b00333 [ Links ]

46. Cappai G, De Gioannis G, Friargiu M, Massi E, Muntoni A, Polettini A, et al. An experimental study on fermentative H2 production from food waste as affected by pH. Waste Manage. 2014;34(8):1510-1519. https://doi.org/10.1016/j.wasman.2014.04.014 [ Links ]

47. Rosen MA, Koohi-Fayegh S. The prospects for hydrogen as an energy carrier: An overview of hydrogen energy and hydrogen energy systems. Energy Ecol Environ. 2016;1(1):10-29. https://doi.org/10.1007/s40974-016-0005-z [ Links ]

48. Nikolaidis P, Poullikkas A. A comparative overview of hydrogen production processes. Renew Sust Energ Rev. 2017;67:597-611. https://doi.org/10.1016/j.rser.2016.09.044 [ Links ]

49. Liczbiñski P Borowski S. Effect of hyperthermophilic pretreatment on methane and hydrogen production from garden waste under mesophilic and thermophilic conditions. Bioresour Technol. 2021;335, Art. #125264. https://doi.org/10.1016/j.biortech.2021.125264 [ Links ]

50. Statistics South Africa (Stats SA). Mid-year population estimates. Pretoria: Stats SA; 2021 [cited 2021 Sep 18]. Available from: http://www.statssa.gov.za/?page_id=1854 [ Links ]

51. Friedrich E, Trois C. Current and future greenhouse gas (GHG) emissions from the management of municipal solid waste in the eThekwini Municipality -South Africa. J Clean Prod. 2016;112:4071-4083. https://doi.org/10.1016/j.jclepro.2015.05.118 [ Links ]

52. Du Plessis R. Evaluation of the applicability of draft national norms and standards for organic waste composting to composting facilities on landfill sites. In: Godfrey L, Gorgens JF, Roman H, editors. Opportunities for biomass and organic waste valorisation. London: Routledge; 2018. p. 29-46. [ Links ]

53. WWF. Food loss and waste: Facts and futures. Cape Town: WWF South Africa; 2017. Available from: www.wwf.org.za/food_loss_and_waste_facts_and_futures [ Links ]

54. Nahman A, De Lange W. Costs of food waste along the value chain: Evidence from South Africa. Waste Manage. 2013;33(11):2493-2500. https://doi.org/10.1016/j.wasman.2013.07.012 [ Links ]

55. Notten P, Bole-Rentel T, Rambaran N. Developing an understanding of the energy implications of wasted food and waste disposal. Cape Town: WWF South Africa; 2014. Available from: http://www.health.uct.ac.za/sites/default/files/image_tool/images/91/2__a16245_developing_an_understanding_of_the_energy_implications_of_wasted_food_lores.pdf [ Links ]

56. Ramukhwatho F, Du Plessis R, Oelofse S. Preliminary drivers associated with household food waste generation in South Africa. Appl Environ Educ Commun. 2018;17(3):254-265. https://doi.org/10.1080/1533015X.2017.1398690 [ Links ]

57. Silbernagl P What's the composition of your domestic waste stream? Is there value in recycling? In: The Waste Revolution handbook. Johannesburg: Waste Revolution; 2011. p. 136-141. Available from: https://issuu.com/alive2green/docs/the_waste_revolution_handbook_volum [ Links ]

58. Oelofse S, Nahman A, Barjees Baig M, Salemdeeb R, Nizami A-S, Reynolds C. Food waste within South Africa and Saudi Arabia. In: Reynolds C, Soma T, Spring C, Lazell J, editors. Routledge handbook of food waste. London: Routledge; 2020. p. 207-224. Available from: https://www.taylorfrancis.com/books/9780429870705/chapters/10.4324/9780429462795-17 [ Links ]

59. Oelofse S, Muswema A, Ramukhwatho F. Household food waste disposal in South Africa: A case study of Johannesburg and Ekurhuleni. S Afr J Sci. 2018;114(5/6), Art. #2017-0284. https://doi.org/10.17159/sajs.2018/20170284 [ Links ]

60. Nahman A, De Lange W, Oelofse S, Godfrey L. The costs of household food waste in South Africa. Waste Manage. 2012;32(11):2147-2153. https://doi.org/10.1016/j.wasman.2012.04.012 [ Links ]

61. Porter SD, Reay DS, Higgins P Bomberg E. A half-century of production-phase greenhouse gas emissions from food loss & waste in the global food supply chain. Sci Total Environ. 2016;571:721-729. https://doi.org/10.1016/j.scitotenv.2016.07.041 [ Links ]

62. Friedrich E, Trois C. GHG emission factors developed for the collection, transport and landfilling of municipal waste in South African municipalities. Waste Manage. 2013;33(4):1013-1026. https://doi.org/10.1016/j.wasman.2012.12.011 [ Links ]

63. Friedrich E, Trois C. Quantification of greenhouse gas emissions from waste management processes for municipalities - A comparative review focusing on Africa. Waste Manage. 2011;31(7):1585-1596. https://doi.org/10.1016/j.wasman.2011.02.028 [ Links ]

64. South African Department of Forestry, Fisheries and the Environment (DFFE). National GHG Inventory Report - South Africa 2017. Pretoria: DFFE; 2021. Available from: https://www.environment.gov.za/sites/default/files/docs/nir-2017-report.pdf [ Links ]

65. Song Y Meng S, Chen G, Yan B, Zhang Y Tao J, et al. Co-digestion of garden waste, food waste, and tofu residue: Effects of mixing ratio on methane production and microbial community structure. J Environ Chem Eng. 2021;9(5), Art. #105901. https://doi.org/10.1016/j.jece.2021.105901 [ Links ]

66. Panigrahi S, Sharma HB, Dubey BK. Anaerobic co-digestion of food waste with pretreated yard waste: A comparative study of methane production, kinetic modeling and energy balance. J Clean Prod. 2020;243, Art. #118480. https://doi.org/10.1016/j.jclepro.2019.118480 [ Links ]

67. Mu L, Zhang L, Zhu K, Ma J, Ifran M, Li A. Anaerobic co-digestion of sewage sludge, food waste and yard waste: Synergistic enhancement on process stability and biogas production. Sci Total Environ. 2020;704, Art. #135429. https://doi.org/10.1016/j.scitotenv.2019.135429 [ Links ]

68. eThekwini Municipality. eThekwini Municipality Integrated Waste Management Plan 2016-2021. Durban: eThekwini Municipality; 2016. Available from: http://www.durban.gov.za/City_Services/cleansing_solid_waste/Documents/eThekwini%20Municipality%20Integrated%20Waste%20Management%20Plan%202016%202021.pdf [ Links ]

69. Lavagnolo MC, Girotto F, Rafieenia R, Danieli L, Alibardi L. Two-stage anaerobic digestion of the organic fraction of municipal solid waste - Effects of process conditions during batch tests. Renew Energy. 2018;126:14-20. https://doi.org/10.1016/j.renene.2018.03.039 [ Links ]

70. Anjum M, Khalid A, Mahmood T, Aziz I. Anaerobic co-digestion of catering waste with partially pretreated lignocellulosic crop residues. J Clean Prod. 2016;117:56-63. https://doi.org/10.1016/j.jclepro.2015.11.061 [ Links ]

71. Fountain Green Energy, New Horizons Energy. New Horizons waste to energy: Athlone Municipal and Organic Waste to Energy [document on the Internet]. c2017 [cited 2021 Oct 27]. Available from: http://www.energy.gov.za/files/biogas/2017-Biogas-Conference/day2/New-Horizons-Waste-to-Energy.pdf [ Links ]

72. Cabinet approves extension of Hydrogen Society Roadmap [webpage on the Internet]. c2021 [cited 2021 Oct 27]. Available from: https://www.sanews.gov.za/south-africa/cabinet-approves-extension-hydrogen-society-roadmap [ Links ]

73. Christensen TH, Damgaard A, Levis J, Zhao Y Bjorklund A, Arena U, et al. Application of LCA modelling in integrated waste management. Waste Manage. 2020;118:313-322. https://doi.org/10.1016/j.wasman.2020.08.034 [ Links ]

74. Kissoon S, Trois C. Application of the WROSE model to municipal Integrated Waste Management Plans: Focus on socio-economic and institutional indicators. In: Proceedings of the Sixteenth International Waste Management and Landfill Symposium; 2017 October 2-6; Sardinia, Italy. Padua: CISA Publisher; 2017. p. 8. [ Links ]

75. US Environmental Protection Agency. Waste Reduction Model (WARM) [webpage on the Internet]. c2016 [cited 2021 Oct 27]. Available from: https://www.epa.gov/warm [ Links ]

76. WRATE [homepage on the Internet]. No date [cited 2021 Oct 27]. Available from: http://www.wrate.co.uk/ [ Links ]

77. Nahman A, Oelofse S, Strydom W, Muswema A, Matinise S, Stafford W. Decision support tool for implementing municipal waste separation at source: Incorporating socio-economic and environmental impacts [document on the Internet]. c2018 [cited 2021 Oct 27]. Available from: https://wasteroadmap.co.za/wp-content/uploads/2020/03/2_CSIR_Final_Technical_report.pdf [ Links ]

78. Cesaro A, Russo L, Farina A, Belgiorno V. Organic fraction of municipal solid waste from mechanical selection: Biological stabilization and recovery options. Environ Sci Pollut Res. 2016;23(2):1565-1575. https://doi.org/10.1007/s11356-015-5345-2 [ Links ]

79. Intergovernmental Panel on Climate Change (IPCC). EFDB - Emission Factor Database [database on the Internet]. c2021 [cited 2021 Oct 27]. Available from: https://www.ipcc-nggip.iges.or.jp/EFDB/main.php [ Links ]

80. Friedrich E, Trois C. GHG emission factors developed for the recycling and composting of municipal waste in South African municipalities. Waste Manage. 2013;33(11):2520-2531. https://doi.org/10.1016/j.wasman.2013.05.010 [ Links ]

Correspondence:

Correspondence:

Andrea Dell'Orto

Email: dellortoa@ukzn.ac.za

Received: 27 Oct. 2021

Revised: 22 Feb. 2022

Accepted: 14 Apr. 2022

Published: 31 Aug. 2022

Editor: Michael Inggs

Funding: South African Department of Science and Innovation; South African National Research Foundation (grant UID 115447); SANEDI