Serviços Personalizados

Artigo

Indicadores

Links relacionados

-

Citado por Google

Citado por Google -

Similares em Google

Similares em Google

Compartilhar

South African Journal of Science

versão On-line ISSN 1996-7489

versão impressa ISSN 0038-2353

S. Afr. j. sci. vol.118 no.7-8 Pretoria Jun./Ago. 2022

http://dx.doi.org/10.17159/sajs.2022/9534

RESEARCH ARTICLE

Causality between challenges, availability, and extent of use of local building materials

Abimbola WindapoI; Oluseye OlugboyegaI; Francesco PomponiII; Alireza MoghayediI; Fidelis EmuzeIII

IDepartment of Construction Economics and Management, University of Cape Town, Cape Town, South Africa

IIResource Efficient Built Environment Lab, Edinburgh Napier University, Edinburgh, United Kingdom

IIIDepartment of Built Environment, Central University of Technology, Bloemfontein, South Africa

ABSTRACT

The promotion of sustainable practice in construction has resulted in a renewed focus on local building materials (LBMs). However, existing studies have not provided an extensive understanding of the challenges in the use and awareness of the availability of LBMs. In this study, we examine the challenges in the use and awareness of the availability and environmental performance of LBMs in South Africa. Based on a review of related literature, a questionnaire survey was undertaken to collect data from stakeholders in the construction industry. Structural equation modelling was conducted to validate the causality between the constructs. We found that the negative impacts of the challenges in the use of LBMs significantly reduce if stakeholders are aware of the environmental performance of LBMs in South Africa. The extent of the use of LBMs will increase with an awareness of their environmental performance and availability. Acquisition of the technical knowledge associated with LBM-based construction processes and recognition of the use of LBMs for building projects in building requirements and regulations are recommended.

SIGNIFICANCE:

The study provides an understanding of the challenges in using LBMs linked to construction stakeholder awareness of their availability and environmental performance. This understanding will promote the use of LBMs in the construction industry and provide a valuable reference for stakeholders in decision-making and policymaking on their use.

Keywords: climate, environmental performance, local building materials, sustainable building materials

Introduction

Building construction is resource-intensive, and it is associated with environmental problems such as global warming, ozone layer depletion, and waste accumulation. Building construction accounts for one sixth of the world's freshwater consumption because the requirement for mixing water for building materials, such as concrete, is approximately 1 trillion litres per year.1,2 As a result of construction activity, fresh, clean water is getting scarcer every day.1,3,4 Besides this intense water consumption, building construction also requires the mining of large quantities of raw building materials, which results in extensive deforestation and loss of topsoil.1,2

The majority of buildings are constructed using conventional and imported building materials.5-9 Conventional building materials are those materials which have been accepted and used for a long time in a locality.7 The production of conventional building materials has a direct impact on natural biodiversity as a result of the fragmentation of natural resources and severe ecological damage.5 Imported building materials have huge transport and import duty costs.9 These materials negatively impact the environment and economy because they are costly and consume much energy in the manufacturing process.6 However, the mitigation of the negative impacts of these building materials is possible through the use of local building materials (LBMs).6,8

LBMs refer to building materials that are non-conventional and enable sustainable building practices. LBMs have been referred to as green building technologies or sustainable building materials.10-13 Chan et al.10 posited that materials for green roof technologies, solar technologies, and prefabricated construction technologies are examples of green building technologies. The term 'green' encompasses sustainable and alternative materials because it describes the practice of using healthier and more resource-efficient building materials.13

The promotion of sustainable practice in construction has resulted in the development of LBMs.14 This development aimed to improve the environmental or sustainability performance of building materials, through reduced water usage, greater energy efficiency, improved indoor quality and minimisation of construction waste.15,16 The benefits attributed to the availability of LBMs contribute to the competitiveness of building contractors, optimise building performance, and make buildings' use more predictable for an extended period. Darko et al.17 noted that the availability of LBMs has led to unique building products that have good marketing opportunities in Ghana. The availability of LBMs has also been linked to the possibility of meeting the ever-increasing demand for buildings, stemming from population growth and over-urbanisation.11,18 However, LBMs are facing challenges in penetrating the market.18

Several studies have provided evidence that there are challenges to the use of LBMs. Durdyev et al.11, Ahn et al.15 and Mesthrige and Kwong19 focused on the challenges of alternative and sustainable design and construction. Chan et al.10,13 and Nguyen et al.18 investigated the challenges of adopting green building technologies. These past studies suggest that imported materials are preferred to LBMs, owing to the lack of awareness of the availability and environmental performance of LBMs.

However, these studies did not give an extensive analysis and understanding of the challenges to the use of LBMs caused by lack of awareness of the availability and environmental performance of LBMs. Hence, it becomes vital to investigate specifically the challenges in the use of LBMs associated with the lack of awareness of their availability and environmental performance amongst construction industry professionals. According to Chan et al.10, Darko et al.17, Shen et al.20, and Mesthrige and Kwong19, there is a need to understand the challenges in the use of LBMs. Thus, in this study, we aimed to facilitate the understanding of the challenges linked to construction stakeholder awareness of their availability and environmental performance. This understanding will promote the use of LBMs in the construction industry and provide a valuable reference for stakeholders in decision-making and policymaking on their use. To achieve this aim, we asked: What is the relationship between the challenges, availability and use of LBMs by construction stakeholders?

We aimed to answer this research question through the following objectives: (1) to determine the extent and pattern of the use of LBMs; and (2) to investigate the causality between environmental performance, challenges, and extent of LBM use by construction stakeholders.

Literature review

Environmental performance of LBMs

Numerous studies have reported lower environmental impacts of LBMs. For example, Windapo and Ogunsanmi16 investigated the perception of construction stakeholders of the environmental performance of LBMs and concluded that construction stakeholders perceived the LBMs to be not environmentally sustainable, despite the claims of their manufacturers. Bribián et al.21 reported that materials such as hollow concrete blocks, stabilised soil blocks, or fly ashes could save 20% of the cumulative energy over a building's life cycle and concluded that buildings constructed with wooden structures require less energy and emit less CO2 during their life cycle than buildings with other types of structures. However, the global availability of timber might be an issue, questioning the extent of the real sustainability of the material.22

The findings of these studies suggest that the sustainability assessments of building materials must be based on specific indicators that provide information about the environmental impacts of the materials.23 The findings also suggest that a standard life cycle assessment (LCA) must be used to assess and compare the sustainability of conventional building materials (CBMs) and LBMs. According to Estokova and Porhincak24, the use of a standard LCA as an indicator of the sustainability of LBMs and for the assessment of the environmental impacts of CBMs is needed to achieve an accurate assessment of the performance of building materials and to develop a uniform and standard baseline for both CBMs and LBMs. Several studies have used the LCA as a uniform and standard baseline for CBMs and LBMs.25 27 For example, Monteiro and Freire25 conducted an LCA of CBMs and LBMs for exterior walls; Reza et al.26 studied an LCA of CBMs and LBMs for flooring systems; and Pargana et al.27 undertook a LCA of CBMs and LBMs for thermal insulation materials. The objective of an LCA of LBMs is to ascertain their environmental friendliness and to enable the optimal selection of environmentally preferred materials.28

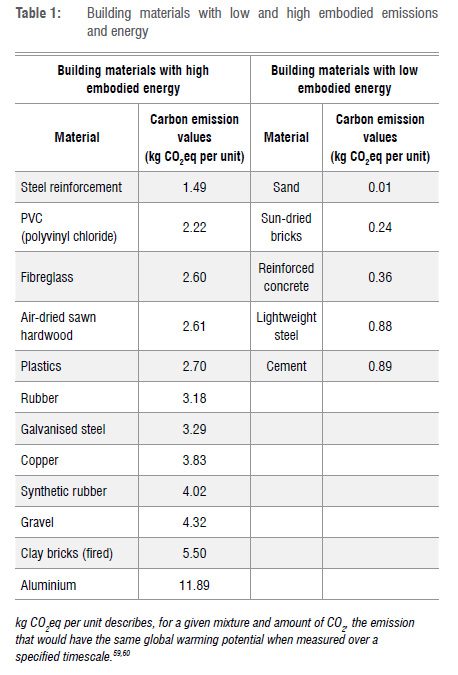

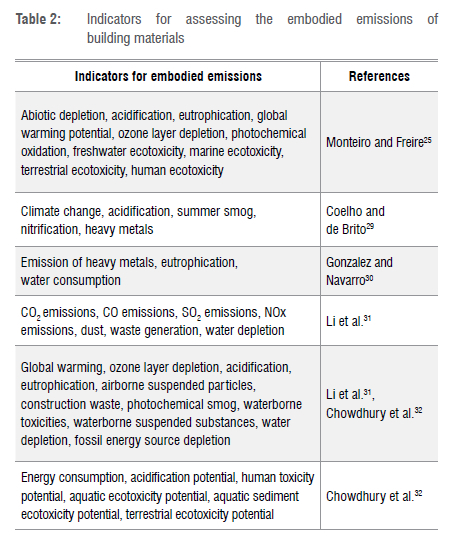

Various authors have suggested different indicators for assessing the embodied emissions of building materials. Table 1 provides a list of building materials, divided into categories of low and high embodied energy, and their corresponding carbon emission values. Table 2 presents a summary of the indicators available in the literature which assess the embodied emissions of building materials.29 32

Embodied energy describes the energy required for the extraction of raw materials, transportation and manufacture of building materials, as well as the energy incurred during their life cycle. This includes repair through to end-of-life disposal.28,33 It is essential to perform an embodied energy analysis of the building materials in the LCA because building materials consume nearly 40% of global energy annually in their life cycle stages and because building materials represent more than 50% of the embodied energy in the building.21,33 A LCA enables the selection of low energy-intensive materials, limits greenhouse gas emissions into the atmosphere, and reduces the cost of materials.33

Energy is being used at an unsustainable rate because the manufacturing, construction, and operation process of building materials are energy-intensive.1 Cabeza et al.28 note that the energy consumption of building materials starts from production to demolition. This suggests that embodied energy consists of both initial embodied energy (energy consumed during manufacturing and transporting the building materials) and recurring embodied energy (energy consumed during construction, demolition, operation, recycling, and renovation).34 Initial embodied energy is pollution-intensive and in large quantities as a result of a great deal of energy consumed during extraction, processing, and transportation of building materials.35 In the same vein, initial embodied energy accounts for 50% or more of the total embodied energy of building materials.36

Examples of high-energy building materials are aluminium, cement, concrete, steel, copper, PVC, glass, baked bricks, timber, crushed rock, gravel, and sand.21,30,31

Buyle et al.34 established that there is a strong link between the environmental impact of building materials and cost implications. This must be established because building materials have economic significance as well.28 Embodied cost as a concept has been described in several ways - including as the total economic cost in the life cycle of a product21, and the total cost of acquiring, installing, operating, maintaining and disposing of building materials28. Despite its importance, according to Buyle et al.34, the embodied cost of building materials is hardly ever taken into account in LCA models.

As noted by Fahimi et al.35, reducing the embodied emission, embodied energy, and embodied cost of building material will ensure its sustainability. LBMs enable the reduction of embodied emissions by supporting the use of cost-saving construction technology such as modular designs and standardised components.37 LBMs are generally lower in embodied energy because they require less processing and transportation.35 Chen et al.36 argued that LBMs are better suited to climatic conditions, and their use supports the local economy. Maintenance consumes a significant portion of a building's operating budget. The cost of maintaining conventional building materials includes the costs of labour, cleaning, equipment, and replacement of the item.38 However, LBMs offer low maintenance over the building's lifetime. This supports a reduction in the embodied cost of building materials. Other ways by which building materials can be made sustainable or by which LBMs reduce embodied emission, cost, and energy include recyclability (LBMs can be reused in their entirety), biodegradability (LBMs naturally decompose when discarded), reusability (LBMs may easily be extracted and reinstalled), and reduced toxicity (LBMs are less hazardous to construction workers, building occupants, and the environment).39,40

Challenges to the use of alternative building materials in construction

The challenges to the use of LBMs can be categorised into technical challenges, environmental challenges, policy challenges, cultural challenges, and economic challenges.41

Technical challenges

Technical challenges describe the practical difficulties and unsatisfactory systems that affect the adoption of innovation or innovative systems.42 Technical challenges constitute a set of practical challenges for the use and installation of LBMs in general.43 Chwieduk41 noted that the technical part of the adoption of LBMs pertains to the roles of human beings in the utilisation or installation of these materials. This suggests that the lack of technical understanding and technical know-how on the use of LBMs has to be addressed to ensure the implementation of sustainable practices in the construction industry.15,44 This is because the technical understanding and know-how of LBMs enable the development of transferable skills, the uptake of technical roles, and leveraging of competencies in the use of LBMs.45

Technical challenges have been found to affect the use of LBMs in construction. Zhang et al.14, O'Neill and Gibbs46 and Lam et al. 43 have identified problems. Such problems include unclear and incomplete technical standards for LBMs, lack of tools for assessing the performance of LBMs, lack of technical knowledge on the use and installation of LBMs, and immaturity of the technology employed for developing LBMs. Other challenges include the ineffective application of LBMs, technical difficulties during the construction process, unfamiliarity with the design and construction of buildings with LBMs, lack of reliable research into the properties of LBMs, and lack of training and education for developers, contractors, and policymakers. The other significant technical challenges are lack of skilled labour in building with LBMs, lack of databases and information on LBMs, unavailability of rating and labelling systems for LBMs, difficulties in providing technical training for construction workers, higher requirements for handling LBMs, and incompatibility with other building components.

Environmental challenges

The use of conventional building materials in building construction has been associated with environmental issues such as thermal discomfort and climatic change.44 Many studies have reported on the environmental challenges to the adoption of LBMs.10,11,13,20,43,47 These environmental challenges include special needs arising from certain climatic and geological conditions, lack of availability of pilot projects, unavailability of reliable LBM suppliers, limited knowledge of the environmental performance of LBMs, lack of information on the effect of LBMs on building occupants' health and comfort, low environmental awareness and consciousness, lack of green ratings for buildings, and the unwillingness of suppliers to exchange environment-related information with manufacturers. All studies highlight the need for an awareness of the environmental performance of LBMs when they are adopted and used.

Policy challenges

The use of LBMs is, to a large extent, dependent on governmental policies and industrial stakeholders' policies.20 Several studies13,47-51 have identified governmental policy as one of the primary ways of promoting the use of LBMs. LBM-friendly policies are required to attract construction stakeholders to the use of LBMs, as well as to stimulate and ensure the development of LBMs. Additionally, LBM-friendly policies are useful in raising awareness and facilitating the adoption of LBMs, as well as leading the construction industry towards being a more environmentally friendly sector. LBM-friendly policies usually come in the form of legislation, planning control, government involvement as a client, and code development.41 However, the non-availability and ineffectiveness of policies inhibit the use of LBMs.20 Specifically, policy challenges in respect of the lack of enforcement of the use of LBMs on new projects, complex certification procedures for LBMs, lack of subsidies and tax reduction for LBMs must be addressed. Also, it is vital to tackle the lengthy planning and approval process for LBMs, lack of regulations, lack of importance attached to LBMs by industry stakeholders, lack of promotion for LBMs, lack of codes for LBMs, rigid requirements, poor information dissemination and publicity, and unavailability of institutional frameworks for implementing the use of LBMs.

Cultural challenges

The ideas, traditions, beliefs, and social behaviour of society are collectively referred to as socio-cultural factors, and they affect the choice of building materials in so many ways.51,52 For example, Chiu52 identified 'social well-being' as a significant determinant of the preference for sustainable materials. The study describes 'social well-being' as the motivation to sustain the socio-cultural values of the society. This suggests that the decision to use LBMs is strongly related to the socio-cultural characteristics of the society in which the LBMs are to be introduced. Understanding the socio-cultural challenges that affect the use of LBMs is imperative because the socio-cultural characteristics of a society determine the preferences and attitudes of its inhabitants towards new products such as LBMs.53 Authors such as O'Neill and Gibbs46 and Liedtke et al.54 have identified the socio-cultural challenges in the adoption of LBMs to include stakeholders' reluctance to use them, the tendency to maintain current practices, the tendency to resist change, a lack of practical cooperation and working relations amongst different stakeholders, distrust of LBMs, unavailability of approved LBMs, risk and uncertainty involved in adopting LBMs, lack of tested and reliable LBMs, fear of employee turnover and joblessness, the inconsistency with best practice, the fragmented nature of the building supply chain, lack of attractiveness of LBMs to building occupants, and lack of client interest.

Economic challenges

Contractors usually procure building materials based on the lowest price.20 Hwang and Tan12 contend that cost is the most significant challenge impeding the use of LBMs. Mulligan et al.48 attribute this to the fact that contractors are mostly concerned that the use of LBMs will erode their financial gain. Kats et al.55 conclude that, compared to conventional building materials, the use of LBMs brings a maximum extra cost of 4%. In the same vein, Zhang et al.14 concluded that the cost of the use of LBMs is higher than that of conventional building materials. This implies that the use of LBMs constitutes an economic or financial risk, which may lower the economic benefits of projects. However, Mesthrige and Kwong19 note that LBMs significantly lower operating costs by 30%, maintenance costs by 9%, enhance property value by 8%, and boost return on investment by 7%.

There are several significant economic challenges to the use of LBMs established in the literature. The major ones are low profitability for contractors, unavailability of LBMs in the local market, lack of information on costs and benefits of using LBMs, the high initial investment for LBMs, high additional cost, long payback periods, and high market prices.11,12,49

Theoretical framework

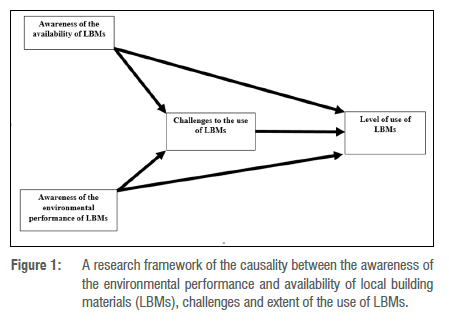

Based on the literature review, a theoretical framework of the causality between the awareness of the environmental performance and availability of LBMs, challenges and extent of the use of LBMs was developed, as shown in Figure 1. The framework explains that an awareness of the environmental performance of LBMs contributes to their adoption in construction projects. The availability of LBMs impacts the challenges to the use and extent of use of the LBMs. The challenges to the use of LBMs were conceptualised as technical, environmental, policy, cultural, and economic challenges. The positive environmental performance of LBMs was theorised to be low embodied emissions, low embodied energy, and low cost. The environmental performance regarding low embodied emissions was based on previous findings that air pollution and greenhouse gas emissions are released as a result of the production and transportation of building materials.16 LBMs are expected to have low embodied emissions because the products do not undergo secondary manufacturing and need no transportation, as materials are sourced locally. The extent of use of LBMs was conceptualised as present and future use of LBMs on projects. The theories that the research is designed to test are:

H1: There is a relationship between the challenges to the use of LBMs, the extent of awareness of their environmental performance, and the extent of use of LBMs by construction organisations.

H2: There is a relationship between the challenges to the use of LBMs, the extent of awareness of their availability, and the extent of use of LBMs by construction organisations.

Research methods

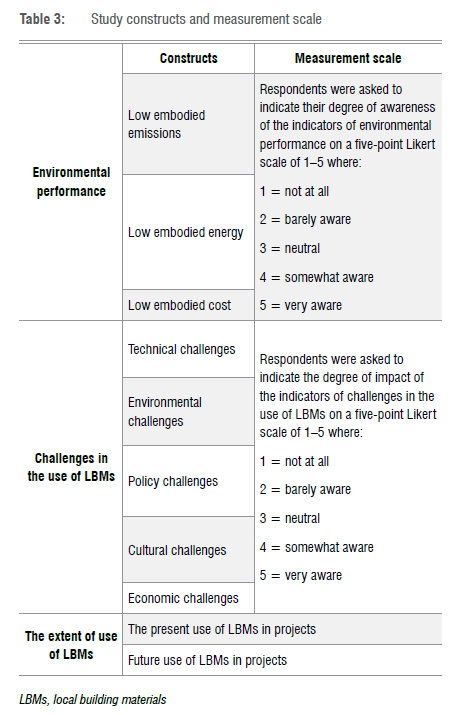

A questionnaire survey was undertaken to find out about construction industry stakeholders' views on awareness of the environmental performance and the availability of selected LBMs (recycled clay bricks, fly ash cement, recycled steel, salvaged timber, compressed earth block (e.g. hydraform), sandbags, recycled polyester fibre, low emissivity glass, polystyrene blocks, eco-friendly paints), the challenges in their use and the extent of their use in the South African construction industry. Respondents were asked to 'indicate the degree of awareness of the indicators of environmental performance' and 'indicate the degree of impact of the indicators of challenges to the use of LBMs'. A five-point Likert scale was taken as the measurement scale.56 The study constructs, the variables used in measuring the study constructs and their corresponding measurement scale are shown in Table 3.

The constructs and sub-constructs were assessed for discriminant validity, reliability, internal consistency, convergent validity, and divergent validity. Convergent validity represents the extent of agreement between two or more variables of the same construct, and it was tested using the average variance. Convergent validity is established if the average variance explained is higher than 0.50. It indicates that the variables in the constructs explain at least half the variance of the constructs. Discriminant validity is established if there is a correlation between the constructs or sub-constructs.

The study population consisted of all the professionals and contractors in the South African construction industry. A total of 5920 email contacts of the registered professionals and contractors were identified from the Construction Industry Development Board (CIDB) database. This formed the target population for the study. Of the 5920 email contacts that were identified, 5% of the target population (296 email contacts) was taken as the sample size for the study. This followed the recommendations of Kotrlik and Higgins57 for a large population. Thus 296 questionnaires were emailed to the respondents via the SurveyMonkey account of the Construction Business and Management Research Group, University of Cape Town, South Africa. At the end of the survey period, 232 valid responses were received, representing a response rate of 78.38%, and these responses were used for the data analysis. The data collected were analysed using descriptive and inferential statistical techniques. Structural equation modelling, a multivariate statistical analysis technique, was used to validate the causality between the constructs based on the estimate of maximum likelihood. Confirmatory factor analysis and path analysis were conducted to assess the validity of the constructs and sub-constructs. This technique has been widely used in built environment research (see, for example, Alaloul et al.58).

Results

Profile of respondents

Figures 2 and 3 present the demographic analysis of the 232 respondents. Figure 2 shows that the majority of the respondents have a Diploma with Grade 12 (34.1%) or a Higher National Diploma (21.1%). The findings on the designation of the respondents show that most are in the Management (18.1%) and Director (66.8%) professional group. Most of the respondents are construction managers (52.6%) and architects (32.3%). About 72% of the respondents work in the private sector, while 23.3% work in the public sector. The results indicate that LBMs are commonly used for residential (46.4%), institutional (20.3%), and commercial buildings (18.84%). Residential buildings constitute the highest percentage of all the buildings.

Figure 3 shows that the majority of the respondents, i.e. 49.1% and 12.9%, provide general contracting and sub-contracting services, respectively. Figure 3 also shows that 39.1% of the building projects identified by the respondents cost below ZAR1 million, while LBMs were also used on 18.8% of the projects that cost ZAR10 million to ZAR20 million. About 40% of the respondents indicated that they had made use of LBMs for projects sponsored by private clients. In comparison, 33.3% indicated that they had made use of LBMs for projects undertaken by provincial departments. Most of these projects (27.4%) were located in KwaZulu-Natal (KZN). Other significant locations for these projects were Gauteng (11.6%), the Western Cape (11.6%), the Free State (10.1%), and Limpopo (8.7%) Provinces of South Africa.

Extent and pattern of use of LBMs

Figure 4 shows that eco-friendly paints (12.6%), sandbags (12.1%), and recycled steel (11.9%) are widely used as LBMs in South Africa. When distributed according to province, the results reveal that the prevailing LBMs used are: sandbags in the Free State; salvaged timber in the Northern Cape; recycled clay bricks, sandbags, and eco-friendly paints in Gauteng; and recycled clay bricks in the Eastern Cape. The results also reveal that recycled clay bricks are used in the Western Cape; recycled clay bricks in KZN and the North-West; sandbags in Limpopo; and recycled clay bricks, sandbags, and eco-friendly paints in Mpumalanga.

The use of LBMs was analysed according to climatic zones, using the Köppen-Geiger climate classification of subtropical, steppe, and arid climates, to group the provinces into climatic zones. Provinces such as the Western Cape, the Eastern Cape, and KZN fit into the subtropical climate classification. Provinces such as the Free State, Limpopo, Mpumalanga, and Gauteng were classified as having a steppe climate. In the classification, North-West and Northern Cape were considered to have an arid climate. As illustrated in Figure 4, recycled clay bricks were found to be the prevailing LBMs in the subtropical and arid climates, while sandbags were found to be commonly used in the steppe climate.

Modelling causality between availability, environmental performance, challenges and use

Analysis of the measurement model

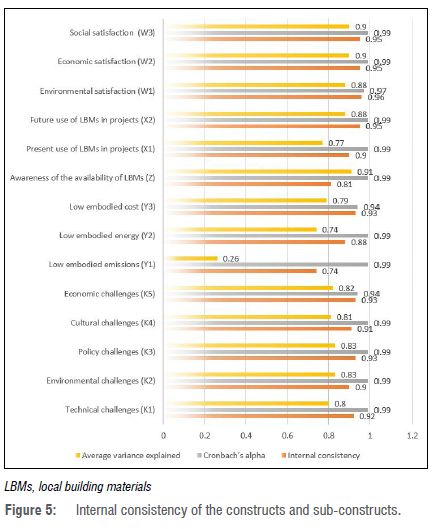

The results of the correlation between the constructs are presented in Table 4, while Figure 5 presents the results of the internal consistency test, Cronbach's alpha coefficient, and the average variance explained. The results show that the factor loading is above 0.50, which is acceptable; the Cronbach's alpha values for the constructs are more significant than 0.70, which indicates reliability. The average variance explained for the constructs is more significant than 0.50, which indicates convergent validity. These results indicate that the constructs and sub-constructs have acceptable validity and internal consistency, as shown by the average variance explained and Cronbach's alpha values, which were above the 0.50 and 0.70 thresholds, respectively.

Analysis of the structural model

Figure 6 illustrates the path analysis diagram for the structural model. It reveals 45 main constructs (X, K, Y, and Z) and 10 sub-constructs (K1, K2, K3, K4, K5, Y1, Y2, Y3, X1, and X2). Table 5 presents the results of the model estimation for the relationship between the main constructs and sub-constructs. As explained in Table 5, K has a negative but moderately significant correlation with X (r=-0.99, z=7.38) and Y (r=-7.02, z=55.39). Construct Y has a negative significant correlation with K (r=-7.02, z=55.39) and positive insignificant correlation with X (r=0.01, z=30.50). This result did not support H1. Construct Z has a positive but highly significant correlation with X (r=22.55, z=10.34) and K (r=3.79, z=38.69). Using the recommended value of 0.60 to determine the strength of the correlation and 0.50 to determine the significance of the correlation in the model, the results in Table 5 show that the parameter estimation for the items in the model is significant. This supports H2. Regarding the association between the constructs and sub-constructs, K1, K2, K3, K4, X1, X2, Y1, Y2, and Y3 have between moderate and high correlation, and significance in the model. Table 5 presents the fit indices for the estimated model and shows that the fit indices are within the recommended values [chi square = 47572.086, RMSEA = 0.039, SRMR = 0.077, CFI = 0.979, TLI = 0.945]. These results (as shown in Table 5 and Figure 6) validate the causality between constructs X, Yand Z as theorised in H2. The causality between K, X, and Z, as proposed in H1, was not validated by the results shown in Table 5 and Figure 6.

Discussion of findings

We tested the theory that the environmental performance of LBMs, which is their advantage, consisted of their demonstrated low embodied emissions, low embodied energy, and low embodied cost. These findings are aligned with the conclusions of previous studies by Darko and Chan13, Mesthrige and Kwong19, Bribián et al.21, Mateus and Braganca23 and Cabeza et al.28 Specifically, Darko and Chan13 concluded that awareness of the environmental friendliness of LBMs would promote their usage. Bribián et al.21 deduced that LBMs have low embodied energy, which will encourage widespread usage; while Mateus and Braganca23 maintained that the use of LBMs depends on the availability of information about their environmental friendliness.

Previous studies11,17,18,20,47,49,51 have provided conclusions that are in line with the finding of a relationship between availability and reduced challenges in the adoption and use of LBMs. The findings by Darko et al.17 and Nguyen et al.18 established that there is a strong link between the availability of LBMs and the use of LBMs. Shen et al.20 found that the awareness of the availability of LBMs through governmental policy will, in no small measure, influence the use of LBMs. Ahn et al.15 concluded that the use of LBMs would promote environmental sustainability; while Mahmoudkelaye et al.53 concluded that the decision to use LBMs is positively associated with the socio-cultural characteristics of the society in which the LBMs are to be used. Similarly, Mesthrige and Kwong19 established that owners derive economic benefits from the use of LBMs because they significantly lower operating and maintenance costs.

The research established the existence of causality between the awareness of the availability of the LBMs, awareness of the environmental performance of the LBMs, and the extent of use of LBMs by construction stakeholders. These causal links, in turn, affect the existing challenges in the use of LBMs, as graphically described in Figure 1. The findings of the structural equation modelling prove the existence of causality between the awareness of the availability and environmental performance of the LBMs. These address the challenges to, and extent of use of LBMs by construction stakeholders. The hypotheses that were tested in this model explain that there is a relationship between challenges in the use of LBMs, the extent of awareness of their environmental performance, and the extent of their use by construction organisations (H1). The model also establishes the relationship between challenges in the use of LBMs, the extent of awareness of the availability of LBMs, and the extent of their use by construction stakeholders (H2). As revealed in Figure 6, H1 was not validated.

The findings provide empirical evidence for the need to create awareness of the availability and environmental performance of LBMs, as well as the usefulness of awareness, in reducing the challenges in the use of LBMs and increasing their use in building projects. The non-validation of H1 suggests that the negative impacts of the challenges in the use of LBMs on the extent of their use will significantly reduce if there is an awareness of their environmental performance in the South African construction industry. This means that the awareness of the environmental performance of LBMs will convince the stakeholders in the construction industry of the advantages of using LBMs rather than conventional building materials.

Likewise, the validity of H2 indicates that the awareness of the availability of the LBMs will significantly increase the use of LBMs and indirectly reduce the challenges in the use of LBMs. The use of LBMs is advantageous as a result of their environmental friendliness; however, these advantages are not enough to promote their usage, unless they are readily available at building material stores, or from the building material suppliers.

Conclusion

We investigated the extent and pattern of the use of LBMs in South Africa through two hypotheses (H1 and H2) testing the causality between availability and knowledge of the benefits of using LBMs, which were found to cause the extent of the low use of LBMs. The findings on the extent and pattern of use of LBMs revealed information about materials which are available and perform well in specific environments; for example, recycled clay bricks and sandbags were found to be the prevailing LBMs in subtropical, arid, and steppe climates. We conclude that climatic zones determine the choice and availability of LBMs in South Africa, which thus affects the extent of their use. The suitability of recycled clay bricks and sandbags to the climatic zones in South Africa confirms them as LBMs in this region.

We also conclude from the findings on causality between awareness of environmental performance, and use of LBMs (H1), that technical, environmental, policy, cultural, and economic challenges are limiting the use of LBMs on projects despite their positive environmental performance. The decision to use LBMs for building construction very much depends on the awareness of the availability and environmental performance of LBMs.

Based on the findings on challenges, awareness of availability, and use of LBMs (H2), we conclude that increasing awareness of environmental performance and availability of LBMs will bring about a reduction in the challenges in the use of LBMs. The results suggest that an increase in the use of LBMs for building projects will be caused by such awareness and that the negative influence of challenges in the use of LBMs on the extent of their use for building projects will be mitigated by awareness of the availability and environmental performance of LBMs. Based on these conclusions, there is a need for government agencies to alter their requirements and regulations in order to recognise the use of LBMs in building projects. These agencies should also investigate the technical properties of LBMs to establish whether they are suitable for use in construction. The conclusions also suggest the need to create awareness of the technical properties of LBMs through videos, seminars and workshops. Future studies should determine the properties of LBMs; scale up the use of LBMs; and test and standardise this technology for use in construction.

Acknowledgements

This work was financially supported by the Royal Academy of Engineering (UK) under the Industry Academia Partnership Programme (grant no. IAPP 18/19 - 215).

Data availability

The data contained in this paper are available in an open source repository (https://www.surveymonkey.com/results/SM-Vm1nXDEihk6T pM0UAxrxSg_3D_3D/), operated and maintained by the University of Cape Town.

Competing interests

We have no competing interests to declare.

Authors' contributions

A.W.: Lead author - made a substantial contribution to the conception of the research; acquisition, analysis and interpretation of the data; drafted the work and revised it critically for important intellectual content.

O.O.: Made a substantial contribution to the acquisition, analysis and interpretation of the data; drafted the work and revised it critically for important intellectual content. F.P: Made a substantial contribution to the conception of the work; critically revised the work for important intellectual content. A.M.: Made a substantial contribution to the conception of the work and data acquisition. F.E.: A substantial contribution to writing and revising the work critically for important intellectual content.

References

1. Mehta PK. Reducing the environmental impact of concrete. Concr Int. 2001;23(10):61-66. [ Links ]

2. Song X, Carlsson C, Kiilsgaard R, Bendz D, Kennedy H. Life cycle assessment of geotechnical works in building construction: A review and recommendations. Sustainability. 2020;12(20):8442. https://doi.org/10.3390/su12208442 [ Links ]

3. Gokarakonda S, Shrestha S, Caleb PR, Rathi V Jain R, Thomas S, et al. Decoupling in India's building construction sector: Trends, technologies and policies. Build Res Inf. 2019;47(1):91-107. https://doi.org/10.1080/09613218.2018.1490054 [ Links ]

4. Chang Y Li X, Masanet E, Zhang L, Huang Z, Ries R. Unlocking the green opportunity for prefabricated buildings and construction in China. Resour Conserv Recycl. 2018;139:259-261. https://doi.org/10.1016/j.resconrec.2018.08.025 [ Links ]

5. Najjar M, Figueiredo K, Palumbo M, Haddad A. Integration of BIM and LCA: Evaluating the environmental impacts of building materials at an early stage of designing a typical office building. J Build Eng. 2017;14:115-126. https://doi.org/10.1016/j.jobe.2017.10.005 [ Links ]

6. Farooq S, Yaqoob I. Awareness towards efficiency of green and conventional building materials used in Pakistan: Efficiency of green and conventional building materials. Proc Pakistan Acad Sci A. 2019;56(3):75-84. [ Links ]

7. Mohamed AF, Mokhtar M, Elghobashy S. Comparative study of bio-materials versus conventional materials in building construction methods; economical evaluation of different building materials. SN Appl Sci. 2019;1(10), Art. #1179. https://doi.org/10.1007/s42452-019-1218-5 [ Links ]

8. Ibrahim SH, Zaini N, Baharun A, Zaini AA, Koesmeri DRA, Nawi MNM, et al. Embodied energy and CO2 analysis of industrialised building system (IBS) and conventional building system. J Adv Res Fluid Mech Therm Sci. 2018;51(2):259-266. [ Links ]

9. Haik R, Peled A, Meir IA. Thermal performance of alternative binders in lime hemp concrete (LHC) building: Comparison with conventional building materials. Build Res Inf. 2021;49(7):763-776. https://doi.org/10.1080/09613218.2021.1889950 [ Links ]

10. Chan APC, Darko A, Olanipekun AO, Ameyaw EE. Critical barriers to green building technologies adoption in developing countries: The case of Ghana. J Clean Prod. 2018;172:1067-1079. https://doi.org/10.1016/j.jclepro.2017.10.235 [ Links ]

11. Durdyev S, Zavadskas EK, Thurnell D, Banaitis A, Ihtiyar A. Sustainable construction industry in Cambodia: Awareness, drivers and barriers. Sustainability. 2018;10(2):392. https://doi.org/10.3390/su10020392 [ Links ]

12. Hwang BG, Tan JS. Green building project management: Obstacles and solutions for sustainable development. Sustain Dev. 2012;20(5):335-349. https://doi.org/10.1002/sd.492 [ Links ]

13. Darko A, Chan APC. Review of barriers to green building adoption. Sustain Dev. 2017;25(3):167-179. https://doi.org/10.1002/sd.1651 [ Links ]

14. Zhang X, Shen L, Wu Y Green strategy for gaining competitive advantage in housing development: A China study. J Clean Prod. 2011;19(2-3):157-167. https://doi.org/10.1016/j.oneear.2020.07.018 [ Links ]

15. Ahn YH, Pearce AR, Wang Y, Wang G. Drivers and barriers of sustainable design and construction: The perception of green building experience. Int J Sustain Build Technol Urban Dev. 2013;4(1):35-45. https://doi.org/10.1080/2093761X.2012.759887 [ Links ]

16. Windapo A, Ogunsanmi O. Construction sector views of sustainable building materials. Proc Inst Civ Eng Eng Sustain. 2014;167(2):64-75. https://doi.org/10.1680/ensu.13.00011 [ Links ]

17. Darko A, Chan AP, Yang Y, Shan M, He BJ, Gou Z. Influences of barriers, drivers, and promotion strategies on green building technologies adoption in developing countries: The Ghanaian case. J Clean Prod. 2018;200:687-703. https://doi.org/10.1016/j.jclepro.2018.07.318 [ Links ]

18. Nguyen HT, Skitmore M, Gray M, Zhang X, Olanipekun AO. Will green building development take off? An exploratory study of barriers to green building in Vietnam. Resour Conserv Recycl. 2017;127:8-20. https://doi.org/10.1016/j.resconrec.2017.08.012 [ Links ]

19. Mesthrige JW, Kwong HY. Criteria and barriers for the application of green building features in Hong Kong. Smart Sustain Built Environ. 2018;7:251-276. https://doi.org/10.1108/SASBE-02-2018-0004 [ Links ]

20. Shen L, Zhang Z, Zhang X. Key factors affecting green procurement in real estate development: A China study. J Clean Prod. 2017;153:372-383. https://doi.org/10.1016/jJjclepro.2016.02.021 [ Links ]

21. Bribián IZ, Capilla AV, Usón AA. Life cycle assessment of building materials: Comparative analysis of energy and environmental impacts and evaluation of the eco-efficiency improvement potential. Build Environ. 2011;46(5):1133-1140. https://doi.org/10.1016/j.buildenv.2010.12.002 [ Links ]

22. Pomponi F, Hart J, Arehart JH, D'Amico B. Buildings as a global carbon sink? A reality check on feasibility limits. One Earth. 2020;3(2):157-161. https://doi.org/10.1016/j.oneear.2020.07.018 [ Links ]

23. Mateus R, Bragança L. Sustainability assessment and rating of buildings: Developing the methodology SBToolPT-H. Build Environ. 2011;46(10):1962-1971. https://doi.org/10.1016/j.buildenv.2011.04.023 [ Links ]

24. Estokova A, Porhincak M. Environmental analysis of two building material alternatives in structures with the aim of sustainable construction. Clean Technol Environ Policy. 2015;17(1):75-83. https://doi.org/10.1007/s10098-014-0758-z [ Links ]

25. Monteiro H, Freire F. Life-cycle assessment of a house with alternative exterior walls: Comparison of three impact assessment methods. Energy Build. 2012;47:572-583. https://doi.org/10.1016/j.enbuild.2011.12.032 [ Links ]

26. Reza B, Sadiq R, Hewage K. Sustainability assessment of flooring systems in the city of Tehran: An AHP-based life cycle analysis. Constr Build Mater. 2011;25(4):2053-2066. https://doi.org/10.1016/j.conbuildmat.2010.11.041 [ Links ]

27. Pargana N, Pinheiro MD, Silvestre JD, De Brito J. Comparative environmental life cycle assessment of thermal insulation materials of buildings. Energy Build. 2014;82:466-481. https://doi.org/10.1016/j.enbuild.2014.05.057 [ Links ]

28. Cabeza LF, Rincón L, Vilarino V Pérez G, Castell A. Life cycle assessment (LCA) and life cycle energy analysis (LCEA) of buildings and the building sector: A review. Renew Sust Energ Rev. 2014;29:394-416. https://doi.org/10.1016/j.rser.2013.08.037 [ Links ]

29. Coelho A, De Brito J. Influence of construction and demolition waste management on the environmental impact of buildings. J Waste Manag. 2012;32(3):532-541. https://doi.org/10.1016/j.wasman.2011.11.011 [ Links ]

30. Gonzalez MJ, Navarro J4G. Assessment of the decrease of CO2 emissions in the construction field through the selection of materials: Practical case study of three houses of low environmental impact. Build Environ. 2006;41(7):902-909. https://doi.org/10.1016/j.buildenv.2005.04.006 [ Links ]

31. Li X, Zhu Y, Zhang Z. An LCA-based environmental impact assessment model for construction processes. Build Environ. 2010;45(3):766-775. https://doi.org/10.1016/j.buildenv.2009.08.010 [ Links ]

32. Chowdhury R, Apul D, Fry T. A life cycle based environmental impacts assessment of construction materials used in road construction. Resour Conserv Recycl. 2010;54(4):250-255. https://doi.org/10.1016/j.resconrec.2009.08.007 [ Links ]

33. Dixit MK, Fernández-Solís JL, Lavy S, Culp CH. Need for an embodied energy measurement protocol for buildings: A review paper. Renew Sustain Energy Rev. 2012;16(6):3730-3743. https://doi.org/10.1016/j.rser.2012.03.021 [ Links ]

34. Buyle M, Braet J, Audenaert A. Life cycle assessment in the construction sector: A review. Renew Sustain Energy Rev. 2013;26:379-388. https://doi.org/10.1016/j.rser.2013.05.001 [ Links ]

35. Fahimi A, Federici S, Depero LE, Valentim B, Vassura I, Ceruti F, et al. Evaluation of the sustainability of technologies to recover phosphorus from sewage sludge ash based on embodied energy and CO2 footprint. J Clean Prod. 2021;289:125762. https://doi.org/10.1016/j.jclepro.2020.125762 [ Links ]

36. Chen J, Zhou W, Yang H. Is embodied energy a better starting point for solving energy security issues? - Based on an overview of embodied energy-related research. Sustainability. 2019;11(16):4260. https://doi.org/10.3390/su11164260 [ Links ]

37. Svajlenka J, Kozlovská M, Spisáková M. The benefits of modern method of construction based on wood in the context of sustainability. Int J Sci Environ. 2017;14(8):1591-1602. https://doi.org/10.1007/s13762-017-1282-6 [ Links ]

38. Pan W, Iturralde K, Bock T, Martinez RG, Juez OM, Finocchiaro P. A conceptual design of an integrated façade system to reduce embodied energy in residential buildings. Sustainability. 2020;12(14):5730. https://doi.org/10.3390/su12145730 [ Links ]

39. Henry CS, Lynam JG. Embodied energy of rice husk ash for sustainable cement production. CSCEE. 2020;2:100004. https://doi.org/10.1016/j.cscee.2020.100004 [ Links ]

40. Bansal D, Minocha VK, Kaur A, Dakwale VA, Ralegaonkar RV. Reduction of embodied energy and construction cost of affordable houses through efficient architectural design: A case study in Indian scenario. Adv Civ Eng. 2021;2021, Art. #5693101. https://doi.org/10.1155/2021/5693101 [ Links ]

41. Chwieduk D. Towards sustainable-energy buildings. Appl Energy. 2003;76(1-3):211-217. https://doi.org/10.1016/S0306-2619(03)00059-X [ Links ]

42. McMeekin A, Southerton D. Sustainability transitions and final consumption: Practices and socio-technical systems. Technol Anal Strateg Manag. 2012;24(4):345-361. https://doi.org/10.1080/09537325.2012.663960 [ Links ]

43. Lam PTI, Chan EHW, Poon CS, Chau CK, Chun KP. Factors affecting the implementation of green specifications in construction. J Environ Manage. 2010;91(3):654-661. https://doi.org/10.1016/j.jenvman.2009.09.029 [ Links ]

44. Du Plessis C, Irurah D, Scholes RJ. The built environment and climate change in South Africa. Build Res Inf. 2003;31(3-4):240-256. https://doi.org/10.1080/0961321032000097665 [ Links ]

45. Schweber L, Harty C. Actors and objects: A socio - technical networks approach to technology uptake in the construction sector. Constr Manag Econ. 2010;28(6):657-674. https://doi.org/10.1080/01446191003702468 [ Links ]

46. O'Neill KJ, Gibbs DC. Towards a sustainable economy? Socio-technical transitions in the green building sector. Local Environ. 2014;19(6):572-590. https://doi.org/10.1080/13549839.2013.818954 [ Links ]

47. Portnov BA, Trop T, Svechkina A, Ofek S, Akron S, Ghermandi A. Factors affecting homebuyers' willingness to pay green building price premium: Evidence from a nationwide survey in Israel. Build Environ. 2018;137:280-291. https://doi.org/10.1016/j.buildenv.2018.04.014 [ Links ]

48. Mulligan T, Mollaoglu-Korkmaz S, Cotner R, Goldsberry A. Public policy and impacts on adoption of sustainable built environments: Learning from the constuction industry playmakers. J Green Build. 2014;9(2):182-202. https://doi.org/10.3992/1943-4618-9.2.182 [ Links ]

49. Onuoha IJ, Aliagha GU, Rahman MSA. Modelling the effects of green building incentives and green building skills on supply factors affecting green commercial property investment. Renew Sustain Energy Rev. 2018;90:814-823. https://doi.org/10.1016/j.rser.2018.04.012 [ Links ]

50. Hong J, Shen GQ, Li Z, Zhang B, Zhang W. Barriers to promoting prefabricated construction in China: A cost-benefit analysis. J Clean Prod. 2018;172:649-660. https://doi.org/10.1016/j.jclepro.2017.10.171 [ Links ]

51. Khan SAR, Zhang YAnees M, GolpTra H, Lahmar A, Qianli D. Green supply chain management, economic growth and environment: A GMM based evidence. J Clean Prod. 2018;185:588-599. https://doi.org/10.1016/j.jclepro.2018.02.226 [ Links ]

52. Chiu RLH. Socio - cultural sustainability of housing: A conceptual exploration. Hous Theory Soc. 2004;21(2):65-76. https://doi.org/10.1080/14036090410014999 [ Links ]

53. Mahmoudkelaye S, Taghizade Azari K, Pourvaziri M, Asadian E. Sustainable material selection for building enclosure through ANP method. Case Stud Constr Mater. 2018;9, e00200. https://doi.org/10.1016/j.cscm.2018.e00200 [ Links ]

54. Liedtke C, Jolanta Welfens M, Rohn H, Nordmann J. Living Lab: User - driven innovation for sustainability. Int J Sustain High Educ. 2012;13(2):106-118. https://doi.org/10.1108/14676371211211809 [ Links ]

55. Kats G, Braman J, James M. Greening our built world: Costs, benefits, and strategies. Washington DC: Island Press; 2010. [ Links ]

56. Chyung SY Roberts K, Swanson I, Hankinson A. Evidence - based survey design: The use of a midpoint on the Likert scale. Perform Improv Q. 2017;56(10):15-23. https://doi.org/10.1002/pfi.21727 [ Links ]

57. Kotrlik JWKJW, Higgins CCHCC. Organizational research: Determining appropriate sample size in survey research. Inf Technol Learn Perform J. 2001;19(1):43. [ Links ]

58. Alaloul WS, Liew MS, Zawawi NAW, Mohammed BS, Adamu M, Musharat MA. Structural equation modelling of construction project performance based on coordination factors. Cogent Eng. 2020;7(1), Art. #1726069. https://doi.org/10.1080/23311916.2020.1726069 [ Links ]

59. Winnipeg.ca. Emission factors in kg CO2-equivalent per unit [document on the Internet]. c2012 [cited 2021 Sep 21]. Available from: https://bit.ly/2XR2FUw [ Links ]

60. Dabaieh M, Heinonen J, El-Mahdy D, Hassan DM. A comparative study of life cycle carbon emissions and embodied energy between sun-dried bricks and fired clay bricks. J Clean Prod. 2020;275, Art. #122998. https://doi.org/10.1016/j.jclepro.2020.122998 [ Links ]

Correspondence:

Correspondence:

Abimbola Windapo

Email: Abimbola.windapo@uct.ac.za

Received: 16 Feb. 2021

Revised: 07 Oct. 2021

Accepted: 20 Jan. 2022

Published: 28 July 2022

EDITOR: Michael Inggs

FUNDING: UK Royal Academy of Engineering Industry Academia Partnership Programme (grant no. IAPP18/19-215)