Servicios Personalizados

Articulo

Indicadores

Links relacionados

-

Citado por Google

Citado por Google -

Similares en Google

Similares en Google

Compartir

South African Journal of Science

versión On-line ISSN 1996-7489

versión impresa ISSN 0038-2353

S. Afr. j. sci. vol.117 no.7-8 Pretoria jul./ago. 2021

http://dx.doi.org/10.17159/sajs.2021/8694

REVIEW ARTICLE

Fish farm effluent as a nutrient source for algae biomass cultivation

Uzochukwu O. EnwereuzohI, II, III; Kevin G. HardingI, II; Michelle LowI, II

IIndustrial and Mining Water Research Unit (IMWaRU), University of the Witwatersrand, Johannesburg, South Africa

IICentre in Water Research and Development (CiWaRD), University of the Witwatersrand, Johannesburg, South Africa

IIIDepartment of Environmental Management, Federal University of Technology Owerri, Ihiagwa, Nigeria

ABSTRACT

One of the challenges of microalgae biotechnology is the cost of growth media nutrients, with microalgae consuming enormous quantities of fertilisers, more than other oil crops. The traditional use of synthetic fertilisers in mass cultivation of microalgae is associated with rising prices of crude oil and competition from traditional agriculture. The fact that fish farm wastewater (FFW) nutrients are released in the form preferred by microalgae (NH3 for nitrogen and PO4-3 for phosphate), and the ability of microalgae to use nitrogen from different sources, can be exploited by using fish farm effluent rich in nutrients (nitrogen and phosphorus) in the cultivation of cheaper microalgae biomass for production of biodiesel. The cultivation of algae biomass in FFW will also serve as wastewater treatment. We reviewed the benefits and potential of fish effluent in algae cultivation for the production of biodiesel. Microalgae can utilise nutrients in FFW for different applications desirable for the production of biomass, including the accumulation of lipids, and produce a fuel with desirable properties. Also, treating wastewater and reducing demand for fresh water are advantageous. The high lipid content and comparable biodiesel properties of Chlorella sorokiniana and Scenedesmus obliquus make both species viable for FFW cultivation for biodiesel production.

SIGNIFICANCE:

• The cost associated with microalgae growth media nutrients can be saved by using fish farm wastewater, which contains nutrients (nitrogen and phosphorus) suitable for microalgae cultivation.

• Fish farm wastewater has lower nutrient concentrations when compared to standard growth media suitable for higher lipid accumulation.

• Microalgae used as a biodiesel feedstock, cultivated in fish farm wastewater, has added benefits, including wastewater treatment.

Keywords: fish farm wastewater, microalgae, biodiesel, nitrogen, phosphorus, growth media

Introduction

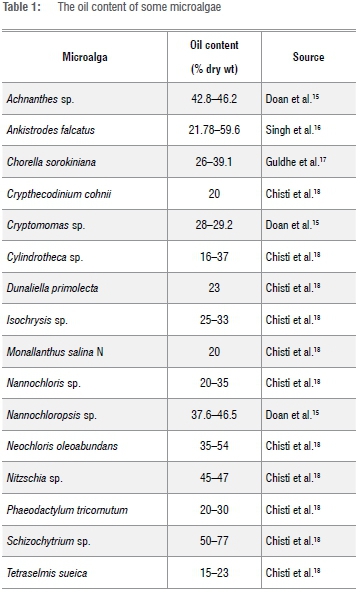

The ability of microalgae to adapt in a diverse environment is reflected in the patterns of lipids produced as well as their ability to synthesise various unusual compounds.1 The kinetics of microalgae growth, lipid productivities, and the amount of biomass vary with the algal strain, culture, and physiological conditions.2 Some species of microalgae, such as Dunaliella Salina, Chlamydomonas reinhardtii, Chlorella, and Botryococcus braunii can contain more than 60% lipid by dry cell weight.3 However, microalgal species with high lipid accumulation (50-70% of dry cell weight) generally have a slow growth rate.4 It is possible to find examples of microalgae that are fast growing and have a high lipid accumulation, e.g. Nannochloropsis oculata and Chlorella vulgaris (Table 1), and that have been used for biodiesel production.5

Increasing lipid production is possible through the cessation of cell division under environmental stress conditions. This switches from the synthesis of carbon dioxide (CO2) to lipid production as energy storage and thereby increases the lipid content to 20-50% dry cell weight of mostly triacylglycerol.2,6-9 Environmental stress conditions that can lead to lipid production include:

• low nitrogen concentration10,11;

• low temperature12;

• high light intensity13; and

• high ion concentrations14.

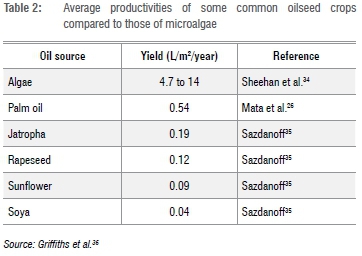

Microalgae have a higher growth rate when compared to land-based plants19-21 and can be harvested every few days22. Microalgae require less land than other oil crops21,23,24 and can be grown on marginal lands not required for food cultivation25,26. Microalgae feedstock has a high lipid production advantage with 15-300 times more oil than plant-based biomass27,28 (Table 2). Microalgae can make use of nutrients, especially nitrogen and phosphorus, from different sources of waste, including concentrated animal feed operations, industrial and municipal wastewater, and agricultural run-off.7,29 This offers cost-savings from the purchase of exogenous nutrients such as sodium nitrate and potassium phosphate30, reduces the use of fresh water30,31 and provides the additional bioremediation benefits of wastewater treatment7,29,32. The production of microalgae biomass offers real opportunities for solving issues of CO2 sequestration32, and at the same time, generates economic value through the conversion of CO2 into energy and chemical products33, utilising about 1.83 kg of CO2 for the production of 1 kg of microalgae biomass18.

Microalgae growth requirements

The use of wastewater to efficiently grow microalgae is dependent on different variables, including the concentration of essential nutrients (such as nitrogen, phosphorus, organic carbon), temperature, pH of the medium, availability of light, CO2, and oxygen.37

Nutrients

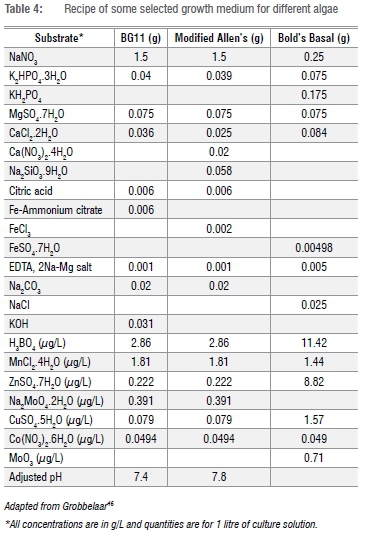

Microalgae require nutrients for growth, particularly carbon (in the form of CO2), nitrogen and phosphorus18,38 (Table 3). To provide these nutrients, different recipes for algae culture media exist (Table 4). The concentrations of nitrogen and phosphorus in the algae growth medium are considered fundamental factors affecting algae growth kinetics directly and are closely related to lipid accumulation and nutrient removal.6 The main mechanism for nutrient removal by microalgae is by uptake into microalgae cells6,39, while the rate of nutrient removal is directly affected by the microalgae population growth rate6.

The usual carbon source for microalgae photosynthetic culture is CO2, supplied either continuously or intermittently, from industrial exhaust gases, atmospheric CO2, or chemically fixed CO2 in the form of soluble carbonates, e.g. NaCO3 and NaHCO3.30,40 The efficiency at which microalgae cells use carbon through photosynthesis is directly proportional to the microalgal biomass production rate.41 The pH change in microalgae cultures is predominantly from the consumption of CO2, while changes due to degradation of metabolites excreted or from the uptake of other nutrients are minimal.42 Increasing the concentration of CO2 can result in higher production of biomass and a decrease in pH which can cause harm to the microalgae physiology.43

The next most important element required for the nutrition of microalgae is nitrogen.44 Nitrogen is directly involved with primary metabolism as it constitutes protein and nucleic acids.40,45 The nitrogen content of the biomass can vary from 1% to above 10% (even within the same species) and depends on the type and availability of the nitrogen source.46 Microalgae cultivation utilises a higher amount of chemical fertilisers (N-fertiliser), about 8-16 tons N/H, than other oil-bearing terrestrial plants.47 The use of nutrients from wastewater, especially agricultural sources rich in inorganic pollutants (nitrogen and phosphorus), can be one alternative to traditional chemical fertiliser sources.47

Ammonia is the preferred form of nitrogen for micro-organisms.46 Nutrients released from aquaculture are most suitable for the cultivation of algae as nitrogen is released as NH3 and phosphorus as PO4-3.48 On the other hand, microalgae species with a fast growth rate prefer the primary source of nitrogen in the form of ammonia over nitrate49, although they can grow well with different sources of nitrogen46,47,50.

Assimilation of either NH4+ or NO3- is related to the pH of the growth medium. The pH of the growth medium could drop during active algal growth when ammonia is used as the only nitrogen source. This is due to the release of H+ ions. On the other hand, pH increases when nitrate is used as the only nitrogen source in the growth medium. At high pH, nitrate could be lost due to volatilisation. However, it is important to ensure an adequate supply of this important nutrient to achieve a high growth rate. Culture media are formulated to supply nutrients in excess to avoid nutrients becoming a limiting factor, except in specific applications.46

Another important nutrient for microalgae growth is phosphorus, even though it forms less than 1% by mass.46 According to Kumar et al.40, phosphorus is the third most important nutrient for microalgae growth and is required in significantly excess supply because not all compounds of phosphorus are bioavailable, especially those combined with metal ions18,46,51. Microalgae store excess phosphorus in phosphate bodies, which they can use when phosphorus becomes limiting. The ratio of N:P in the growth medium is important, both in determining the growth potential and maintaining the dominance of cultured species in the culture.46

In Mostert and Grobbelaar's52 study, nitrogen was supplied at concentrations between 25 mg/L and 5000 mg/L for Scenedesmus sp., Chlorella sp. and Monoraphidium, with a suggested optimal nitrogen concentration for maximum productivity of between 2 mg/L and 619 mg/L and a variation on phosphorus of between 0.98 mg/L and 179 mg/L. Studies with Chlorella vulgaris at different ammonia concentrations obtained algae growth at all concentrations of algae. Low algae growth was obtained at very high ammonia concentrations (above 750 mg/L) and very low ammonia concentrations (below 10 mg/L) while maximum cell density was obtained at nitrogen concentrations between 20 mg/L and 250 mg/L, with no difference in specific growth rates. The growth rate in the different ammonia media studied was comparable to growth in commercial Bristol medium in which nitrate was the nitrogen source.53

Under nitrogen-rich conditions, rapid cell division and chlorophyll accumulation occur. Under depleted nitrogen conditions, no cell division occurs, but there is high lipid biomass accumulation for several more days, together with a rapid drop in chlorophyll.34 At 2.5 mg/L nitrogen limitation, Scenedesmus sp. LX1 accumulated up to 30% lipids and up to 53% at phosphorus limitation of 0.1 mg/L.6 Other studies have cultivated microalgae in different nitrogen and phosphorus concentrations. One example is Aslan and Kapdan54 with 13.2-110 mg/L ammonia, 7.7199 mg/L phosphorus and 25-200 mg/L urea.

Light

Light is an important requirement in microalgae growth, and should be delivered optimally to all microalgae cells within the culture. The highest photosynthetic efficiencies are realised at low light, as high light intensities not only cause inefficient use of absorbed light energy but also cause biochemical damage to photosynthetic machinery (photo-inhibition), as well as a reduction in dry weight.3 Generally, the light intensity requirement of microalgae cultivation is lower than the light intensity needed for higher plants.40 Microalgae photosynthesis and productivity is equal to the efficiency of light conversion when the only limiting factor is light.55,56 Generally, specific growth increases with an increase in irradiance to a maximum point beyond which inhibition may occur due to any further increase.55

Temperature

One of the major factors controlling cellular, physiological, and morphological responses of microalgae is temperature. Generally, an increase in temperature increases the rate of metabolism, while a decrease in temperature decreases the growth of algae. Environmental parameters such as light intensity affect optimal temperature, with 2025 °C reported as optimal for some species, and highest cell density occurring at 23 °C.40

Fish farm wastewater

Globally, aquaculture has been one of the food production sectors with rapid development and production growth, significant investment, and technical innovation.57 The main pollutants of concern in fish farm wastewater (FFW) are particulate and dissolved nutrients (nitrogen and phosphorus), and specific inorganic and organic compounds.58 The volume of waste discharged from aquaculture depends on the feeding regime, stocking density, and feeding rate, as these three factors determine the quantity of feed used.59

Nitrogen

Transformations of nitrogen are key biochemical processes in aquaculture systems, with protein as the major form of nitrogen in the fish feed.45 In every ton of fish produced, approximately 132.5 kg nitrogen and 25.0 kg phosphorus are released to the environment.59 Fish feed consumed is converted partially into fish biomass, egested as faeces or excreted through the gills as un-ionised ammonia, a major product of protein metabolism.45,60,61

Most ammonia produced in fish occurs in the liver and is voided through the epithelial surface and renal routes. Production of ammonia also occurs in the kidney, intestine, and muscle due to the presence of the amino acid deamination enzyme in the tissues.62 Ammonia in fresh water is from excretion via passive NH3 diffusion across the branchial epithelium. Next to the gill, this NH3 subsequently gets trapped as NH4+ in an acidic boundary layer, which maintains the partial pressure gradient of blood-to-gill water NH3.63 Urea is produced through argininolysis or hepatic uricolysis and is excreted through the gills, kidneys, skin or faeces.

Nitrogen loading in fish farms can be generally grouped into three sources59,61:

1. feed wasted due to poor management and farm practice;

2. poor feed quality, leading to poor feed stability and rapid dissolution of fish feed in water; and

3. low absorption and retention of food ingested that can be due to poor food digestibility of fish metabolism.

Large amounts of nitrogen in FFW are dissolved, with only 7-30% occurring in the form of particulates.64 Nitrogen in aquaculture is predominantly excreted as ammonia65 and only about 20-40% of total nitrogen is excreted as urea62. Ammonia nitrogen build-up is the second most limiting factor to an increased level of production in intensive aquaculture after dissolved oxygen.66 Even at very low concentrations, ammonia - especially un-ionised (NH3) ammonia - is toxic to fish, with maximum concentrations below 0.0l25 mg/L seen as acceptable.67

In flow-through aquaculture systems, most of the total nitrogen in the system is produced as ammonia while recirculating systems with biofilters produce mostly nitrates.68 As the most reactive nitrogenous species, the pelagic microbial community quickly take ups ammonia and produces other nitrogenous species such as nitrate.69 The rate of ammonia reaction in water is rapid, having a half-life of fewer than 50 ms for interconversion of NH4+ to NH3.70 However, temperature, pH, and salinity of the water affect the relative proportion of the two forms of ammonia.70 In natural water, ammonia exists as a component of pH and temperature-dependent equilibrium. Aqueous ammonia, an ionised form of ammonium (NH4+), is favoured within equilibrium pH (6.5 to 8.0), while a high pH >9 favours un-ionised form of ammonia (NH3).71

Phosphorus

Phosphorus is a limiting nutrient in a freshwater ecosystem72,73 and is excreted through urine in fishes74. Excretion of phosphorus, usually 60-86% of dietary phosphorus, is related to the source of origin, which different species use in different ways.65 Water quality can be influenced by phosphorus from aquaculture75, as elevated levels of phosphorus cause premature eutrophication73. Soluble phosphorus is not produced when feed with low phosphorus levels is consumed.76 The particulate total phosphorus and particulate total nitrogen fractions of effluent from a salmonid farm range from 30% to 84% and 7% to 32%, respectively.64,77,78

Phosphorus is usually not lost in an aquatic environment but remains conserved in a series of fractions as a result of dissolution, adsorption, and precipitation.79 This changes the form of phosphorus availability from dissolved orthophosphates to phosphorus attached to the suspended load.80 This makes phosphorus a useful indicator of the environmental impact of fish effluent.81 Modern agriculture relies on non-renewable phosphate from rocks for phosphorus supply, which is estimated to run out in 50-100 years with the estimated increase in phosphorus use.82 This makes it essential to recycle phosphorus in wastewater sources, manure, and even within production processes of biofuels to eliminate direct competition for phosphorus between algae cultivation and conventional agriculture.83

Impact of aquaculture discharge to the environment

Aquaculture's impact on the environment depends on feed type, stocking density, species, culture method, and farm practices.84 The concentration or total amount of effluents released and the capacity of the environment to assimilate the particular constituent also affects the impact of aquaculture on the environment.58 Nitrogen and phosphorus as major constituents of fish loading can affect the environment as a whole as well as the rearing of the fish.65 The introduction of organic and inorganic materials through feed for fishes has significantly impacted the nutrient and organic matter loading in coastal waters.

Rapidly growing intensive aquaculture systems would lead to various adverse effects on the environment. These effects might include:

• increased release of nutrients, which leads to eutrophication of coastal waters85-88;

• shortage of drinking water resources as a result of release of toxic chemicals, including ammonia (NH3) and nitrite (NO2) from aquaculture, especially in intensive systems of fish culture89;

• reduction of wild-fish supplies which can affect the ecosystem through large input of wild-fish feed used in feeding carnivorous species, and also habitat modification for some aquaculture systems90;

• competition for land and disturbance of wild ecosystems from escaped farmed fish91;

• pollution from drug residues used in the prevention and treatment of diseases in aquaculture can lead to a change in biodiversity92; and

• environmental concerns from the use of chemicals (including antifoulants, vitamins) and the introduction of new genetic strains and pathogens. Cleaning of fouled cages can also add to the organic loading of the water.84

Microbial nitrification and denitrification are reactions common in aquaculture systems, which lead to the release of nitrous oxide (N2O), a major greenhouse gas with 310 times more global warming potential than CO2 over a lifespan of 100 years (Figure 1). Nitrous oxide destroys the ozone and has a lifespan of 114 years. It is estimated that aquaculture N2O emissions will contribute roughly 5.72% anthropogenic N2O-N emissions by 2030 if aquaculture maintains the current annual development rate of about 7.10%.45

Benefits of utilising microalgae in FFW nutrient recovery

The use of algae for nutrient removal, especially nitrogen and phosphorus, has been demonstrated and has numerous advantages. These advantages include:

• low operating costs30,54,89 by saving money for the purchase of exogenous nutrients such as potassium phosphorus and sodium nitrate;

• saving of freshwater resources89;

• a suitable growth material with high tolerance89;

• pollutant conversion and effluent conversion to clean water93;

• extra income when economic important species are used87;

• increased productivity by eliminating pollutant nutrients84; and

• recycling nitrogen and phosphorus trapped in algae biomass as fertiliser avoids problems of sludge handling and oxygenated effluent discharge into the receiving water body.54

The use of algae for nutrient removal is not environmentally dangerous as it follows the principles of the natural ecosystem and also does not lead to secondary pollutants as long as the biomass produced is reused.94 Furthermore, the process is attractive for the treatment of secondary sludge as it has no carbon requirement for nitrogen and phosphorus removal.54 Moreover, the use of wastewater from agricultural, industrial, and municipal activities can provide a sustainable and cost-effective means of cultivating algae for biofuels.37 An alternative to synthetic fertiliser and eliminating the traditional use of synthetic fertilisers in the mass cultivation of algae is beneficial because of the rising prices of crude oil.95 The use of residual nutrient and nutrient recycling can overcome the high cost of algae biomass production - a major drawback in algae biotechnology for biodiesel production.96 Cultivation of microalgae also benefits the fish farmer by savings associated with the treatment of aquaculture wastewater before discharge, reducing demand for fresh water, and supplying algae biomass fish feed for the cultivation of fish.97

Microalgae cultivation in FFW

Recently, studies using FFW have been carried out for different purposes.97-106 Most of the studies98-100,102,105 focused on the growth rate of algae in aquaculture wastewater, the rate of nutrient removal, the effect of aquaculture wastewater on algae composition, enhancing microalgae harvesting through bioflocculation by co-cultivation of microalgae with fungus and feed production. A few studies97,101,103,104 determined the lipid content of the microalgae grown in FFW while fewer studies97 went further to determine the fatty acid composition of the lipid accumulated. Enwereuzoh et al.106 determined the quality of biodiesel from the FAME obtained from microalgae cultivated in FFW. However, most of the studies reviewed characterised the FFW used, determined biomass yield, and nutrient removal.

The characteristics of the FFW (Table 5) specific growth rate, biomass yield, biomass productivity, and lipid content (Table 6) are provided. All the studies utilising FFW for microalgae cultivation agree that FFW has sufficient nutrients to support microalgae cultivation. The concentration of nutrients in FFW were 0.48-433 mg/L for ammonia, 0.13-157 mg/L for nitrate, 0.14-28 mg/L for nitrite and 0.42-16.9 mg/L for phosphorus. These ranges are lower than concentrations obtained in standard growth media. For instance, the higher range of 157 mg/L obtained in FFW is only about 10% of the concentration of nitrate in both BG11 and Modified Allen's media and 62.8% in Bold's Basal standard media (Table 3). The lower biomass yield and productivity obtained in FFW when compared to the yield obtained in standard growth media have been attributed to the lower concentrations of nutrients in FFW.100

In this review, the highest biomass yield of 2.96 g/L and biomass productivity of 160.96 mg/L/d were obtained in Ankistrodesmus falcatus - cultivated in FFW with 5.32 mg/L ammonia, 40.67 mg/L nitrate and 8.82 mg/L phosphorus - are lower than the biomass yield and productivity obtained in the same species cultivated in standard growth media.104 Biomass yield and productivity in the same study increased with increased supplementation of nutrients. These findings also confirm that nutrients in FFW support the growth of microalgae but are not sufficient for comparable biomass yield and productivity obtained with standard growth media. The high biomass productivity of Ankistrodesmus falcatus obtained in FFW cultivation may suggest that the species be included in future studies aimed at high biomass productivity with FFW. Most studies utilising FFW for cultivation have focused on Scenedesmus sp. and Chlorella sp.

Microalgae utilised nutrients in FFW for growth and accumulation of biochemical compounds and biomass production. The accumulation of more lipids by Scenedesmus obliquus, Chlorella sorokiniana and Ankistrodesmus falcatus cultivated in FFW104 and in most species cultivated in FFW97 when compared to the lipid content of the same species in standard growth media suggest that FFW is more desirable for cultivating microalgae for improved lipid content. The nutrient load of FFW reduced significantly after microalgae cultivation, indicating the suitability of the use of microalgae in the removal of nutrients in FFW. Nutrient removal efficiencies of up to 80% were recorded in studies in which nutrient removal was determined. In studies using Scenedesmus obliquus, Chlorella sorokiniana and Ankistrodesmus falcatus, nutrient removal of 98.21% of ammonia, 80.85% of nitrate and 100% of phosphate was obtained.104

Additionally, FFW supported the accumulation of desirable fatty acid methyl esters in cultivated Tetradesmus obliquus, Heterochlorella luteoviridis and Chlamydomonas reinhardtii.106Better biodiesel properties were produced in Chlamydomonas reinhardtii cultivated in FFW than in standard growth media, and comparable biodiesel properties to those in standard growth media were produced in Tetradesmus obliquus and Heterochlorella luteoviridis in FFW. Ankistrodesmus falcatus had the highest biomass yield and productivity, but not the highest lipid content (25.2%), with Chlorella sorokiniana (31.85%) and Scenedesmus obliquus (30.85%) both accumulating more lipids. This makes Chlorella sorokiniana and Scenedesmus obliquus better producers of lipids, which is required for biodiesel production. Both species, when cultivated in FFW, have shown comparable biodiesel properties to the same species cultivated in standard growth media.

Conclusion

With an increasing world population and increased dependence on aquaculture for fish supplies, fish farm effluents are expected to grow. These effluents could provide nutrients for microalgae cultivation. Several studies have shown that the cultivation of microalgae in aquaculture wastewater is suitable for microalgae growth and biomass productivity coupled with efficient nutrient removal. The replacement of inorganic fertilisers with nutrient-rich fish farm effluent would eliminate the cost of purchasing fertiliser. This should lead to cheaper cultivation of microalgae biomass production for biodiesel production. When high costs - one of the major setbacks of algae biotechnology - are eliminated, the potential of microalgae biodiesel will be enhanced. Fish farm effluent nutrient recycling for microalgae cultivation for biodiesel production will at the same time eliminate numerous negative environmental effects associated with nutrient-rich effluent discharge to the environment, while also reducing the volume of water used.

Acknowledgements

We acknowledge funding support through the NRF-TWAS African Renaissance PhD Fellowship Programme (grant no. 99798) and a NEEDS Assessment Scholarship from the Federal University of Technology Owerri.

Competing interests

We have no competing interests to declare.

Authors' contributions

U.O.E.: Conceptualisation, methodology, data collection, data analysis, writing initial draft, writing revisions. K.G.H.: Conceptualisation, methodology, student supervision, project leadership. M.L.: Conceptualisation, methodology, student supervision, project leadership.

References

1. Guschina IA, Harwood JL. Lipids and lipid metabolism in eukaryotic algae. Prog Lipid Res. 2006;45(2):160-186. https://doi.org/10.1016/j.plipres.2006.01.001 [ Links ]

2. Purkayastha J, Bora A, Gogoi HK, Singh L. Growth of high oil yielding green alga Chlorella ellipsoidea in diverse autotrophic media, effect on its constituents. Algal Res. 2017;21:81-88. https://doi.org/10.1016/j.algal.2016.11.009 [ Links ]

3. Scott SA, Davey MP Dennis JS, Horst I, Howe CJ, Lea-Smith DJ, et al. Biodiesel from algae: Challenges and prospects. Curr Opin Biotechnol. 2010;21(3):277-286. https://doi.org/10.1016/j.copbio.2010.03.005 [ Links ]

4. Banerjee A, Sharma R, Chisti Y Banerjee UC. Botryococcus braunii: A renewable source of hydrocarbons and other chemicals. Crit Rev Biotechnol. 2002;22(3):245-279. https://doi.org/10.1080/07388550290789513 [ Links ]

5. Converti A, Casazza AA, Ortiz EY Perego P Del Borghi M. Effect of temperature and nitrogen concentration on the growth and lipid content of Nannochloropsis oculata and Chlorella vulgaris for biodiesel production. Chem Eng Process Process Intensif. 2009;48(6):1146-1151. https://doi.org/10.1016/j.cep.2009.03.006 [ Links ]

6. Xin L, Hong-ying H, Ke G, Ying-xue S. Effects of different nitrogen and phosphorus concentrations on the growth, nutrient uptake, and lipid accumulation of a freshwater microalga Scenedesmus sp. Bioresour Technol. 2010;101(14):5494-5500. https://doi.org/10.1016/j.biortech.2010.02.016 [ Links ]

7. Hu Q, Sommerfeld M, Jarvis E, Ghirardi M, Posewitz M, Seibert M, et al. Microalgal triacylglycerols as feedstocks for biofuel production: Perspectives and advances. Plant J. 2008;54(4):621-639. https://doi.org/10.1111/j.1365-313X.2008.03492.x [ Links ]

8. Hsieh CH, Wu WT. Cultivation of microalgae for oil production with a cultivation strategy of urea limitation. Bioresour Technol. 2009;100(17):3921-3926. https://doi.org/10.1016/j.biortech.2009.03.019 [ Links ]

9. Miao X, Wu Q. High yield bio-oil production from fast pyrolysis by metabolic controlling of Chlorella protothecoides. J Biotechnol. 2004;110(1):85-93. https://doi.org/10.1016/j.jbiotec.2004.01.013 [ Links ]

10. Piorreck M, Baasch K-HH, Pohl P Biomass production, total protein, chlorophylls, lipids and fatty acids of freshwater green and blue-green algae under different nitrogen regimes. Phytochemistry. 1984;23(2):207-216. https://doi.org/10.1016/S0031-9422(00)80304-0 [ Links ]

11. Illman AM, Scragg AH, Shales SW. Increase in Chlorella strains calorific values when grown in low nitrogen medium. Enzyme Microb Technol. 2000;27(8):631-635. https://doi.org/10.1016/S0141-0229(00)00266-0 [ Links ]

12. Renaud SM, Thinh L-V Lambrinidis G, Parry DL. Effect of temperature on growth, chemical composition and fatty acid composition of tropical Australian microalgae grown in batch cultures. Aquaculture. 2002;211(1):195-214. https://doi.org/10.1016/S0044-8486(01)00875-4 [ Links ]

13. Khotimchenko SV Yakovleva IM. Lipid composition of the red alga Tichocarpus crinitus exposed to different levels of photon irradiance. Phytochemistry. 2005;66(1):73-79. https://doi.org/10.1016/j.phytochem.2004.10.024 [ Links ]

14. Liu ZY Wang GC, Zhou BC. Effect of iron on growth and lipid accumulation in Chlorella vulgaris. Bioresour Technol. 2008;99(11):4717-4722. https://doi.org/10.1016/j.biortech.2007.09.073 [ Links ]

15. Doan TTY Sivaloganathan B, Obbard JP. Screening of marine microalgae for biodiesel feedstock. Biomass Bioenergy. 2011;35:2534-2544. https://doi.org/10.1016/j.biombioe.2011.02.021 [ Links ]

16. Singh P Guldhe A, Kumari S, Rawat I, Bux F. Investigation of combined effect of nitrogen, phosphorus and iron on lipid productivity of microalgae Ankistrodesmus falcatus KJ671624 using response surface methodology. Biochem Eng J. 2015;94:22-29. https://doi.org/10.1016/j.bej.2014.10.019 [ Links ]

17. Guldhe A, Ansari FA, Singh P Bux F. Heterotrophic cultivation of microalgae using aquaculture wastewater: A biorefinery concept for biomass production and nutrient remediation. Ecol Eng. 2017;99:47-53. https://doi.org/10.1016/j.ecoleng.2016.11.013 [ Links ]

18. Chisti Y Biodiesel from microalgae. Biotechnol Adv. 2007;25:294-306. https://doi.org/10.1016/j.biotechadv.2007.02.001 [ Links ]

19. Sheehan J, Camobreco V Duffield J, Graboski M, Shapouri H. An overview of biodiesel and petroleum diesel life cycles. US Department of Agriculture and US Department of Energy; 1998. https://doi.org/10.2172/1218368 [ Links ]

20. Gouveia L. Microalgae as a feedstock for biofuel production. SpringerBriefs Microbiol. 2011;1:62-71. https://doi.org/10.1007/978-3-642-17997-6 [ Links ]

21. Gao K, McKinley KR. Use of macroalgae for marine biomass production and CO2 remediation: A review. J Appl Phycol. 1994;6(1):45-60. https://doi.org/10.1007/BF02185904 [ Links ]

22. Danielo O. An algae-based fuel. Biofutur. 2005;255, 4 pages. [ Links ]

23. Clarens AF, Resurreccion EP, White MA, Colosi LM. Environmental life cycle comparison of algae to other bioenergy feedstocks. Environ Sci Technol. 2010;44(5):1813-1819. https://doi.org/10.1021/es902838n [ Links ]

24. Li Y Horsman M, Wu N, Lan CQ, Dubois-Calero N. Biofuels from microalgae. Biotechnol Progress. 2008;24(4):815-820. https://doi.org/10.1021/bp070371k [ Links ]

25. Sturm BSMM, Lamer SL. An energy evaluation of coupling nutrient removal from wastewater with algal biomass production. Appl Energy. 2011;88(10):3499-3506. https://doi.org/10.1016/j.apenergy.2010.12.056 [ Links ]

26. Mata TM, Martins AA, Caetano NS. Microalgae for biodiesel production and other applications: A review. Renew Sustain Energy Rev. 2010;14(1):217-232. https://doi.org/10.1016/j.rser.2009.07.020 [ Links ]

27. Lam MK, Lee KT. Microalgae biofuels: A critical review of issues, problems and the way forward. Biotechnol Adv. 2012;30(3):673-690. https://doi.org/10.1016/j.biotechadv.2011.11.008 [ Links ]

28. Lee JY Yoo C, Jun SY Ahn CY Oh HM. Comparison of several methods for effective lipid extraction from microalgae. Bioresour Technol. 2010;101:S27-S77. https://doi.org/10.1016/j.biortech.2009.03.058 [ Links ]

29. Rodolfi L, Zittelli GC, Bassi N, Padovani G, Biondi N, Bonini G, et al. Microalgae for oil: Strain selection, induction of lipid synthesis and outdoor mass cultivation in a low-cost photobioreactor. Biotechnol Bioeng. 2009;102(1):100-112. https://doi.org/10.1002/bit.22033 [ Links ]

30. Wang B, Li Y Wu N, Lan CQ. CO2 bio-mitigation using microalgae. Appl Microbiol Biotechnol. 2008;79(5):707-718. https://doi.org/10.1007/s00253-008-1518-y [ Links ]

31. Schenk PM, Thomas-Hall SR, Stephens E, Marx UC, Mussgnug JH, Posten C, et al. Second generation biofuels: High-efficiency microalgae for biodiesel production. BioEnergy Res. 2008;1(1):20-43. https://doi.org/10.1007/s12155-008-9008-8 [ Links ]

32. Grobbelaar JU. Microalgal biomass production: Challenges and realities. Photosynth Res. 2010;106(1-2):135-144. https://doi.org/10.1007/s11120-010-9573-5 [ Links ]

33. Klinthong W, Yang YH, Huang CH, Tan CS. A review: Microalgae and their applications in CO2 capture and renewable energy. Aerosol Air Qual Res. 2015;15(2):712-742. https://doi.org/10.4209/aaqr.2014.11.0299 [ Links ]

34. Sheehan J, Dunahay T, Benemann J, Roessler P Look back at the U.S. Department of Energy's Aquatic Species Program: Biodiesel from algae. Close-out report; 1998. https://doi.org/10.2172/15003040 [ Links ]

35. Sazdanoff N. Modeling and simulation of the algae to biodiesel fuel cycle [thesis]. Columbus, OH: The Ohio State University; 2006. [ Links ]

36. Griffiths MJ, Dicks RG, Richardson C, Harrison STL. Advantages and challenges of microalgae as a source of oil for biodiesel. In: Stoytcheva M, editor. Biodiesel - Feedstocks and processing technologies. Rijeka: InTech; 2011. p. 178-200. Available from: https://cdn.intechopen.com/pdfs-wm/22999.pdf [ Links ]

37. Pittman JK, Dean AP Osundeko O. The potential of sustainable algal biofuel production using wastewater resources. Bioresour Technol. 2011;102(1):17-25. https://doi.org/10.1016/j.biortech.2010.06.035 [ Links ]

38. Goldman JC. Outdoor algal mass cultures-II. Photosynthetic yield limitations. Water Res. 1979;13(2):119-136. https://doi.org/10.1016/0043-1354(79)90083-6 [ Links ]

39. Bich NN, Yaziz MI, Bakti NAK. Combination of Chlorella vulgaris and Eichhornia crassipes for wastewater nitrogen removal. Water Res. 1999;33(10):2357-2362. https://doi.org/10.1016/S0043-1354(98)00439-4 [ Links ]

40. Kumar A, Ergas S, Yuan X, Sahu A, Zhang Q, Dewulf J, et al. Enhanced CO2 fixation and biofuel production via microalgae: Recent developments and future directions. Trends Biotechnol. 2010;28(7):371-380. https://doi.org/10.1016/j.tibtech.2010.04.004 [ Links ]

41. Williams PJ le B, Laurens LML. Microalgae as biodiesel & biomass feedstocks: Review & analysis of the biochemistry, energetics & economics. Energy Environ Sci. 2010;3(5):554-590. https://doi.org/10.1039/b924978h [ Links ]

42. Rubio FC, Acié N Ferná Ndez FG, Sá Nchez Pé Rez JA, Camacho FG, Molina Grima E. Prediction of dissolved oxygen and carbon dioxide concentration profiles in tubular photobioreactors for microalgal culture. Biotechnol Bioeng. 1999;62:71-86. https://doi.org/10.1002/(SICI)1097-0290(19990105)62:1 <71::AID-BIT9>3.0.CO;2-T [ Links ]

43. Oswald J. Large-scale algal culture systems (engineering aspects). In: Microalgal biotechnology. Cambridge: Cambridge University Press; 1988. p. 357-395. [ Links ]

44. Becker E. Microalgae: Biotechnology and microbiology. Cambridge: Cambridge University Press; 1994. [ Links ]

45. Hu Z, Lee JW, Chandran K, Kim S, Khanal SK. Nitrous oxide (N2O) emission from aquaculture: A review. Environ Sci Technol. 2012;46(12):6470-6480. https://doi.org/10.1021/es300110x [ Links ]

46. Grobbelaar JU. Algal nutrition: Mineral nutrition. In: Richmond A, editor. Handbook of microalgal culture: Biotechnology and applied phycology. Oxford: Blackwell Publishing Ltd; 2004. p. 97-115. [ Links ]

47. Markou G, Georgakakis D. Cultivation of filamentous cyanobacteria (blue-green algae) in agro-industrial wastes and wastewaters: A review. Appl Energy. 2011;88(10):3389-3401. https://doi.org/10.1016/j.apenergy.2010.12.042 [ Links ]

48. Troell M, Halling C, Neori A, Chopin T, Buschmann AH, Kautsky N, et al. Integrated mariculture: Asking the right questions. Aquaculture. 2003;226(1-4):69-90. https://doi.org/10.1016/S0044-8486(03)00469-1 [ Links ]

49. Green BR, Durnford DG. The chlorophyll-carotenoid proteins of oxygenic photosynthesis. Annu Rev Plant Physiol Plant Mol Biol. 1996;47(1):685-714. https://doi.org/10.1146/annurev.arplant.47.L685 [ Links ]

50. Alberto J, Costa V Cozza KL, Oliveira L, Magagnin Ã. Different nitrogen sources and growth responses of Spirulina platensis in microenvironments. World J Microbiol Biotechnol. 2001;17:439-442. https://doi.org/10.1023/A:1011925022941 [ Links ]

51. Martinez ME, Jimenez JM, Yousfi FE. Influence of phosphorus concentration and temperature on growth and phosphorus uptake by the microalga Scenedesmus obliquus. Bioresour Technol. 1999;67:233-240. https://doi.org/10.1016/S0960-8524(98)00120-5 [ Links ]

52. Mostert ES, Grobbelaar JU. The influence of nitrogen and phosphorus on algal growth and quality in outdoor mass algal cultures. Biomass. 1987;13(4):219-233. https://doi.org/10.1016/0144-4565(87)90061-8 [ Links ]

53. Tam NFY Wong YS. Effect of ammonia concentrations on growth of Chlorella vulgaris and nitrogen removal from media. Bioresour Technol. 1996;57:45-50. https://doi.org/10.1016/0960-8524(96)00045-4 [ Links ]

54. Aslan S, Kapdan IK. Batch kinetics of nitrogen and phosphorus removal from synthetic wastewater by algae. Ecol Eng. 2006;28(1):64-70. https://doi.org/10.1016/j.ecoleng.2006.04.003 [ Links ]

55. Grima EM, Acie FG, Chisti Y Acien Fernandez FG, Garcia Camacho F, Chisti Y et al. Photobioreactors: light regime, mass transfer, and scaleup. J Biotechnol. 1999;70(1-3):231-247. https://doi.org/10.1016/S0168-1656(99)00078-4 [ Links ]

56. Richmond A, Cheng-Wu Z, Zarmi Y Efficient use of strong light for high photosynthetic productivity: Interrelationships between the optical path, the optimal population density and cell-growth inhibition. Biomol Eng. 2003;20(4-6):229-236. https://doi.org/10.1016/S1389-0344(03)00060-1 [ Links ]

57. Muir J. Managing to harvest? Perspectives on the potential of aquaculture. Philos Trans R Soc B Biol Sci. 2005;360(1453):191-218. https://doi.org/10.1098/rstb.2004.1572 [ Links ]

58. Piedrahita RH. Reducing the potential environmental impact of tank aquaculture effluents through intensification and recirculation. Aquaculture. 2003;226(1-4):35-44. https://doi.org/10.1016/S0044-8486(03)00465-4 [ Links ]

59. Islam MS. Nitrogen and phosphorus budget in coastal and marine cage aquaculture and impacts of effluent loading on ecosystem: Review and analysis towards model development. Mar Pollut Bull. 2005;50(1):48-61. https://doi.org/10.1016/j.marpolbul.2004.08.008 [ Links ]

60. Krom MD, Porter C, Gordin H. Nutrient budget of a marine fish pond in Eilat, Israel. Aquaculture. 1985;51(1):65-80. https://doi.org/10.1016/0044-8486(85)90240-6 [ Links ]

61. Handy RD, Poxton MG. Nitrogen pollution in mariculture: toxicity and excretion of nitrogenous compounds by marine fish. Rev Fish Biol Fish. 1993;3(3):205-241. https://doi.org/10.1007/BF00043929 [ Links ]

62. Mommsen TP Walsh PJ. Biochemical and environmental perspectives on nitrogen-metabolism in fishes. Experientia. 1992;48(6):583-593. https://doi.org/10.1007/BF01920243 [ Links ]

63. Wilkie MP. Ammonia excretion and urea handling by fish gills: Present understanding and future research challenges. J Exp Zool. 2002;293(3):284-301. https://doi.org/10.1002/jez.10123 [ Links ]

64. Cripps SJ, Bergheim A. Solids management and removal for intensive land-based aquaculture production systems. Aquac Eng. 2000;22(1-2):33-56. https://doi.org/10.1016/S0144-8609(00)00031-5 [ Links ]

65. Lazzari R, Baldisserotto B. Nitrogen and phosphorus waste in fish farming. B Inst Pesca. 2008;34(344):591-600. [ Links ]

66. Ebeling JM, Timmons MB, Bisogni JJ. Engineering analysis of the stoichiometry of photoautotrophic, autotrophic, and heterotrophic removal of ammonia-nitrogen in aquaculture systems. Aquaculture. 2006;257(1-4):346-358. https://doi.org/10.1016/j.aquaculture.2006.03.019 [ Links ]

67. Meade JW. Allowable ammonia for fish culture. Progress Fish-Culturist. 1985;47(3):135-145. https://doi.org/10.1577/1548-8640(1985)47<135:AAFFC>2.0.CO;2 [ Links ]

68. Bergheim A, Asgard T. Waste production from aquaculture. In: Baird D, Beveridge MCM, Kelly LA, Muir J, editors. Aquaculture and water resource management. Oxford: Blackwell Science; 1996. p. 50-80. [ Links ]

69. Black KD. Environmental aspects of aquaculture. In: Culver K, Castle D, editors. Aquaculture, innovation and social transformation. The International Library of Environmental, Agricultural and Food Ethics vol 17. Dordrecht: Springer;. 2008. p. 97-113. https://doi.org/10.1007/978-1-4020-8835-3_8 [ Links ]

70. Stumm W, Morgan J. Aquatic chemistry. New York: Wiley; 1981. [ Links ]

71. Hargreaves JA. Nitrogen biogeochemistry of aquaculture ponds. Aquaculture. 1998;166(3-4):181-212. https://doi.org/10.1016/S0044-8486(98)00298-1 [ Links ]

72. Hudson JJ, Taylor WD, Schindler DW. Planktonic nutrient regeneration and cycling efficiency in temperate lakes. Nature. 1999;400(1986):659-661. https://doi.org/10.1038/23240 [ Links ]

73. McDaniel NK, Sugiura SH, Kehler T, Fletcher JW, Coloso RM, Weis P et al. Dissolved oxygen and dietary phosphorus modulate utilization and effluent partitioning of phosphorus in rainbow trout (Oncorhynchus mykiss) aquaculture. Environ Pollut. 2005;138(2):350-357. https://doi.org/10.1016/j.envpol.2005.03.004 [ Links ]

74. Bureau DP Cho CY Phosphorus utilization by rainbow trout (Oncorhynchus mykiss): Estimation of dissolved phosphorus waste output. Aquaculture. 1999;179(1-4):127-140. https://doi.org/10.1016/S0044-8486(99)00157-X [ Links ]

75. Reid GK, Moccia RD. Estimating aquatic phosphorus concentrations 30 metres down-current from a rainbow trout cage array. J Environ Monit. 2007;9(8):814-821. https://doi.org/10.1039/b703585c [ Links ]

76. Coloso RM, King K, Fletcher JW, Hendrix MA, Subramanyam M, Weis P et al. Phosphorus utilization in rainbow trout (Oncorhynchus mykiss) fed practical diets and its consequences on effluent phosphorus levels. Aquaculture. 2003;220(1-4):801-820. https://doi.org/10.1016/S0044-8486(02)00403-9 [ Links ]

77. Schulz C, Gelbrecht J, Rennert B. Treatment of rainbow trout farm effluents in constructed wetland with emergent plants and subsurface horizontal water flow. Aquaculture. 2003;217(1-4):207-221. https://doi.org/10.1016/S0044-8486(02)00204-1 [ Links ]

78. Sindilariu PD. Reduction in effluent nutrient loads from flow-through facilities for trout production: A review. Aquac Res. 2007;38(10):1005-1036. https://doi.org/10.1111/j.1365-2109.2007.01751.x [ Links ]

79. Paytan A, Cade-Menun BJ, McLaughlin K, Faul KL. Selective phosphorus regeneration of sinking marine particles: Evidence from 31P-NMR. Mar Chem. 2003;82(1-2):55-70. https://doi.org/10.1016/S0304-4203(03)00052-5 [ Links ]

80. Bowman MJ, Barber RT, Mooers CNK, Raven JA, editors. Coastal and estuarine studies. Cham: Springer; 1992. [ Links ]

81. Kus G, Kljakovic Z, Matijevic S, Kuspilic G, Kljakovic-Gaspic Z, Bogner D. Impact of fish farming on the distribution of phosphorus in sediments in the middle Adriatic area. Mar Pollut Bull. 2008;56(3):535-548. https://doi.org/10.1016/j.marpolbul.2007.11.017 [ Links ]

82. Cordell D, Drangert JO, White S. The story of phosphorus: Global food security and food for thought. Glob Environ Chang. 2009;19(2):292-305. https://doi.org/10.1016/j.gloenvcha.2008.10.009 [ Links ]

83. Borowitzka MA, Moheimani NR. Sustainable biofuels from algae. Mitig Adapt Strateg Glob Chang. 2013;18(1):13-25. https://doi.org/10.1007/s11027-010-9271-9 [ Links ]

84. Wu RSS. The environmental impact of marine fish culture: Towards a sustainable future. Mar Pollut Bull. 1995;31:4-12. https://doi.org/10.1016/0025-326X(95)00100-2 [ Links ]

85. Troell M, Rönnbäck P Halling C, Kautsky N, Buschmann A. Ecological engineering in aquaculture: Use of seaweeds for removing nutrients from intensive mariculture. J Appl Phycol. 1999;11(1):89-97. https://doi.org/10.1023/A:1008070400208 [ Links ]

86. Páez-Osuna F, Guerrero-Galván SR, Ruiz-Fernández AC. The environmental impact of shrimp aquaculture and the coastal pollution in Mexico. Mar Pollut Bull. 1998;36(1):65-75. https://doi.org/10.1016/S0025-326X(98)90035-2 [ Links ]

87. Marinho-Soriano E, Nunes SO, Carneiro MAA, Pereira DC. Nutrients' removal from aquaculture wastewater using the macroalgae Gracilaria birdiae. Biomass Bioenergy. 2009;33(2):327-331. https://doi.org/10.1016/j.biombioe.2008.07.002 [ Links ]

88. Paudel SR, Choi O, Khanal SK, Chandran K, Kim S, Lee JW. Effects of temperature on nitrous oxide (N2O) emission from intensive aquaculture system. Sci Total Environ. 2015;518-519:16-23. https://doi.org/10.1016/j.scitotenv.2015.02.076 [ Links ]

89. Heidari SA, Farhadian O, Soofiani NM. Biomass production and ammonia and nitrite removal from fish farm effluent by Scenedesmus quadricauda culture. J Environ Stud. 2011;37(59):15-28. [ Links ]

90. Naylor RL, Goldburg RJ, Primavera JH, Kautsky N, Beveridge MC, Clay J, et al. Effect of aquaculture on world fish supplies. Nature. 2000;405(6790):1017-1024. https://doi.org/10.1038/35016500 [ Links ]

91. Bisson PA. Assessment of the risk of invasion of national forest streams in the Pacific Northwest by farmed Atlantic salmon. General Technical Report PNW-GTR-697. Portland, OR: US Department of Agriculture, Forest Service, Pacific Northwest Research Station; 2006. https://doi.org/10.2737/PNW-GTR-697 [ Links ]

92. Tovar A, Moreno C, Manuel-Vez MP Garcia-Vargas M. Environmental impacts of intensive aquaculture in marine waters. Water Res. 2000;34(1):334-342. https://doi.org/10.1016/S0043-1354(99)00102-5 [ Links ]

93. Neori A, Chopin T, Troell M, Buschmann AH, Kraemer GP, Halling C, et al. Integrated aquaculture: Rationale, evolution and state of the art emphasizing seaweed biofiltration in modern mariculture. Aquaculture. 2004;231(1-4):361-391. https://doi.org/10.1016/j.aquaculture.2003.11.015 [ Links ]

94. Martínez M. Nitrogen and phosphorus removal from urban wastewater by the microalga Scenedesmus obliquus. Bioresour Technol. 2000;73(3):263-272. https://doi.org/10.1016/S0960-8524(99)00121-2 [ Links ]

95. Fenton O, Ó hUallacháin D. Agricultural nutrient surpluses as potential input sources to grow third generation biomass (microalgae): A review. Algal Res. 2012;1(1):49-56. https://doi.org/10.1016/j.algal.2012.03.003 [ Links ]

96. Schlagermann P Göttlicher G, Dillschneider R, Rosello-Sastre R, Posten C. Composition of algal oil and its potential as biofuel. J Combust. 2012;2012:1-14. https://doi.org/10.1155/2012/285185 [ Links ]

97. Malibari R, Sayegh F, Elazzazy AM, Baeshen MN, Dourou M, Aggelis G. Reuse of shrimp farm wastewater as growth medium for marine microalgae isolated from Red Sea - Jeddah. J Clean Prod. 2018;198:160-169. https://doi.org/10.1016/j.jclepro.2018.07.037 [ Links ]

98. Gao F, Li C, Yang ZH, Zeng GM, Feng LJ, Liu J zhi, et al. Continuous microalgae cultivation in aquaculture wastewater by a membrane photobioreactor for biomass production and nutrients removal. Ecol Eng. 2016;92:55-61. https://doi.org/10.1016/j.ecoleng.2016.03.046 [ Links ]

99. Nasir NM, Bakar NSA, Lananan F, Abdul Hamid SH, Lam SS, Jusoh A. Treatment of African catfish, Clarias gariepinus wastewater utilizing phytoremediation of microalgae, Chlorella sp. with Aspergillus niger bio-harvesting. Bioresour Technol. 2015;190:492-498. https://doi.org/10.1016/j.biortech.2015.03.023 [ Links ]

100. Egloff S, Tschudi F, Schmautz Z, Refardt D. High-density cultivation of microalgae continuously fed with unfiltered water from a recirculating aquaculture system. Algal Res. 2018;34:68-74. https://doi.org/10.1016/j.algal.2018.07.004 [ Links ]

101. Halfhide T, Âkerstram A, Lekang OI, Gislerad HR, Ergas SJ. Production of algal biomass, chlorophyll, starch and lipids using aquaculture wastewater under axenic and non-axenic conditions. Algal Res. 2014;6:152-159. https://doi.org/10.1016/j.algal.2014.10.009 [ Links ]

102. Michels MHAA, Vaskoska M, Vermuë MH, Wijffels RH. Growth of Tetraselmis suecica in a tubular photobioreactor on wastewater from a fish farm. Water Res. 2014;65:290-296. https://doi.org/10.1016/j.watres.2014.07.017 [ Links ]

103. Guerrero-Cabrera L, Rueda JA, García-Lozano H, Navarro AK. Cultivation of Monoraphidium sp., Chlorella sp. and Scenedesmus sp. algae in Batch culture using Nile tilapia effluent. Bioresour Technol. 2014;161:455-460. https://doi.org/10.1016/j.biortech.2014.03.127 [ Links ]

104. Ansari FA, Singh P, Guldhe A, Bux F. Microalgal cultivation using aquaculture wastewater: Integrated biomass generation and nutrient remediation. Algal Res. 2017;21:169-177. https://doi.org/10.1016/j.algal.2016.11.015 [ Links ]

105. Guo Z, Liu Y, Guo H, Yan S, Mu J. Microalgae cultivation using an aquaculture wastewater as growth medium for biomass and biofuel production. J Environ Sci. 2013;25:S85-S88. https://doi.org/10.1016/S1001-0742(14)60632-X [ Links ]

106. Enwereuzoh U, Harding K, Low M. Characterization of biodiesel produced from microalgae grown on fish farm wastewater. SN Appl Sci. 2020;2, Art. #970. https://doi.org/10.1007/s42452-020-2770-8 [ Links ]

Correspondence:

Correspondence:

Kevin Harding

Email: kevin.harding@wits.ac.za

Received: 25 July 2020

Revised: 02 Feb. 2021

Accepted: 02 Feb. 2021

Published: 29 July 2021

Editors: Teresa Coutinho, Salmina Mokgehle

Funding: NRF-TWAS African Renaissance PhD Fellowship Programme (grant no. 99798); NEEDS Assessment Scholarship, Federal University of Technology Owerri