Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

South African Journal of Science

On-line version ISSN 1996-7489

Print version ISSN 0038-2353

S. Afr. j. sci. vol.113 n.9-10 Pretoria Sep./Oct. 2017

http://dx.doi.org/10.17159/sajs.2017/20160354

RESEARCH ARTICLE

The potential of South African timber products to reduce the environmental impact of buildings

Philip L. Crafford; Melanie Blumentritt; C. Brand Wessels

Department of Forest and Wood Science, Stellenbosch University, Stellenbosch, South Africa

ABSTRACT

South Africa was the first country in Africa to implement a locally developed green building rating tool and has a growing number of rated green building projects. The method of life-cycle assessment can help to compare and assess the environmental performance of building products. At present, more than 70% of all sawn timber in South Africa is used in buildings, mainly in roof structures. Light gauge steel trusses have recently also been gaining market share. However, to date, no studies have been conducted that quantify and compare the environmental impacts of the different roof truss systems in South Africa. We thus compared several roof truss systems (South African pine, Biligom and light gauge steel) found in low- and medium-income house designs in South Africa using a simplified life-cycle assessment approach. Our results show that the two timber systems had overall the lowest environmental impact. Although the difference between the timber systems was small, light gauge steel had a 40% higher normalised impact over all assessed environmental impact categories. The benefit of biogenic carbon dioxide present in timber proved to play a significant positive role in the global warming potential impact and could even be further reduced if wood were used to generate energy at its end-of-life. This study demonstrates the potential advantage of using local timber products to reduce the environmental impact of the truss and building industry in South Africa.

SIGNIFICANCE:

• Timber truss systems showed overall lower environmental impact than light gauge steel trusses, with implications for green building.

Keywords: life-cycle assessment; pine; steel; novel truss materials; green building

Introduction

Buildings are major emitters of carbon dioxide and contribute significantly to global climate change.1,2 A growing global awareness of the environmental footprint of buildings and the necessity to lower greenhouse gas emissions has led to the implementation of green building practices and the introduction of green building rating tools that have been used to measure the environmental impact and sustainability of buildings since the 1990s.3 Numerous studies have shown that substituting steel, concrete and brick materials with renewable and sustainable wood products can significantly lower the environmental impact of a building over its lifetime.4-9

Residential roof truss construction in South Africa is the single biggest user of locally produced structural timber. According to Crickmay and Associates10, more than 70% of all structural timber is used in the local building market. Structural timber in South Africa is mostly South African pine (various Pinus species). In addition eucalyptus (mostly Eucalyptus grandis) timber is also used in structural applications, such as laminated beams and Biligom - a new, moist, glued, finger-jointed structural timber product for truss systems.11 Traditionally, structural steel is known for its ability to cover large spans and use in high stress applications such as reinforced concrete. Recently, light gauge steel (LGS) construction as well as LGS roof truss systems have gained a noticeable market share and offer another option as roof truss material. With steel prices currently low, many building projects and smaller roof spans with steel have become economically viable options in South Africa, and in many cases replaced wood as the preferred truss material.12,13

In a combined life-cycle assessment (LCA) and cost study performed by Worth et al.14, in which softwood timber trusses were compared with imported LGS in New Zealand, the authors found that LGS requires at least 6.65 times more energy to manufacture than wood. In a study by Bolin and Smith15, it was found that in their manufacture, use and disposal, CCA-treated wood guard rails require lower fossil fuel use, produce lower greenhouse gas (GHG) emissions and have lower environmental impacts in the acidification, smog potential and eco-toxicity categories compared with that of galvanised steel posts. Ximenes and Grant8 assessed the GHG benefits of the use of wood products compared with those of steel-reinforced concrete in two popular house designs in Sydney, Australia. The timber frame option for the roof resulted in a net GHG emission reduction ranging from 51% to 66% compared with steel frames for the equivalent roofing material.

Governments, architects, developers and the general public are under an increasing obligation to make environmentally responsible decisions when it comes to selecting building materials and methods.16 South Africa was the first country in Africa to implement a locally developed green building rating tool and has a growing number of rated green building projects.17 At the same time, however, marketing is used to promote materials and buildings as green and environmentally sound without concrete evidence in support of these claims.

Nearly 70% of all sawn timber in South Africa is utilised in buildings, specifically in roof trusses. LGS trusses are also gaining market share. However, to date no studies have been conducted quantifying the environmental impacts of the different truss systems in South Africa. End-users of trusses, therefore, do not have the necessary information to make environmentally responsible choices when selecting a truss system. Additionally, manufacturers of both timber and LGS trusses have little information to guide them in reducing the environmental impacts of their processes and products.

In this study, we investigated and compared the potential environmental impact of different roof truss systems typically found in low- and medium-income house designs in South Africa using a simplified LCA approach. Environmental impacts were compared over 11 different impact categories. We present the potential environmental impact of the modelled products and discuss adjustments and assumptions made with regard to the availability of South Africa specific life-cycle inventory (LCI) data and validity of obtained results.

Life-cycle assessment is a methodical framework for estimating and assessing the potential environmental impacts of a product system or process over its entire life cycle, including raw material extraction, manufacturing, use, and end-of-life disposal and/or recycling.18 Thus, LCA is often considered a 'cradle-to-grave' approach to evaluate environmental impacts.19 The International Organization for Standardization (ISO) adopted an environmental management standard in the 1990s as part of its 14000 standards series, with the 14040 series focusing on establishing methodologies for LCA.20,21 The ISO standards define a four-stage interactive framework for conducting LCA analysis. The first stage is the definition of the goal and scope of the study including the establishment of the functional unit, system boundaries and quality criteria for LCI data. Life-cycle inventory, the second stage, deals with the collection and synthesis of information of system inputs and outputs of material and energy flows and associated environmental impacts in all stages of the life cycle. During the life-cycle impact assessment (LCIA), the third stage, these environmental impacts are assigned to different environmental impact categories and by means of characterisation factors, the contribution of each constituent is calculated for different environmental impact categories (e.g. global warming potential, human toxicity, acidification, resource depletion, land use). The final stage is the interpretation of the results from both LCI and LCIA.20,21

Goal and scope

Objective

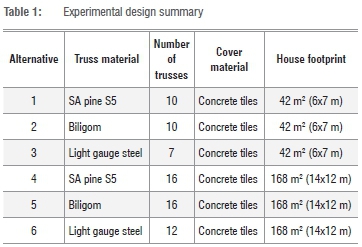

The goal of this study was to assess the potential environmental impact associated with the manufacture, use and disposal of timber and light gauge steel roof truss systems commonly found and used in South Africa. We compared three different truss materials - South African pine (S5), LGS and Biligom - in two house designs (Table 1). Biligom is a new sawn timber product made from green finger-jointed E. grandis wood. A 42-m2 Reconstruction and Development Programme (RDP) house and a 168-m2 single-story family house were chosen to represent commonly found house sizes in the South African lower- and middle-income market. Concrete tiles were selected as the roof cover material.

Limitations

A significant portion of the overall life-cycle energy requirements of buildings is from occupational energy use. However, owing to time and data constraints, occupational energy consumption over the design life of the roof and associated building was not considered in this study. In reality, different roofing materials will have, next to their own embodied energy, an impact on the energy usage required for space heating and ventilation and further investigation is necessary to address this issue properly. The assessment of the roof configurations is limited to the environmental factors associated with each type of roof truss system, excluding the cover material (i.e. concrete tiles) and the supporting building structure. Costing was also not included in the analyses.

Methodology

A detailed description of the LCA methodology and framework is available in the ISO 14040 Environmental Management series.20,21 Many of the recommendations set out in these documents are above and beyond the scope of the current study; however, the sections of these guidelines relevant to this study were followed.

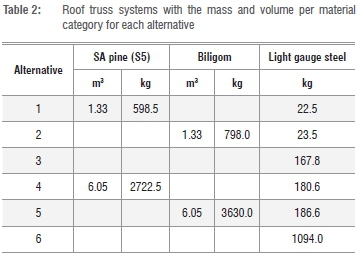

The functional unit, as defined in ISO 14041, was chosen for this study as the quantity of materials required to construct the roof truss system of a house with a predefined footprint (i.e. 42 m2 or 168 m2). Both theoretical house designs have cement block walls. All structural components required that make up the roof structure were considered (namely truss material, bracing material, battens, purlins, nails and screws). The cover material (i.e. concrete tiles) and insulation material were not included, but were considered for the design (e.g. in terms of load-bearing capacity of the roof structure). The roofs were designed with a 17.5° pitch and for a 50-year service life in the Western Cape Province of South Africa. The roof structures were calculated and designed by MiTek South Africa (Pty) Ltd engineers (Cape Town) according to national timber construction standards. MiTek design software provided a detailed material and cutting list for all structural components per design, either per mass or per volume (Table 2). Waste produced from cutting standard lengths to size was not accounted for. We assumed that no maintenance work or replacements would be necessary over the design lifespan.

Biligom structural timber is 25-35% stronger than South African pine structural grade S5 in terms of flexural properties, i.e. bending strength and stiffness11; in this theoretical comparison, because of current design constraints and data availability, Biligom was assumed to be equal in volume/dimensions to South African pine (S5).

Life-cycle inventory

In this study, openLCA 1.4.2 modelling software was used to determine the LCI. The materials used in the LCIs were assumed to be sourced and processed locally. As there is little to no LCI data available for South Africa, global data sets from the ecoinvent database 3.1 (Weidema et al.22) were used. Adjustments were made to existing processes in the ecoinvent database when possible to better represent local conditions (e.g. by using local electricity data available in ecoinvent or adjusting conversion factors).

Timber

We assessed two types of timber: South African pine in grade S5 and Biligom. Plantation forestry for pine and eucalyptus is practised In South Africa. LCI data from the Australian life-cycle inventory database (AUSLCI) was used and integrated into the ecoinvent database to model the softwood forestry process, as it reasonably represents local conditions. Sawmilling, drying and planing of the timber were modelled using ecoinvent processes for softwood, but adjusted to use South African specific conversion factors and electricity.

Biligom is a recent development of finger-jointed moist glued eucalyptus timber and original LCI data were gathered from BILIGOM® International (Pty) Ltd. The AUSLCI process for hardwood (eucalyptus) forestry was used to model the forestry process. Both product systems were modelled in openLCA using the ecoinvent database for background data.

Depending on the region in South Africa, both pine and eucalyptus timber used in load-bearing applications need to be preservative treated to comply with national building codes. Biligom uses TanalithE as preservative and copper chromated arsenate (CCA) was chosen for pine, as it is widely used in South Africa. Original LCI data on the chemical composition of both preservatives used locally were provided by Arch Wood Protection (SA) Pty Ltd and modelled in openLCA using the ecoinvent database for background data on chemicals, preservative production and pressure treatment.

Light-gauge steel

Light-gauge steel is made from galvanised sheet material, on continuous zinc coating lines from either cold-rolled (thickness range of 0.27 mm to < 2.0 mm) or hot-rolled (thickness of 2.01-3.0 mm) steel in coil form. It is produced to the requirements of a range of national and international standards as well as Mittal Steel South Africa's ISQ standards.23 Continuous zinc-coated cold-rolled sheet metal, also known as LGS, and the machining thereof was modelled based on rest-of-world steel data, available in the ecoinvent database 3.1, including processes for steel production, sheet rolling, metal working and zinc coating. The rest-of-world data are assumed to closer reflect local process conditions than are European or global data sets, especially in terms of the primary energy mix as it was not feasible to adjust all background processes included in LGS production to use South African electricity data.

Transportation

Transportation of materials to the processing facilities and from there to the building site in the Western Cape was included. We assumed that the LGS was sourced from the Gauteng Province, Biligom from the plant in Tzaneen, Limpopo and pine timber was standard averaged and originated in the Southern Cape and Limpopo Provinces. At the end-of-life, it was assumed that all materials were transported over 50 km to their respective final destination (e.g. for incineration, landfilling or recycling).

End-of-life

Formal recycling and burning of wood waste for energy was not considered as it is currently not common practice in South Africa. According to the South African Wood Preservers Association's treated timber guidelines, treated timber should be disposed of at a registered landfill site.24 However, in South Africa, significant amounts of waste wood are used in peri-urban and rural areas as fuel for cooking and heating. A study performed by Niyobuhungira25 showed that more than 50% of the residential fuel wood used in peri-urban areas in the Western Cape was CCA treated. In this study we chose disposal of timber by incineration, modelled with processes from the ecoinvent database as the most likely final fate scenario.

For the LGS, no recycling benefits were considered in the disposal phase as locally manufactured galvanised LGS is mainly produced from virgin material and the majority of steel scrap is exported and reused outside South Africa.26

Life-cycle impact assessment

All inputs and outputs considered in the cradle-to-grave analyses, and intermediate steps, were analysed in openLCA 1.4.2 with the CML baseline impact assessment method version 4.4 as of January 2015 (GreenDelta27) including normalisation data for different countries and years and using physical allocation. Additionally, impact category GWP100 was calculated without including biogenic carbon dioxide sequestration and emissions, thus assuming carbon neutrality of biogenic carbon dioxide.

Results and discussion

The potential environmental impact of the three roof truss assemblies was assessed and compared. Both cradle-to-gate and cradle-to-grave results are presented below. Table 3 shows the cradle-to-gate results of the 42-m2 and 168-m2 houses. Over all categories, Biligom has the lowest impact in most categories, closely followed by pine, and LGS has the highest impact. The difference between the two timber alternatives is small compared to the differences between them and LGS. The order of impact in the individual categories is the same for the larger truss assemblies. The impact in the individual categories is on average 4.5 times higher for the two timber alternatives and 6.5 times higher for LGS between the 42-m2 and 168-m2 house sizes. These differences are explained and directly correlated to the material volume ratio, required per material alternative as displayed in Table 2. It is interesting to note that although the timber alternatives use more trusses per house, the LGS system mass ratio is higher between the two house design footprints (Table 1).

Only the global warming potential (GWP) has negative values indicating a positive impact at the gate. More specifically, the results indicate the amount of carbon dioxide equivalents sequestrated in the material at this stage minus carbon dioxide emissions from processing and excluding emissions from end-of-life. Table 4 shows the same results as in Table 3 from cradle-to-grave. As expected, there is mostly a small increase in all categories and the timber alternatives are better than LGS. The most significant change can be seen in the GWP100, which is a result of the inclusion of emissions from wood incineration at the end-of-life of the timber systems. A significant increase in fossil fuel depletion and eutrophication for the wood alternatives and aquatic ecotoxicity for LGS must also be attributed to the end-of-life treatment as well as transportation processes.

Pine showed significantly higher human toxicity impact values compared to the others because of the CCA treatment process. According to the LCA process contribution analysis, chromium oxide production is responsible for more than 90% of the human toxicity impact of pine from cradle-to-gate. The higher photochemical oxidation impact value for Biligom is again because of the carbon monoxide emissions created by the forest management process. The forest management LCI data used in the Biligom LCA (the best available data) are from an Australian-based hardwood management process which used natural gas as part of their energy mix, which was responsible for 88% of the photochemical oxidation impact.

Over the last decade, carbon sequestration, carbon footprints and carbon emissions have become globally familiar terms. GWP is often one of the key impact factors when assessing the environmental performance of building materials. Timber is unique in the sense that trees sequestrate carbon dioxide during growth. By using wood in long-lived products, the re-emission can be delayed; additionally, by using wood products and by-products for energy generation, emission associated with fossil fuels can be avoided. Furthermore, wood products generally require less energy for manufacturing than equivalent alternatives.7,28-30 There is an ongoing debate in the research community on how to treat biogenetic carbon emissions.31,32 While the assumption of carbon neutrality is true given a long time perspective, climate neutrality is a different matter.

In order to better understand the climate change impact of using wood compared to LGS in this study, Figures 1 to 3 present a more differentiated view of the GWP and associated carbon dioxide streams.

Figure 1 shows the cradle-to-grave GWP incline for the three materials and the two house sizes. The graph clearly indicates that the two timber alternatives follow a similar near-flat GWP impact trend, whereas the LGS system shows a sharp increase between the small and bigger house footprints. Once again, this increase can be explained by the higher material mass ratio required to scale up the LGS systems from the 42-m2 to the 168-m2 house, compared to the timber alternatives. Note that because only two house footprints were analysed, the gradients in this graph are not equitable, but rather show a trend.

The rest of the analyses will focus on the 42-m2 house roof designs.

Global warming potential is expressed in kilograms carbon dioxide equivalents (kg CO2 eq.) and represents the impact of a number of gases (e.g. carbon monoxide, carbon dioxide, methane, HFC) standardised with their lifespan in the atmosphere to a unit of carbon dioxide.

Anthropogenic carbon dioxide emissions are produced from various sources, such as fossil fuel use, waste material decomposition and organic material burning. The carbon dioxide flows over the life cycle of South African pine and Biligom are displayed in Figure 2. Three major carbon dioxide flows were captured in both GWP data reports: sequestrated carbon dioxide from the air and biogenic and fossil-derived carbon dioxide emissions. According to the US Environmental Protection Agency:

Biogenic CO2 emissions are defined as CO2 emissions related to the natural carbon cycle, as well as those resulting from the production, harvest, combustion, digestion, fermentation, decomposition, and processing of biologically based materials.33

The sequestrated carbon dioxide in the air is a negative value because of the carbon that is stored in the tree through photosynthesis during growth. The biogenic carbon dioxide emissions in Figure 2 are 99% attributed to the incineration process whereas the fossil-derived carbon dioxide emissions are mainly attributed to manufacturing and transport processes. The difference in the magnitude of the carbon dioxide flows between the two timber systems is interesting to note. The lower biogenic carbon dioxide levels for pine can be explained by the lower material density. The slightly lower fossil carbon dioxide level for pine is mostly as a result of the shorter transportation distance to the building site and also a lower density (smaller mass to transport). Fossil fuel impact breakdown per alternative from the manufacturing stage, transport and disposal can be seen in Figure 4 to accentuate the transportation impact.

In theory, adding sequestrated carbon dioxide from the air and the biogenic carbon dioxide emission should be close to a net result of zero. By analysing the flows for both materials visually, it is evident that these two carbon dioxide flows do not exactly match up, but show a slight negative carbon dioxide net result. The most likely explanation for this negative net result is a difference in wood volume in the forestry background data, compared to the wood used in the trusses and the wood used in the modelled, Swiss-based, incineration process. Furthermore, the incineration process does not emit all the carbon contained in the wood as pure carbon dioxide. Although timber sequesters carbon dioxide in the growing phase, by adding the three types of carbon dioxide flows as seen in Figure 2, both pine and Biligom still result in a small positive carbon dioxide footprint.

Therefore, under a general simplified assumption of carbon neutrality of biomass, a closer look at the GWP (excluding biogenic carbon monoxide, carbon dioxide and methane flows) can help in the understanding of the global warming impact of the truss alternatives (Figure 3). This time not considering carbon dioxide, the net GWP impact of the LGS truss system is only about double the two wood alternatives. Both wood alternatives have a large contribution attributed to transportation-associated emission from the factory to the building site. This finding highlights the importance of the transportation method and resource location. Although alternative transportation methods - i.e. shipping and rail - might be more environmentally friendly, it was not part of the scope of this study. The final stage (i.e. site to grave) includes incineration of all three truss systems and shows a non-significant overall non-biogenic impact contribution compared to the cradle-to-gate and cradle-to-site impact.

Figure 4 displays the fossil fuel depletion per life-cycle stage. A similar trend to the contribution profile for the non-biogenic GWP (Figure 3) can be seen, with a large contribution from transportation to the wood alternatives, especially for Biligom.

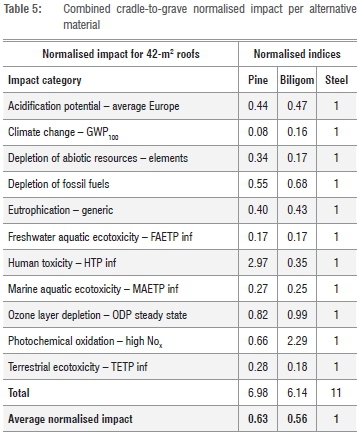

While GWP and fossil fuel depletion are important and relatively easy to understand impact factors, to assess the largely fossil fuel based climate change impact of building products, other environmental indicators need to be considered for a holistic evaluation of the potential environmental impact of building materials beyond GWP. In the following section, normalisation was used to evaluate the overall environmental impact between truss systems based on the 11 baseline impact categories. Normalisation is a simple technique to equate different categories and magnitudes by adjusting values measured on different scales to a notionally common scale. In Table 5, normalised indices of each cradle-to-grave impact category for all three truss systems are displayed. In each case, the LGS impact was set as one and the remaining two in relation to one. Finally, the combined or pooled normalised impact was computed by repeating the process using the total normalised values per truss system. Equal weighting was used to compute the compiled impact.

This method indicates that the overall environmental performance of the two timber systems is about 40% better than that of the LGS system. It also shows that one should be cautious of considering only one impact category to evaluate materials. For example, considering only climate change or human toxicity potential will portray a skewed picture. However, considering all impact data and results presented in this study, both timber truss systems outperform LGS but indicate a similar or higher impact in the human toxicity, ozone layer depletion and photochemical oxidation categories.

Sensitivity analysis

Process contribution, end-of-life modelling and data uncertainty were identified as important independent variables that could impact the dependent variables and thus overall LCIA under the system assumptions.

Data uncertainty and availability

Data uncertainty with a likely significant impact on results is the lack of LCI data for the wood preservation chemicals. A local timber treatment expert provided chemical composition and quantities of treatment required per cubic metre of timber, but impacts that could possibly occur when the treated product is disposed of were not accounted for. Similarly, no detailed LCI data were available for galvanised LGS. Global steel manufacturing processes in ecoinvent, including steel production, sheet rolling, zinc coating and metal working were combined and adjusted to approximate a local LGS product model. Metal working was included to represent the machining and press factory processes which produce profiled LGS truss components. This process contributes 36% to the LGS GWP and might be a slight overestimate as a result of the difference in general metal machining and LGS.

Although the Australian forestry models used reasonably represent local conditions, in order to better assess the impact of forestry on local land and water use, local LCI data would be required. In general, global LCI data are good enough for a general comparison, to assess trends and identify weak points in a system, but the calculated numbers should not be taken as absolute values. The work by Nebel et al.34, on adapting European data for use in New Zealand, highlights the difficulty of using data from one country or region for another country that does not share common manufacturing resources. The latter can be especially difficult to assess in terms of appropriateness for an LCA practitioner.

End-of-life scenario discussion

Only one scenario was considered in this study: 100% material waste incineration. The assumption satisfies the reality of local wood waste treatment and scrap steel disposal. However, a study done by Blengini35 showed that building material recycling has the potential to save between 18% and 35% on GWP over the building's life cycle.

Additional climate benefits of wood use can also be realised at the end of its life depending on biogenic carbon and GWP accounting approaches and by granting substitution benefits. In general, wood use can help reduce GHG effects by four main routes, which are closely interlinked: (1) carbon can be stored in forests and (2) wood products, (3) wood products can substitute for other products, thus using less fossil fuel during manufacturing, avoiding process emissions and fuel emissions through biofuel substitution, and (4) carbon dynamics in landfills.7 Previous studies on the topic of wood substitution have found that the greatest potential for positively effecting climate change mitigation lies in increasing the amount of carbon stored in wood products and by substituting fossil fuels using wood energy or products that use a large amount of fossil fuel in their production.28-30

In this study, we chose a conservative approach to account for climate change benefits of wood use and substitution without accounting for carbon pools, carbon pool changes and substitution benefits to facilitate a relatively simple and easy direct comparison of the different roof truss systems and materials.

Conclusion

In both cradle-to-gate and cradle-to-grave analyses, the two timber alternatives - Biligom and South African pine truss systems - showed significantly lower environmental impact than LGS. For the smaller truss system, LGS had about twice the GWP impact of the timber systems and the normalised impact over all environmental indicators was about 40% higher. The benefit of biogenic carbon dioxide and low embodied energy present in timber proved to play a significant role in the GWP impact and could be further reduced if wood were used at its end-of-life to generate energy and substitute for fossil fuel use.

Overall, we have shown the potential advantage of using local timber products to reduce the environmental impact of the truss and building industry in South Africa. More local LCI data and research are required in order to promote and simplify direct system comparison in the local building industry and to better account for localised environmental emissions e.g. end-of-life fate of preservative treated timber. While better data would produce more reliable and robust absolute data, no changes to the general trends of this study are likely.

Acknowledgements

We thank the following persons for their insightful contributions and valuable data: Conrad van Zyl from Mitek South Africa, Spencer Drake, Biligom International, Doug Sayce, Lonza and Herman Aucamp. We gratefully acknowledge the Hans Merensky Foundation for providing study sponsorships which enabled the research to be undertaken.

Authors' contributions

P.L.C. was responsible for the article design, technical analyses and write-up; M.B. was responsible for the model analyses and write-up; C.B.W. supervised the research and revised the manuscript.

References

1. Wang L, Toppinen A, Juslin H. Use of wood in green building: A study of expert perspectives from the UK. J Clean Prod. 2014;65:350-361. http://doi.org/10.1016/j.jclepro.2013.08.023 [ Links ]

2. US Energy Information Administration. How much energy is consumed in residential and commercial buildings in the United States? [homepage on the Internet]. No date [updated 2016 Apr 06; cited 2017 Apr 25]. Available from: http://www.eia.gov/tools/faqs/faq.cfm?id=86&t=1 [ Links ]

3. Ding GKC. Sustainable construction - The role of environmental assessment tools. J Environ Manage. 2008;86(3):451-464. http://doi.org/10.1016/j.jenvman.2006.12.025 [ Links ]

4. Petersen AK, Solberg B. Environmental and economic impacts of substitution between wood products and alternative materials: A review of micro-level analyses from Norway and Sweden. Forest Policy Econ. 2005;7(3):249-259. http://doi.org/10.1016/S1389-9341(03)00063-7 [ Links ]

5. Werner F, Richter K. Wooden building products in comparative LCA: A literature review. Int J Life Cycle Assess. 2007;12(7):470-479. http://doi.org/10.1065/lca2007.04.317 [ Links ]

6. Upton B, Miner R, Spinney M, Heath LS. The greenhouse gas and energy impacts of using wood instead of alternatives in residential construction in the United States. Biomass Bioenerg. 2008;32(1):1-10. http://doi.org/10.1016/j.biombioe.2007.07.001 [ Links ]

7. Sathre R, O'Connor J. Meta-analysis of greenhouse gas displacement factors of wood product substitution. Environ Sci Policy. 2010;13(2):104-114. http://doi.org/10.1016/j.envsci.2009.12.005 [ Links ]

8. Ximenes FA, Grant T. Quantifying the greenhouse benefits of the use of wood products in two popular house designs in Sydney, Australia. Int J Life Cycle Assess. 2012;18:891-908. http://doi.org/10.1007/s11367-012-0533-5 [ Links ]

9. Oliver CD, Nassar NT, Lippke BR, McCarter JB. Carbon, fossil fuel, and biodiversity mitigation with wood and forests. J Sustainable For. 2014;33(3):248-275. http://doi.org/10.1080/10549811.2013.839386 [ Links ]

10. Crickmay and Associates. South African lumber index: September 2016. Pietermaritzburg: Crickmay and Associates (Pty) Ltd; 2016. [ Links ]

11. Crafford PL, Wessels CB. The potential of young, green finger-jointed Eucalyptus grandis lumber for roof truss manufacturing. South Forests. 2016;78(1):61-71. http://dx.doi.org/10.2989/20702620.2015.1108618 [ Links ]

12. Evans S. SA steel industry on the brink of collapse. Mail and Guardian [serial on the Internet]. 2015 August 29 [cited 2017 Apr 25]. Available from: http://mg.co.za/article/2015-08-27-sa-steel-industry-on-the-brink-of-collapse/ [ Links ]

13. Spotlight on steel in South Africa. SA Roofing. 2015;70:14-15. Available from: https://issuu.com/trademaxpublications/docs/sar_june_2015_dload?e=7285681/13191678 [ Links ]

14. Worth Z, Boyle C, McDowall WR. Combined life-cycle cost assessment of roof construction. Proc Inst Civil Eng Eng Sustain. 2007;160(4):189-198. http://dx.doi.org/10.1680/ensu.2007.160.4.189 [ Links ]

15. Bolin CA, Smith ST. Life-cycle assessment of CCA-treated wood highway guard rail posts in the US with comparisons to galvanised steel guard rail posts. J Transp Technol. 2013;3:58-67. http://dx.doi.org/10.4236/jtts.2013.31007 [ Links ]

16. United Nations. Millennium development goals and beyond [homepage on the Internet]. No date [updated 2015 Nov 10; cited 2017 Apr 25]. Available from: http://www.un.org/millenniumgoals/ [ Links ]

17. Wilkinson B. South Africa - leading the green building charge in Africa [homepage on the Internet]. c2016 [cited 2017 Apr 25]. Available from: http://www.worldgbc.org/news-media/south-africa-leading-green-building-charge-africa [ Links ]

18. Curran MA. Life cycle assessment: Principles and practice [document on the Internet]. No date [updated 2006 May 01; cited 2017 Apr 25]. Available from: http://www.cs.ucsb.edu/~chong/290N-W10/EPAonLCA2006.pdf [ Links ]

19. Ciambrone DF. Environmental life cycle analysis. Boca Raton, FL: CRC Press; 1997. [ Links ]

20. ISO. Environmental management: Life cycle assessment: Principles and framework. ISO14040:2006. [ Links ]

21. ISO Environmental management: Life cycle assessment: Requirements and guidelines. ISO14044:2006. [ Links ]

22. Weidema BP, Bauer C, Hischier R, Mutel C, Nemecek T, Reinhard J, et al. Overview and methodology: Data quality guideline for the ecoinvent database version 3 [document on the Internet]. c2013 [cited 2016 Aug 16]. Available from: https://www.ecoinvent.org/files/dataqualityguideline_ecoinvent_3_20130506.pdf [ Links ]

23. ArcelorMittal. ArcelorMittal South Africa [homepage on the Internet]. No date [cited 2017 Apr 25]. Available from: http://southafrica.arcelormittal.com/ [ Links ]

24. South African Wood Preservers Association. CCA treated timber [document on the Internet]. No date [cited 2017 Apr 25]. Available from: http://www.sawpa.co.za/documents/THE%20SAFETY%20OF%20CCA%20TREATED%20TIMBER%20Revision%20final.pdf [ Links ]

25. Niyobuhungira RV. An investigation of CCA-treated wood in informal caterers' fuel stocks and related airborne arsenic in the Cape Town region [thesis]. Cape Town: University of Cape Town; 2012. [ Links ]

26. South African Waste Information Centre. Scrap metal fact sheet [document on the Internet]. No date [cited 2016 May 16]. Available from: http://sawic.environment.gov.za/documents/5329.pdf [ Links ]

27. openLCA. GreenDelta [homepage on the Internet]. No date [cited 2017 Apr 25]. Available from: http://www.openlca.org/ [ Links ]

28. Perez-Garcia J, Lippke B, Comnick J, Manriquez C. An assessement of carbon pools, storage, and wood products market substitution using life-cycle analysis results. Wood Fiber Sci. 2005;37(Corrim special issue):140-148. [ Links ]

29. Gustavsson L, Pingoud K, Sathre R. Carbon dioxide balance of wood substitution: Comparing concrete- and wood-framed buildings. Mitig Adapt Strategies Glob Chang. 2006;11(3):667-691. http://dx.doi.org/10.1007/s11027-006-7207-1 [ Links ]

30. Lippke B, Jonhson L, Wilson J, Puettmann M. Life-cycle environmental performance of renewable building materials in the context of residential construction [document on the Internet]. c2011 [cited 2017 Apr 25]. Available from: http://www.sefs.washington.edu/research.corrim/pubs/reports/2010/phase2/Ph2_Main_Report.pdf [ Links ]

31. Cherubini F, Peters GP Berntsen T, Stromman AH, Hertwich E. CO2 emissions from biomass combustion for bioenergy: Atmospheric decay and contribution to global warming. Glob Change Biol Bioenergy. 2011;3(5):413-426. http://dx.doi.org/10.1111/j.1757-1707.2011.01102.x [ Links ]

32. Helin T, Sokka L, Soimakallio S, Pingoud K, Pajula T. Approaches for inclusion of forest carbon cycle in life-cycle assessment - a review. Glob Change Biol Bioenergy. 2013;5:475-486. http://dx.doi.org/10.1111/gcbb.12016 [ Links ]

33. US Environmental Protection Agency. Framework for assessing biogenic CO2 emissions from stationary sources [document on the Internet]. c2014 [cited 2017 Apr 25]. Available from: https://yosemite.epa.gov/sab/sabproduct.nsf/0/3235DAC747C16FE985257DA90053F252/$File/Framework-for-Assessing-Biogenic-CO2-Emissions+(Nov+2014).pdf [ Links ]

34. Nebel B, Alcorn A, Wittstock B. Life-cycle assessment: Adopting and adapting oversear LCA data and methodologies for building materials in New Zealand [document on the Internet]. c2011 [cited 2017 Apr 25]. Available from: http://maxa.maf.govt.nz/forestry/publications/lca-materials.pdf [ Links ]

35. Blengini GA. Life-cycle of buildings, demolition and recycling potential: A case study in Turin, Italy. Build Environ. 2009;44:319-330. http://dx.doi.org/10.1016/j.buildenv.2008.03.007 [ Links ]

Correspondence:

Correspondence:

Philip Crafford

pcrafford@sun.ac.za

Received: 16 Nov. 2016

Revised: 25 Apr. 2017

Accepted: 17 May 2017