Serviços Personalizados

Artigo

Indicadores

Links relacionados

-

Citado por Google

Citado por Google -

Similares em Google

Similares em Google

Compartilhar

South African Dental Journal

versão On-line ISSN 0375-1562

versão impressa ISSN 0011-8516

S. Afr. dent. j. vol.73 no.4 Johannesburg Mai. 2018

RESEARCH

Effect of diamond-like carbon coating on implant drill wear during implant site preparation

M AborassI; MT PeckII; H HolmesIII

IBChD, MSc. Division of Oral Medicine and Periodontics, Faculty of Dentistry, University of the Western Cape

IIBChD, MSc, MChD, MRD RCSEd, FDS RCSEd, MDTFEd. Division of Oral Medicine and Periodontics, Faculty of Dentistry, University of the Western Cape

IIIBChD, MSc, MChD. DMsion of Oral Medicine and Periodontics, Faculty of Dentistry, University of the Western Cape

ABSTRACT

Dental implant drills are made of different materials such as stainless steel (SS), zirconia and ceramic. Diamond-like carbon (DLC) coating has been added to increase the cutting efficiency and wear resistance. Aim: To determine the impact of DLC coating on dental implant drill wear after implant site preparation.

OBJECTIVES: To determine: a. drilling times b. geometric features and chisel Integrity of drills with different surfaces after repeated use. Methods and Materials: 13 pilot drills were sourced from different manufacturers, providing five groups for testing. The drills were sequentially attached to a hand piece fitted to a drill press and used 20 times, drilling to a depth of 10mm in artificial bone. Drilling times were recorded with a digital stopwatch. SEM images were taken of the bur before and after 0, 5, 10, 15 and 20 penetrations. Results: No significant differences in drilling times were detected. The drills showed signs of wear, while coating delamination was detected in DLC coated drills. Conclusion: No significant differences in drilling times were found. SEM images showed that most of the drills revealed signs of wear after 20 uses.

INTRODUCTION & LITERATURE REVIEW

Dental implants are artificial titanium fixtures that are surgically inserted into the jaws.1,3 Through a process known as osseointegration, implants provide firm support for dental prostheses such as bridges, crowns, and dentures. Osseointegration was initially defined by Bránemark1,2 as "a direct functional and structural connection between living bone and the surface of a load-carrying implant". Zarb and Alberktsson3 proposed that osseointegration was "a process whereby clinically asymptomatic rigid fixation of alloplastic materials is achieved and maintained in bone during functional loading". The success of dental implant treatment is dependent on achieving successful osseointegration,4which is influenced by factors such as trauma during dental implant site preparation. This has been reported to affect the long-term predictability of the implant.4

Implant-specific drills are used to prepare the host bone for fixture Insertion. During the drilling process, a thin layer of necrotic tissue Is formed in the osteotomy site. Excessive drilling trauma during Implant site preparation causes an increased thickness of this necrotic layer, resulting in reduced bone formation and tissue maturation, reportedly leading to implant failure.6

Heat is generated by the drilling procedure during implant site preparation, an effect which influences bone metabolism. An Increase in temperature above 47°C after one minute of drilling time leads to decreased bone regeneration.6 Several factors Influence heat generation during the drilling procedure. These Include cortical bone thickness, drilling pressure, cutting motion, Irrigation, drilling time, drill speed, shape and diameter of drills.7 Repeated use of a dental drill can decrease its cutting efficiency.3

Implant drills are made of different materials, such as SS, zirconia and ceramic. Most do not have ideal cutting efficiency and resistance to wear.8 Recently, diamond like carbon (DLC) was added as a drill coating to improve the cutting efficiency, increase wear resistance and drill hardness 9. DLC is an amorphous carbon or non-crystalline structure, with properties similar to diamonds.10 Surface coating with DLC confers the advantageous properties of the diamond on the coated material surface.11 Studies evaluating the wear patterns of various drill materials, the effect of changes In temperature and the mass associated with these materials are well documented.12 However, conclusive studies comparing drill wear and drilling time specifically for DLC coated drills have not been reported. The purpose of this study was to compare the drilling time and wear of DLC coated implant drills to SS drills during implant preparation.

MATERIALS AND METHODS

This in vitro study was carried out using twenty artificial bones (Straumann® Basel, Switzerland) of standardized bone density and quality. A total of thirteen stainless steel and DLC pilot drills were sourced from different manufacturers and divided into five groups (Table 1). The implant drill was attached to a surgical Implant hand piece (Nobel Biocare® W&H Dentalwerk Austria). The implant hand piece was fitted to a drill press with a mechanical arm to allow for controlled vertical movement (MK-dent® RT2010 Germany); and could be managed by a single operator (Figure 1). Drill speed and torque were determined by the manufacture's recommendation (Osseoset 200, SI-923; Nobel Biocare® W&H Dentalwerk Austria). All Implant drills were used 20 times to a 10mm drilling depth in a stabilized artificial bone block. Isotonic saline was used as external Irrigation. Drill time was recorded (in seconds) for each use with a digital stopwatch. After each series of five uses, drills were rinsed in distilled water, dried using compressed air and sterilized in an autoclave (Steri-vac®: gas sterilizer, 3M Medical Surgical division, Paul, U.S.A) In Tygerberg Hospital at 127°c for 40 minutes. SEM images were taken of new drills and after 5,10,15 and 20 penetrations (Figure 2).

Photomicrographs of SEM images were taken at 30X and 150X magnifications to document the geometric features, wear and chisel integrity of all drills at the various stages.

RESULTS

Drilling time results

Significant differences in drilling times were detected in the first four groups between the diamond-like carbon and stainless steel drills. Figure 3 summarizes the means and various drill time patterns. The first four groups show similar patterns with an initial increase In speed, followed by a gradual and steady reduction In time. The fifth group (Champion Stainless Steel) showed a dramatic and erratic increase In drilling time after the fifth preparation.

SEM analysis

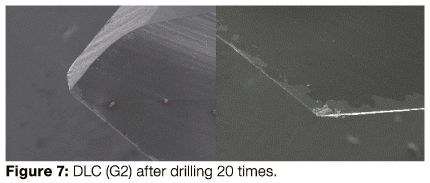

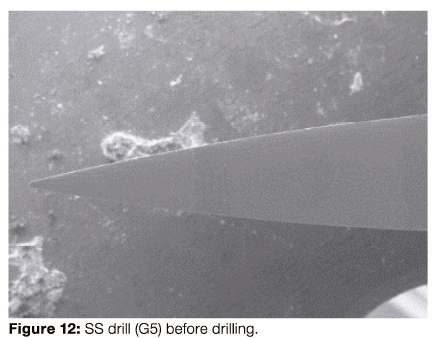

All Implant drills from groups G1, G2, G3, and G5 showed signs of wear after 20 uses. Evaluation of the drill surfaces was conducted after intervals of 5,10,15 uses and 20 uses (Figures 4 to 13). The first three surface examinations were done at 30X magnification and the last examination (after 20 uses) at 150X magnification. The latter revealed damage to the cutting surface and blunting of the tips. Coating delamination was detected In the DLC drills in G2 (Figure 7) and drills from G1, G3, and G5 showed irregular surfaces and a higher tip wear (Figures 4, 5, 8, 9,12 and 13). In contrast, stainless steel drills from G4 maintained regular cutting edge surfaces, with no differences noted before or after drilling procedures (Figure 10,11).

DISCUSSION

Introduction

Dental implant drills used for implant preparation are made of different materials Including ceramic, zirconia and stainless steel. Most of these materials do not have sustained long-term wear resistance nor cutting efficiency.8 Recently DLC has been added as a drill coating to improve cutting efficiency, increase wear resistance and to increase drill hardness.8 The aim of this study was to determine the effect of a DLC coating on dental implant drilling time and drill wear during implant site preparation.

Drilling time

To the author's knowledge, this Is the first reported study measuring drilling time of Implant drills with varying surface properties, after repeated use. The first four groups (SS Adin®, DLC Adln®, SS Megagen® and SS Straumann®) showed no statistically significant difference in drilling time after 5, 10, 15 and 20 uses. Group 5 (SS Champions® implants) showed an increase in drilling time with subsequent drill use and the average drilling time was slower compared with the other groups. This may be attributed to the low recommended drill speed of 250 rpm. The drilling time influences the amount of frlctional heat generated between the drill and the surrounding bone. The long-term effect of heating bone to 47°C for 5 minutes is reported to be bone resorption, associated with an invasion of fat cells and reduced osteogenic activity.6

A number of studies using high-speed rotary instruments have demonstrated that a decrease In drilling time will reduce the rise in temperature.13,14 Cordioli and Majzoub15 concluded that the depth of the cavity, diameter and the flute geometry of the drill contributed to the time required for the maximum temperature to return to normal. However, further investigations are required to support this hypothesis. In addition, In the case of the Champion drills, the manufacturer recommended that the drills be used a maximum of five times at a low speed of 250 rpm, which may explain the slower drilling times seen after five uses.

SEM descriptive analysis

Signs of wear were observed for all drill types tested after repeated use. An in vitro study9 reported variable signs of drill wear after 40 uses of each SS, zlrconia and DLC drills. In the present study, DLC coating delamlnation was observed whereas an Irregular surface was detected in SS drills, implying that more wear occurred in the SS drills. Oliveria8 also reported signs of increased drill wear after 50 uses for stainless steel twist drills compared with zirconia drills. Significantly, Dos Santos16 showed that drill deformation and roughness were directly proportional to the number of times the drills were used.

In this study, there was no difference with regards to wear resistance and cutting efficiency between DLC coated and SS drills after repeated use. Most drills tested were consistent up to after 15 times of use. However, SS and DLC coated drills revealed signs of wear after being used 20 times. Damage, irregular cutting surface and higher tip wear were detected in stainless steel drills from group 1(SS Adin®) and was noticeable after 20 drillings. No differences were found between stainless steel drills in groups G1 and G3 with regards to irregular cutting surface and tip wear after being used up to 20 times.

A significant finding was that delamination of DLC coated drills was observed after 20 drillings. This was seen mostly affecting the drill tips and along the cutting edges. No evidence of loss of sharpness nor damage in cutting surfaces or wear tips were observed in SS drills in G4 (Straumann®), even after using them for 20 drilling procedures. The most affected drill in the current study appeared to be that of group 5 (Champions®). With increased use, these drills displayed irregular surfaces and a higher tip wear of both edges. This may be attributed to the shape of the drill and using the drill beyond the manufacturer's recommendations.

Drill wear particles

Irrigation systems are used to prevent clogging of drill flutes by bone chips17,18 cited in Tehemar.13 This could also flush out drill particles that arise from drill wear, but has not been reported. Of concern is that these wear particles may remain behind in the osteotomy site and may have an effect on bone healing or osseointegration. This is undetermined and requires further investigation.

Drill Cost

The efficacy of DLC coated and SS drills can also be compared in terms of the drill cost. For the drills tested, the average current price in June 2017 of SS drills were four hundred Rands per drill (30USD - current) compared to eight hundred and forty Rands (62.5USD - current) per DLC coating drill. Since the drilling times for both types of drills were not statistically significantly different, one might consider the purchase of SS drills when drilling time and wear are taken into account if limited reuse is considered.

Accuracy of osteotomy preparation

With regards to accuracy of osteotomy site preparation for the two drill types, this factor was not taken into account and requires further analysis to determine whether there is a significant advantage of one drill type over another.

CONCLUSION

Based on the current study and its recognised limitations, the following conclusions can be made:

-

Drill design, material, and speed significantly affect cutting efficiency, wear resistance and drill time. These factors should be considered during implant drill design and their combined influence evaluated during testing on bone tissue.

-

No significant differences in drilling time were detected in groups 1,2, 3 and 4 between diamond-like carbon coated (DLC) drills and stainless steel (SS) drills after 5,10,15 and 20 times use except for group 5. This group could not be compared with the other groups, as the recommended speed of drilling and drill design was different to the other groups. In addition, the manufacturer's instruction did not allow the drills to be used for more than five times, as opposed to the 20 times in the current study.

-

The SEM images revealed signs of wear after 20 uses for most of the implant drills (groups G1, G2, G3, and G5)

-

DLC coatings on drills do not affect implant drilling time.

-

All drills may wear, leaving drill debris.

Further research is recommended to determine the clinical significance of the above findings.

LIMITATIONS OF THE STUDY

-

Small sample size was tested.

-

In Scanning Electron Microscopy (SEM), no measurable comparison could be made.

-

The drill pressure and force was not standardized.

-

The effect of the sterilization procedure on the wear rate or pattern of the drills was not taken into account.

-

This was a laboratory-based study.

ACRONYMS

DLC: Diamond-like carbon.

SEM: Scanning electron microscopy.

SS: Stainless steel.

References

1. Bränemark PI, Breine U, Adell R, Hansson BO, Lindström J, Ohlsson Ä. Intra-osseous anchorage of dental prostheses: I. Experimental studies. Scandinavian Journal of Plastic and Reconstructive Surgery 1969:3(2):81-100. [ Links ]

2. Branemark R, Branemark PI, Rydevik B, Myers RR. Osseointegration in skeletal reconstruction and rehabilitation: a review. Journal of Rehabilitation Research and Development 2001; 38(2):175. [ Links ]

3. Zarb GA, AlbrektssonT. Osseointegration: a requiem forthe periodontal ligament. Int J Periodontics Restorative Dent. 1991;11(1):88-91. [ Links ]

4. Queiroz TP, Souza FÁ, Okamoto R, Margonar R, Pereira-Filho VA, Garcia IR, Vieira EH. Evaluation of immediate bone-cell viability and of drill wear after implant osteotomies: immunohistochemistry and scanning electron microscopy analysis. Journal of Oral and Maxillofacial Surgery 2008:66(6):1233-40. [ Links ]

5. Ercoli C, Funkenbusch PD, Lee HJ, Moss ME, Graser GN. The influence of drill wear on cutting efficiency and heat production during osteotomy preparation for dental implants: a study of drill durability. International Journal of Oral & Maxillofacial Implants 2004; 19(3):335-49. [ Links ]

6. Eriksson AR, Albrektsson T. Temperature threshold levels for heat-induced bone tissue injury: a vital-microscopic study in the rabbit. The Journal of Prosthetic Dentistry 1983;50(1):101-7. [ Links ]

7. Oh HJ, Wikesjö UM, Kang HS, Ku Y, Eom TG, Koo KT. Effect of implant drill characteristics on heat generation in osteotomy sites: a pilot study. Clinical Oral Implants Research. 2011;22(7):722-6. [ Links ]

8. Oliveira N, Alaejos-Algarra F, Mareque-Bueno J, Ferrés-Padró Ε, Hernández-Alfaro F. Thermal changes and drill wear in bovine bone during implant site preparation. A comparative in vitro study: twisted stainless steel and ceramic drills. Clinical Oral Implants Research 2012;23(8):963-9. [ Links ]

9. Mendes GC, Padovan LE, Ribeiro-Júnior PD, Sartori EM, Valgas L, Claudino Μ. Influence of implant drill materials on wear, deformation, and roughness after repeated drilling and sterilization. Implant Dentistry 2014;23(2):188-94. [ Links ]

10. Lin Y, Zhang L, Mao HK, Chow P, Xiao Y, Baldini Μ, Shu J, Mao WL. Amorphous diamond: a high-pressure superhard carbon allotrope. Physical Review Letters 2011:107(17):175504. [ Links ]

11. Evtukh AA, Litovchenko VG, Litvin YM, Fedin DV, Goncharuk NM, Chaika VE, Chakhovskoi AG, Felter TE. Electron field emission from silicon emitters coated with a thin DLC films. Physics of Low-Dimensional Structures 2001;5:117-27. [ Links ]

12. Sartori EM, Shinohara ÉH, Ponzoni D, Padovan LE, Valgas L, Golin AL. Evaluation of deformation, mass loss, and roughness of different metal burs after osteotomy for osseointegrated implants. Journal of Oral and Maxillofacial Surgery 2012;70(11):e608-21. [ Links ]

13. Tehemar SH. Factors affecting heat generation during implant site preparation: a review of biologic observations and future considerations. International Journal of Oral Maxillofacial Implants 1999 ;14(1):127-36. [ Links ]

14. Rafel SS. Temperature changes during high-speed drilling on bone. Journal of Oral Surgery, Anesthesia, and Hospital Dental Service 1962 ;20:475. [ Links ]

15. Cordioli G, Majzoub Z. Heat generation during Implant site preparation: an in vitro study. International Journal of Oral & Maxillofacial Implants 1997:12(2) :186-93. [ Links ]

16. Dos Santos PL, Pereira Queiroz T, Margonar R, de Souza Carvalho AC, Betonl Jr W, Rezende R, Rocha R, dos Santos PH, Garcia Jr R. Evaluation of bone heating, drill deformation, and drill roughness after Implant osteotomy: guided surgery and classic drilling procedure. International Journal of Oral & Maxillofacial Implants 2014;29(1):51-9 . [ Links ]

17. Kirschner VH. Entwicklung einer Innenkuhlung fur chirugische Bohrer. Dtsch. Zahnarztl Z. 1975;30:436-8. [ Links ]

18. Koch WL. Die zweiphaslge enossale Implantation von intramobilen Zylinderimplantaten-IMZ. Quintessenz 1976;27:21-4. [ Links ]

Correspondence:

Correspondence:

Dr Thabit Peck.

Division of Oral Medicine and Periodontics

Faculty of Dentistry, University of the Western Cape Dental Faculty

Francie Van Zyl Drive, Tygerberg Campus.

Tel 27 21 937 3128.

Email: mpeck@uwc.ac.za