Serviços Personalizados

Artigo

Indicadores

Links relacionados

-

Citado por Google

Citado por Google -

Similares em Google

Similares em Google

Compartilhar

South African Dental Journal

versão On-line ISSN 0375-1562

versão impressa ISSN 0011-8516

S. Afr. dent. j. vol.72 no.2 Johannesburg Mar. 2017

RESEARCH

A comparative study to determine the shock absorption ability of two popular mouth guards available on the South African market

N MohamedI; SR GroblerII; NJ BassonIII; Y OsmanIV; R MulderV

INadia Mohamed: BChD, BSc (Hons), MSc, PhD. Senior Lecturer, Oral and Dental Research Institute, Faculty of Dentistry, University of the Western Cape

IISias R Grobler: BSc, BSc (Hons), MSc (Phys Chem), PhD (Dent), DSc (Chem). Director, Oral and Dental Research Institute, Faculty of Dentistry, University of the Western Cape

IIIScholas J Basson: BSc, BSc (Hons), MSc, PhD (Micro). Principal Researcher, Oral and Dental Research Institute, Faculty of Dentistry, University of the Western Cape

IVYusuf Osman: BChD, MChD, Hons BBA, MBA, PGDHM. Dean, Faculty of Dentistry, University of the Western Cape

VR Mulder: BChD, MSc. Lecturer, Oral and Dental Research Institute, Faculty of Dentistry, University of the Western Cape

ABSTRACT

It is expected that most mouth guards will provide some level of protection to teeth. In this study a device was developed to measure the relative impact absorption of two different mouth guards (Proform, Type III vacuum-formed and Max, Type IV pressure laminate). Seven of each of the two types of mouth guards were made and each batch was exposed to between six and 10 impact trials.

RESULTS: The variations in shock absorption between the batches per mouth guard were found to be not statistically significant on a 1% significance level (two-way ANOVA and the Tukey multiple comparison test). Furthermore, impact absorption on the control where no mouth guard was in place, was more than four times lower. The Max mouth guard was found to be superior with a shock absorption value of 88%. It is advised that a mouth guard should always be used in all contact sports.

CLINICAL SIGNIFICANCE: This study shows that the two tested mouth guards (Max and Proform) have the ability to significantly reduce the force of an impact on teeth.

INTRODUCTION

Mouth guards were originally introduced about 100 years ago for use by boxers. These prototypes were made from sponge, cotton, tape or small pieces of wood.1 Thus, mouth guards have a long history in sport as protective devices worn to prevent direct and indirect injuries to the teeth, soft tissues and jaw.2,3,4 Mouth guards have been shown to protect teeth against the energy generated from potentially traumatic blows. Instead of the energy being transferred directly to the underlying dentition, it is absorbed and dissipated.5 The mouth guard therefore functions as a shock absorber by reducing the forces applied to the oral structures.6

Mouth guards keep the soft tissues away from the teeth. Displacement injuries and soft tissue lacerations are therefore reduced.7 Fractures of the teeth and the alveolar bone (including fractures of the mandible or its condyles) and concussion injuries may also be minimized and even prevented with the use of mouth guards.7,8 Although studies have demonstrated a decrease in dental injuries when mouth guards were used,9 their use in sport is not compulsory in most countries. The American Dental Association, however, has recommended the wearing of mouth guards in 29 sport/ exercise activities.9

Custom-made mouth guards have been shown to provide better adaptation, retention, comfort and stability than over-the-counter versions like stock and "boil-and-bite" mouth guards,3 Further, when compared with mouth guards that are available from sporting goods stores, the custom-made appliances are shown to interfere minimally with speech and to have almost no effect on breathing.3

A guard for personal use is made in the dental clinic or laboratory on a cast poured from an impression taken of the athlete's mouth. These mouth guards are mostly made from ethylene polyvinyl acetate (EVA).4 They may be designed for a specific sport or to accommodate for patients with malocclusions, erupting teeth4 and other orthodontic needs, including fixed appliances.5 The disadvantage3 with this type of mouth guard is that at least two appointments are required with the dentist and it is more expensive than an over-the- counter purchase.10 However, the improved fit, retention and comfort justifies the higher cost4 and enhances the readiness of the sportsman to wear the protective, if somewhat cumbersome, guard.

Custom-made devices are manufactured either by using a single layer of EVA which is adapted to the plaster model of a patient's teeth using low vacuum suction (Type III mouth guard) or by laminating multiple sheets of EVA over the model by using heat and high pressure to produce a Type IV pressure laminate mouth guard.1112 The combination of high heat and pressure allows chemical integration of the layers and eliminates the probability of shrinkage.

Both Type III and Type IV mouth guards have been recommended in favour of the over-the-counter types as they both adapt accurately to the athlete's mouth. Therefore, the purpose of the study was to test the shock absorption ability of two different options of custom-made or model formed mouth guards available in South Africa i.e. the vacuum-formed mouth guard (Type III, Proform) and the pressure laminated mouth guard (Type IV, Max).

MATERIALS AND METHODS

Fourteen guards were manufactured in total i.e. seven of each of the two types. A single standard, reproducible model was used in the manufacture of the Max and Proform mouthguards. The process was standardized in terms of equipment used and heat and pressure applied and both types were manufactured by the same laboratory technician. The pressure- laminate mouth guards (Max) were produced using a Dreve Drufomat machine (Dreve Dentamid, Unna, GmbH, Germany), applying six bars of pressure for 120 seconds. The vacuum-formed mouth guards (Proform) were manufactured on a Buffalo Econo-Va Vacuum Forming System (Buffalo Dental Manufacturing Co., Inc., Syosset, NY, USA) with low vacuum suction and following the standard manufacturing technique.

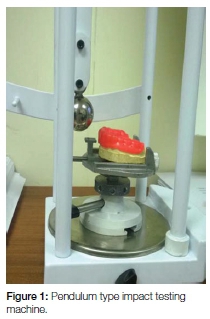

These two varieties of mouth guards were investigated for their ability to absorb impact. The forces were applied using a pendulum type impact testing machine with a steel ball impact object (weight: 172g) attached to the point of the arm (50cm) of the pendulum (Figure 1). This apparatus was manufactured according to specifications published by Handa et al.11A strain gauge which recorded the transmitted forces was attached to the centre of the labial surface of the tooth (Figure 2). The point of impact of the ball was set at the centre of the tooth, precisely where the strain gauge was positioned. Mechanical forces recorded by the strain gauges were amplified (PJ Dynamic Strain Amplifier with SGAO911 Dynamic Strain Amplifier card, Peter Jones Electronic Equipment (PTY) LTD, Rivonia, South Africa) and converted into an electric output in milli voltage and stored as data by the Graphitec GL 900 4 channel logger, Graphitec Corporation (Figure 3).

A plaster model without a mouth guard was used as the control and was subjected to the impact to generate a reference, or control, reading. The mouth guards were then each sequentially fitted to the standard model fitted with the strain gauge and each was exposed to between six and 10 impacts. The pendulum was released from a distance of 10 cm from the tooth surface, which gave a potential energy of 6.6 kg m2/s2.11 The impact force through the mouth guard was measured in millivolts and these data were captured by the apparatus. An increase in the shock absorption of the mouth guard is associated with a drop in millivolts.

All recorded values were entered into the Statistical Package for Social Sciences (SPSS v. 15.0, SPSS Inc., Chicago, IL). Tabled values are presented as means plus or minus the standard deviation. A statistical comparison was made using a two-way ANOVA and the Tukey multiple comparison test (p <0.01).

RESULTS

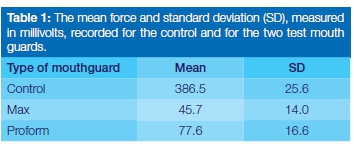

The overall means (mV) and standard deviations (7 batches exposed to six to 10 impacts) are represented in Table 1. (The higher the mV value, the less the impact absorption or vice versa).

The differences between the data recorded for the two mouth guards was tested by a Univariate analysis of variance with MAX and Proform as fixed, and batches as random factors. The Type IV mouth guard (Max) had a significantly higher level of shock absorption (Table 1) than Type III (Proform): F(1,6)=96; p< 0.001 2p = 0.94.

The variations in shock absorption between the batches per mouth guard and the interaction between batches and mouth guard were found not to be statistically significant: p>0.05. Furthermore, impact absorption on the control (where no mouth guard was used), was more than four times lower than with the mouth guards in place (Table 1). (ie the plaster model sustained an impact four times more severe).

DISCUSSION

In this study, an apparatus was first constructed for the measurement of the shock-absorbing ability of different mouth guards (purchasing such an apparatus was prohibitively expensive). The bench-type pendulum (Figure 1) was made by an engineering company (at a fraction of the normal cost) according to the specifications published by Handa et al11The electronic components (Figure 3) were assembled from parts provided by the Peter Jones Electronic Equipment (PTY) LTD, Rivonia, South Africa. This study demonstrated that it is possible to save about 40% of the cost by making use of local companies, enabling the construction of an affordable alternative, albeit with more effort and time.

Different mouth guards have different degrees of shock absorption capability12-25 and this is dependent on many factors such as: the materials used; the thickness of the material; the number of layers of material/s and the fit of the mouth guard. Despite these variations, all mouth guards do generally provide protection.3 Direct comparison of the shock absorbing values as published in the literature is mostly not possible, due to major differences in the experimental designs like variations in impact objects, impact strength, etc.27 Publications have shown a wide range of the shock absorbing potential of mouth guards and mouth guard materials.27,28,29 Thus, studies relying on the same settings (same laboratory) and where many different mouth guards are compared are relevant, because the values can then be directly compared.

Tests on mouth guard products do not really reveal the effect of shock absorption when a sample of the material is simply placed on a model. Therefore, this study focussed on the results of fully prepared mouth guards. It has been reported30 that a custom ethylene vinyl acetate mouth guard (4mm thick) showed a 40% reduction relative to the control (no mouth guard) in comparison with our values of 80% (Pro-form) and 88% (Max). (If we use the average control value of 386.5 mV, as shown in Table 1, to do calculations, only ~12% of the impact came through the one mouth guard (Max) and only ~20% through Proform under our experimental conditions). A study31 involving the development of the "Hard and Space" mouth guard reported an impact absorption rate as high as 95%. However that mouth guard consisted of two layers of EVA with a hard middle layer of acrylic resin. Veris-simo also reported on the advantages of using hard insertions in mouth guards.32 Kataoka tested a four layer EVA (total thickness of 4mm) in a mouth guard and found an impact absorption of 77%.33 This value is close to the 80% found in the current study for a 4mm thickness EVA (Proform). In contrast to many reports a study done on 18 adult mouth guards,34 found that "boil-and-bite" mouth guards were not inferior to custom mouth guards.

However, mouth guards are not only about high shock absorbing abilities but also about comfort, ease of speech and breathing whilst worn. In default, the appliance would not be used at all. Over the past 50 years or more the material of choice for a mouth guard has been mainly the ethylene-vinyl-acetate (EVA) copolymers.35 However, quite recently the mass produced EVA (as a "boil-and-bite") was reported as a failure because the guard did not fit well and had poor retention. In an extensive study35,36 EVA mouth-guards were shown to have a shock absorbing value of 33% in comparison with the 65% for appliances constructed with polyolefin. That study lead to the patented CustMbite MVP Mouthguard manufactured by the Bite Tec Inc which was the only guard approved by the ADA.37 It is claimed that this mouth guard has all the positive features of a custom-made mouth guard, but in a ""boil-and bite" format. Reportedly, it gives a good fit, causes no impairment of speech or breathing and offers protection of teeth, jaws and cranial structures. It is made from a family of the polyolefin elastomers called Vistamaxx38 which is a semi-crystalline polyolefin propylene-ethylene copolymer.39

In our study, two different custom-made mouth guards were evaluated: The Max mouth guard which is made of a semi-crystalline propylene ethylene copolymer (US patent 7950394 as propylene alpha olefin polymer elastomer) and comes in different colours to satisfy users. The other mouth guard, Proform, consists of one layer of EVA (ethyl-ene-vinyl acetate). It also comes in different colours. Today, most mouth guards are made from EVA of which the major component is a copolymer of ethylene and vinyl acetate (virgin ethylene vinyl acetate chemical is approved as safe by the FDA). Mouth guard sheets made from copolymers have recently become available. It was found that the shock absorption capacity of a polystyrene-polyolefin copolymer-based material was higher than that of the EVA, polyolefin-based material.27,29 A thesis investigated the impact energy absorption of three popular mouth guard materials in three different environments (saliva, water and dry).40 The results showed that the mouth guard PolyShock (containing EVA + polyurethane) was the most energy-absorbent material in all three environments and was a better shock absorbing mouth guard than Proform (containing EVA alone) because of the addition of polyurethane. It therefore becomes clear that the main reason why the Max mouth guard showed higher shock absorption than Proform is because of the layers of polyolefin material which are used. In a another study on five different designs of the Bioplast mouth guard, a shock-absorption rate of up to 55% was reported.6

Both mouth guards tested showed a high degree of impact absorption when compared with the control where no mouth guard was used (Table 1). In the comparison to determine whether different samples of a mouth guard varied (Max or Proform) no statistically significant (p<1%) variation was found. However, in total, Max was found to be superior as far as the impact absorption (Table 1) is concerned. These two mouth guards are not the cheapest on the South African market and the cheaper ones should also be evaluated under similar conditions. Furthermore, this study was not done in vivo, which is a limitation. However, the results should still give a good indication of their value as protective devices.

CONCLUSION

Within the limits of the study it can be concluded:

1. Both mouth guards would protect teeth to a considerable extent.

2. The Max mouth guard should give better protection.

3. Although these mouth guards are more expensive than the over-the-counter varieties, both probably afford better protection, may prevent more severe dental injuries and result in greater cost savings in the long run.

4. We would like to stress the importance of using mouth guards for all those who participate in any contact sport as well as in any other activity where injury to the mouth can occur.

Conflict of interest: The authors whose names are listed above certify that they have NO affiliations with or involvement in any organization or entity with any financial interest or non-financial interest in the subject matter or materials discussed in this manuscript.

Acknowledgement: We wish to thank Prof Herman Kruijsse for the statistical treatment of the results.

ACRONYM

EVA: ethylene polyvinyl acetate

References

1. Reed, R. V. Origin and early history of the dental mouthpiece. British Dental Journal 1994; 176:479. [ Links ]

2. Young EJ, Macias CR, Stephens L. Common Dental Injury Management in Athletes. Sports Health: A Multidisciplinary Approach 2013; 1-6. Available from: http://sph.sagepub.com/content/early/2013/04/23/1941738113486077.full [Accessed 4 December 2015]. [ Links ]

3. CDHA Position Paper on Sports Mouth Guards. Putting more bite into injury prevention. Can Dent Hyg Ass 2005; 39(6): 1- 19. [ Links ]

4. Scott J, Burke FJT, Watts DC. A review of dental injuries and the use of mouth guards in contact team sports. Brit Dent J 1994; 176: 310- 4. [ Links ]

5. Hoffmann J, Alfter G, Rudolph NK, Goz G. Experimental com parative study of various mouth guards. Endod Dent Traumatol 1999; 15: 157- 63. [ Links ]

6. De Wet FA, Heyns M, Pretorius J. Shock absorption potential of different mouth guard materials. J Prosthet Dent 1999; 82: 301-6. [ Links ]

7. Mekayarajjananonth T, Winkler S, Wongthai P. Improved mouth guard design for protection and comfort. J Prosthet Dent 1999; 82:627-30. Available from: http://www.sciencedi-rect.com/science/article/pii/S0022391399700016 [Accessed 3 December 2015]. [ Links ]

8. Takeda T, Ishigami K, Hoshina S, et al. Can mouth guards prevent mandibular bone fractures and concussions? A laboratory study with an artificial skull model. Dent Traumatol 2005; 21(3):134- 40. [ Links ]

9. Knapik JJ, Marshall SW, Lee RB, et al. Mouth guards in sport activities: history, physical properties and injury prevention effectiveness. Sports Med 2007; 37(2):117- 44. [ Links ]

10. ADA Council on Scientific Affairs. Using mouth guards to reduce the incidence and severity of sports-related oral injuries. JADA 2006; 137: 1712- 20. [ Links ]

11. Handa J, Takeda T, Kurokawa K, Ozawa T, Nakajima K, Ishigami K. Influence of pre-laminated material on shock absorption ability in specially designed mouthguards with hard insert and space. J Prosthodont Res 2011; 55:214-220. Available from: http://www.sciencedirect.com/science/article/pii/S1883195811000375 [Accessed 3 December 2015]. [ Links ]

12. Padilla R. A technique for fabricating modern athletic mouth guards. J Can Dent Assoc 2005; 33 (5):399- 407. [ Links ]

13. Abe K, Takahashi H, Churei H, Iwasaki N, Ueno T. Flexural properties and shock-absorbing capabilities of new face guard materials reinforced with fiberglass cloth. Dent Trauma-tol 2013; 29(1):23-8. Doi: 10.1111/j.1600-9657. [ Links ]

14. Bemelmanns P, Pfeiffer P. Shock absorption capacities of mouth guards in different types and thicknesses. Int J Sports Med 2001; 22:149-53. [ Links ]

15. Bulsara YR, Matthew IR. Forces transmitted through a laminated mouth guard material with a Sorbothane insert. Endod Dent Traumatol 1998; 14:45-7. [ Links ]

16. Chowdhury RU, Churei H, Takahashi H, Sharin S, Fukasawa S, Shrestha S. Suitable mouth guard for sports-active person with spaced dentition. Dent Traumatol 015, 31(3):238-42. Doi: 10.1111/edt12142. [ Links ]

17. Chowdhury RU, Churei H, Takahashi H, et al. Combined analysis of shock absorption capability and force dispersion effect of mouth guard materials with different impact objects. Dent Mat J 2014; 33(4): 551-6. [ Links ]

18. Ihara C, Takahashi H, Matsui R, Yamanaka T, Ueno T. Bonding durability of custom-made mouthpiece of scuba diving after water storage under pressure. Dent Mat J 2009; 28; 487-92. [ Links ]

19. Labella CR, Smith BW, Sigurdsson A. Effect of mouthguards on dental injuries and concussions in college basketball. Med Sci Sports Exerc 2002; 34:41-4. [ Links ]

20. Maeda Y, Kumamoto D, Yagi K, Ikebe K. Effectiveness and fabrication of mouth guards. Dent Traumatol 2009; 25:556-64. [ Links ]

21. Newsome PR, Tran DC, Cooke MS. The role of the mouth guard in the prevention of sports-related dental injuries: a review. Int J Paediatr Dent 2001; 11:396-404. [ Links ]

22. Reza F, Churei H, Takahashi H, Iwasaki N, Ueno T. Flexural impact force absorption of mouth guard materials using film sensor system. Dent Traumatol 2014; 30(3):193-7. doi: 10.1111/edt12068. [ Links ]

23. Takeda T, Ishigami K, Handa J, et al. Does hard insertion and space improve shock absorption ability of mouth guard? Dent Traumatol 2006; 22:77-82. [ Links ]

24. Westerman B, Stringfellow PM, Eccleston JA. Beneficial effects of air inclusions on the performance of ethylene vinyl acetate (EVA) mouth guard material. Br J Sports Med 2002; 36:51-3. [ Links ]

25. Westerman B, Stringfellow PM, Eccleston JA, Harbrow DJ. Effect of ethylene vinyl acetate (EVA) closed cell foam on transmitted forces in mouth guard material. Br J Sports Med 2002; 36:205-8. [ Links ]

26. Westerman B, Stringfellow PM, Eccleston JA. The effect on energy absorption of hard inserts in laminated EVA mouth guards. Aust Dent J 2000; 45:21-3. [ Links ]

27. Fukasawa S, Churei H, Chowdhury RU, et al. Difference among shock-absorbing capabilities of mouth guard materials. Dent Traumatol 2016; doi: 10.1111/edt.12275. [Epub ahead of print]. [ Links ]

28. Yokota K, Churei H, Takahanshi H, Ueno T. Preliminary study for developing a new mouth guard material. Ann Japan Prostho Soc 2010; 2:151-6. https://en.wikipedia.org/wiki/Mouthguard. [ Links ]

29. Takamata T, Hashi K, Yamaki T, Okafunji N. Shock absorption characteristics of commercial custom-made sports mouth guard materials. Conference Paper, IADR General Session, April 2009. [ Links ]

30. Tanaka Y, Miyanaga H, Maeda Y, Abe M, Miwa S. A method for detecting the deterioration in the shock absorption capability of mouthguards. Int J Sports Med 2015; 36:684-7. [ Links ]

31. Takeda T, Ishigami K, Mishima O, Karasawa K, Kurokawa K, Kajima T. Easy fabrication of a new type of mouthguard incorporating a hard insert and space and offering improved shock absorption ability. Dent Traumatol 2011; 27:489-95. [ Links ]

32. Verissimo C, Santos-Filho PC, Tantbirojn D, Versluis A, Soares CJ. Modifying the biomechanical response of mouthguards with hard inserts: A finite element study. Am J Dent 2015; 28:116-20. [ Links ]

33. Kataoka SH, Setzer FC, Gondim E, Caldeira CL. Impact absorption and force dissipation of protective mouthguards with or without titanium reinforcement. J Am Dent Assoc 2014; 145:956-9. [ Links ]

34. Hume PA, Schipper R, Mcintyre J, Sheerin K, Inskip C, Gianotti S. Impact testing of 18 adult mouthguards. XXIV ISBS Symposium 2006, Salzburg.-Austria. [ Links ]

35. Rabeony M, Elkin M. A custom fit boil-and-bite mouth guard without the need of a dentist impression. http://www.custmbite.com/Website_Article[1].pdf Retrieved Nov 2016. [ Links ]

36. Grewal D. Impact study. http://www.custmbite.com/Dr_Gre-wal_CustMbite_Impact_Study.pdf Retrieved Nov 2016. [ Links ]

37. Bite Tec, Inc. http://www.bitetech.com/2011/11/10/bite-tech-inc-announces-acquisition-of-custmbite-llc/ Retrieved Nov 2016. [ Links ]

38. Vistamaxx. Plastics Technology. http://www.ptonline.com/articles/new-metallocene-tp-elastomers-tackle-films-fibers-tpos Retrieved Nov 2016. [ Links ]

39. Cozewith C, Data S, Hu W. Propylene-ethylene polymers. U.S. Pat. No 6,525,157. ExxonMobil Chemical Patents, Inc (2003). Retrieved Nov. 2016. [ Links ]

40. Lunt DR. Impact energy absorption of three mouth guard materials for three environments. A Thesis; MSc, Graduate School of The Ohio State University, The Ohio State University, 2009. [ Links ]

Correspondence:

Correspondence:

R Grobler:

Oral and Dental Research Institute,

Faculty of Dentistry, University of the Western Cape.

E-mail: srgrobler@uwc.ac.za