Serviços Personalizados

Artigo

Indicadores

Links relacionados

-

Citado por Google

Citado por Google -

Similares em Google

Similares em Google

Compartilhar

South African Dental Journal

versão On-line ISSN 0375-1562

versão impressa ISSN 0011-8516

S. Afr. dent. j. vol.70 no.4 Johannesburg Mai. 2015

RESEARCH

Effects of various parameters of alumina air abrasion on the mechanical properties of low fusing feldspathic porcelain laminate material

G S AswalI; C K NairII

IMDS. Assistant lecturer, Department of Restorative Dentistry, Libyan International Medical University, Benghazi, Libya

IIMDS. Professor and Head of Department of Prosthodontics, AECS Maaruti College of Dental Sciences and Research Centre,Bangalore, India

ABSTRACT

RATIONALE: Alumina air abrasion is a commonly used surface treatment for porcelain veneers. This in vitro study determined the influence of various parameters of alumina air abrasion on the mechanical properties of porcelain.

OBJECTIVES: To ascertain the influence of alumina particle size, air stream delivery pressure and distance from the nozzle, on surface roughness, material loss and bi-axial flexural strength of low fusing feldspathic porcelain and to determine the optimum combination of these factors.

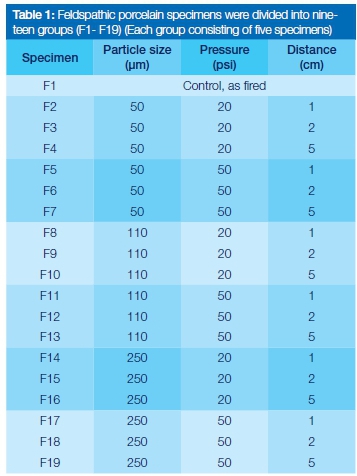

MATERIALS AND METHODS: 95 specimens of feldspathic ceramic measuring 1mm in thickness by 15 mm in diameter were prepared. Alumina air abrasion was carried out with varying parameters viz three different particle sizes (50μm, 110μm, 250μm), two different pressures (20psi, 50psi) and three different distances (1cm, 2cm, 5cm.

RESULTS: The various combinations which produced the greatest and the least effects on the test parameters were identified and the results were statistically analysed using the factorial ANOVA test.

CONCLUSIONS: The combination of 50μm alumina particle size, 20psi air stream pressure and either 2cm or 5cm distance between the nozzle and the ceramic surface produced optimum surface roughness with reduced impact on the flexural strength of the ceramic.

Keywords: Feldspathic ceramic, alumina air abrasion, surface roughness, material loss, flexural strength

INTRODUCTION

Porcelain laminate restorations do not biologically compromise the tooth to any extent because the technique reduces the need for radical invasion into vital dentinal tissues. The materials commonly used for the fabrication of veneers (feldspathic as well as lithium disilicate) ensure good aesthetic qualities, reasonable flexural strength and acceptable surface hardness. The thin veneers achieve their full potential only when intimately bonded to the prepared tooth surface. Bonding of a well-fitting veneer is mediated through a resin. The resin binds with the internal surface of the veneer after appropriate surface roughening treatment has been effected,1,2 whether through acid etching3 or alumina abrasion.4 Hydrofluoric acid has inherent hazards which are associated with storage, use and its disposal.5 Many studies have shown that alumina particle abrasion provides a roughened surface adequate-for the bonding of laminate veneers to the tooth structure. 6,7,8,9

The factors influencing the effect of alumina air abrasion are alumina particle size, hardness and velocity, their morphology and angle of impact.10 The properties of the substrate, the pressure at which alumina particles are propelled and the distance between the ceramic substrate and the delivery nozzle all have a qualitative and quantitative impact on the porcelain. To optimize the abrasive quality, the alumina particle size should be controlled. Particles of the same size propelled in an air stream can behave differently under varying pressures rate. Surface roughness is desirable for it improves the bonding between the laminate and the resin. Roughening the surface should not reduce the flexural strength of the restoration to a clinically unacceptable level. Many studies have shown the negative effects of surface treatments on the flexural strength of porcelain.3,4,11

Information on all these variable factors has not previously been integrated, which is now the intention of this study.

MATERIALS AND METHODS

Ninety five feldspathic discs of 15mm diameter and a thickness of one mm were fabricated, using a vinyl polysiloxane (Affinis, Switzerland) mould (Figure 1). 0.99mg of the Duceram feldspathic ceramic (Duceram-LFC, Dentsply, USA) was pre-weighed in an electronic balance and mixed with 0.33ml of distilled water to make each sample,12 the mix being compacted into the silicone mould. The excess moisture was absorbed by using an absorbent tissue paper. After removal from the mould, the specimens were placed in a porcelain-firing oven which was preheated to 650oC and then fired to approximately 940-960oC. Polishing was carried out using Noritake polishing paste (KurarayNoritake Dental Inc) and a rubber wheel.

All the specimens were dried, firstly with tissue paper followed by oil and water free hot air for one minute. The initial weight of each disc was determined with an analytical balance (ALC 6100, Acculab, USA) having a precision of 0.001 gm.

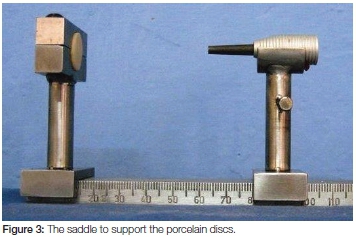

Specimens were surface treated as tabulated in Table 1. F1 was the control group. Specimens F2 - F19 were alumina air-abraded in a sandblaster (Easyblast, BEGO, Germany) (Figure 2) using varying abrasion parameters. The distance between nozzle and surface was standardized with the help of a custom made tool (Figure 3). After surface treatment all the specimens were washed thoroughly in running water and then placed in an ultrasonic cleaner for 10 minutes. Each disc was dried with a tissue paper and hot air for one minute. The weight of each disc was measured after surface treatment with the analytical balance.

The specimen was placed below the stylus of the contact profilometer (Wyko NT1100, Veeco, UK) for the evaluation of surface roughness (Ra values), which was recorded in micrometers.13 The diamond stylus was moved in one direction for a specified distance of 1.5mm and then in a second direction perpendicular to the first, again for 1.5mm. The contact force was standardised at 15gms. The change in position of the diamond stylus generated an analogue signal which was converted into a digital signal, stored, analyzed and displayed.

Specimens were sequentially placed on a support with a span of 10mm for a ball on ring test to determine the flexural strength. A flexural load was applied at the midpoint of each supported specimen using a universal testing machine (Model 6025 Instron, UK) at a crosshead speed of 5mm per minute. The flexural strength was recorded in MPa.

RESULTS

Alumina air abrasion and material loss

The mean net weight loss of feldspathic specimens following alumina abrasion is given in Table 2. The highest material loss of 0.1055gm was observed in group F17 (particle size: 250μm, air pressure:50psi, nozzle distance:1cm) and the lowest material loss of 0.0382gm was observed in group F4 (50μm, 20psi, 5cm).

Alumina air abrasion and surface roughness

The mean surface roughness of feldspathic specimens following alumina abrasion is given in Table 3. Group F5 (50μm, 50 psi, 1cm) showed the highest surface roughness of 3.2935 μm and the lowest surface roughness of 1.8477 μm was observed in group F17 (250 μm, 50 psi, 1cm).

Alumina air abrasion and biaxial flexural strength

The mean flexural strength of feldspathic specimens following alumina air abrasion is given in Table 4. Highest flexural strength of 63.35 MPa was observed in group F4 (50μm, 20psi, 5cm) and the lowest flexural strength of 39.96 MPa was observed in group F17 (250μm, 50psi, 1cm).

STATISTICAL ANALYSIS

The data were statistically analyzed using a factorial ANOVA test. Multiple comparisons (post hoc-test) were carried out using the Bonferroni method to ascertain between which pairs or groups there existed a significant difference.

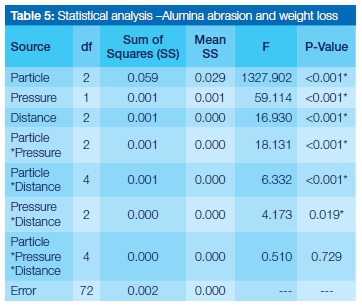

Alumina abrasion and weight loss (Table 5)

Particle size was found to be the most important factor influencing weight loss. The larger the particle size, the greater the weight loss. The differences in mean weight loss associated with the different particles were found to be statistically significant (P<0.001).

Air pressure variations also recorded a direct relationship to weight loss. A pressure of 50 Psi caused a higher mean weight loss compared to that resulting from 20 Psi and the difference between them was found to be statistically significant (P<0.001). The mean weight loss was found to be greater at a distance of 1cm followed by 2cms and 5cms distance respectively and the differences are statistically significant (P<0.001).

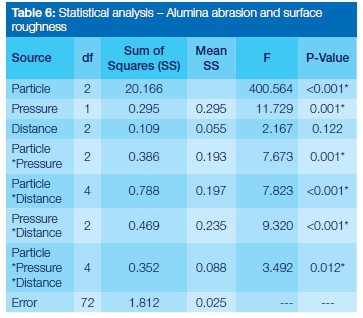

Alumina abrasion and surface roughness (Table 6)

Particle size was found to be the most important factor influencing surface roughness. The smaller the particle size, the greater was the surface roughness produced. The differences between the mean surface roughnesses recorded by the three particle sizes were found to be statistically significant (P<0.001). Slightly greater mean surface roughness was recorded at 50 Psi pressure compared with 20Psi pressure, but the differences were not statistically significant (P>0.05). Among the three distances tested, slightly greater mean surface roughness was recorded when nozzle distance was set at 1cm followed by the 2cms and 5cms settings respectively but the differences were not statistically significant (P>0.05).

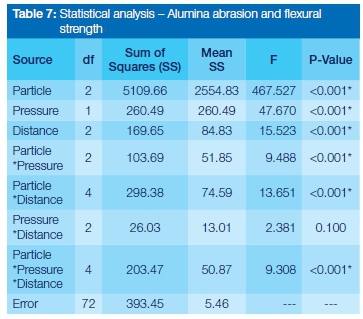

Alumina abrasion and flexural strength (Table 7)

Particle size was found to be the most important factor influencing flexural strength. The smaller the particle size, the less effect on the flexural strength. The difference in mean flexural strength recorded between the three particle sizes was found to be statistically significant (P<0.001). Between the two pressures, higher mean flexural strengths were recorded at 20Psi compared with 50 Psi and the differences were statistically significant (P<0.001). Among the three nozzle to surface distances, higher mean flexural strength was recorded at a distance of 5cms followed by 2cms and 1cm respectively. The differences in mean flexural strength were statistically significant (P<0.001).

DISCUSSION

Clinical success of bonded porcelain restorations is attributed to the intimate bond obtained between the restoration and the underlying tooth structure, mediated by an intervening resin. The bond has both chemical and physical dimensions. The ceramic-resin bonding is enhanced by improving the internal surface of the restoration by way of incorporating microscopic irregularities.1,2 For this, air abrasion using alumina particles and acid etching using hydrofluoric acid are commonly employed. By incorporating such irregularities, the surface area available to bind with the resin is increased. The shear bond strength of dental ceramics to bonding resins is also enhanced by surface treatment.5

It is a common practice in effecting surface preparation to use a sandblaster to propel alumina particles under air pressure. The surface modifications caused by sandblasting is dependent on the particle size, air pressure, hardness of particle, velocity, distance between the nozzle and the ceramic surface and the angle of impact. The properties of the substrate will be critical in determining the results of interaction. Air abrasion using alumina particles may preferentially chip the weaker glassy phase resulting in surface modification and material loss. This phenomenon has been shown to have a degrading effect on the flexural strength of low fusing feldspathic porcelain,3,4,11 borne out by the results of the present study.3

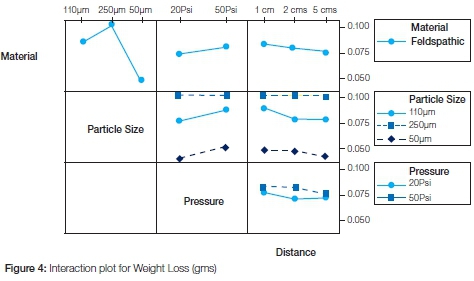

Alumina air abrasion and material loss (Figure 4)

Of the three variables, namely particle size of the abrasive, air pressure employed and the distance between the nozzle and ceramic disc, particle size was found to be the most important factor influencing weight loss. The larger the particle size used, the greater was the weight loss. 250μm particle size caused the most weight loss followed by 110μm and 50μm particle size respectively. 50Psi caused a greater mean weight loss compared with that associated with 20 Psi. Higher pressure caused more weight loss. The mean weight loss was found to be higher at a distance of 1cm followed by losses seen at distances of 2cm and 5cm in decreasing order. Material loss is undesirable because of its effect on the strength profile.

The combination of 50μm, 20psi, 5cm seems to be the most desirable because it causes the least material loss. However this combination does not produce greater roughness.

It appears that no previous study has assessed the effect of various alumina abrasion parameters on material loss of ceramic material.

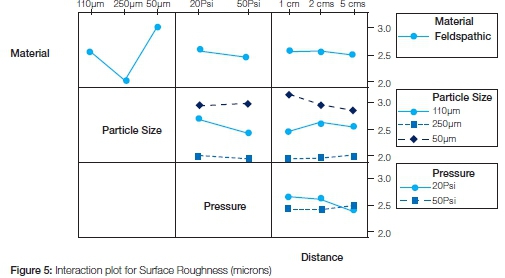

Alumina air abrasion and surface roughness (Figure 5)

Particle size was found to be the most important factor influencing surface roughness after sandblasting. The smaller the particle size used for abrasion, the greater the surface roughness obtained. This could be attributed to the fact that in case of smaller size particles, greater numbers of particles acted on a given unit area whereas in the case of large sized particles, a lesser number acted on a given unit area. Particle size of 50μm caused a higher mean surface roughness at 50 Psi compared with that produced by a pressure of 20 Psi whereas particle size of 110μm and 250μm caused a higher mean surface roughness at 20 Psi compared with that effected by 50 Psi. The role of pressure differs with the particle size. Surface roughness increased with increase of pressure only with smaller particle size. With larger particle sizes, when the pressure was increased, surface roughness decreased. Particle size of 50μm caused a greater mean surface roughness at a nozzle distance of 1cm followed by 2cm and 5cm respectively. But particle size of 110μm caused a greater mean surface roughness at 2cm followed by 5cm and 1cm respectively. The mean surface roughness at 250μm was found to be slightly higher at 5 cm compared to 1cm and 2cm. Greater surface roughness was obtained at shorter distances with lower particle sizes. With particle sizes 110μm and 250μm, greater nozzle distances produced higher surface roughness. Therefore to obtain greater surface roughness with larger particle size, the nozzle to surface distance has to be increased. At 1cm and 2cm distances, a pressure of 20 Psi showed a greater mean surface roughness but at a distance of 5cms, a pressure of 50 Psi yielded a slightly greater mean surface roughness. When pressure and distance are related, it was observed that when the distance increases a higher pressure has to be used in order to obtain more surface roughness. A higher pressure will ensure the reach of the particles to distant substrates. Ayad et af9found in their study that a mean surface roughness of 2.54μm obtained by alumina air abrasion improved the bond strength between the ceramic and the tooth structure. Curtis et al14 also observed that increasing alumina particle size for abrasion resulted in a decrease in the prepared surface roughness of porcelain.

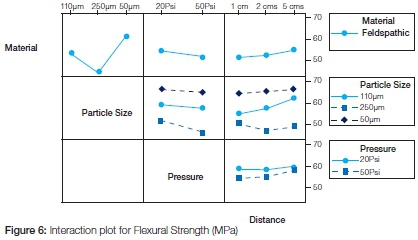

Alumina air abrasion and biaxial flexural strength (Figure 6)

Increased weight loss had a weakening effect on the specimens, thus causing a reduction in the biaxial flexural strength of the porcelain discs. Particle size had the most influential role with air pressure having a supplementary role. The use of smaller particle sizes allowed for a decreased effect on alteration of the flexural strengths. Those specimens exposed to bombardment with particles of 50μm recorded a higher mean flexural strength after testing than did those abraded by 110μm and 250μm particles respectively, at different pressures as well as at different distances. Larger particle size resulted in greater material loss and a weakening of the ceramic. Abrasive particles blasted at 1cm distance caused greater material loss than that seen when blasting at 2cm and 5cm distances. Fleming et al15 in their study found that with an increase in alumina particle size from 25μm to 110μm, the mean flexural strength decreased from 85MPa to 49MPa. In another study by Fleming et al,4it was found that with increase in particle size from 25μm to 110μm, the mean biaxial flexural strength decreased from 94MPa to 54MPa. Bhamra et al also observed a relative increase in the mean biaxial flexure strength when there was a decreased degree of coarseness of the bombarding silica particles.16

CONCLUSIONS

The following conclusions were drawn from the present study|:

a) Particle size was the main factor affecting the post-abrasive-treatment-effects of weight loss, surface roughness and flexural strength of feldspathic ceramic material.

b) Increase in particle size caused an increase in material loss, a decrease in surface roughness and a decrease in the flexural strength of the feldspathic ceramic material.

c) Increase in the pressure of the air blast caused an increase in material loss, an increase in surface roughness and a decrease in the flexural strength of the feldspathic ceramic material. It was only with the lower particle size that surface roughness increased with an increase in pressure. When the pressure was increased with larger particle sizes, the resulting surface roughness decreased.

d) Increased distances between the nozzle and ceramic surface reduced material loss and surface roughness with a relatively lesser effect on reduction in the flexural strength of feldspathic ceramic material.

e) The best combinations of alumina abrasion parameters which in this study produced optimum surface roughness with reduced loss of flexural strength of ceramic were 50μm alumina particle size, 20psi air stream pressure and 2cm distance between the nozzle and the ceramic surface or 50μm alumina particle size, 20psi air stream pressure and a 5cm distance between the nozzle and the ceramic surface.

Limitations of the study: The study is limited to only one type of ceramic. It cannot be assumed that other porcelain laminate material will show similar results due to possible differences in their composition and inherent properties. Further studies could evaluate the effects of hydrofluoric acid etching in comparison with those of alumina air abrasion.

Acknowledgements

1. Dr Nagabhusan Patil, PhD, Department of Material Science, Indian Institute of Sciences, Bangalore, India.

2. Dr Shyamsundar, PhD, Department of Mechanical Engineering, Indian Institute of Sciences, Bangalore, India.

3. Dr Shivshankar MDS, Consultant Prosthodontist, Confident Dental Clinic and Laboratory, Bangalore, India

4. Mr Tejasvi, Statistician, Bangalore, India

References

1. Fleming GJP, Shelton RM, Marquis PM. Resin strengthening of dental ceramics-The impact of surface texture and silane, J Dent 2007; 35:416-24. [ Links ]

2. Fleming GJP, Shelton RM, Marquis PM. Quantifying the strength of a resin-coated dental ceramic, J Dent Res 2008; 87(6):542-7. [ Links ]

3. Fleming GJP, Shelton RM, Impact of hydrofluoric acid surface treatment on the performance of a porcelain laminate restorative material, Dent Mater 2007;23:461-8. [ Links ]

4. Addison O, Marquis PM, Fleming GJP. Impact of modifying alumina air abrasion parameters on the fracture strength and surface roughness of a porcelain laminate restorative material. Dent Mater 2007;23:1332-41. [ Links ]

5. Wolf DM, Powers JM, O'Keefe KL. Bond strength of composite to etched and sandblasted porcelain. Am J Dent 1993;155-8. [ Links ]

6. Oh W, Shen C. Effect of surface topography on the bond strength of composite to three different types of ceramic. J Prosthet Dent 2003; 90:241-6. [ Links ]

7. Lacy AM. Clinical techniques for intraoral repair of fractured porcelain when metal is exposed. Quintessence Int 1989; 20:595-8. [ Links ]

8. Kato H, Matsumara H, Atsuta M, Effect of etching and sandblasting on bond strength to sintered porcelain of unfilled resin, J Oral Rehab 2000;27(2):103-11. [ Links ]

9. Ayad MF, Fahmy NZ, Rosenstiel ST, Effect of surface treatment on roughness and bond strength of a heat pressed ceramic, J Prosthet Dent 2008;99:123-30. [ Links ]

10. Darwell BW, Material Science for Dentistry, 7th ed. Hong Kong 2002. pages 408-10. [ Links ]

11. Fleming GJP, Shaini FJ, Marquis PM. An assessment of the influence of mixing induced variability on the bi-axial flexure strength of dentine porcelain discs and the implications for laboratory testing of porcelain specimens. Dent Mater 2000; 16:114-9. [ Links ]

12. Addison O, Fleming GJP. The i nfluence ofcement lute, thermocycling and surface preparation on the strength of a porcelain laminate veneering material. Dent Mater 2004; 20:286-92. [ Links ]

13. Della bona A, Anusavice KJ, Microstructure, composition and etching topography of dental ceramics. Int J Prosthodont 2002;15:159-67 [ Links ]

14. Curtis AR, Wright AJ, Fleming GJP. The influence of surface modification techniques on the performance of a Y-TZP dental ceramic, J Dent 2006; 34:195-206. [ Links ]

15. Fleming GJP, Jandu HS, Nolan L, Shaini FJ. The influence of alumina abrasion and cement lute on the strength of a porcelain laminate veneering material. J Dent 2004; 32: 67-74. [ Links ]

16. Bhamra G, Palin W M, Fleming GJP, The effect of surface roughness on the flexure strength of an alumina reinforced all-ceramic crown material, J Dent 2002;30: 153-60. [ Links ]

Correspondence:

Correspondence:

G S Aswal

Tel: -91 998 074 4211 (India ) 021 894 480 6928 (Libya)

E-mail: aswallibya@gmail.com